Reversely-rotating pre-filament-separation system device for mother filaments

A technology of reverse rotation and system device, which is applied in the field of FDY mother wire appliances, can solve the problems of low absolute breaking strength, mother wire splitting failure, and unstable single-filament tension, so as to improve the position of the splitting point and reduce the breakage of the splitting wire. Head rate, the effect of avoiding single-filament breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

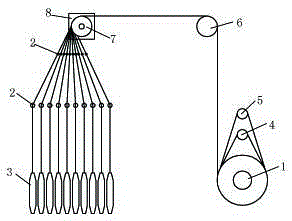

[0011] Combine below figure 1 Specific description embodiment:

[0012] Such as figure 1 As shown, the mother wire uses a reverse-rotating pre-separation system device, including an FDY mother wire rack 1, a wire guide hook 2 and a monofilament cake 3, and a lower guide wire rod is arranged above the FDY mother wire rack 1 4 and the upper guide wire rod 5, a speed measuring wheel 6 is arranged near the FDY female wire frame 1, and a reverse rotation godet wheel 7 is arranged between the speed measurement wheel 6 and the guide wire hook 2, and the reverse rotation guide wire The wire wheel 7 is driven by the guide wheel drive motor 8 so that the reverse rotation guide wheel 7 and the female wire produce uniform reverse rotation. The mother wire and the reverse rotation godet 7 generate a stable frictional tension, so that the mother wires are naturally scattered and arranged side by side on the reverse rotation godet 7, and the single filaments are naturally separated when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com