Partition comber board for jacquard weaving and mounting method

A large jacquard and mesh board technology, applied in jacquard machines, textiles, papermaking, textiles, etc., can solve the problems of not being able to arrange at a ratio of 1:1, not being able to weave, and high weaving ends, and achieve uniform and stable warp tension and uniform tension , the effect of large operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

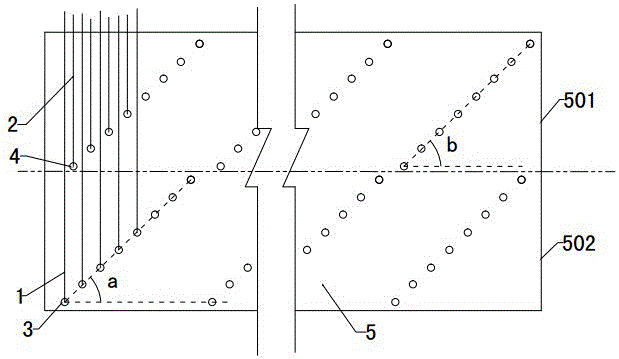

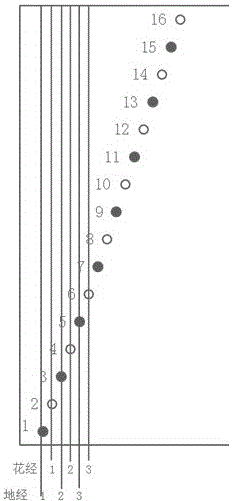

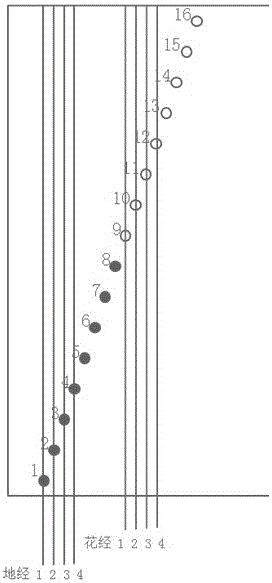

[0025] Each group of 8 odd-numbered holes 3 is equidistantly arranged on a straight line with an angle of 80° to the transverse midline of the main body 5 of the partition board, and the arrangement of the remaining groups of odd-numbered holes 3 is analogously repeated 400 times. The straight lines are all parallel; the corresponding 8 adjacent even-numbered holes 4 are equidistantly arranged on a straight line parallel to the straight line where the adjacent odd-numbered holes 3 are located, and the arrangement of the remaining even-numbered holes 4 is analogously repeated. 400 times, the straight lines are all parallel; the lateral distance between adjacent odd-numbered holes 3 or adjacent even-numbered holes 4 is 0.06cm, and the lateral distance between adjacent odd-numbered holes 3 and even-numbered holes 4 is 0.03cm; 1. The flower axis warp yarns 2 are arranged in the order of 1:1, the ground axis warp yarns 1 pass through the odd number holes 3 in sequence according to t...

Embodiment 2

[0027] Every adjacent 7 odd-numbered holes 3 are equidistantly arranged on a straight line with an angle of 80° to the transverse midline of the partition board main body 5, and the arrangement of the remaining odd-numbered holes 3 is analogously repeated 380 times. The straight lines where are located are all parallel; correspondingly every adjacent 7 even-numbered holes 4 are equidistantly arranged on a straight line parallel to the straight line where the adjacent odd-numbered holes 3 are located, and the arrangement of the remaining even-numbered holes 4 is analogous, Repeat 400 times, the straight lines are all parallel; the lateral distance between adjacent odd-numbered holes 3 or adjacent even-numbered holes 4 is 0.08cm, and the lateral distance between adjacent odd-numbered holes 3 and even-numbered holes 4 is 0.04cm; Warp 1 and flower axis warp 2 are arranged in the order of 1:1, ground axis warp 1 passes through odd number holes 3 in sequence according to odd numbers,...

Embodiment 3

[0029]Every adjacent 8 odd-numbered holes 3 are equidistantly arranged on a straight line with an angle of 75° with the transverse midline of the subdivision board main body 5, and the arrangement of the remaining odd-numbered holes 3 is analogously repeated 420 times. The straight lines where are located are all parallel; correspondingly every adjacent 8 even-numbered holes 4 are equidistantly arranged on a straight line parallel to the straight line where the adjacent odd-numbered holes 3 are located, and the arrangement of the remaining even-numbered holes 4 is deduced by analogy. Repeat 400 times, the straight lines are all parallel; the lateral distance between adjacent odd-numbered holes 3 or adjacent even-numbered holes 4 is 0.10 cm, and the lateral distance between adjacent odd-numbered holes 3 and even-numbered holes 4 is 0.05 cm; Warp yarn 1 and flower axis warp yarn 2 are arranged in 1:1 order, and ground axis warp yarn 1 passes through odd number holes 3 in sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com