A car group pull type belt conveyor

A technology of belt conveyors and car groups, which is applied in the direction of conveyors, transportation and packaging, etc. It can solve the problems of unsafe running belt deviation, large running resistance, and poor belt tension, etc., to reduce belt deviation and increase contact rigidity , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

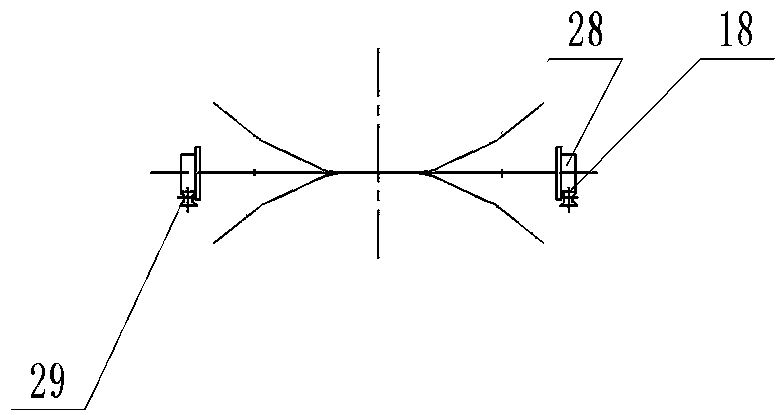

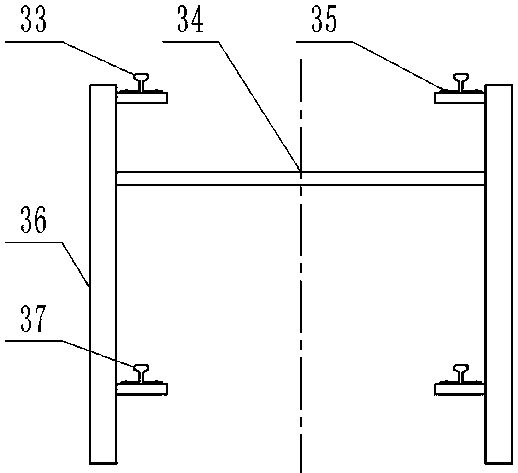

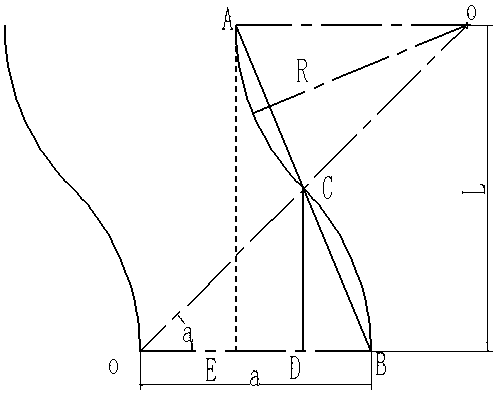

[0020] refer to Figure 1 to Figure 4 The present invention is further elaborated, a car group pull-type belt conveyor, comprising a fixed bearing frame and a driving device, a traction mechanism and a guide mechanism arranged on the fixed bearing frame, the fixed bearing frame is composed of a head frame, a machine Tailstock, middle fuselage frame 12 forms, and nose frame comprises nose guide rail frame 13 and nose tape frame 17, and tail frame comprises machine tail guide rail frame 10 and machine tail tape frame 4, and nose guide rail machine A guide rail 18 is arranged between the frame 13, the middle fuselage frame 12 and the tail guide rail frame 10, and the guide rail 18 includes a straight section guide rail and a curved section guide rail which is arranged symmetrically at both ends of the straight section guide rail and deviates from the center line of the frame; The device comprises a motor 27, the output shaft of the motor 27 is connected with the input shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com