Radial tire with circumferential spirally wound belt layer

A radial tire and spiral winding technology, applied in tire parts, reinforcement layers of pneumatic tires, wheels, etc., can solve the problems of not being able to obtain the clamp effect, unable to maintain the normal shape, etc., to improve handling stability, ground contact Good shape, small increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

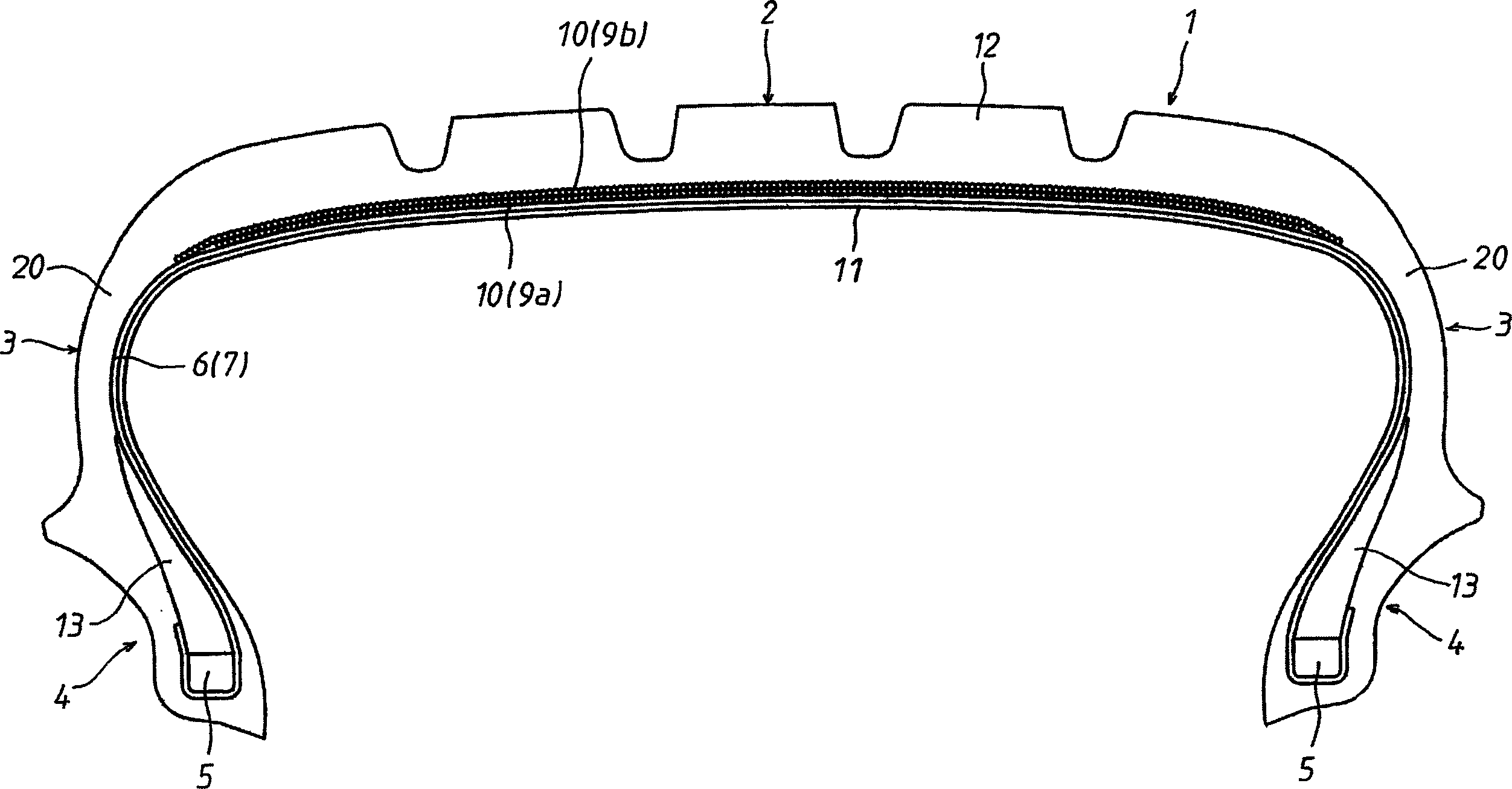

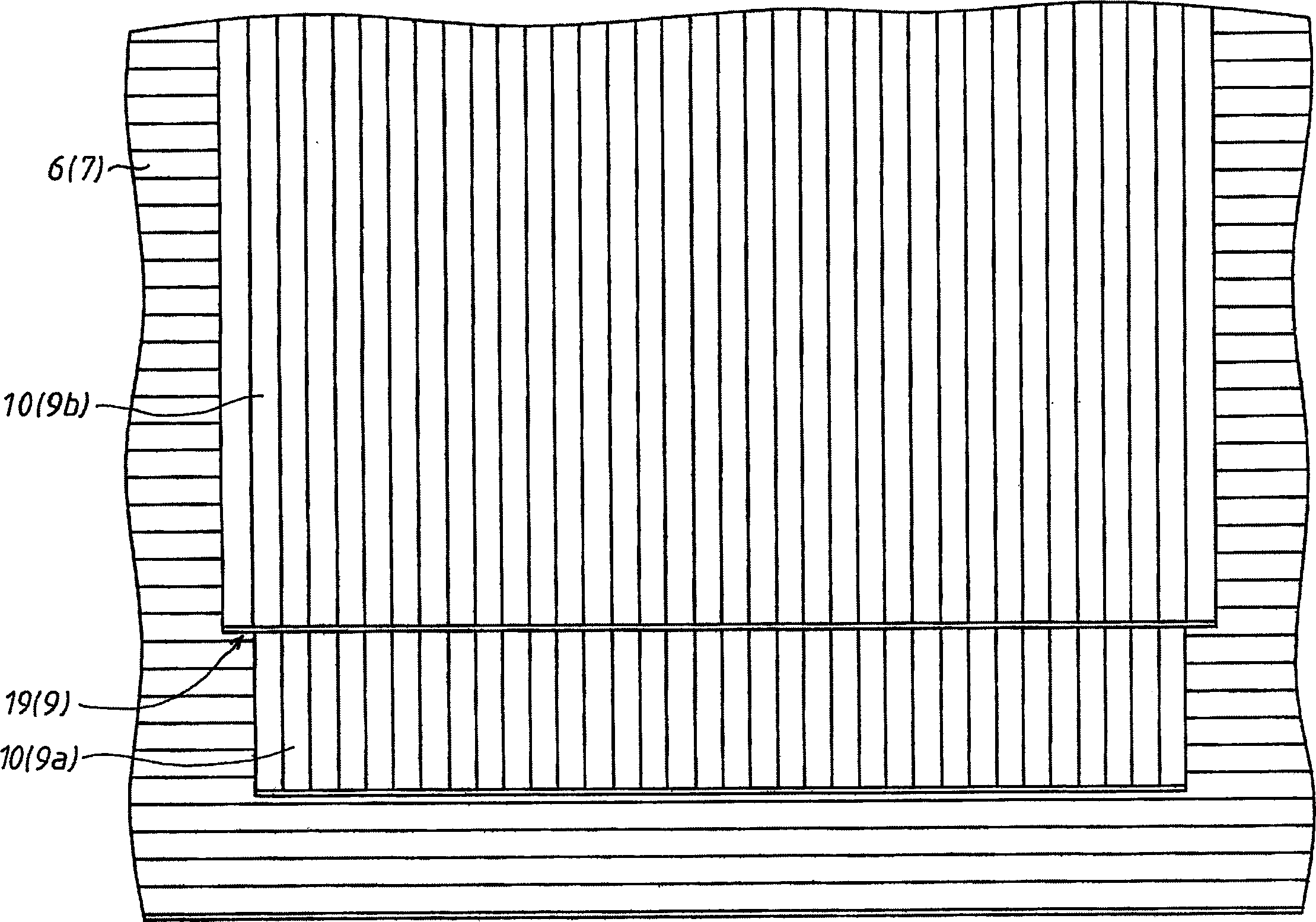

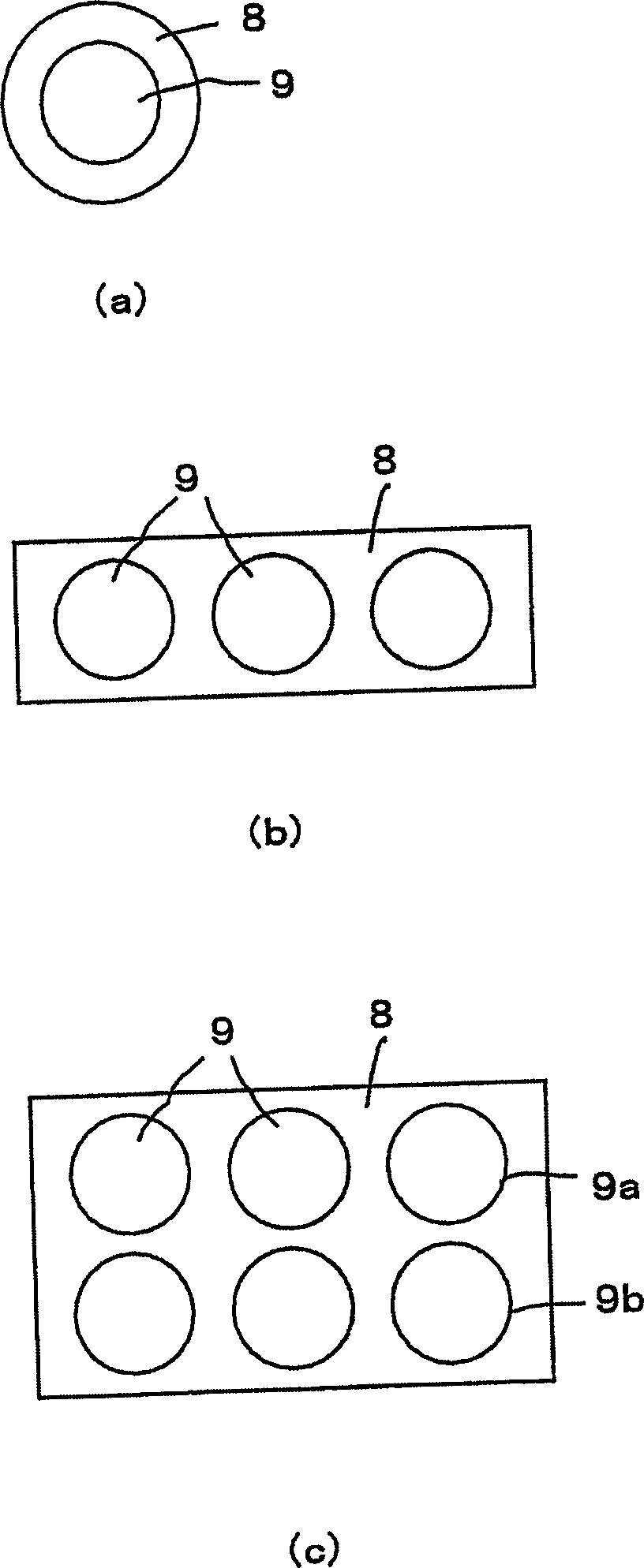

[0051] Next, a radial tire having a belt layer wound spirally in the circumferential direction according to a first embodiment in which the present invention is applied to a radial tire for vehicles will be described with reference to the drawings. like figure 1 , 2 As shown, the radial tire 1 includes: a tire tread portion 2; from the two ends of the tire tread portion 2 to the tire axis, the tire sidewall portions 3 on both sides of the tire are curved and connected in the radial direction; An annular bead portion 4 on the peripheral edge. Bead cores 5 in which steel cords are wound annularly are provided on the bead portions 4 on both sides. The main body ply 6 is folded and held at each bead core 5 from the tire tread portion 2 via the tire sidewall portions 3 on both sides, and is stretched between the beads on both sides. On the main body ply 6 , rubber-coated main body ply cords 7 are arranged at an inclination angle of 85 to 90 degrees with respect to the tire circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com