isochronous transfer structure

A technology of synchronous transmission and transmission wheel, applied in the direction of sending objects, object supply, pile separation, etc., can solve the problems of beating, phase difference, large tension difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The synchronous transmission structure of the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

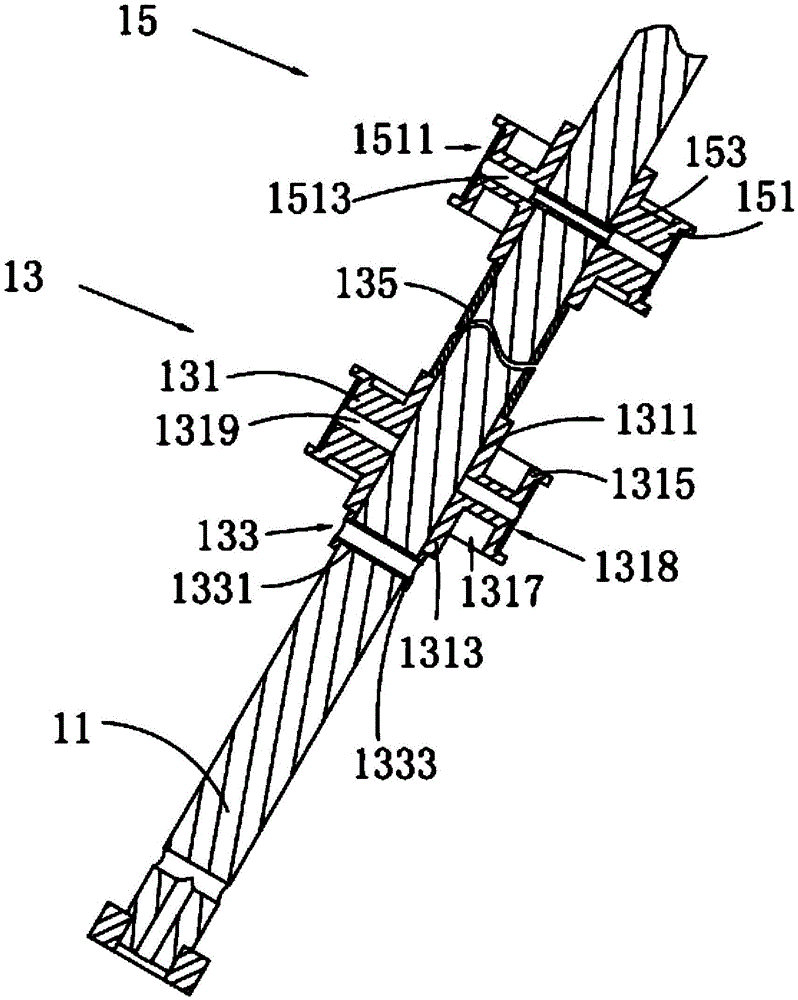

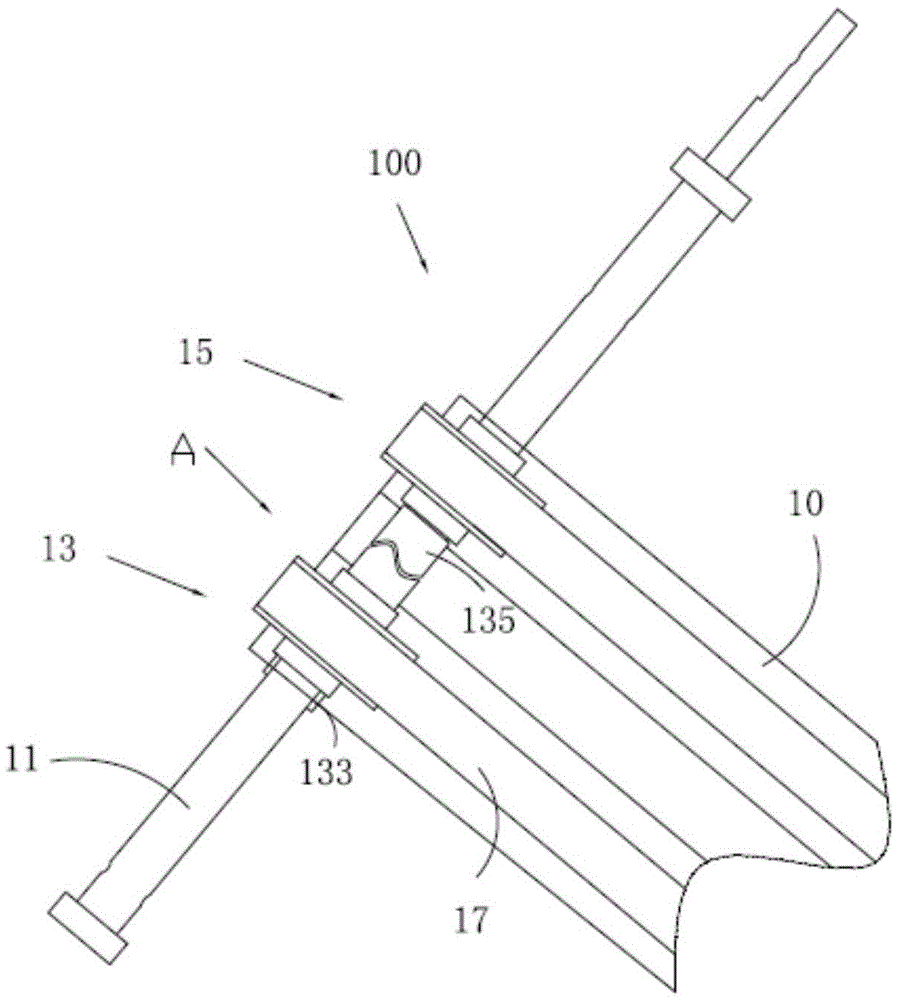

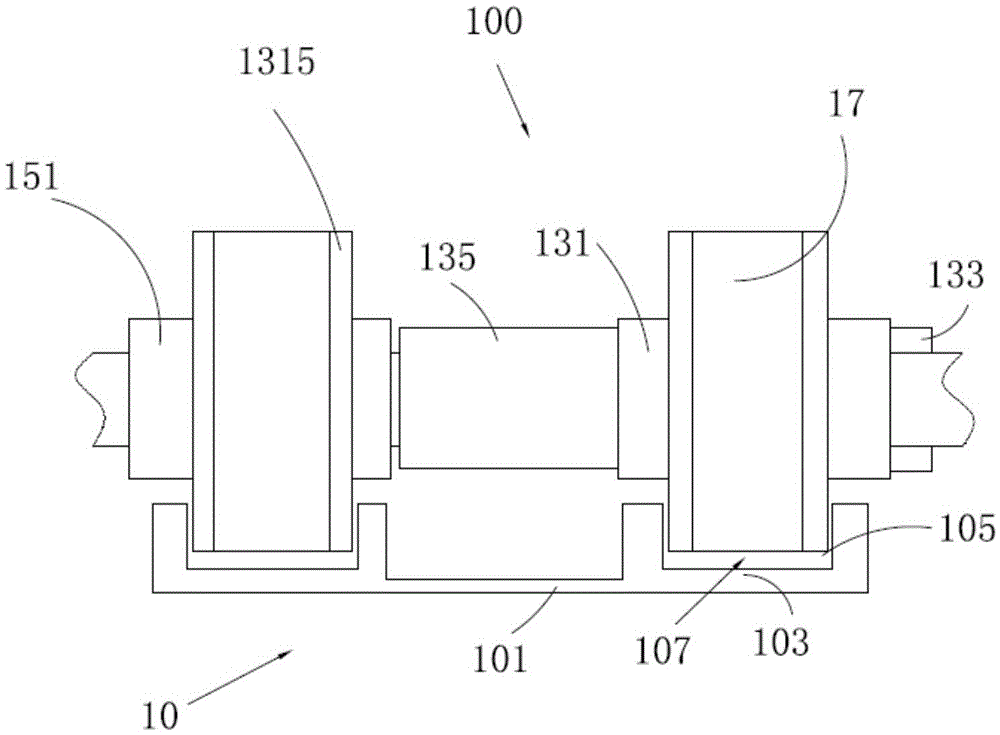

[0019] see figure 1 , the synchronous transmission structure 100 of the present invention includes a delivery seat 10, a driven shaft 11 perpendicular to the delivery seat 10 and arranged at intervals, a first transmission wheel assembly 13 and a second transmission wheel assembly 15 sleeved on the driven shaft 11 at intervals , and two transmission belts 17 respectively arranged on the first transmission wheel assembly 13 and the second transmission wheel assembly 15 . In this embodiment, the synchronous transmission structure 100 is used in an automatic teller machine, and two transmission belts 17 are sandwiched between the transmission seat 10 to transport money.

[0020] Please also refer to figure 2 , the conveying seat 10 is strip-shaped, which includes a bottom plate 101 and two conveying parts 103 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com