Technical method for eliminating defects of sparse and dense ways of textile temple

A process method and technology of thinning and denseness, applied in the field of twill textile weaving, can solve the problems of increased warp tension difference, affecting product quality, and thinning and denseness of temple cloth surface defects, etc., so as to achieve small warp weaving tension difference and reduce thinning The effect of reducing dense road defects and reducing dense road defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

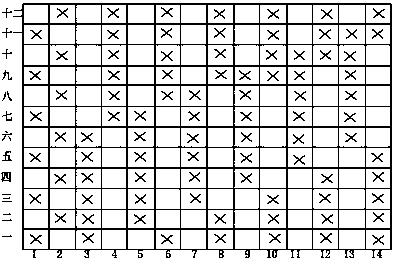

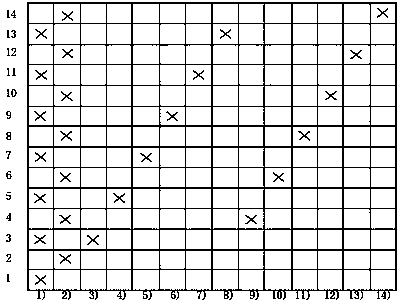

[0012] When weaving 6 / 6 twill fabrics, the heald frames used include 14 pages from 1 to 14 heald frames. During the movement of the heald frames, there are a total of 12 weaving openings from one to twelve. The frame is up and down;

[0013] Reference attached figure 1 : Raise all the odd-numbered weaves of the heald frame on page 1, and all the even-numbered weaves of the heald frame on page 2. The warp and weft on pages 1 and 2 are interlaced to form a plain weave weave that alternates up and down, page 3 The first to sixth weaves of the heald frame are lifted, the seventh to twelve weaves of the heald frame on page 4, the second to seventh weaves of the heald frame on page 5, the one, eight to twelve weaves of the heald frame on page 6 Lift up, the third to eight weaves of the heald frame on page 7, the first, two, and nine to twelve weaves of the heald frame on page 8, the fourth to nine weaves of the heald frame on page 9, the heald frame on page 10 The first to third, ten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com