Strip deviation correction control method for cold rolling pickling unit

A technology of pickling unit and control method, applied in rolling mill control device, metal rolling, metal rolling, etc., can solve the problem that the quality of finished strip steel cannot be improved, the occurrence rate of burrs cannot be reduced, and the strip deviation cannot be effectively compensated. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

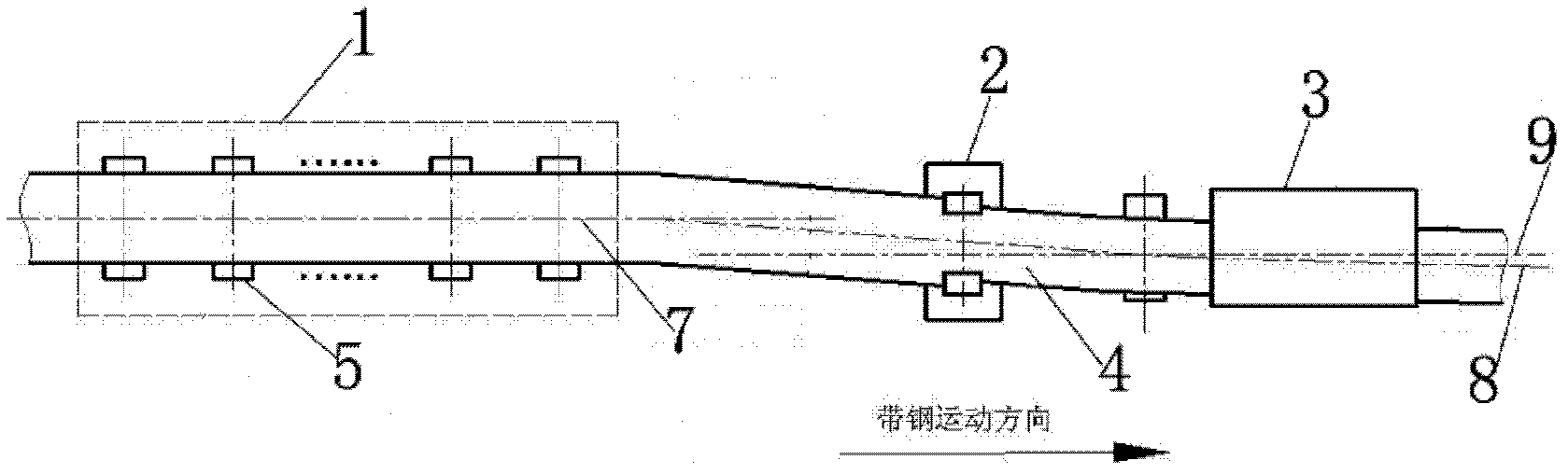

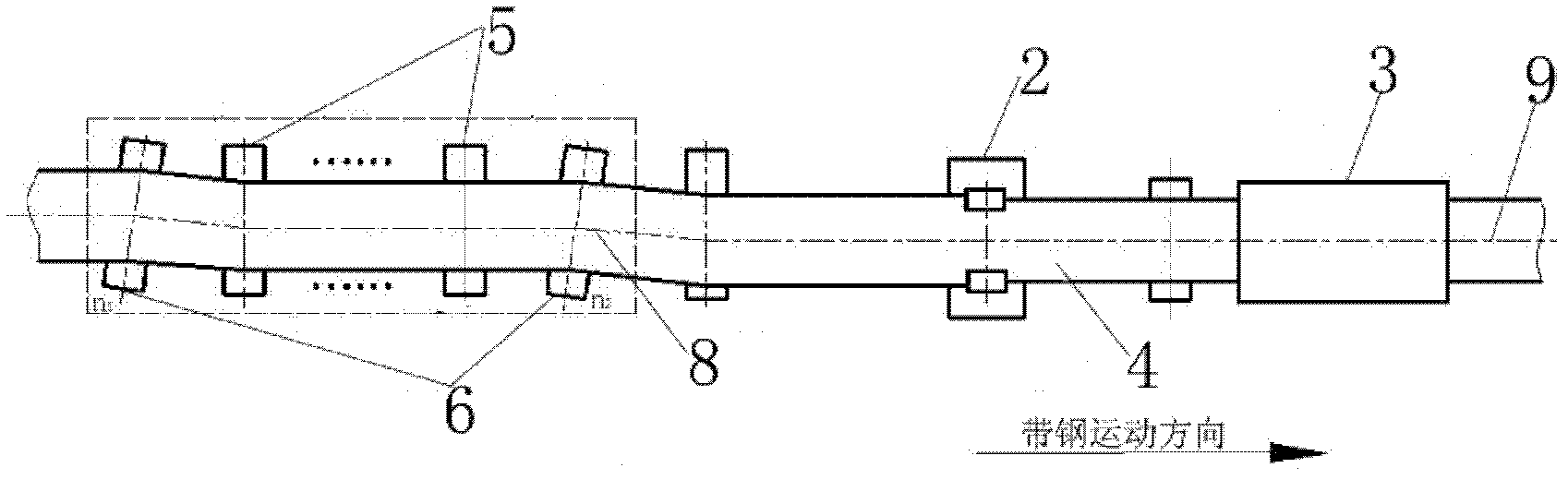

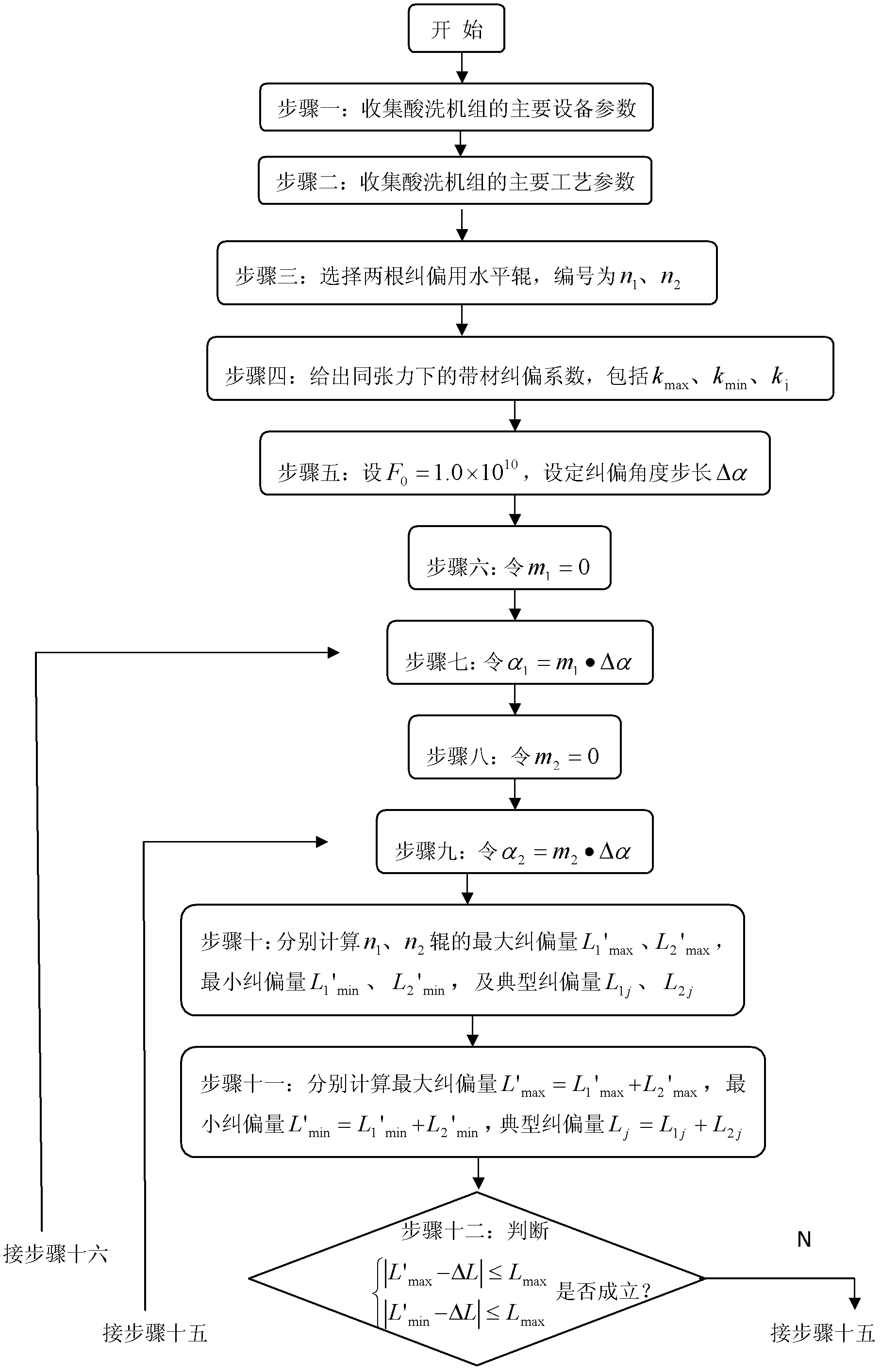

[0050] In order to further illustrate the application process of the related technology described in the present invention, the promotion and application of the disc shears in the 1420 pickling mill of Baosteel Cold Rolling Plant is now used to describe the comprehensive control process of the strip deviation correction of the pickling mill in detail.

[0051] (1) Collect the equipment parameters of the pickling unit, and the result is that the center line of the pickling unit and the rolling center line of the cold rolling unit have a deviation of 70 mm, the number of horizontal rolls of the pickling unit is 20, and the allowable maximum deviation of the disc shears The measurement is 10mm, and the maximum allowable offset angle of the horizontal roller is 5°;

[0052] (2) Collect the process parameters of the pickling unit, mainly including the maximum tension setting value of the unit 25MPa, and the minimum tension setting value of the unit 15MPa. Commonly used typical tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com