Patents

Literature

47results about How to "Reduce stretch deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catheter balloon formed of ePTFE and a diene polymer

InactiveUS6946173B2Improve performanceImprove adhesionEnvelopes/bags making machineryMouldsElastomerTetrafluoroethylene

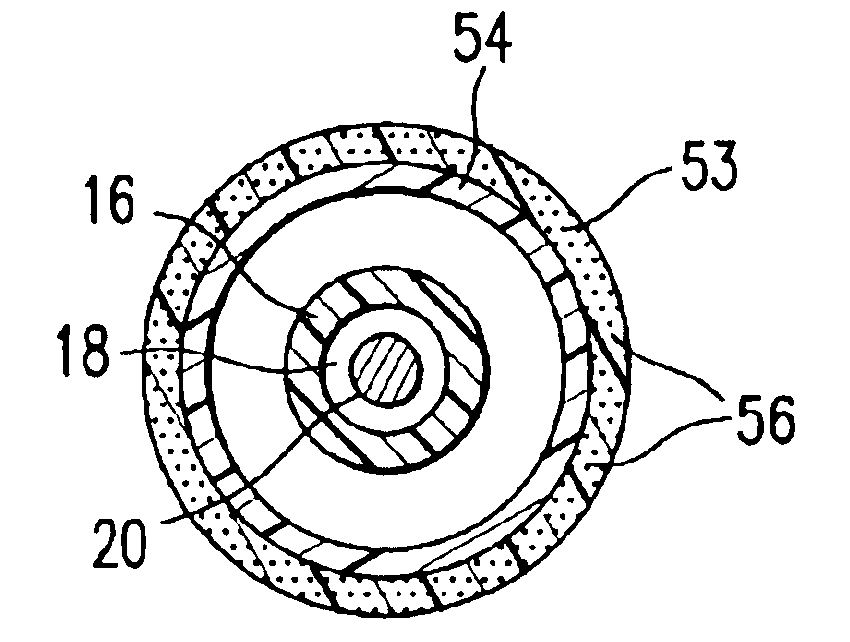

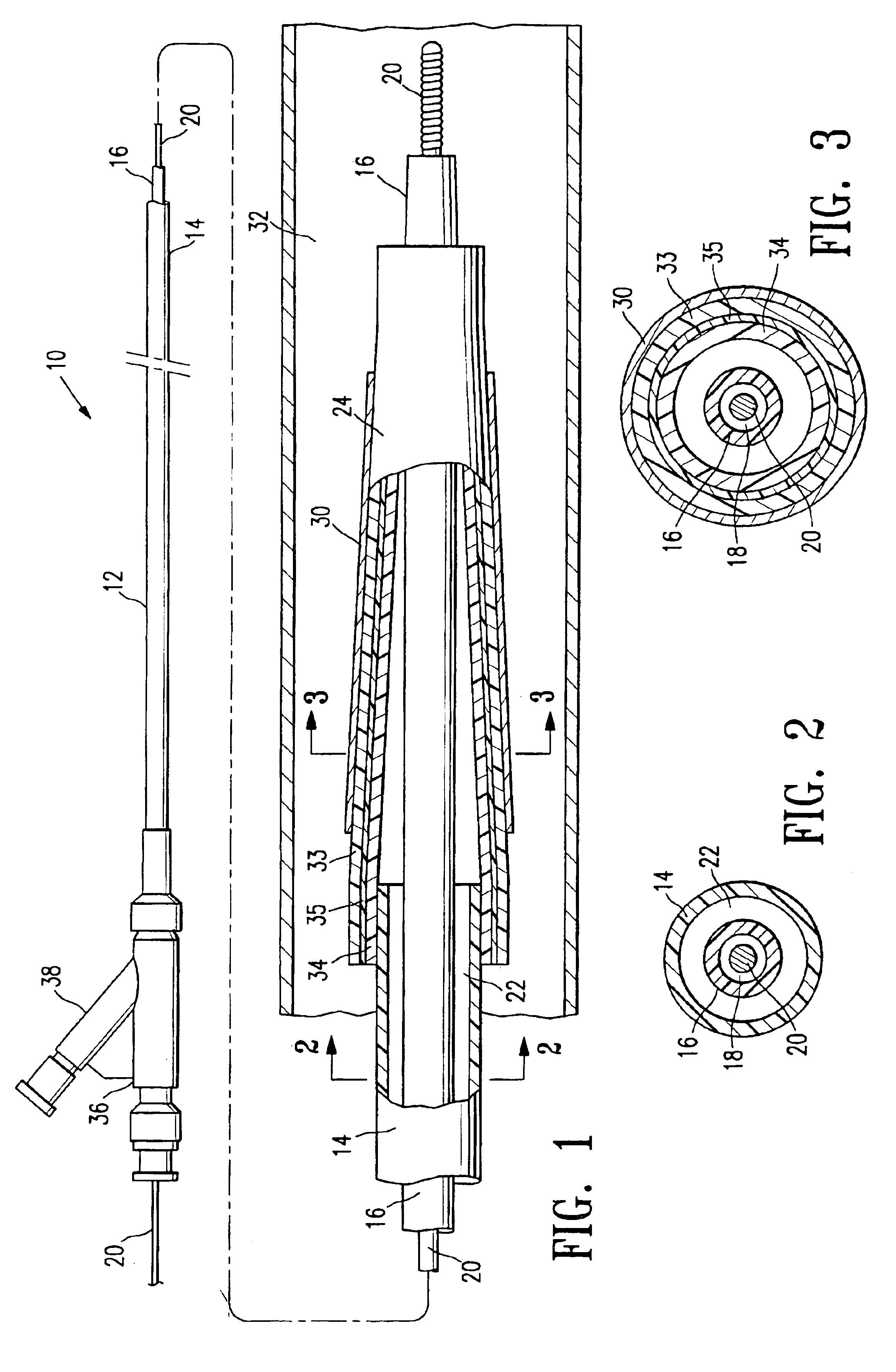

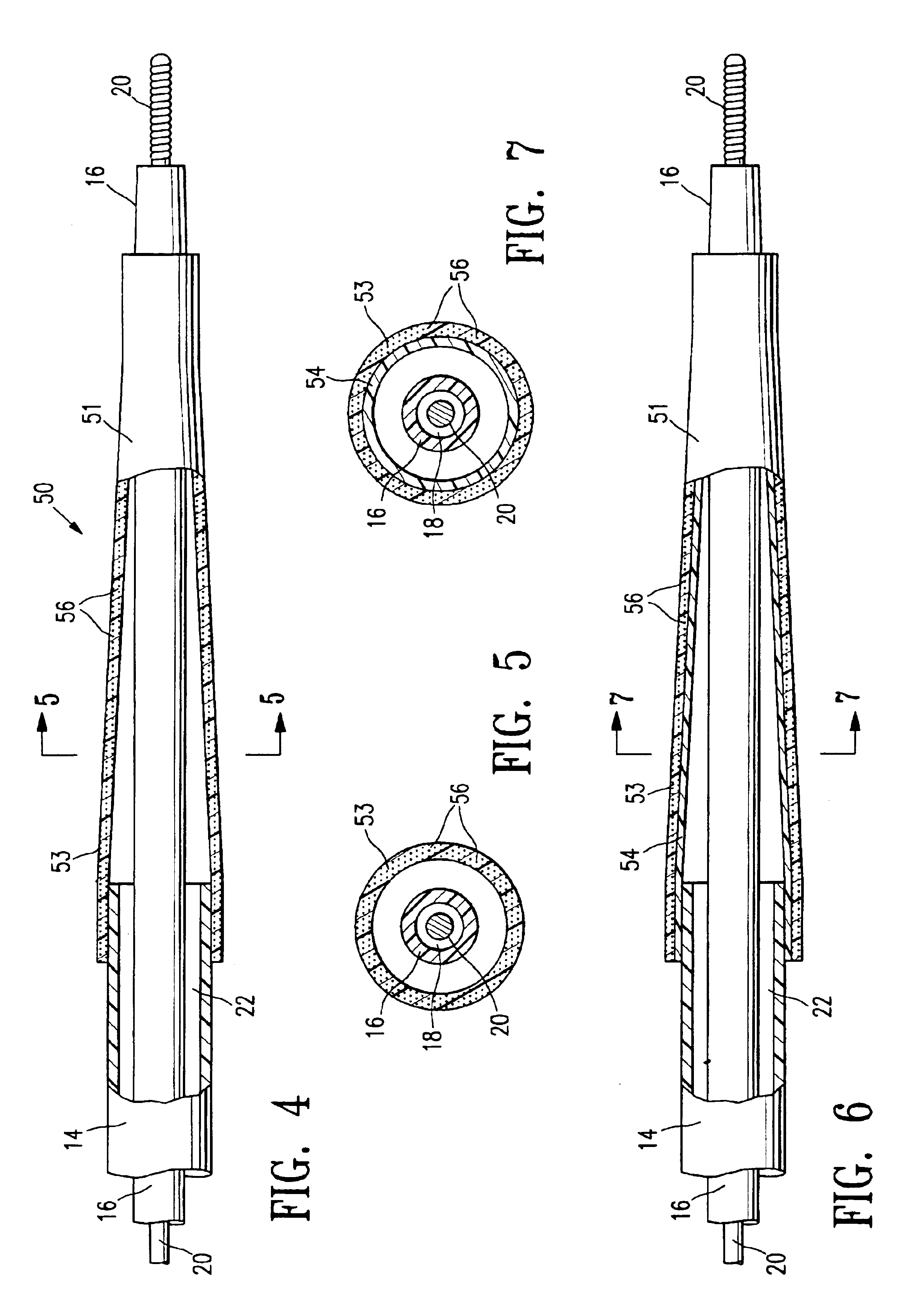

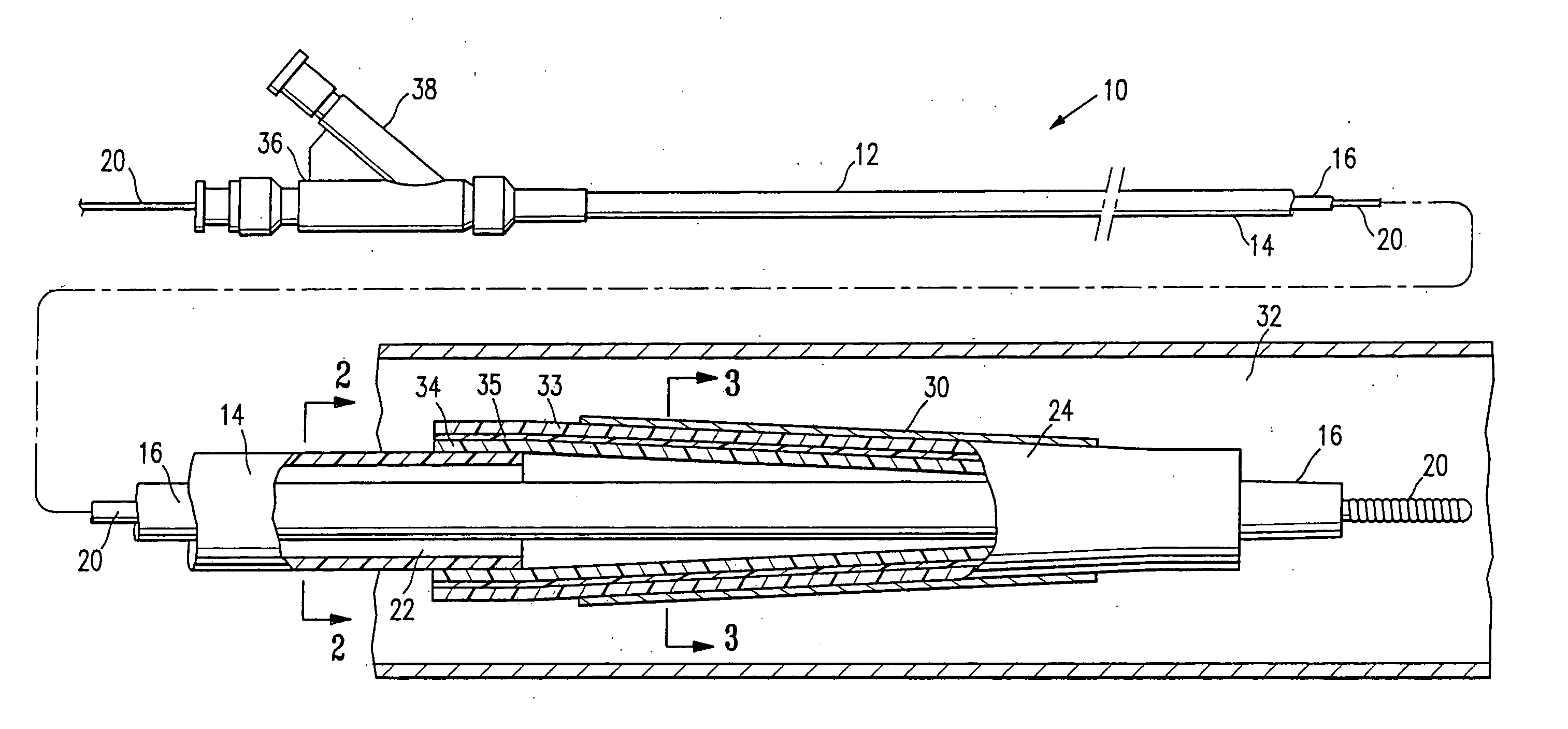

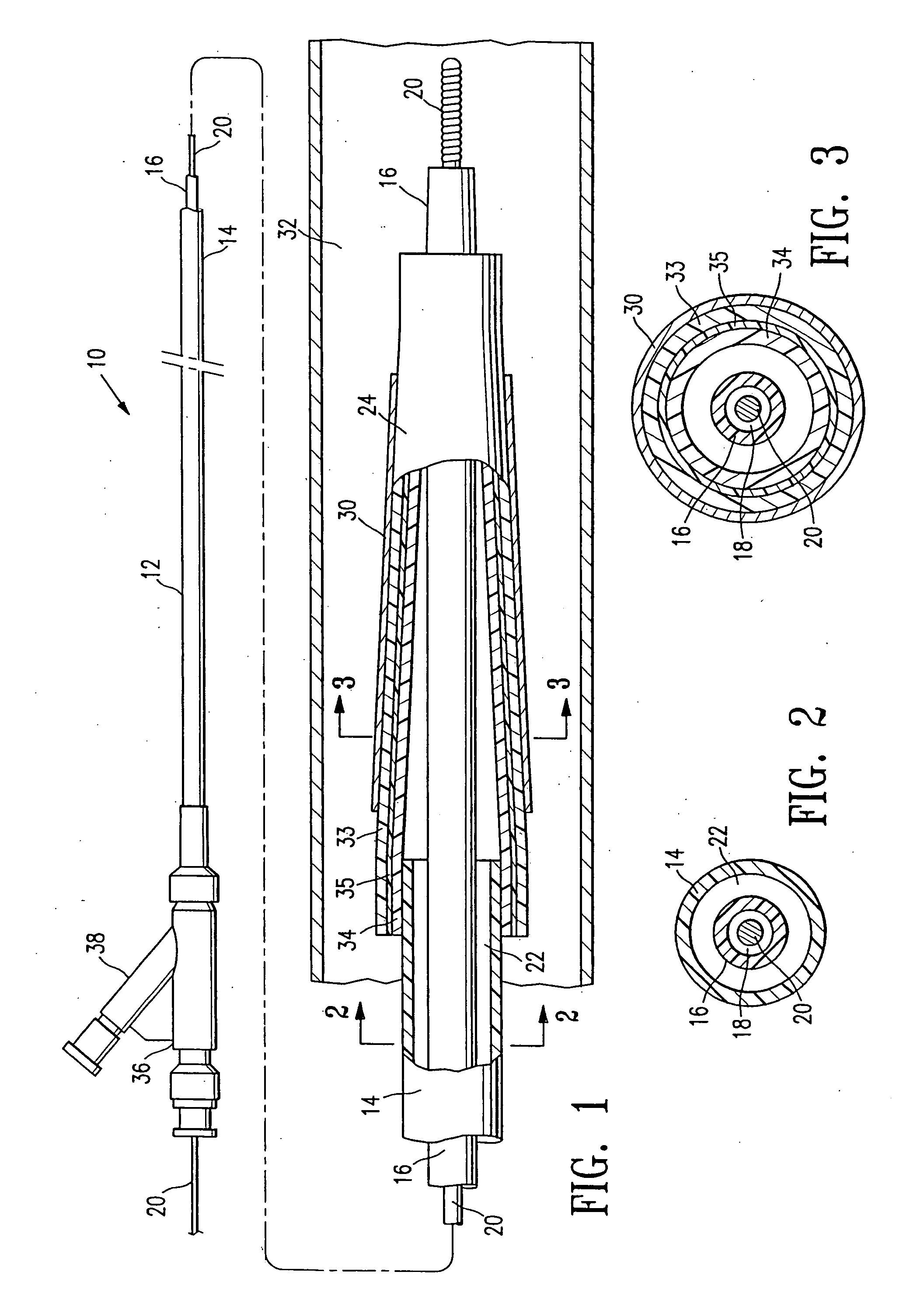

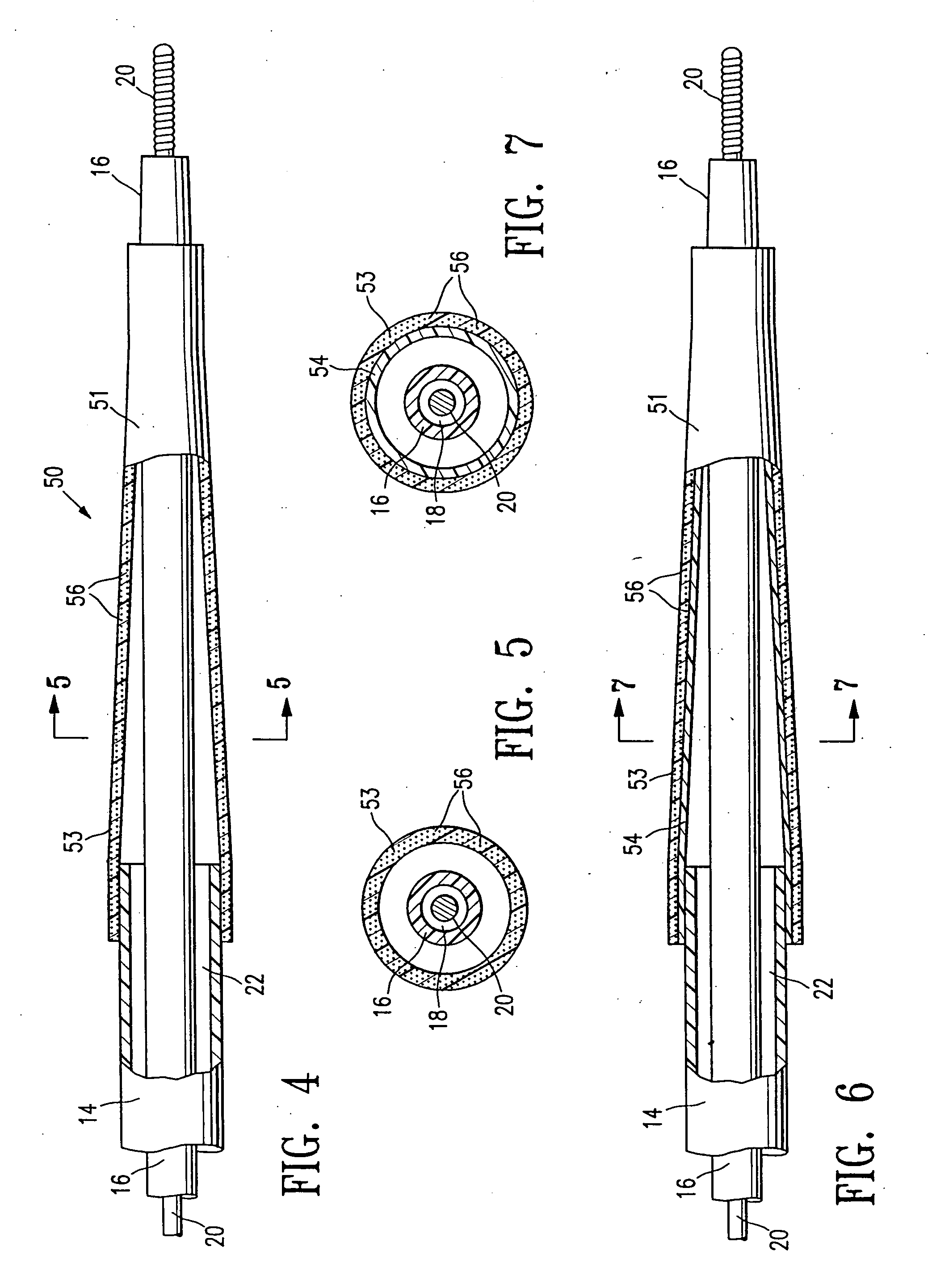

A catheter balloon formed of a polymeric material such as expanded polytetrafluoroethylene (ePTFE) bonded to a second layer formed of a low tensile set polymer and / or impregnated with a low tensile set polymer. In a presently preferred embodiment, the low tensile set polymer is a silicone-polyurethane copolymer elastomer or a diene polymer elastomer. The low tensile set polymer has high strength, low modulus, high elongation, and low tensile set. The diene or silicone-polyurethane has a low tensile set, which facilitates deflation of the balloon to a low profile deflated configuration. One aspect of the invention provides improved attachment of the diene to the ePTFE. In one embodiment, the second layer is formed of a diene mixed with a bonding promoter such as a vulcanizing agent which is covalently bonded to the diene.

Owner:ABBOTT CARDIOVASCULAR

Coffee carbon fiber plush printed blanket and preparation method thereof

InactiveCN102162170AIncrease weaving densityReduce stretch deformationCarbon fibresWarp knittingEngineeringAcrylic fiber

The invention discloses a coffee carbon fiber plush printed blanket and a preparation method thereof. The blanket is knitted by a double-needle-bed warp knitting machine; and the plush yarn of the blanket is a yarn obtained by blended knitting of coffee carbon fibers and acrylic fibers, wherein the double-yarn specification of the yarn obtained by the blended knitting is 28-36s; the base material terylene is warped, and then the coiled head is used as the knitting yarn and weft insertion yarn of the blanket. The preparation method comprises the following steps: starching and high-temperature setting of a white grey cloth, fuzzing, lustering, shearing, flat screen printing, aging and fixation, washing, dehydrating and drying, carding, fuzzing, lustering, shearing, binding and packaging and warehousing. The coffee carbon fiber plush printed blanket disclosed by the invention has the characteristics of bright color, soft handfeel, heat accumulation, warm keeping and the like, special healthcare functions of dehumidification, anion release, antibacterium and the like, and advantages of economy and environmental protection.

Owner:JIANGSU QIYING HOME TEXTILE

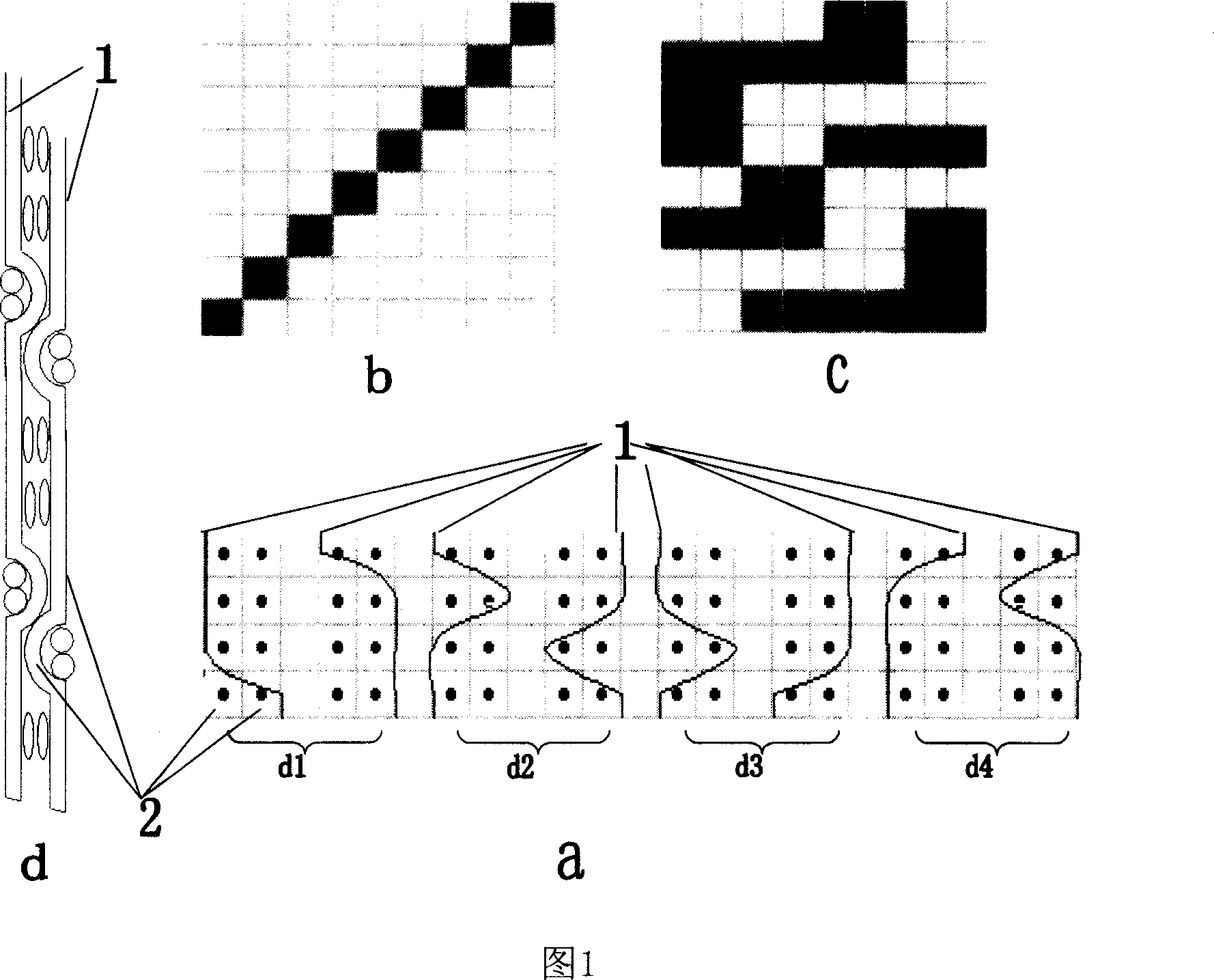

Image inhomogeneous mapping method based on grid deformation optimization

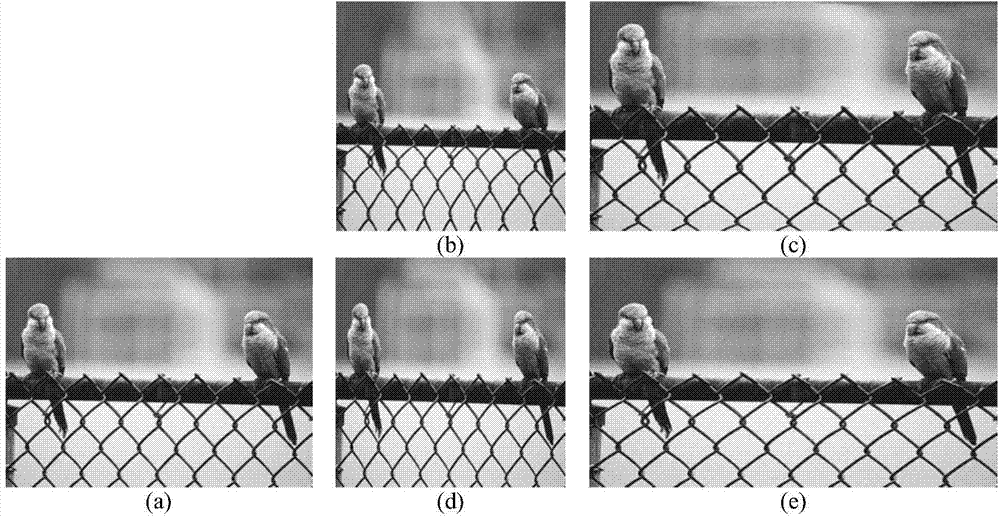

ActiveCN103617599AGuaranteed viewing qualityNo deformationImage enhancementGeometric image transformationEnergy functionalSelf adaptive

The invention discloses an image inhomogeneous mapping method based on grid deformation optimization and belongs to the field of image processing. According to the image inhomogeneous mapping method based on grid deformation optimization, a fast image scaling technology based on content sensing and suitable for different user terminals is provided, images with fixed sizes can be displayed on different types of terminal equipment in a self-adaptive mode, important contents in an original image can be kept as much as possible, key objects are kept distortionless, and the import structure, namely the spatial position relation, in the image is kept unchanged so that optimal image observing quality can be guaranteed. According to the image inhomogeneous mapping method based on grid deformation optimization, a content-based image scaling optimal model is established by defining a series of energy functions capable of effectively controlling grid deformation, deformation of obvious key areas is avoided during image scaling, and in this way, user experience of browsing images on mobile digital equipment is improved; the quality of a scaling result can be effectively improved, and tensile deformation of the edges of the key areas can be avoided to a certain degree.

Owner:BEIJING UNIV OF TECH

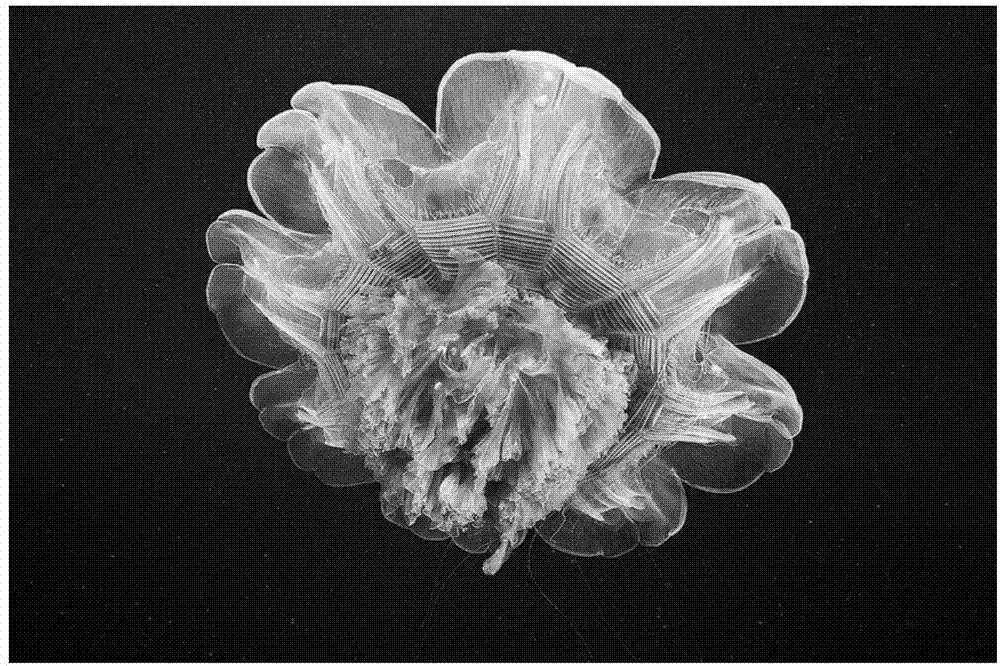

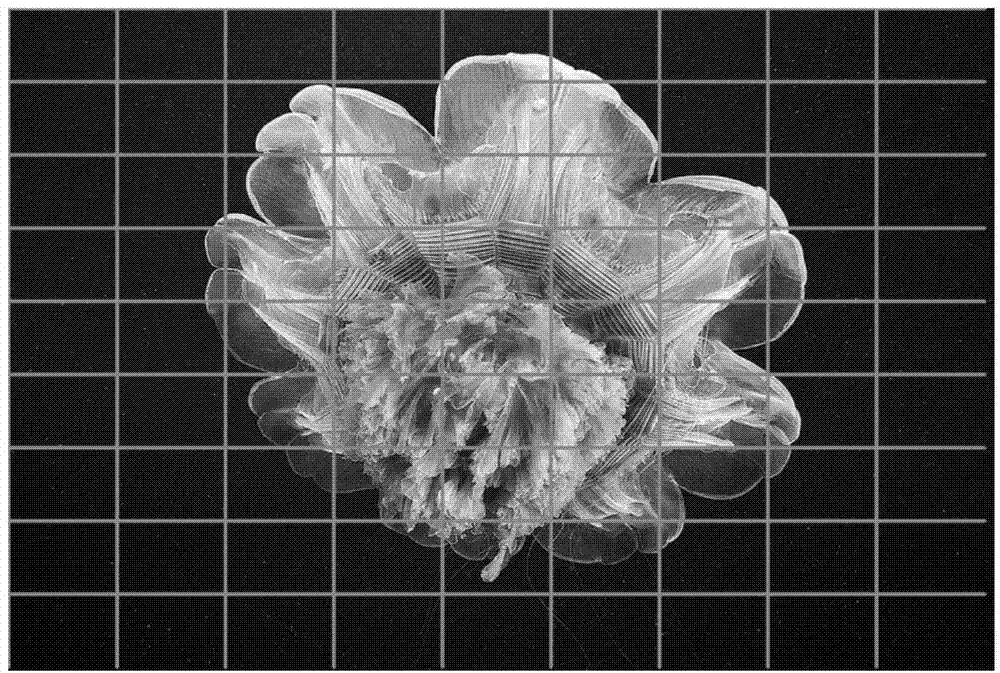

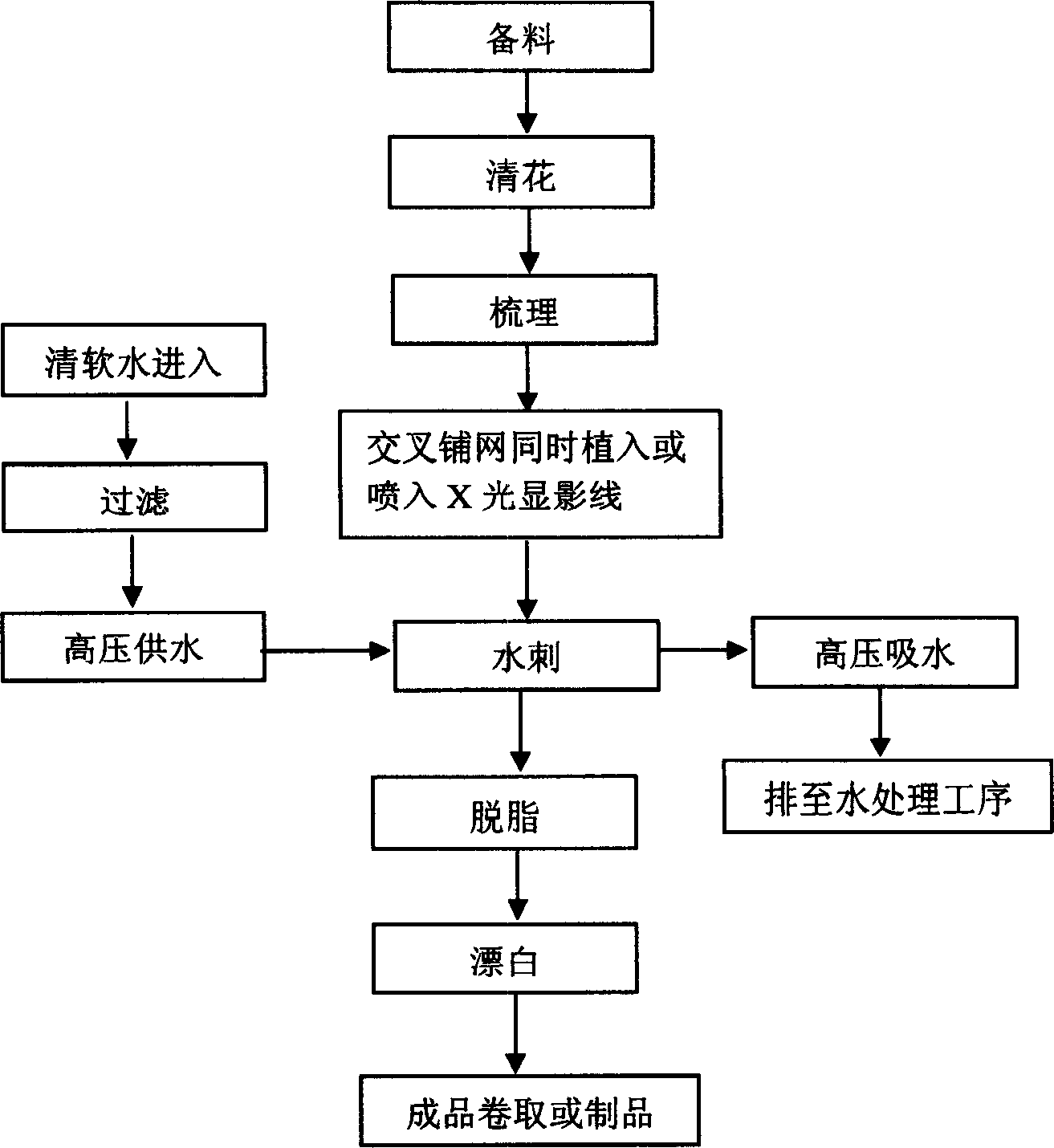

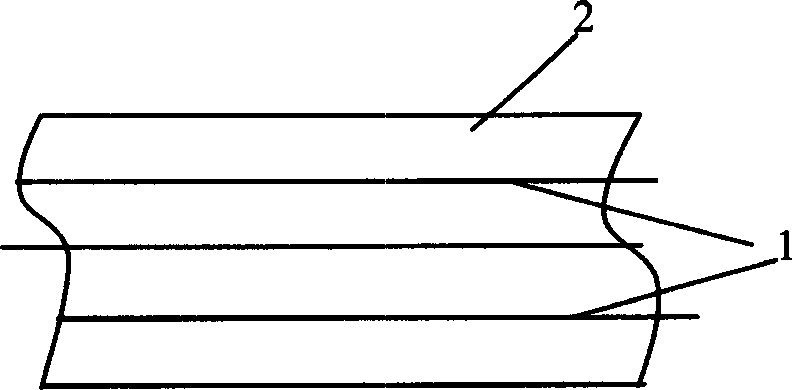

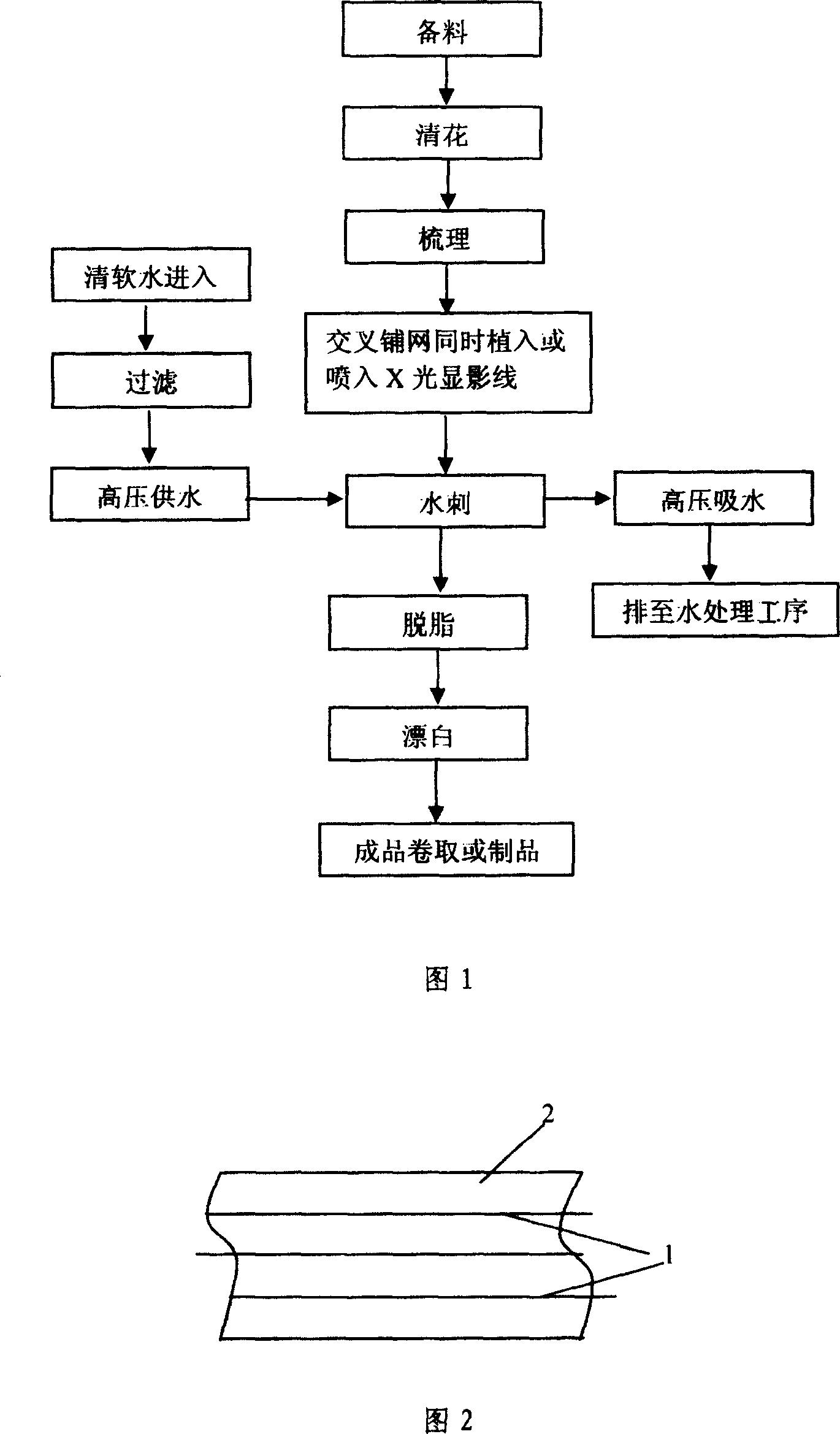

Hydro-entangled non-woven fabric containing X-ray developer and its producing method

ActiveCN1683708AReduce initial contaminationReduce stretch deformationFibre treatmentNon-woven fabricsX-rayEngineering

The present invention relates to hydro-entangled non-woven fabric, and is a kind of hydro-entangled non-woven fabric containing X-ray developer and its production process. The X-ray developer line may be added into or on the hydro-entangled non-woven fabric before winding, and is preferably implanted or sprayed to the fiber web before the hydro-entangling step so as to make the X-ray developer line and the fiber web entangled together. The present invention has reduced production process, lowered cost, less pollution, firm combination of the X-ray developer line and the fiber web, and raised product quality and safety.

Owner:WINNER MEDICAL CO LTD

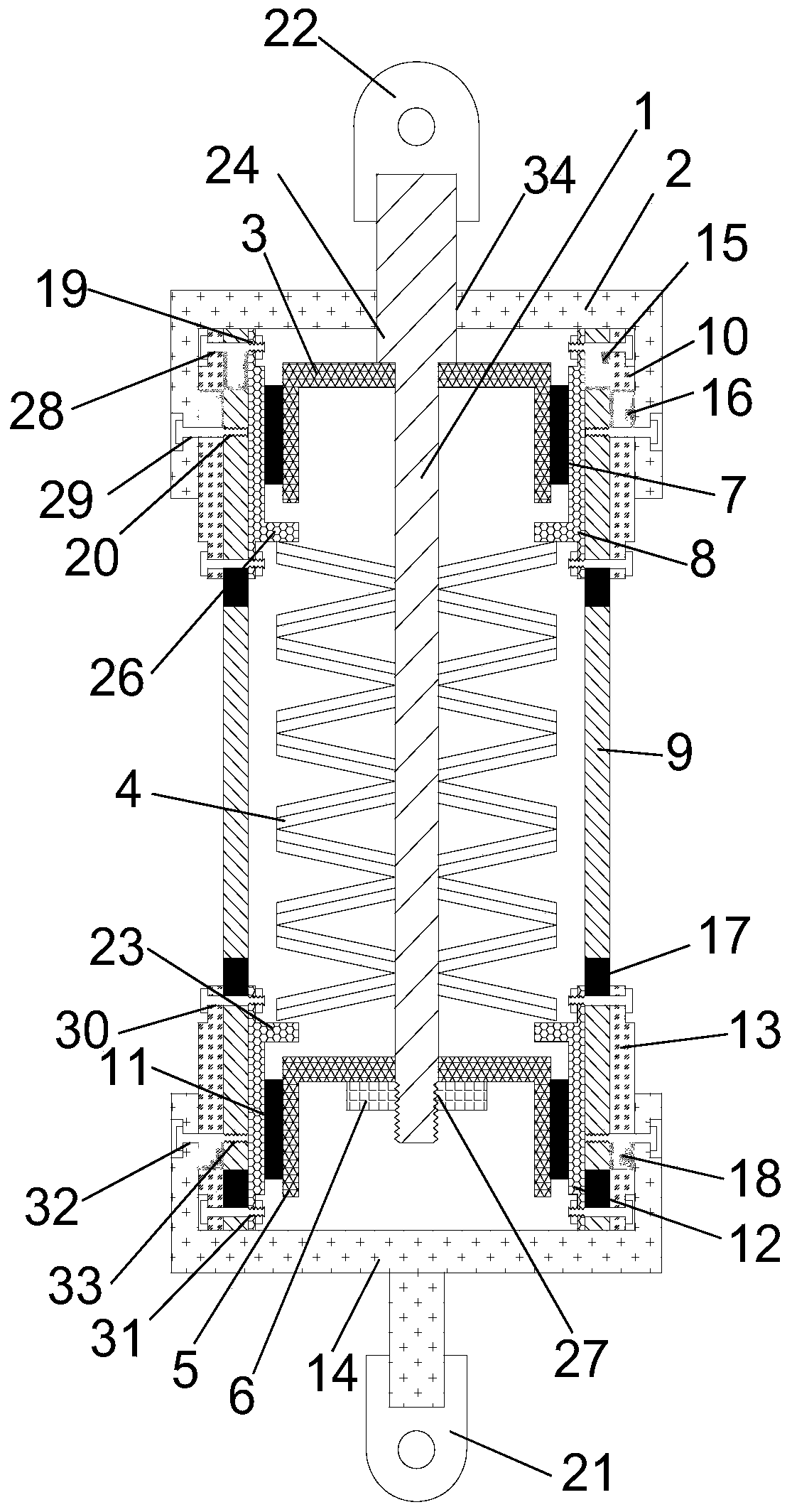

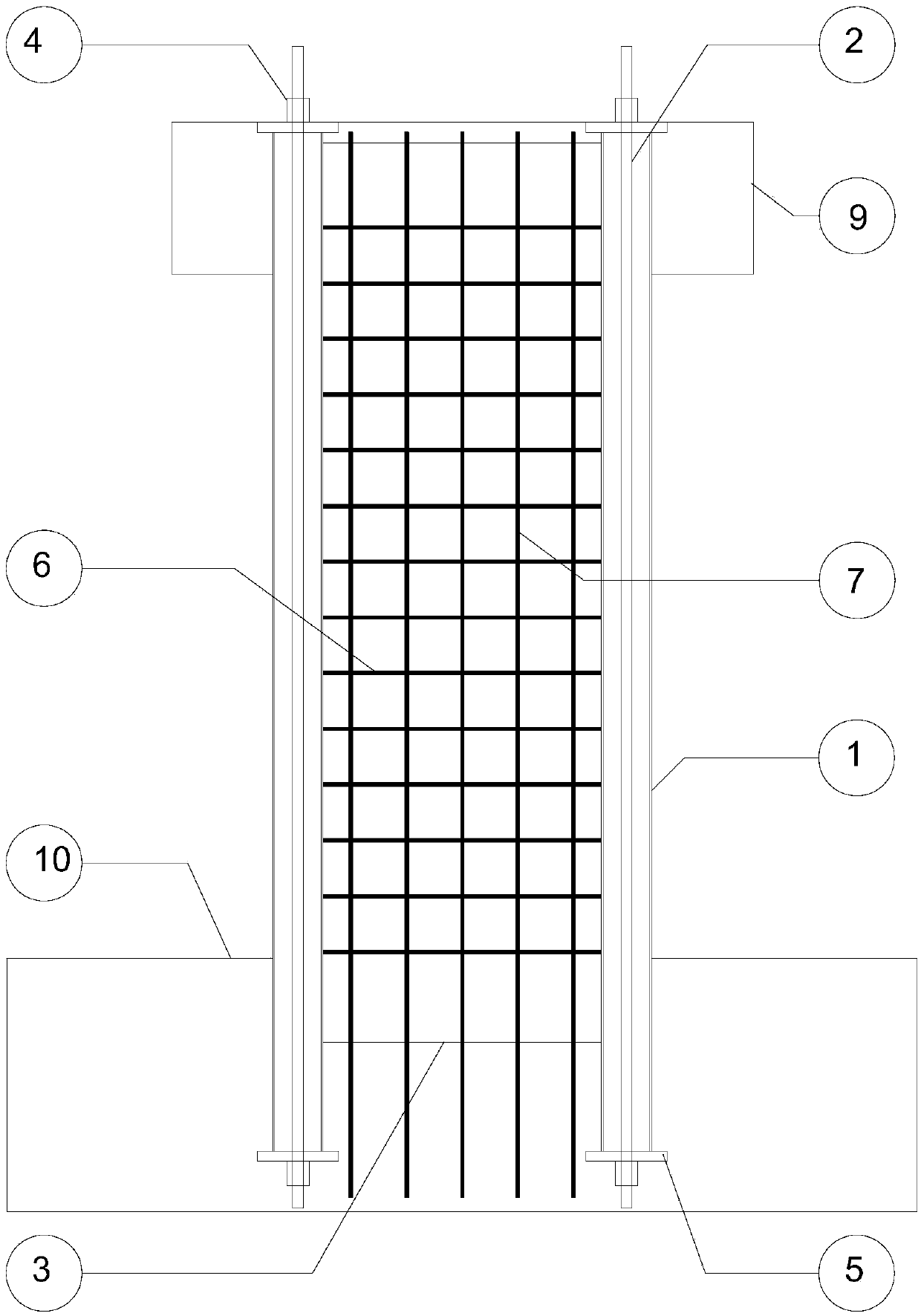

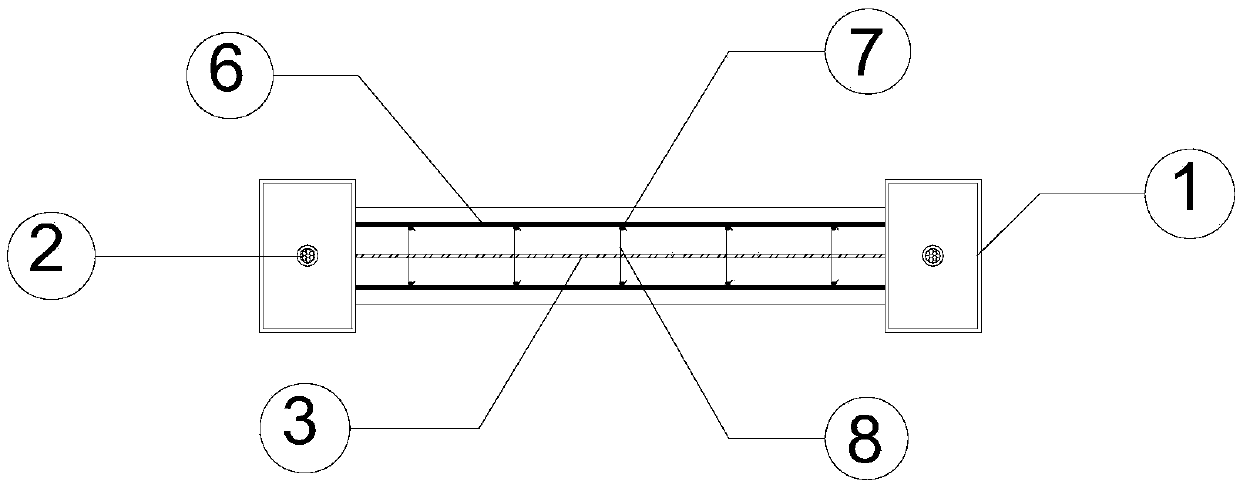

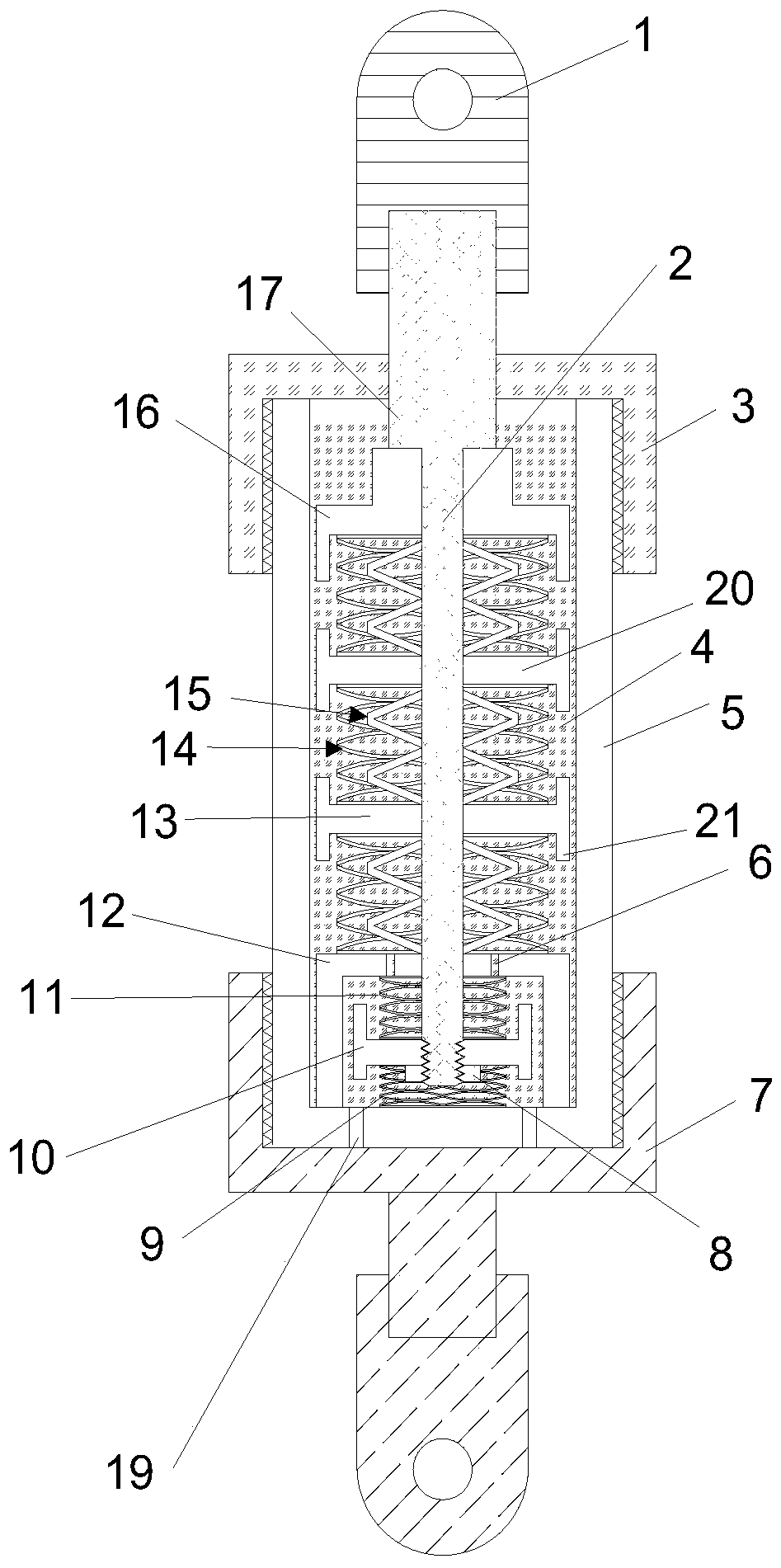

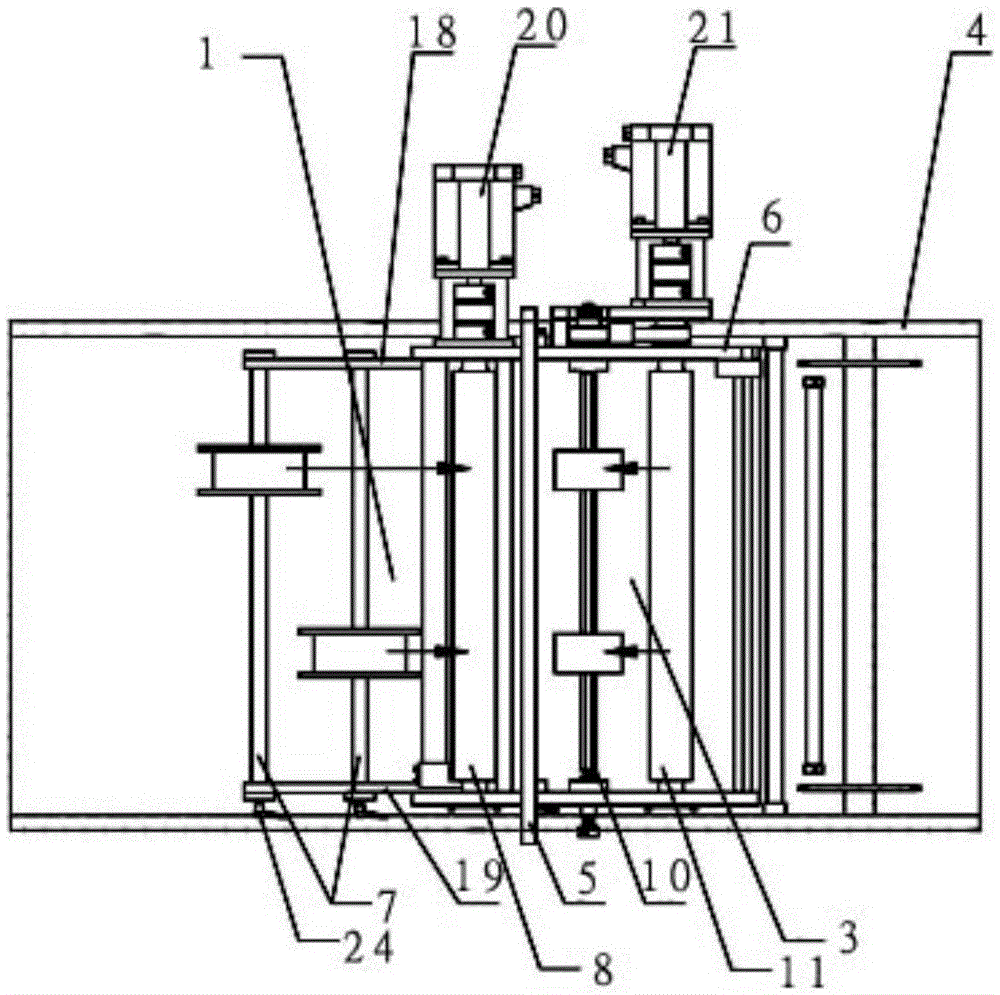

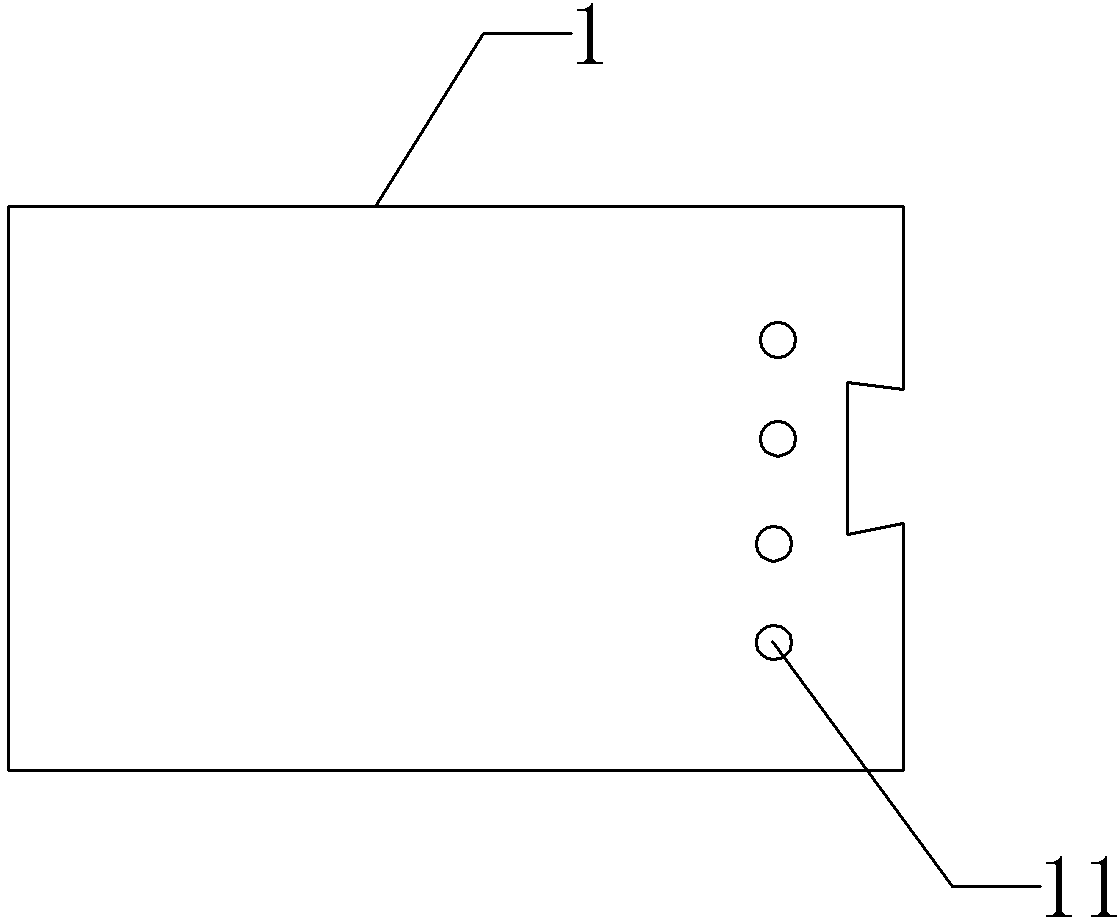

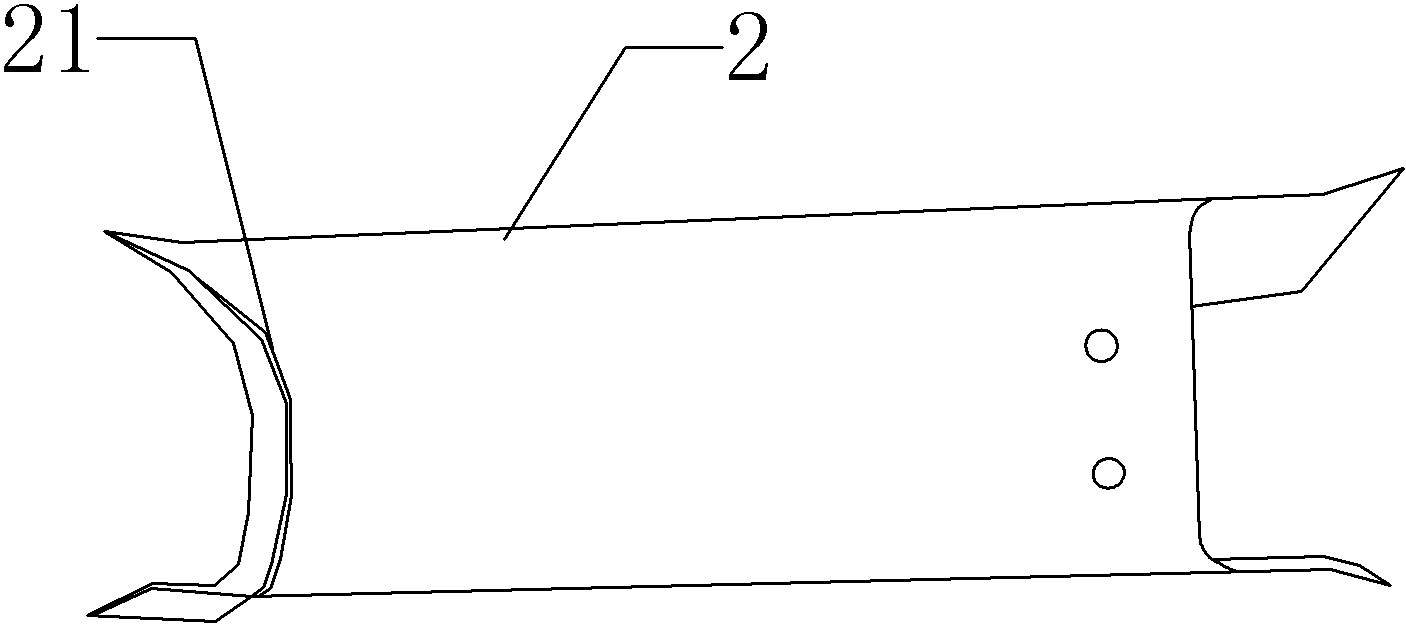

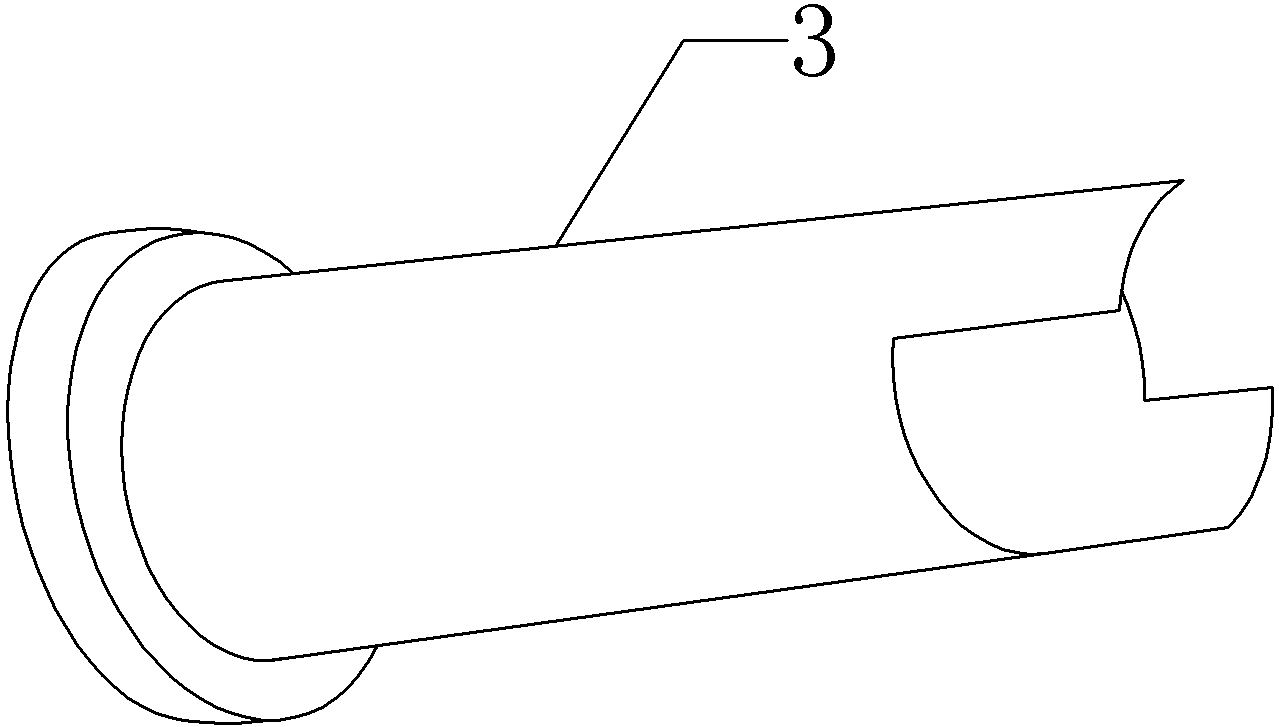

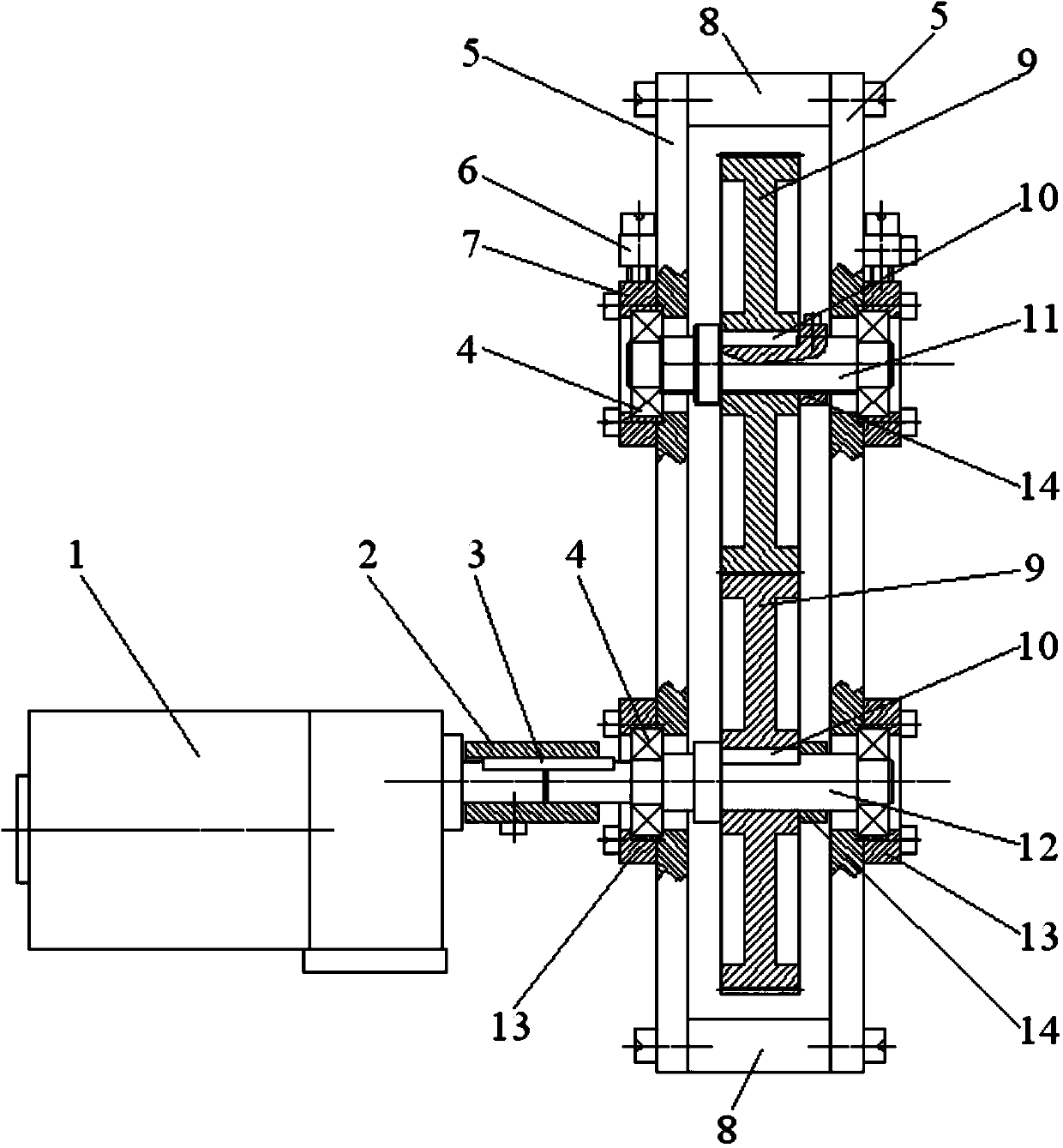

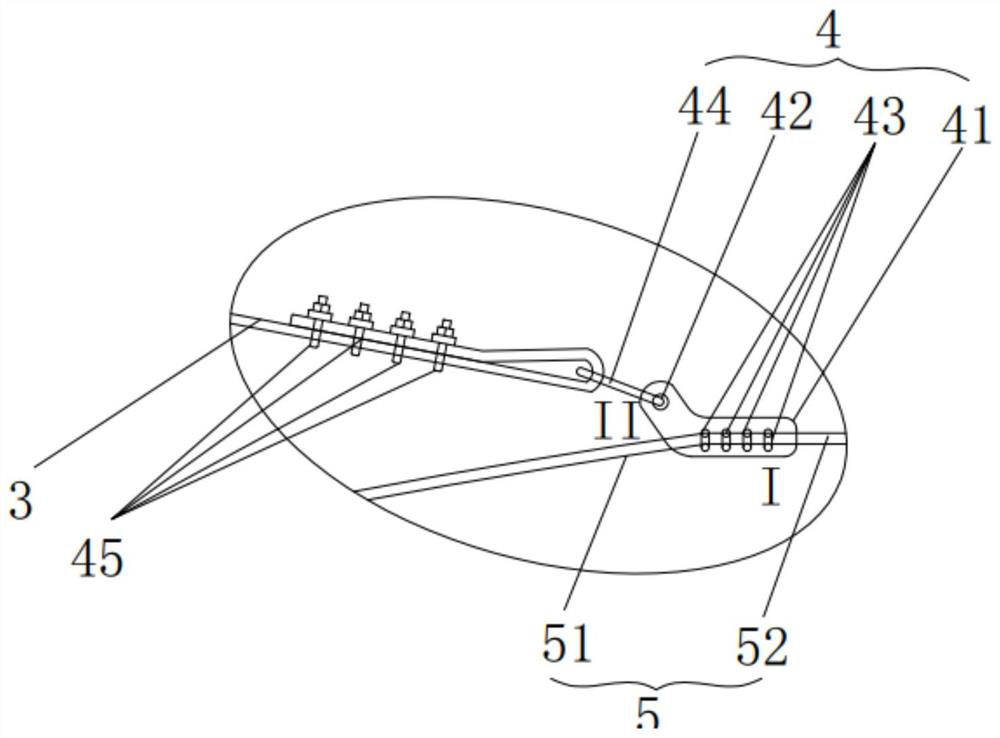

Viscoelastic friction type energy dissipation self-resetting buckling-restrained brace

PendingCN111005613AEnsure movement coordinationGuaranteed deformation coordinationProtective buildings/sheltersShock proofingEngineeringMechanical engineering

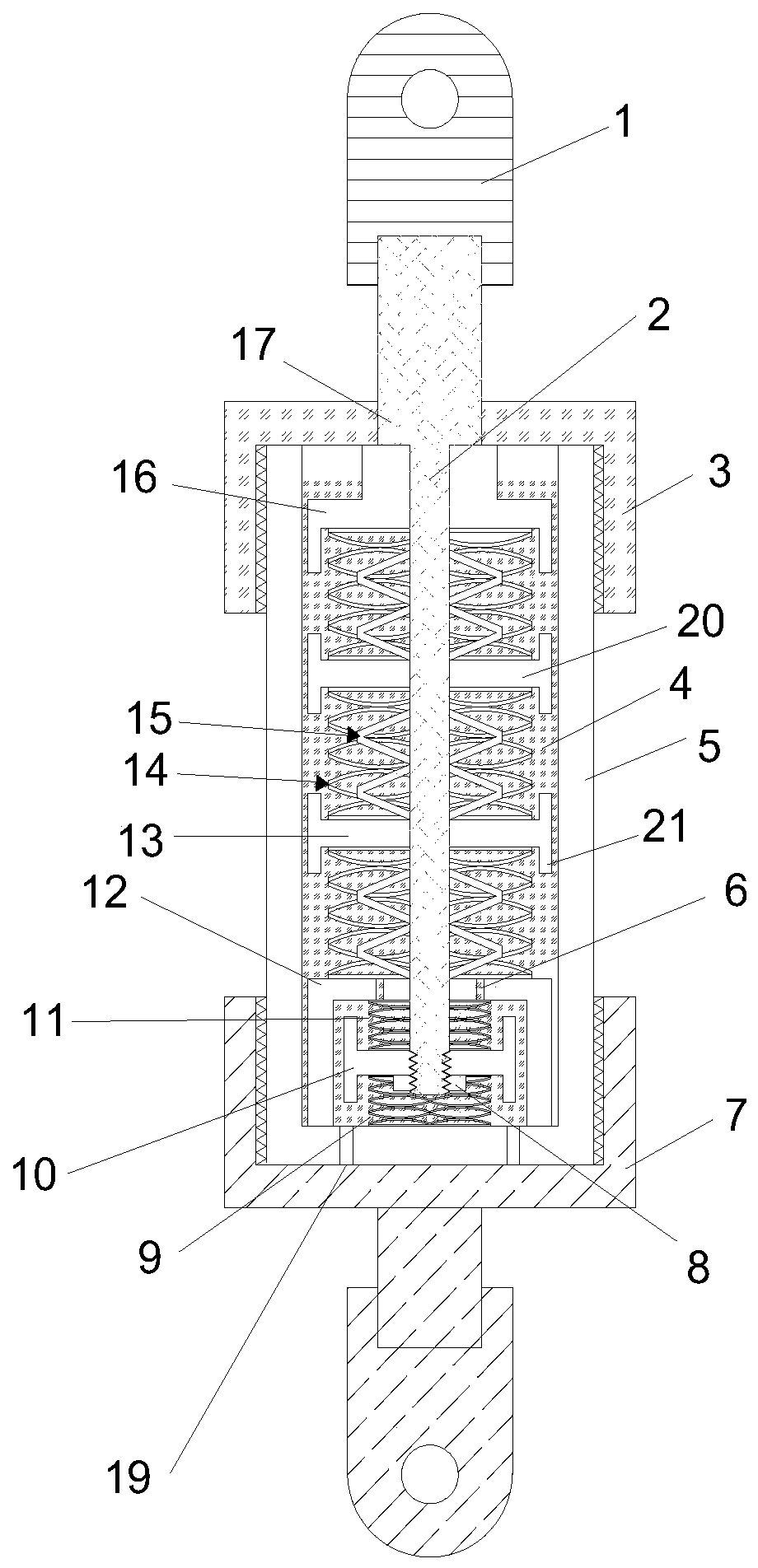

The invention provides a viscoelastic friction type energy dissipation self-resetting buckling-restrained brace. The viscoelastic friction type energy dissipation self-resetting buckling-restrained brace comprises an upper fixing cylinder, a lower fixing cylinder, fixing guide plates, a piston rod, a fixing end plate, springs, a first viscoelastic energy dissipation assembly, a second viscoelasticenergy dissipation assembly, first friction structures and second friction structures. Both ends of the fixing guide plates are separately inserted and fixed into the upper fixing cylinder and the lower fixing cylinder. The piston rod is arranged between the interior of the upper fixing cylinder and the interior of the lower fixing cylinder. The first viscoelastic energy dissipation assembly andthe second viscoelastic energy dissipation assembly separately sleeve both ends of the piston rod. The springs are arranged between the first viscoelastic energy dissipation assembly and the second viscoelastic energy dissipation assembly. The first end of the piston rod limits the first viscoelastic energy dissipation assembly, and the fixing end plate limits the second viscoelastic energy dissipation assembly. The viscoelastic friction type energy dissipation self-resetting buckling-restrained brace has self-resetting capability, can be automatically adjusted according to the brace force deformation characteristics to prevent damage to the internal components of the brace, and has stable and efficient energy dissipation capability.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

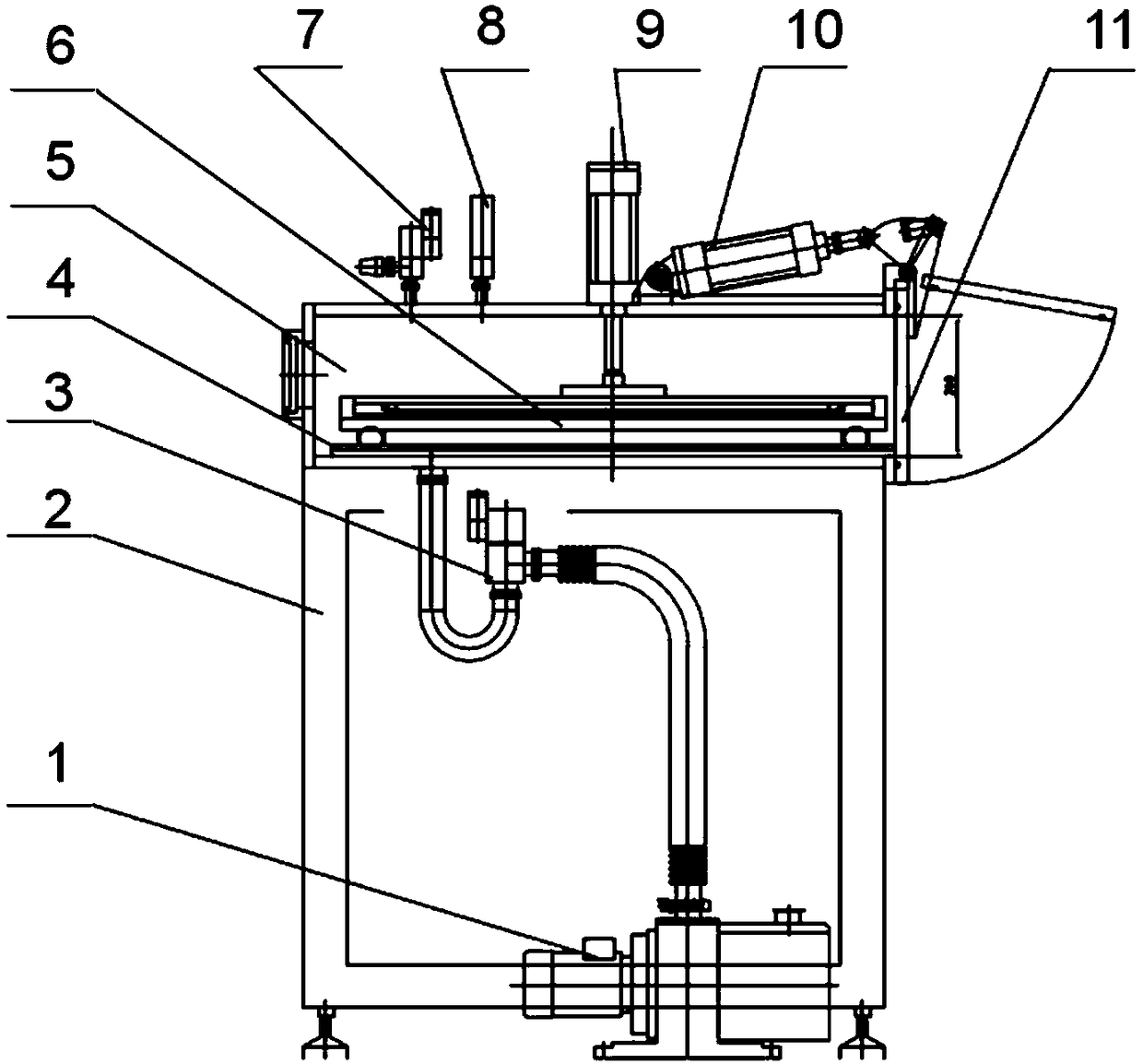

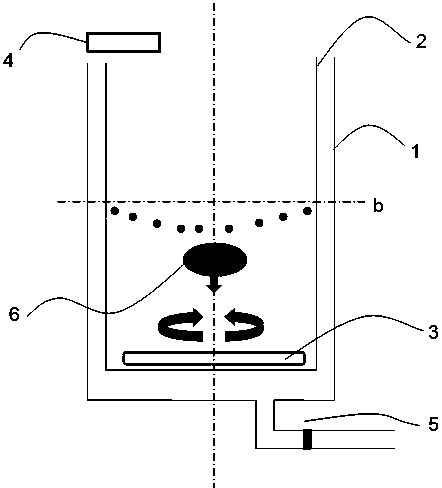

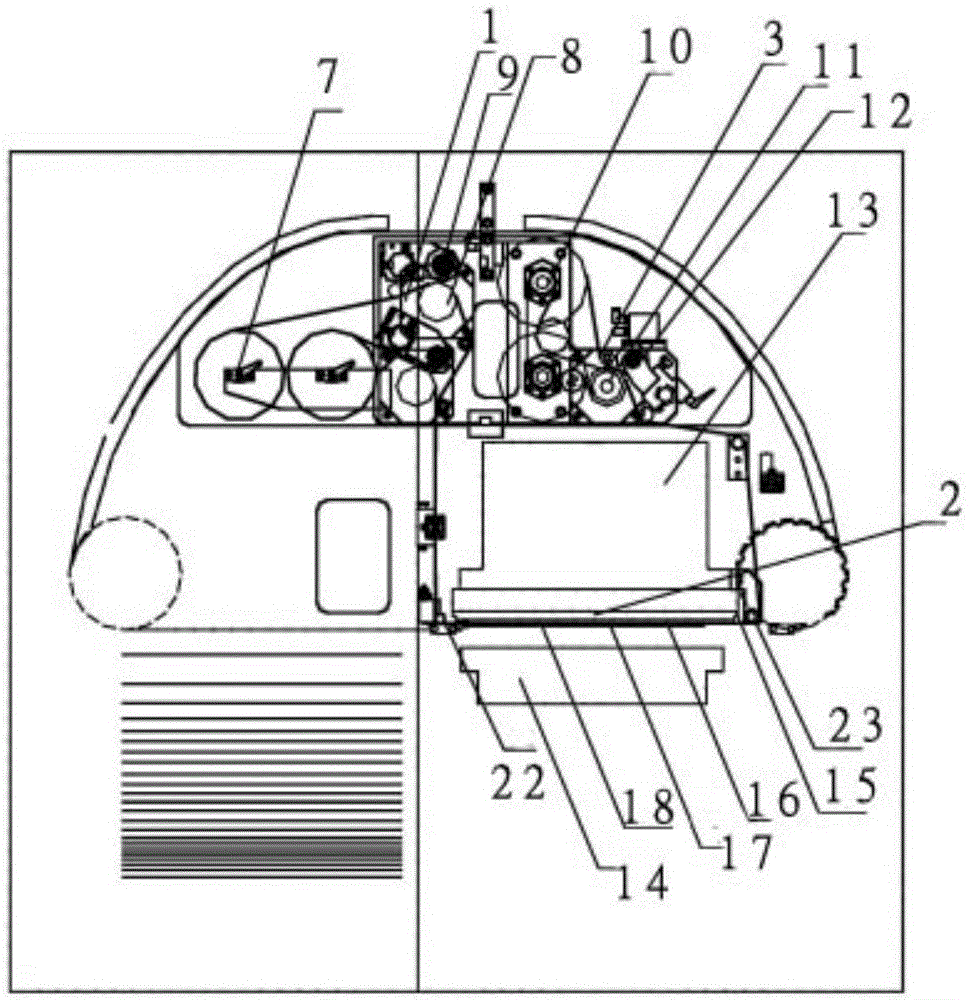

A vacuum attachment apparatus for contact lithography of a flexible thin film substrate

ActiveCN109143791AIncrease pressureImprove uniformitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusContact formationLithographic artist

The invention provides a vacuum attachment device for contact lithography of a flexible film substrate, comprising a vacuum pump, a frame, a flapper valve, a support table limiter, a vacuum chamber, amask support table, a bleed valve, a vacuum gauge, a top pressure mechanism, a sealing door opening / closing mechanism, a sealing door, a film holder, a flexible film, a sealing pad, and a photolithography mask. Wherein the mask support table can carry the photolithography mask and the film to be attached to move into and out of the vacuum chamber, the lithography mask is separated from that flexible film and spaced apart with the sealing pad, the support table limiter realizes positioning of the mask support table, the sealing door is closed, the vacuum pump and vacuum gauge control the degree of vacuum, As that action of the top pressure mechanism lowers the film support, the flexible film is in close contact with the sealing pad on the surface of the mask plate to form an airtight space, the pressure difference introduce by the vacuum is broken outside the airtight space by the bleed valve, the airtight space is compressed, the flexible film is closely adhered to the surface of themask plate, the mask support table is taken out and the mask plate and the flexible film are treated as a whole to be exposed.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

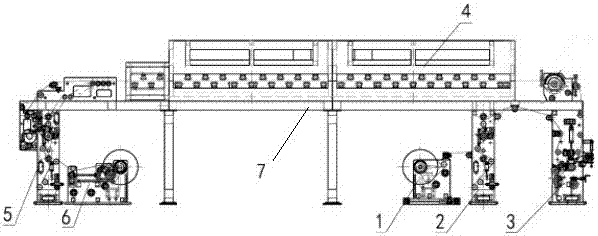

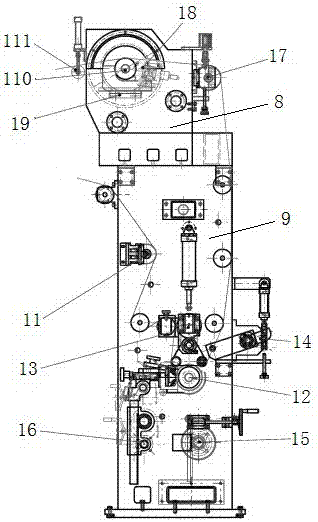

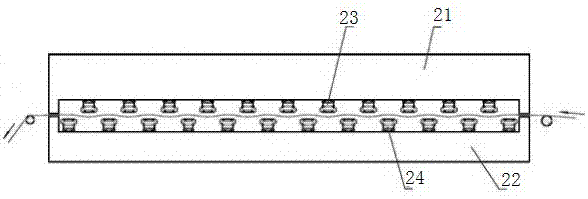

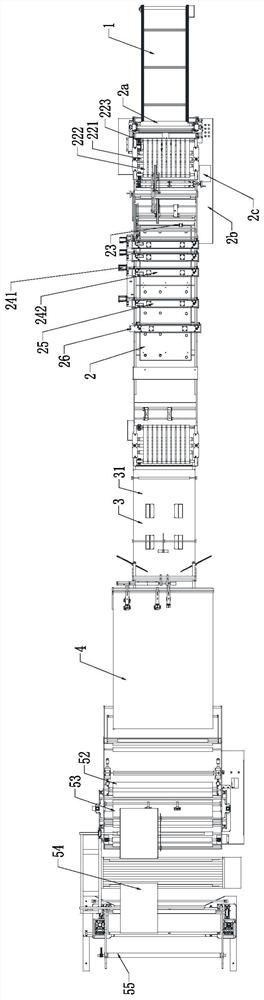

Aluminum foil double-face fast coating device and method

InactiveCN107159524ASave spaceFast coatingPretreated surfacesCoatingsEngineeringStructural engineering

The invention provides an aluminum foil double-face fast coating device. The aluminum foil double-face fast coating device comprises a first frame, an unwinding mechanism, a feeding drawing mechanism, a coating mechanism, a drying oven, a discharging drawing mechanism and a winding mechanism, wherein the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism are arranged on the first frame. The coating mechanism is a double-face ladder type coating mechanism which comprises a front side coating mechanism body and a back side coating mechanism body. The drying oven is a suspension drying oven. Aluminum foil sequentially passes through the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism, and then double-face coating is completed. An aluminum foil double-face fast coating method sequentially comprises the steps of unwinding, front side coating, back side coating, double-face drying and winding. According to the aluminum foil double-face fast coating device and method, through the ladder type one-time front side and back side coating and one-time double-face drying technologies, the material conveying path is greatly shortened, fast coating is achieved, the coating speed can reach 150m / min, in addition, the double faces are dried at a time after being coated, the space of the drying oven is saved, the manufacturing cost is reduced, meanwhile, energy is saved by about 160KW / h, and the aluminum foil double-face fast coating device and method are suitable for gravure coating and reverse kiss coating.

Owner:XIAN XINDA MACHINERY

Combined shear wall with steel plates concealed in internal prestressed tendon CFST (concrete filled steel tube) frame and manufacturing method

PendingCN108678225AReduce yieldReduce stretch deformationWallsUltrasound attenuationReinforced concrete

The invention discloses a combined shear wall with steel plates concealed in an internal prestressed tendon CFST (concrete filled steel tube) frame and a manufacturing method and belongs to the fieldof steel-concrete combined shear walls. The combined shear wall comprises CFST frame columns, prestressed tendons, steel plates and a reinforced concrete shear wall, wherein the CFST frame columns arearranged at two ends of the shear wall; the prestressed tendons are arranged in the CFST frame columns; the two CFST frame columns are connected through the steel plates; shear wall rebars are tied;tying bars penetrate through the steel plates to connect the rebars on two sides; concrete is poured; prestress is applied with a post-tensioning method, and the combined shear wall with steel platesconcealed in the internal prestressed tendon CFST frame is formed. compared with ordinary steel tube-concrete frame shear walls and steel plate shear walls, the combined shear wall has improved bearing capacity, attenuation of the bearing capacity and the rigidity is slow, the later aseismic property is stable, the shear wall has recoverability in the presence of the prestressed tendons, displacement of an overall structure is reduced, and the aseismic property is excellent; non-bonding prestressed tendon construction is convenient, and the combined shear wall can be applied to high-rise buildings or large complicated multi-storey buildings.

Owner:BEIJING UNIV OF TECH

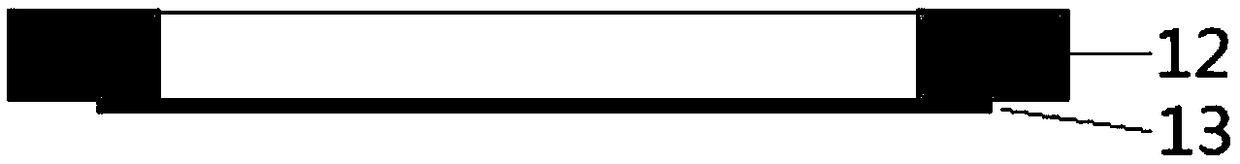

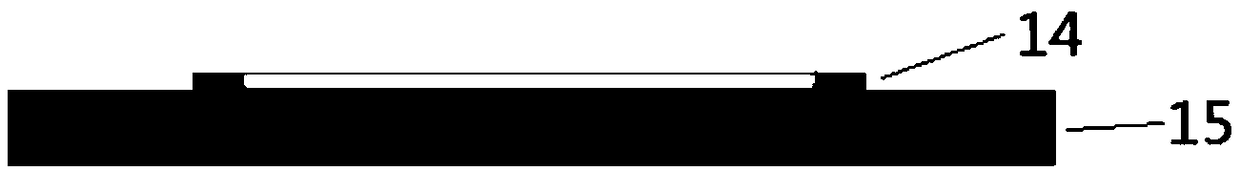

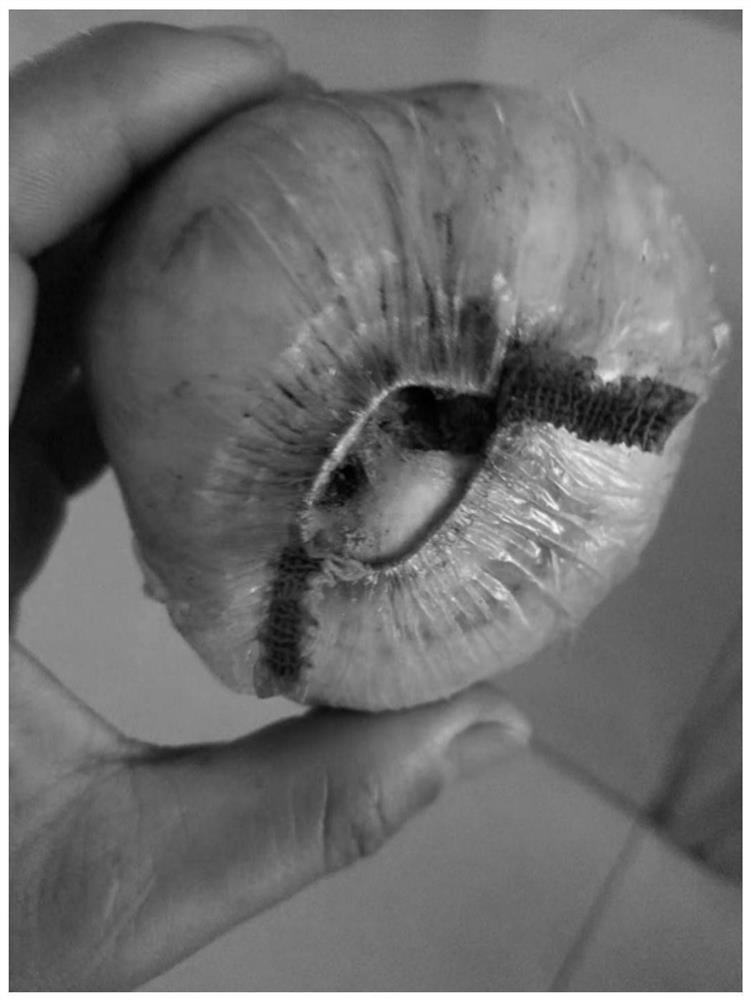

Catheter balloon formed of ePTFE and a diene polymer

InactiveUS20060029756A1Facilitate deflationHigh strengthStentsBalloon catheterElastomerTetrafluoroethylene

A catheter balloon formed of a polymeric material such as expanded polytetrafluoroethylene (ePTFE) bonded to a second layer formed of a low tensile set polymer and / or impregnated with a low tensile set polymer. In a presently preferred embodiment, the low tensile set polymer is an elastomer selected from the group consisting of a silicone-polyurethane copolymer and a diene polymer. The low tensile set polymer has high strength, low modulus, high elongation, and low tensile set, to provide improved balloon performance. The diene or silicone-polyurethane has a low tensile set, which facilitates deflation of the balloon to a low profile deflated configuration. One aspect of the invention provides improved attachment of the diene to the ePTFE. In one embodiment, the second layer is formed of a diene mixed with a bonding promoter such as a vulcanizing agent which is covalently bonded to the diene.

Owner:LIM FLORENCIA +6

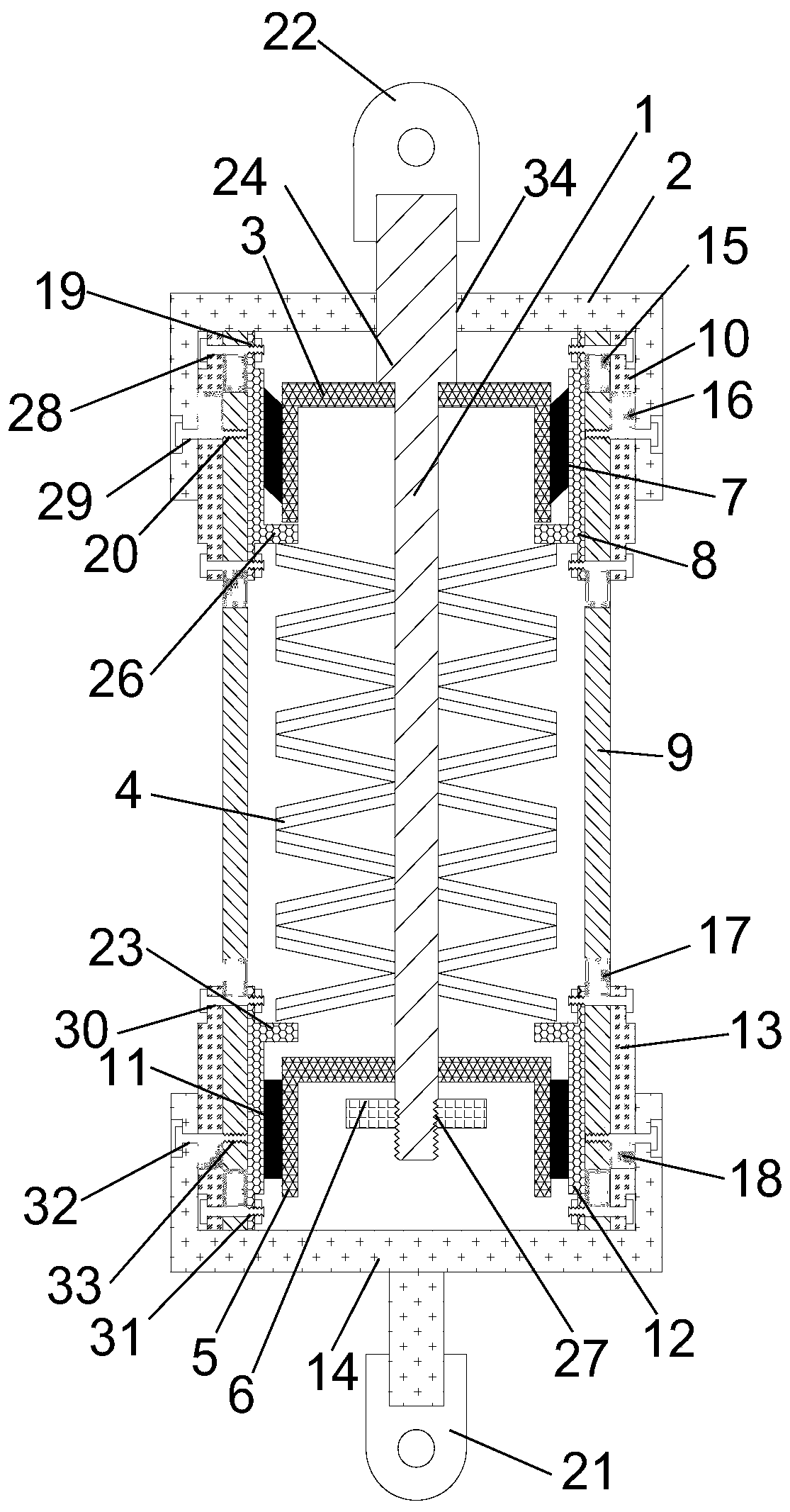

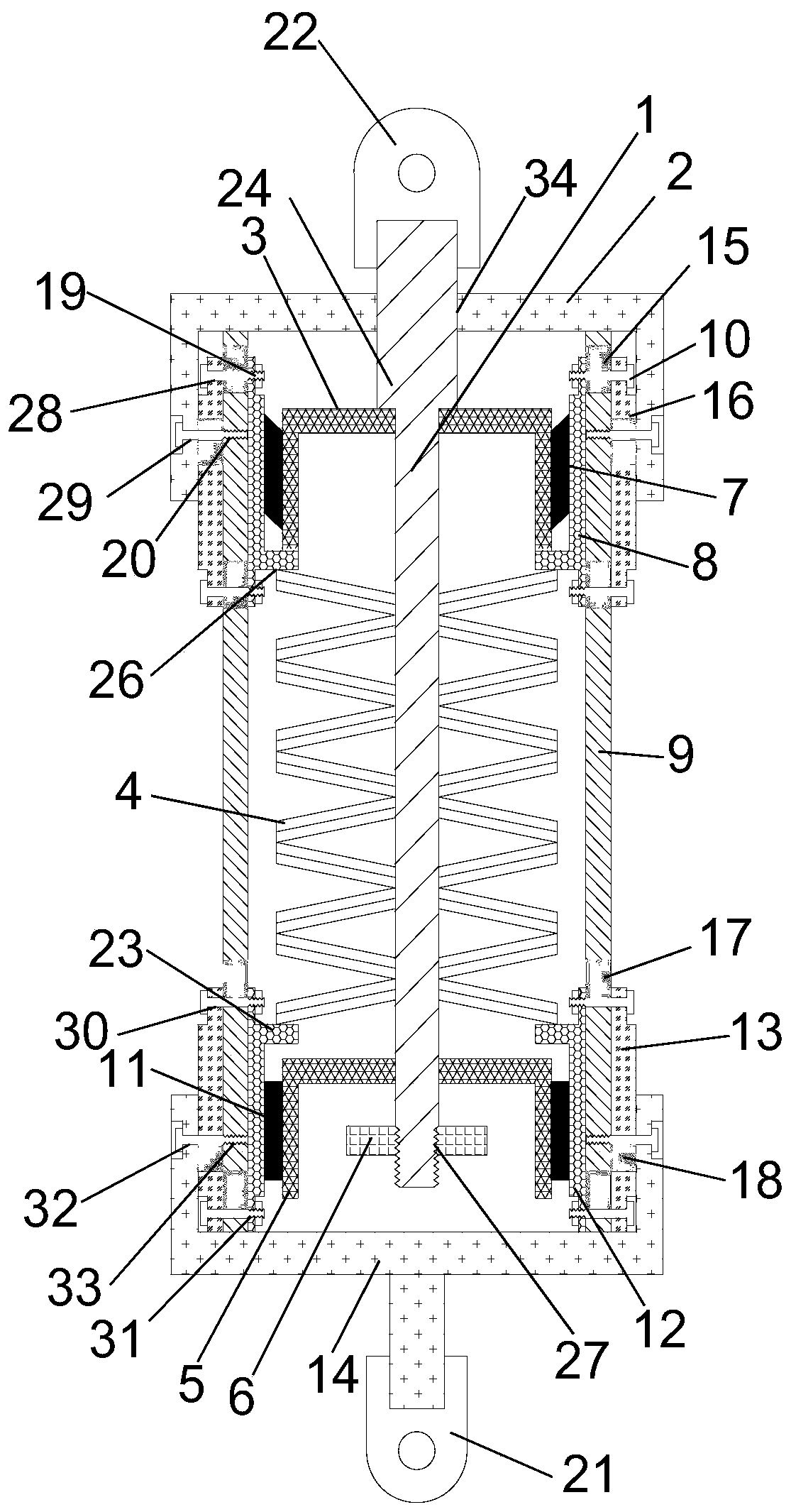

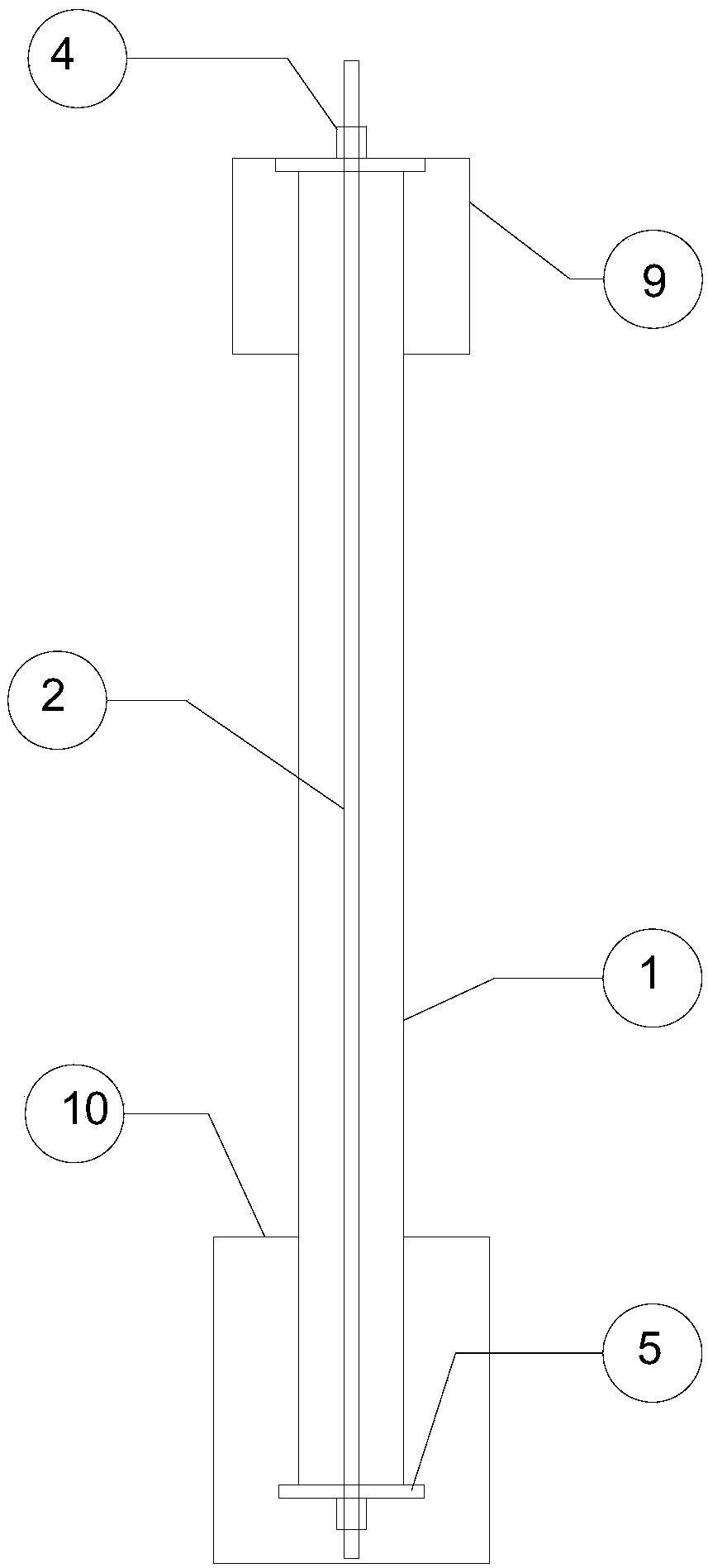

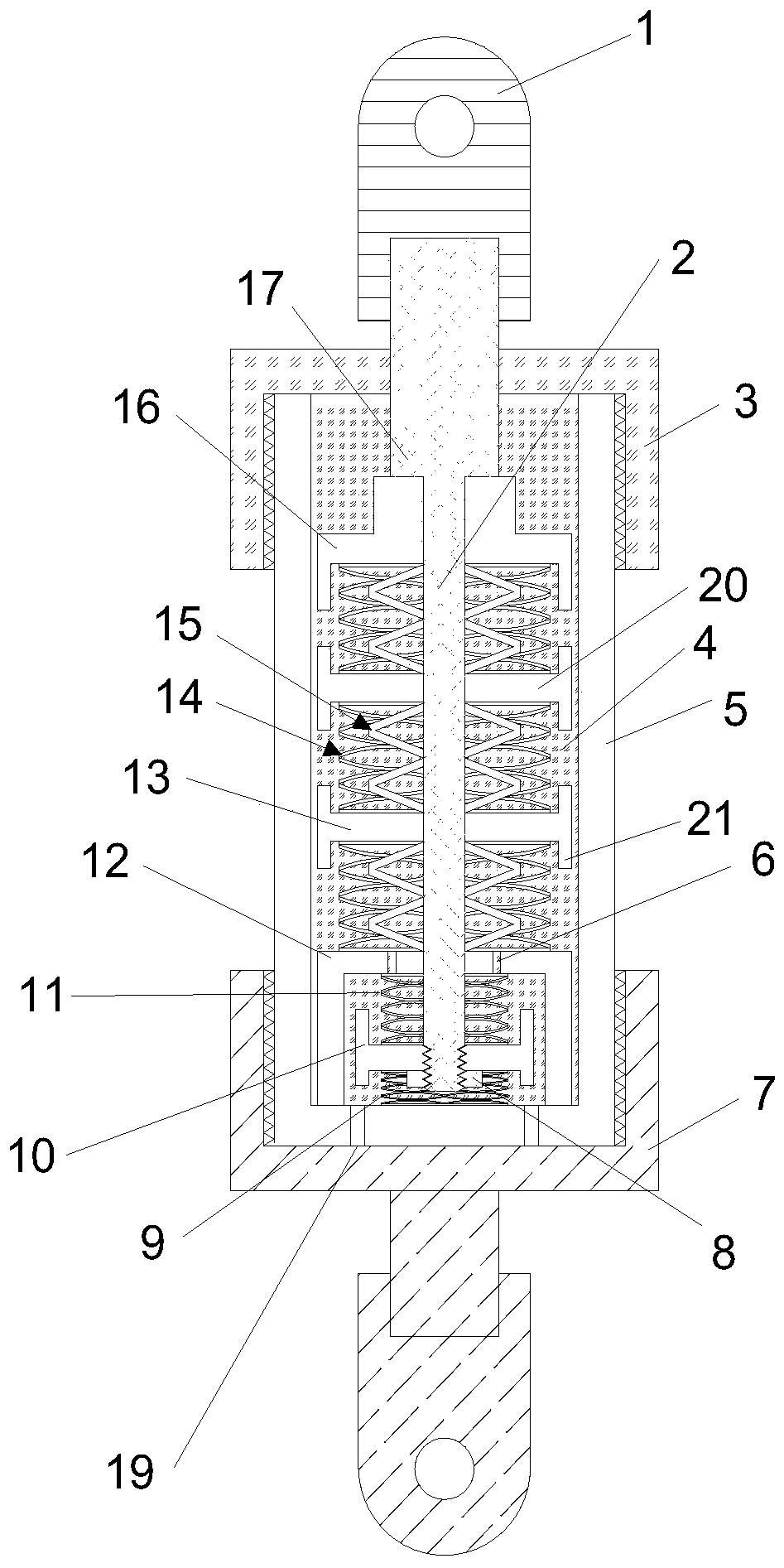

Self-adaptive buckling-preventing support

PendingCN110714546AReduce stretch deformationReduce distortionBuilding repairsProtective buildings/sheltersEngineeringCylinder block

The invention discloses a self-adaptive buckling-preventing support which comprises a sealing cylinder cavity. The top face of the sealing cylinder cavity is open. An upper sealing end cylinder is installed on the top face. A hole matched with a piston rod in radial size is formed in the center of the upper sealing end cylinder. The piston rod penetrates through the center hole of the upper sealing end cylinder and is partially installed in the sealing cylinder cavity. An energy consumption partition plate is installed on the piston rod. The energy consumption partition plate is transversely arranged on the piston rod in a sleeving manner, and moves in the sealing cylinder cavity along with moving of the piston rod. The sealing cylinder cavity is filled with damping liquid. Springs are further installed in the sealing cylinder cavity. The self-adaptive buckling-preventing support has the beneficial effects that the energy consumption partition plate can move along with the piston, an upper oil storing box cylinder, a lower oil storing box limiting cylinder and the energy consumption partition plate arranged internally have shearing and extruding effects on the damping liquid, the first-level spring and the second-level spring deform in an extruding manner to generate restoring force, after external force disappears, the piston rod is driven to carry out self restoring, and selfperformance can be adjusted automatically according to the change of the affected external excitation effect.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

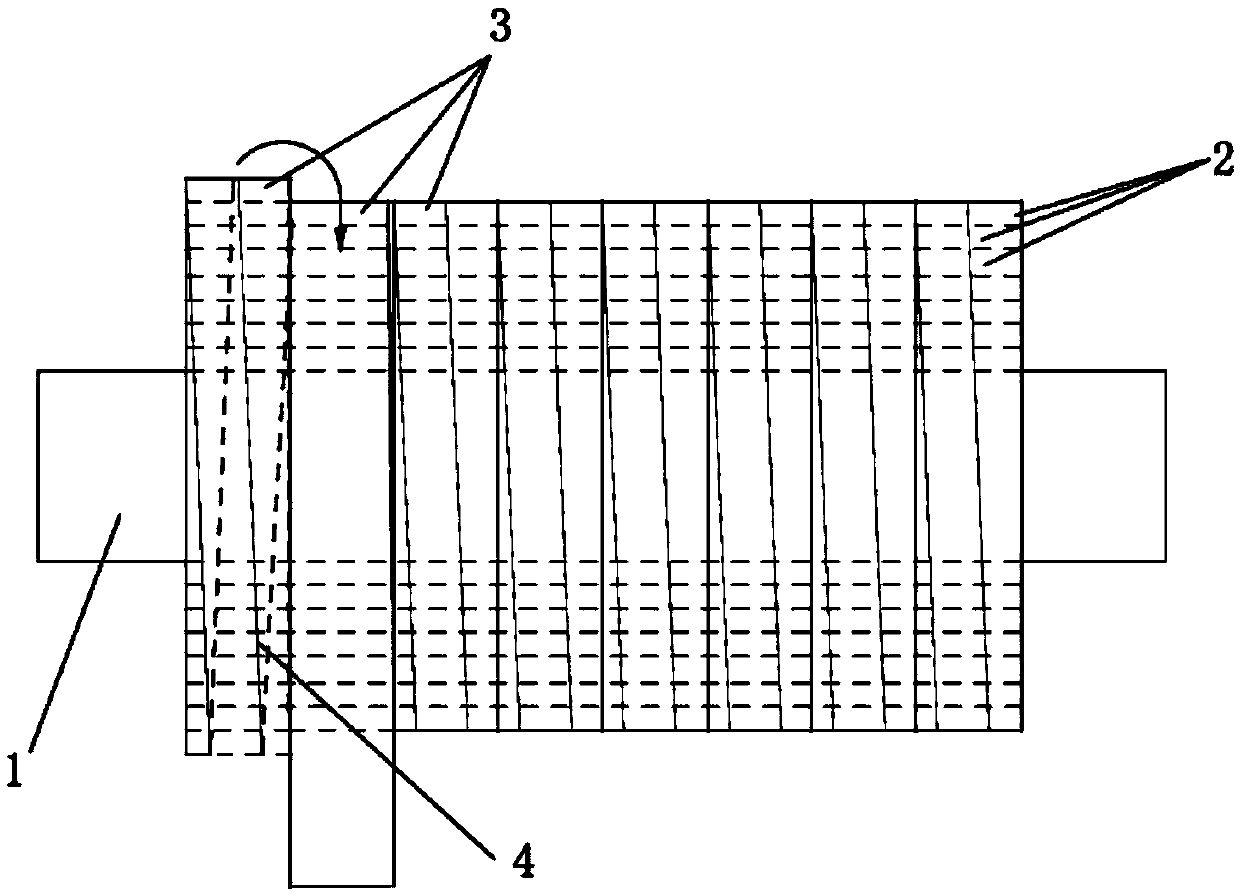

Warp-overlapping-structure carbon cloth gas diffusion layer for fuel cell

InactiveCN101024910AIncrease contactImprove conductivityCell electrodesWoven fabricsFiberElectricity

The invention is a method for making fuel battery gas diffusion layer able to improve gas-water-electricity transparent conductivity, on a loom, adopting carbon fiber as raw material to weave a tissue structured diffusion layer with longer warps and floats, isolated by wefts as brackets and overlapped and arranged in parallel.

Owner:JIANGNAN UNIV

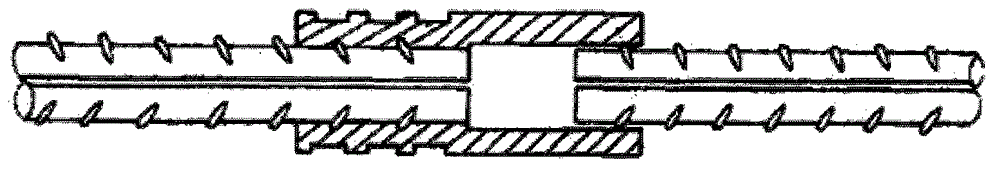

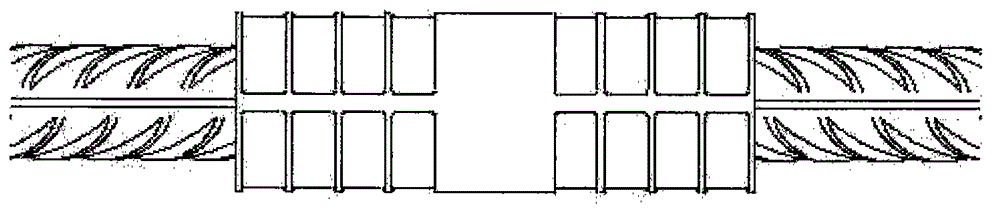

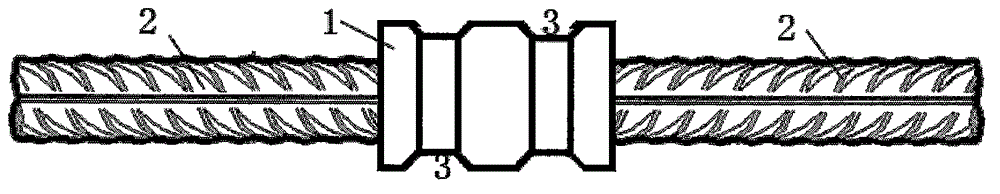

Ribbed bar sleeve extrusion joint and connecting method

InactiveCN105019604ANeutral requirements are not highSimple Rebar Mechanical Joining TechniqueBuilding reinforcementsBuilding material handlingRebarSectional plane

The invention relates to a ribbed bar sleeve extrusion joint and a connecting method. The ribbed bar sleeve extrusion joint comprises a steel sleeve and ribbed bars at two ends, wherein the two ends of the steel sleeve are respectively sleeved with the end parts of the ribbed bars at two sides, and the extrusion joint is formed by once extruding the steel sleeve with the ribbed bars by an extrusion tool and an extrusion die; two or four symmetrical concave continuous extrusion rings are arranged at the middle part of the steel sleeve, the central axis of the concave continuous extrusion rings is coincident with the axis of the steel sleeve, the ring groove section of the concave continuous extrusion rings along the axis direction of the steel sleeve is an isosceles inverted trapezoid or a rectangle, the cross section perpendicular to the axis direction of the steel sleeve is an oval, and an included angle between bevel edges at two sides of the isosceles inverted trapezoid and the axis direction of the steel sleeve is 60-90 degrees; the inner surface of the steel sleeve, on which the concave continuous extrusion rings are positioned, is closely occlusive with ribs on the surfaces of the two ribbed bars; and the diameter of each ribbed bar is 8-14mm.

Owner:北京中睿创工程技术有限公司 +2

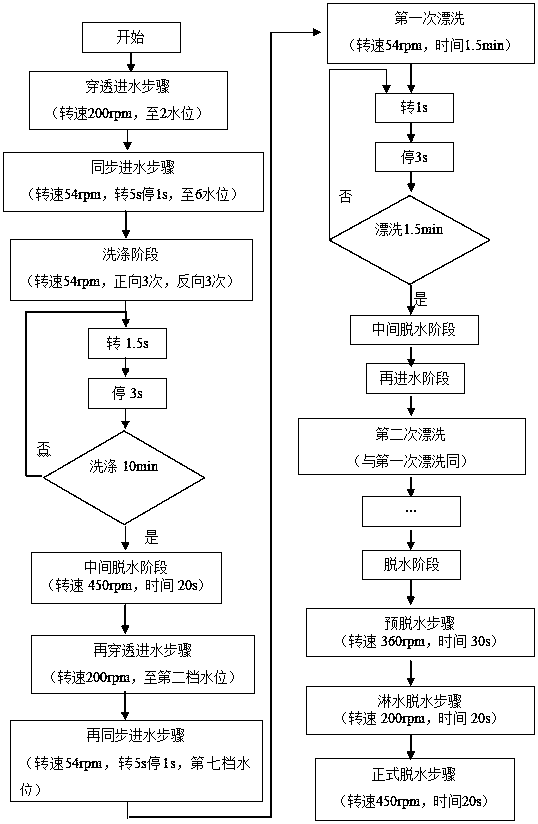

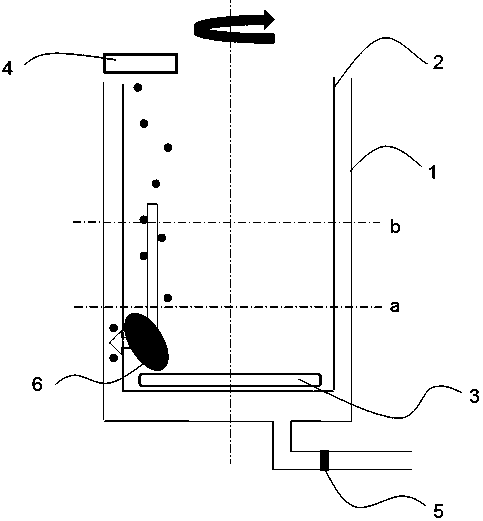

Washing method for cashmere fabric and full-automatic washing machine

ActiveCN107675429APrevent floatingReduce frictionOther washing machinesTextiles and paperImpellerWater flow

The invention provides a washing method for cashmere fabric and a full-automatic washing machine. The washing method comprises the following steps that 1, in a water inflow stage, water inflow is conducted in a penetrating mode at first, and then synchronous water inflow is conducted; 2, in a washing stage, an impeller is driven to rotate in an alternative forward and backward mode at a set washing rotating speed to generate vortex immersion washing water flow, and immersion washing and decontamination are conducted on the cashmere fabric through the combination of the centripetal traction andbuoyancy of the water flow; 3, in a dehydration stage, pre-dehydration, spraying dehydration and normal dehydration are sequentially involved. Since the water inflow in the penetrating mode is involved in the water inflow stage, inflow water sprayed on the cashmere fabric can quickly wet naps on the surface of the cashmere fabric through the impact force and centrifugal force of the water flow under the rotation centrifugal force, and meanwhile through centrifugal force generated by the rotation of the inner drum, floating frictions and pull of the cashmere fabric can be effectively avoided;the cashmere fabric can be completely wet by means of the combination of the water inflow in the penetrating mode and the synchronous water inflow.

Owner:TIANJIN HAIER WASHING ELECTRICAL APPLIANCE CO LTD +1

A kind of melting preparation method of ultra-high molecular weight polyethylene fiber

ActiveCN104250862BImprove processing fluidityImprove liquidityMelt spinning methodsMonocomponent polyolefin artificial filamentElastomerPolymer science

The present invention relates to a melting preparation method of ultra-high molecular weight polyethylene fiber, which is characterized in that it comprises the following steps: a. Organicizing ultra-high molecular weight polyethylene with internal modifiers such as nano-phosphate and antioxidant in a high-speed mixer Mix well, then add to twin-screw extruder to knead and granulate to obtain modified masterbatch, the screw temperature is 150~250℃; Fully mix in a high-speed mixer, then add to a twin-screw extruder for melt spinning, and cool in a water bath to obtain primary fibers. The temperature of each section of the screw is 150~260°C, and the temperature of the water bath is 5~20°C; Three-stage stretching is carried out at ~150°C, and the total stretching ratio is 10 to 20 times.

Owner:JIANGSU LIUJIA TECH CO LTD

Production technology of coreless wound hose

InactiveCN101403451AGuaranteed dimensional stabilityDimensionally stableFlexible pipesWinding machineCircular disc

The invention discloses a non-core winding rubber hose production process comprising the following steps: firstly rubber stuff is prepared; when the inner rubber is extruded out, an axial yarn is attached on a siphonula which takes the axial yarn into a winding machine; after the inner rubber is extruded out, the outer rubber is extruded out; later the siphonula is cooled after the outer rubber is extruded out, then is wounded on a metal disk after a release agent is sprayed, and then thrown into a vulcanizing boiler for vulcanization, finally a finished product is obtained after the vulcanization is finished. The invention changes the existing non-core winding hose production process; as the axial yarn is attached on the siphonula with the inner rubber extruded out, part of the pull fore of the siphonula is distributed, and the tensile deformation of a hot siphonula is reduced, thereby ensuring the dimensional stability of the siphonula. The process has the advantages of simple method, few production process, low cost, high production efficiency, good implementation effect, etc.

Owner:贵州精忠橡塑实业有限公司

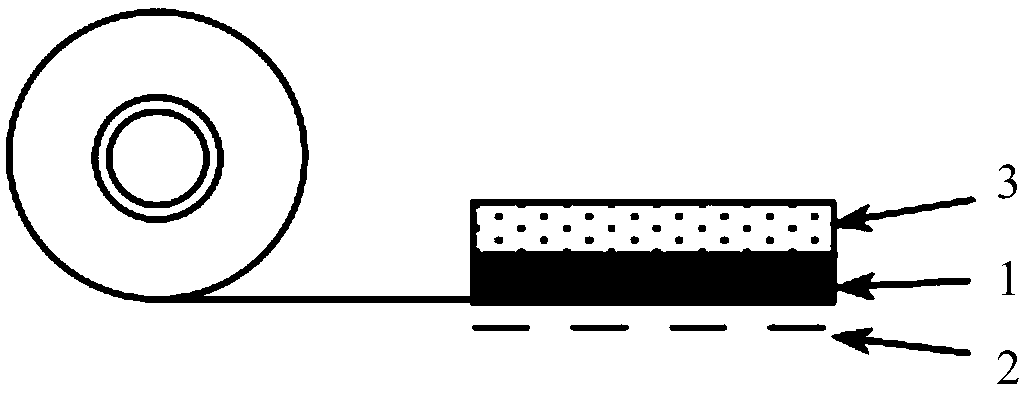

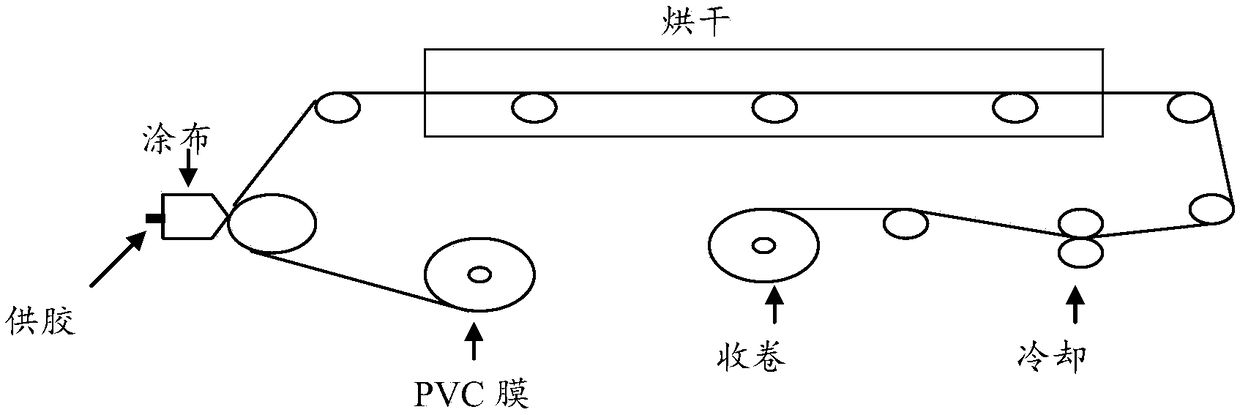

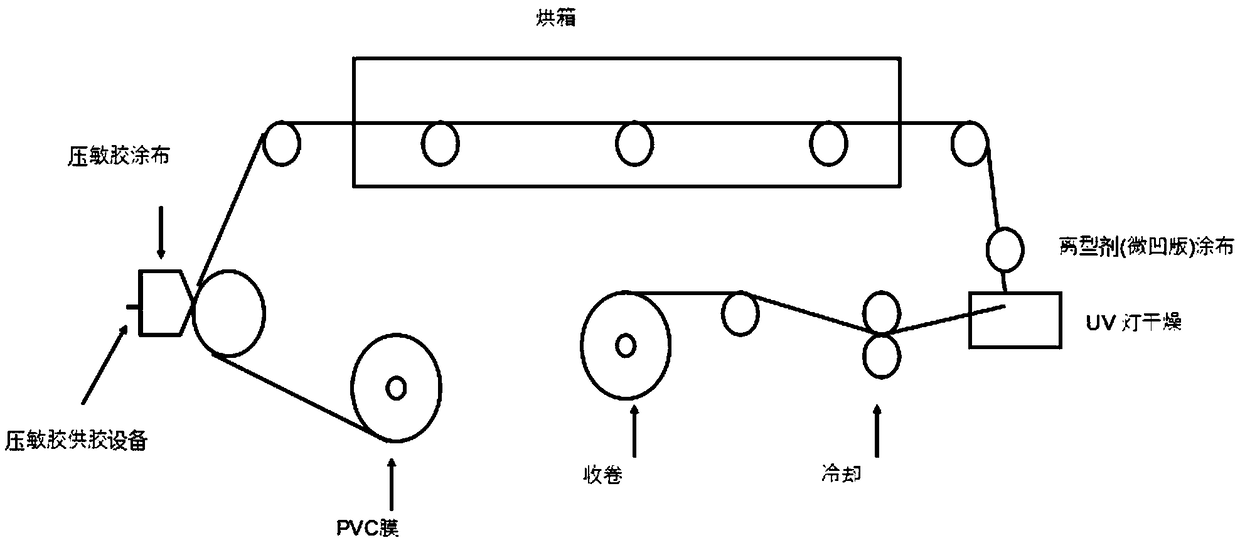

PVC (Polyvinyl Chloride) adhesive tape and preparation method thereof

ActiveCN109321162AAffect attachmentThere will be no loss of catalytic effectCoatingsFilm/foil adhesive release linersPolyvinyl chlorideUltraviolet

The invention discloses a preparation method of a PVC (Polyvinyl Chloride) adhesive tape. The preparation method comprises the following steps of (a) coating one surface of a PVC film with a pressure-sensitive adhesive; (b) afterwards, coating with a mold release agent, which can be hardened by ultraviolet irradiation, on the other surface of the PVC film; and (c) drying through ultraviolet irradiation, so as to harden the mold release agent. According to the method, firstly, the pressure-sensitive adhesive is used for coating; next, the mold release agent is used for coating; and afterwards,the mold release agent is hardened by using an ultraviolet ray. The mold release agent can be prevented from migration, due to a high temperature, by a plasticizer in the PVC film to further influencethe attachment of the mold release agent to the PVC film; and the phenomenon that a platinum catalyst loses a catalytic effect as being toxified by chlorine in the PVC film when in use cannot occur.According to the method provided by the invention, the coating and the drying of glue and the mold release agent can be completed through one-time processing; the processing time and the waste of energy can be reduced; the waste of the transportation cost can also be reduced; and the problem that the lateral extension of a material is nonuniform due to tensile deformation in the processing processcan be also avoided.

Owner:陈裕旺 +1

Protecting method for long-wall strip type coordinated skip-mining under earth and rockfill dams

InactiveCN104806245AEasy to useImprove resource recoveryUnderground miningSurface miningSocial benefitsEconomic benefits

The invention discloses a protecting method for long-wall strip type coordinated skip-mining under earth and rockfill dams. With the adoption of the method, in combination with geological and mining conditions of mining areas and positions of the earth and rockfill dams, mining work surface positions, mining widths and mining sequences are reasonably determined, the earth and rockfill dams are subjected to smaller tensile deformation, cracks are avoided, safe usage of earth and rockfill dam bodies and safe and normal conduction of mining are guaranteed, that is, on the basis that the safety of the earth and rockfill dam bodies is guaranteed, safe mining under the earth and rockfill dam bodies is realized, 'three unders' pressed coal is liberated to the maximum extent, the coal resource mining rate is increased, service lives of mines are prolonged, experience in coal mining under the earth and rockfill dam bodies can be enriched and accumulated, references can be provided for coal mining under similar conditions, and huge economic benefit and social benefit can be obtained.

Owner:HENAN POLYTECHNIC UNIV

Hydro-entangled non-woven fabric containing X-ray developer and its producing method

ActiveCN1329579CReduce initial contaminationReduce stretch deformationFibre treatmentNon-woven fabricsX-rayEngineering

The present invention relates to hydro-entangled non-woven fabric, and is a kind of hydro-entangled non-woven fabric containing X-ray developer and its production process. The X-ray developer line may be added into or on the hydro-entangled non-woven fabric before winding, and is preferably implanted or sprayed to the fiber web before the hydro-entangling step so as to make the X-ray developer line and the fiber web entangled together. The present invention has reduced production process, lowered cost, less pollution, firm combination of the X-ray developer line and the fiber web, and raised product quality and safety.

Owner:WINNER MEDICAL CO LTD

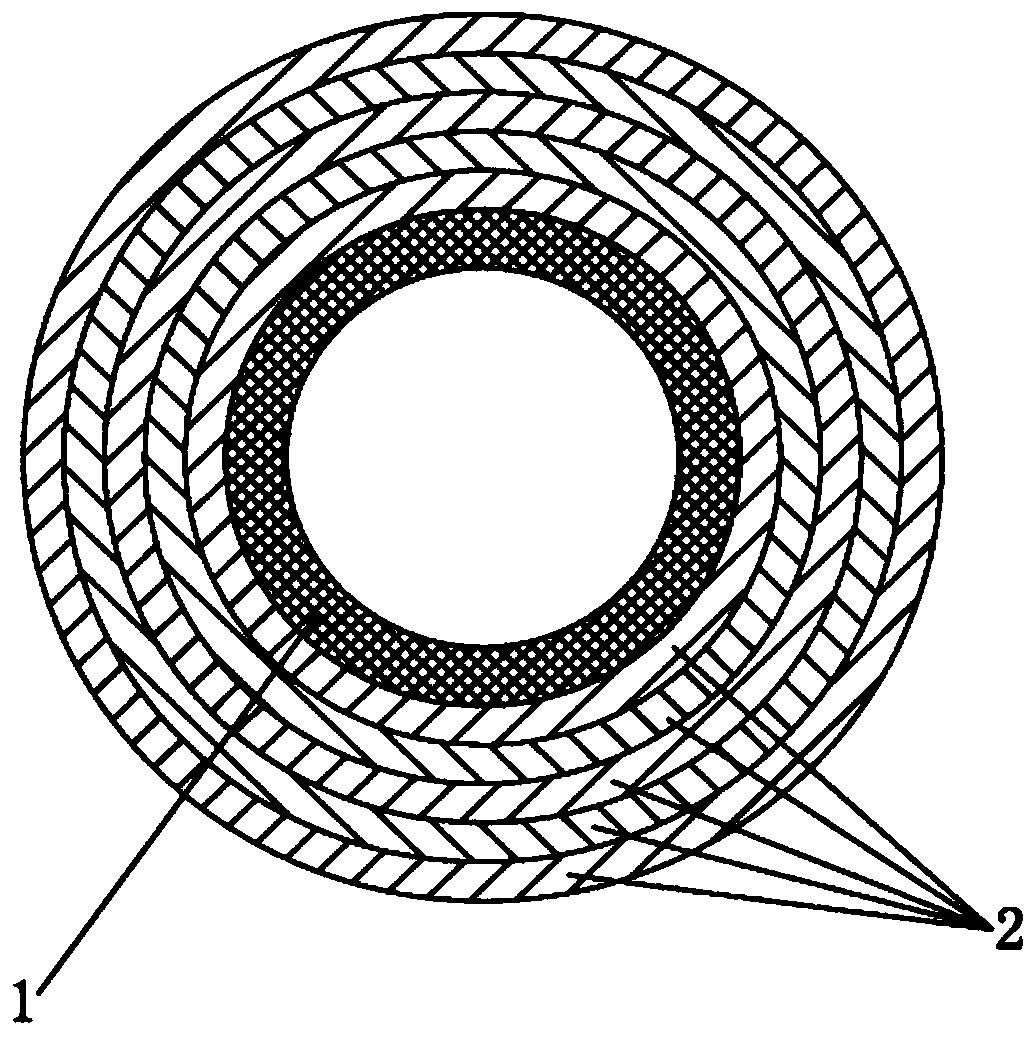

Cable wrapping tape and columnar winding method thereof

InactiveCN109573690AReduce stretch deformationGuarantee tape qualityWebs handlingEngineeringMechanical engineering

The invention discloses a cable wrapping tape and a columnar winding method thereof. The cable wrapping tape comprises a spool and a plurality of material belt layers wound on the spool, and the material belt layers are flat aligned at the outer edges of the spool; the material belt layers comprise a plurality of side-by-side superposed material belts, and the material belt winding superposition layers of the superposed material belts in the same material belt layer are consistent; and the heads and tails of the material belts between the superposed material belts in the same material belt layer are in transition connection through transition material belts uniformly. A film belt columnar material coil is formed by winding a plurality of material belt layers. The thickness of each layer ismoderate; through setting of number of turns, uniformly connected transition belts are formed, so that the material belts of each layer are wound tightly and firmly; the deformation of the material belts is small, and the quality improvement of the material belts is benefited; and columnar coils are formed by a plurality of belt material coil layers, and the cable wrapping belt has the characteristics of small tensile deformation of the material belts and tidy edges. The problems of inherent tensile deformation of belt materials wound with traditional flat plates, collapse of plates and limited width and length are solved.

Owner:TIANJIN TIANSU SCI & TECH GROUP

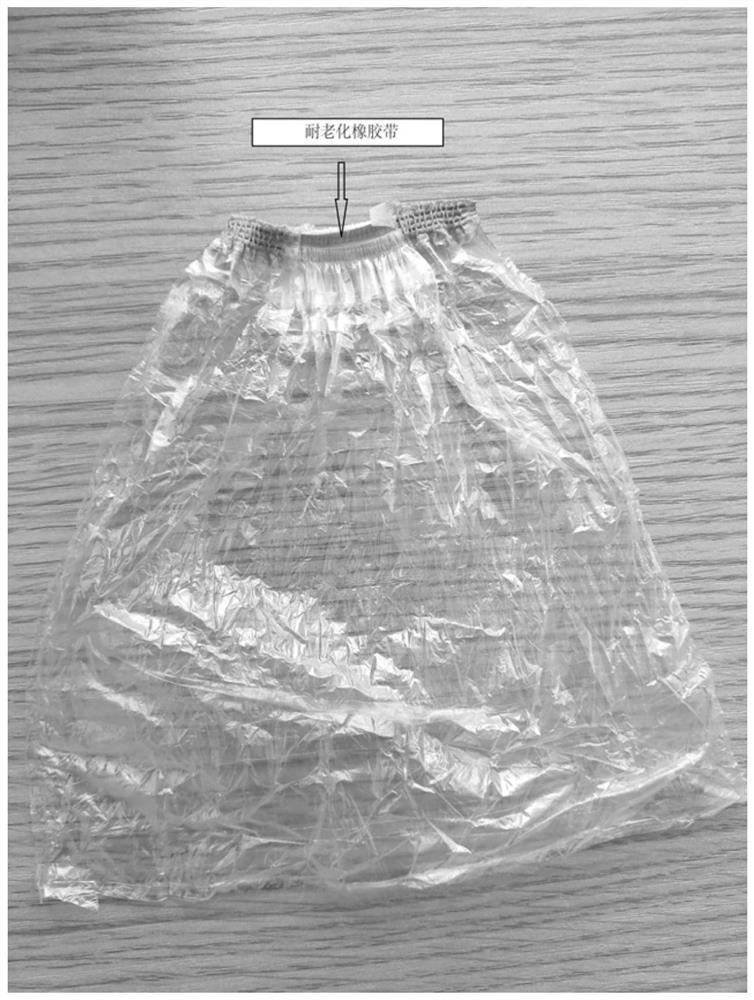

Anti-aging rubber belt and preparation method thereof

The invention discloses an anti-aging rubber belt, and belongs to the field of rubber products. The anti-aging rubber belt comprises the following raw materials in parts by weight: 60-70 parts of natural rubber, 30-40 parts of ethylene propylene diene monomer, 2-2.5 parts of a vulcanizing agent, 3.5-5 parts of an accelerant, 4-6 parts of nano zinc oxide, 1-3 parts of an active agent, 4-6 parts ofan anti-aging agent, 1.5-2.0 parts of protective paraffin, 15-20 parts of reinforcing white carbon black, 10-15 parts of filler, 1-2 parts of an antioxidant and 5-10 parts of softener. The anti-agingrubber belt is good in tensile strength, high in tearing strength and small in tensile deformation, and can be used in a long-term severe environment. The invention further provides a preparation method of the anti-aging rubber belt. The method is simple in preparation process and low in preparation cost, and large-scale industrial production can be achieved. The invention further provides an adhesive tape sleeve containing the anti-aging rubber belt, the adhesive tape sleeve can replace the conventional sealing mode which wastes time and labor, such as an iron wire, a binding wire and the like, so that the labor cost can be greatly saved, and the adhesive tape sleeve is durable and environment-friendly.

Owner:广东狮特龙实业有限公司

Hot stamping device for plastic toys

InactiveCN106564281AEasy to recycleShort transmission pathBronze printingHot stampingResource utilization

The invention discloses a hot stamping device for plastic toys. According to the hot stamping device for plastic toys, a feeding device comprises material roll supporting rods, a feeding shaft and a feeding pressing wheel which are installed on a wallboard; a receiving device comprises a material roll receiving support, a receiving shaft and a receiving pressing wheel; the feeding device feeds hot stamping material to the hot stamping device for plastic toys, and then hot stamping is completed; waste material obtained after hot stamping is recycled and made into a waste material roll through the receiving device; the feeding device and the receiving device are transported from a hot stamping machine in a rolling mode by means of a conveying belt installed on a main machine wallboard; and the feeding device and the receiving device are located on the top of the hot stamping device for plastic toys so as to form a vertical layout. The receiving device can be independently dismounted and can be used for making the waste material obtained after hot stamping into the waste material roll, thus, the machine structure is compact, the transport path of the hot stamping material is shortened, the probability of likely tensile deformation and horizontal dispersion can be reduced, the waste material obtained after hot stamping can be directly made into the waste material roll, resource utilization is achieved, and meanwhile the situation that pollution is caused since the waste material flies swiftly upward and causes dust can be avoided.

Owner:CHANGZHOU BOER PLASTIC

Two ends flaring forming technique of cylindrical barrels

InactiveCN104289624AReduce stretch deformationImprove product qualityCycle equipmentsStructural engineeringMachining process

The invention provides a two ends flaring forming technique of cylindrical barrels and aims to solve the problems of the existing cylindrical barrels of complex processing techniques and large flaring error. The scheme includes that the two ends flaring forming technique is characterized by including the following steps: (1) unfolding raw materials to be sheet materials according to the shapes of workpieces; (2) making the sheet materials to be U-shaped bodies, forming the plane where two ends of each cylindrical barrel are located, and forming bosses of steps; (3) putting a curling die and a mandrel, and then conducting curling; (4) welding straight lines.

Owner:CHONGQING JINLUN IND

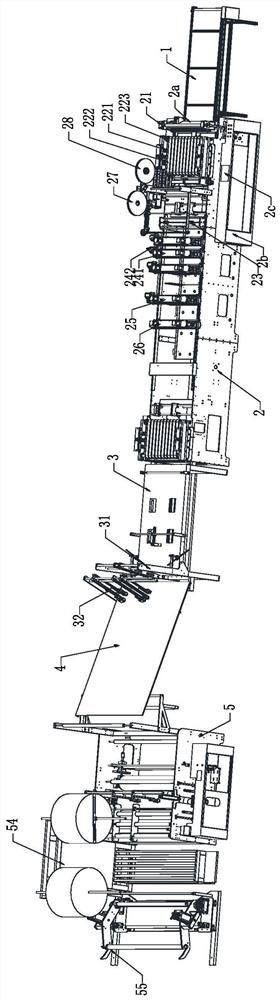

Vertical foil feeding and collecting integrated hot stamping machine

InactiveCN104441952AEasy to recycleReduce stretch deformationRotary pressesBronze printingHot stampingPollution

The invention discloses a vertical foil feeding and collecting integrated hot stamping machine, which comprises a foil collecting and feeding mechanism, wherein the foil collecting and feeding mechanism is used for feeding gold foils to a hot stamping mechanism to be subjected to hot stamping and recovering waste foils generated after hot stamping is carried out to manufacture the waste foils into waste foil rolls, and the foil collecting and feeding mechanism can be mounted in or detached from the hot stamping machine through a guide rail fixed on a host machine wallboard in a slipping manner and is integrally positioned above the hot stamping mechanism to form a vertical layout. The foil collecting and feeding mechanism can be independently mounted and detached and can be used for manufacturing the waste foils generated after hot stamping is carried out into the waste foil rolls, so that the floor area occupied by the whole machine is reduced, the transmission line of the gold foils can be shortened, the possibility of tensile deformation and lateral drift is reduced, and the waste foils generated after hot stamping is carried out can be directly manufactured into the waste foil rolls, and thus recycling is convenient and the problem that scattered waste foils cause droplet pollution and influence the health of operators is solved.

Owner:SHANGHAI YOCO PRINTING MACHINERY

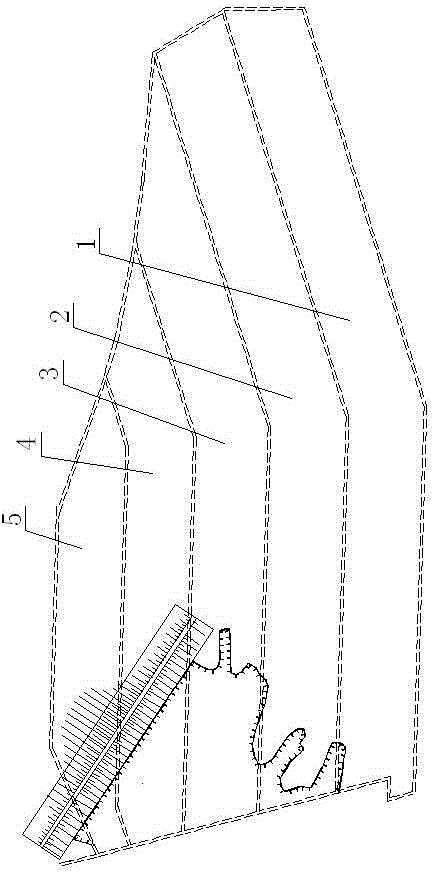

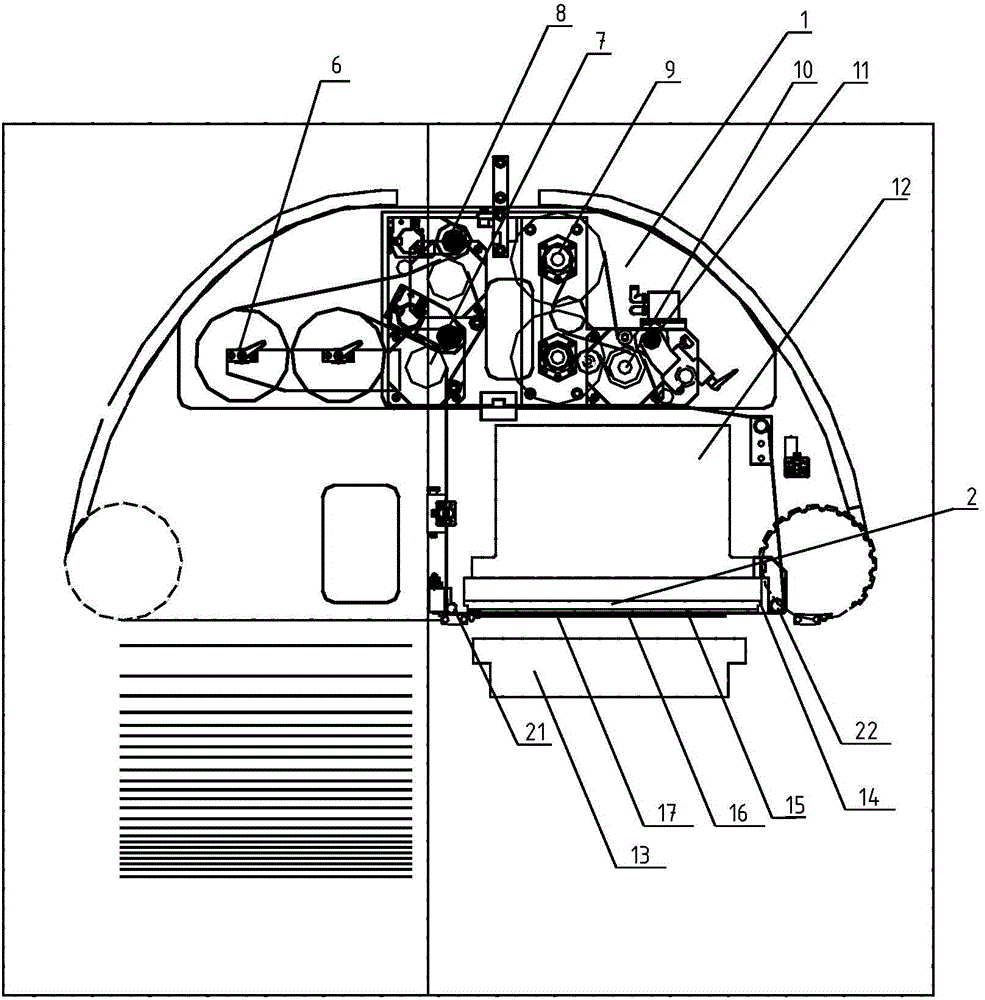

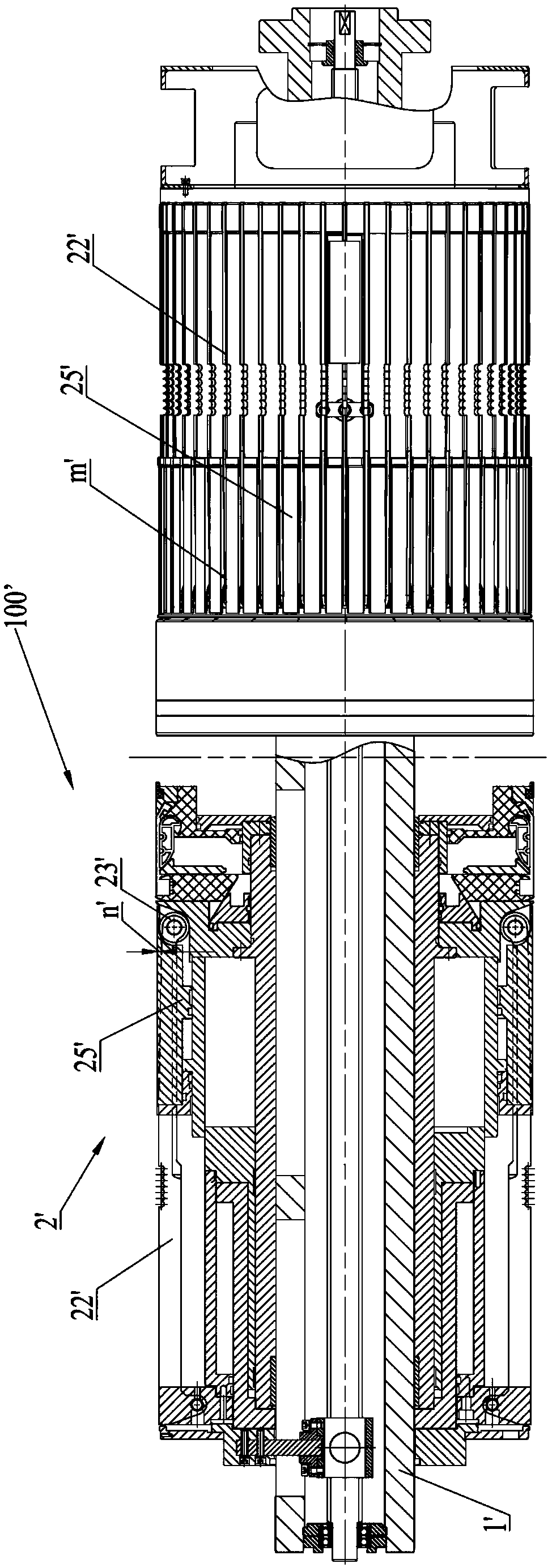

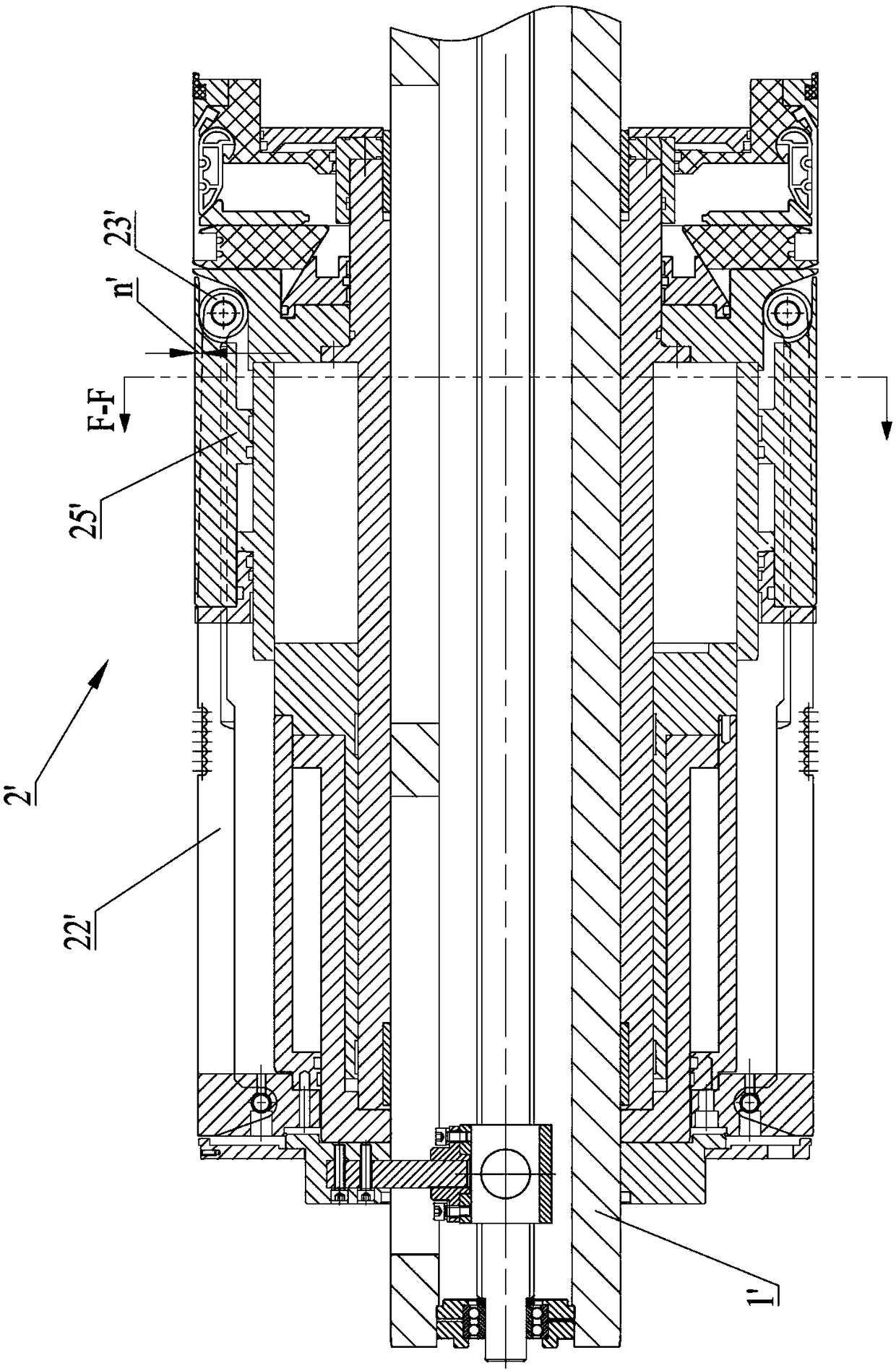

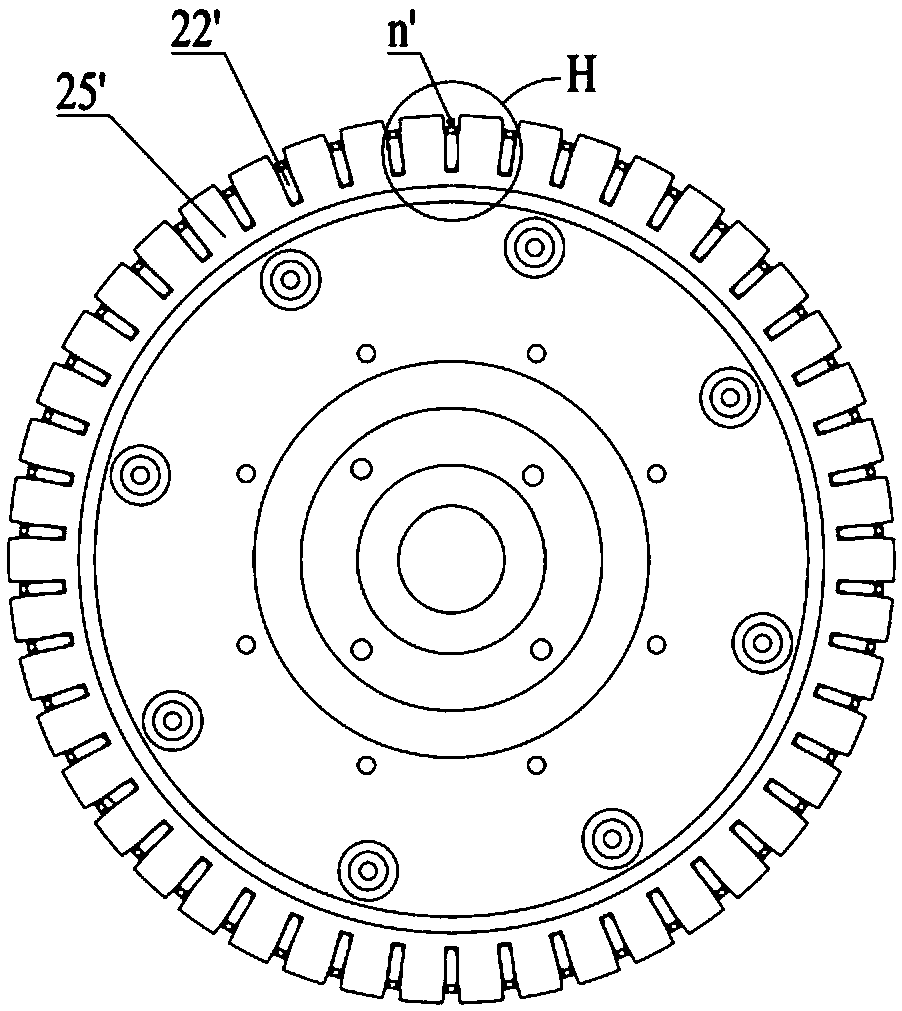

Tyre moulding drum

The invention provides a tyre moulding drum. The tyre moulding drum comprises two semi-drum devices used for sleeving a main shaft; each semi-drum device comprises a reverse coating unit, a guiding body, and a guiding disk; each reverse coating unit comprises a plurality of reverse coating rods and a rolling unit connected with the reverse coating rods through pivotal connection; each guiding bodyis used for guiding and accommodating the reverse coating rods; each rolling unit is designed to be cooperative with the external peripheral arc-shaped surface of the corresponding guiding disk; whenthe plurality of reverse coating rods are at initial positions, a corresponding rolling unit is driven to swing inward, and is stored at the radial inner side of a corresponding guiding body; the radial height of a first periphery surface formed at the outermost radial side of the rolling units is lower than that of a second periphery surface formed by the external surface of the guiding body, and that of a third periphery surface formed by the supporting surfaces of the reverse coating rods; the height of the second periphery surface is equal to the height of the third periphery surface; thereverse coating rods and the guiding bodies are combined so as to form basically sealed flat cylindrical surfaces used for receiving tyres; and at the same time, in reverse coating, the rolling unitsare driven to swing outward, and are higher than the reverse coating rods, so that tyre parts are jacked along the radial direction, and the friction between tyre parts and the reverse coating rods and the guiding body is reduced.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

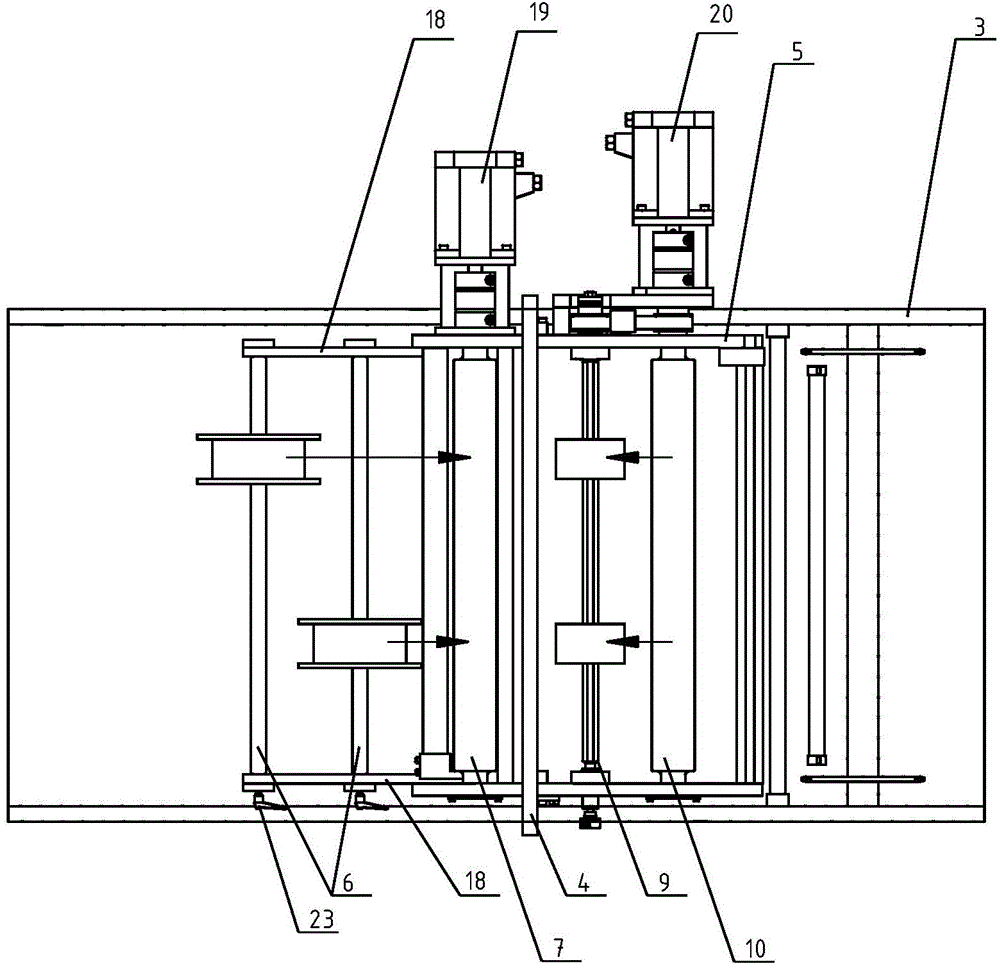

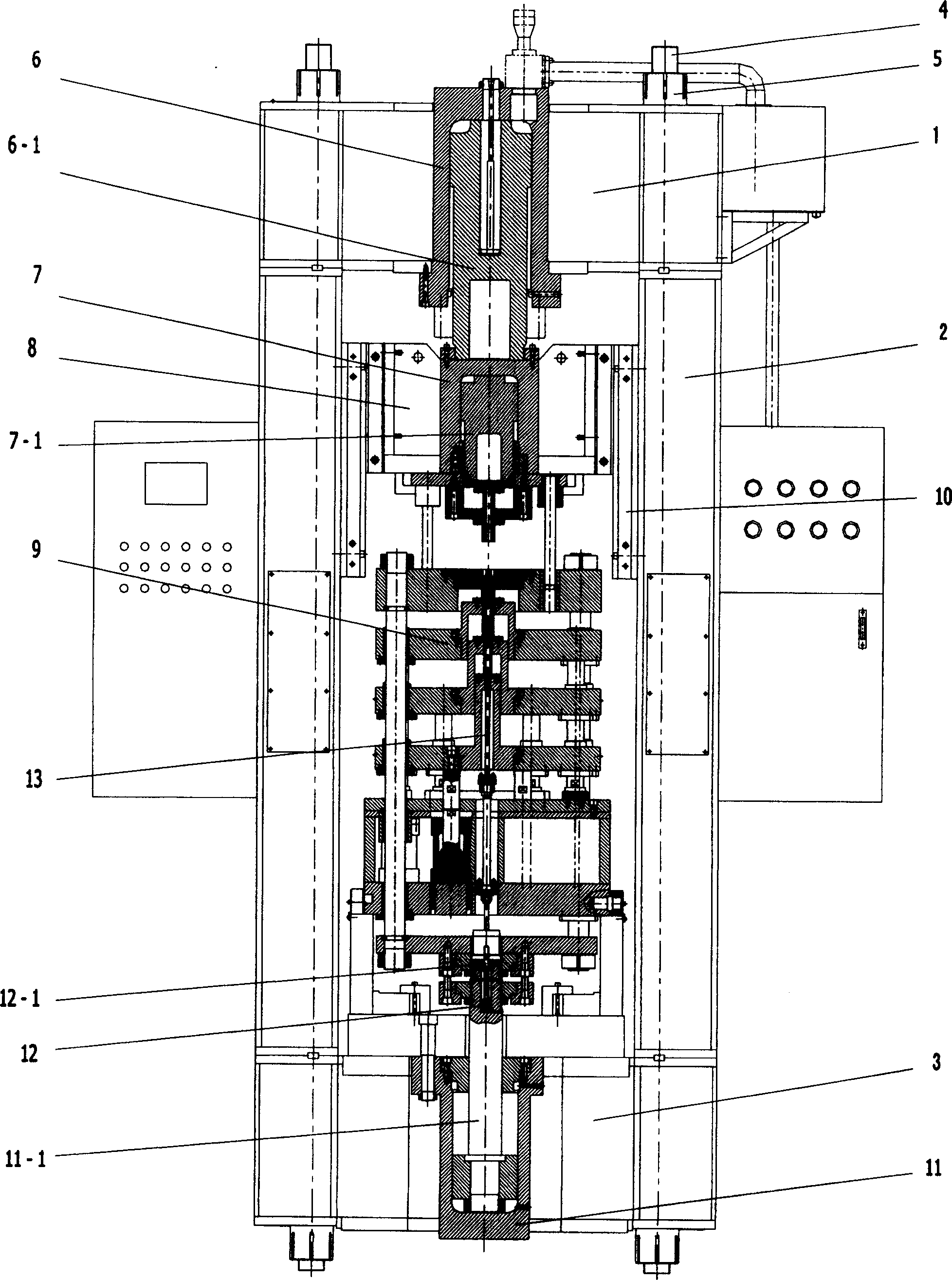

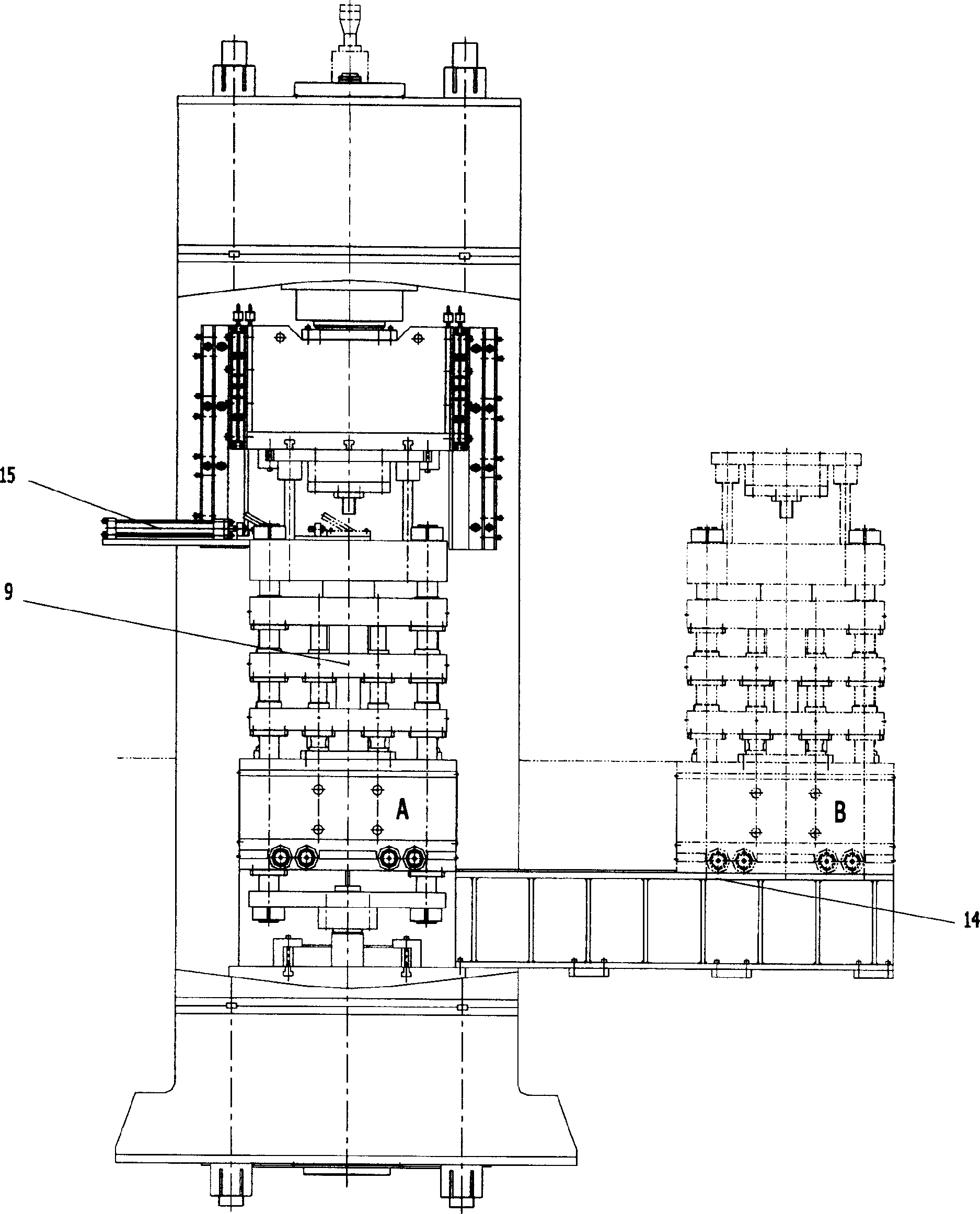

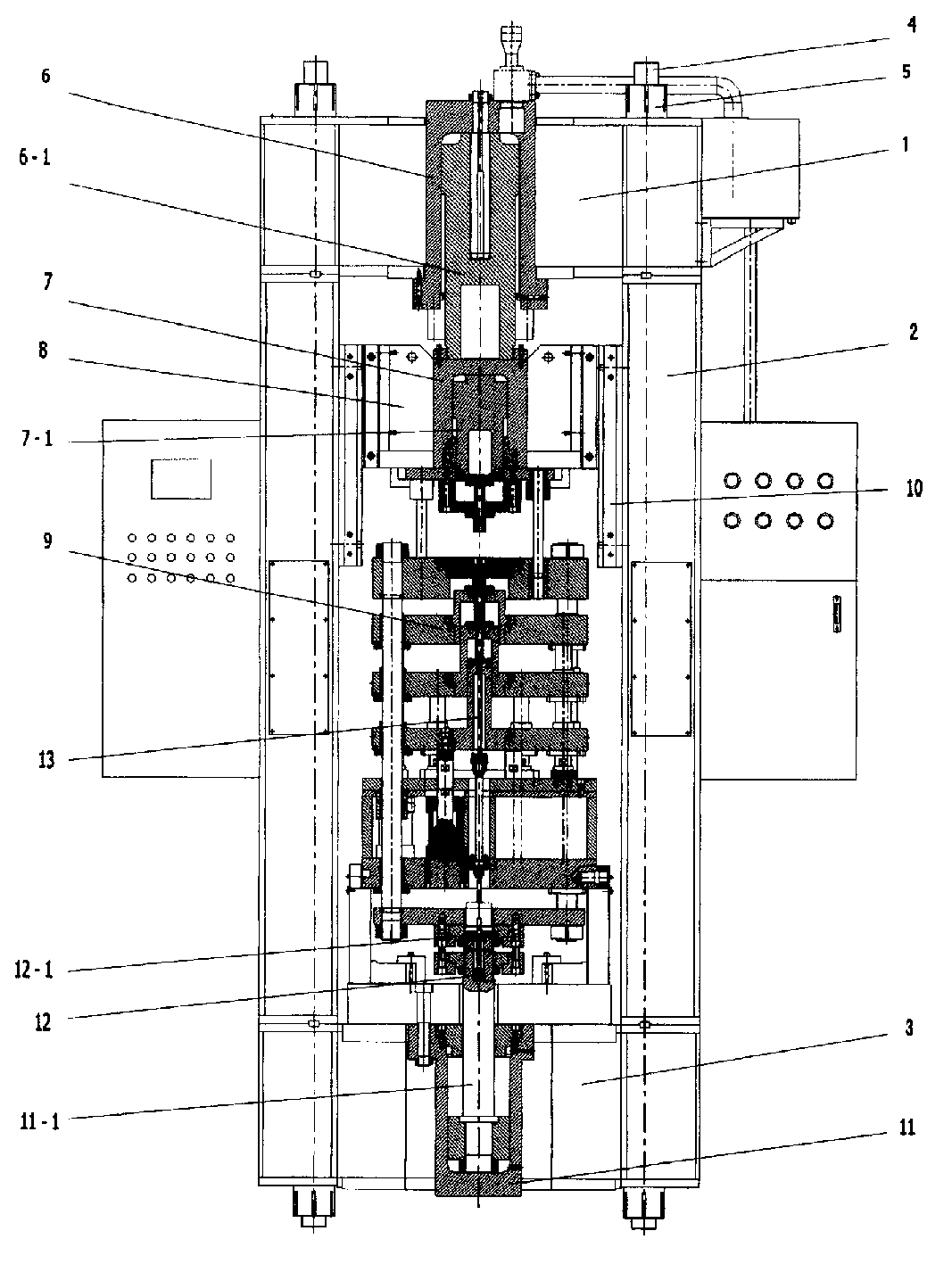

Precise forming powder in type of top tightened frame mount

An accurate powder compacting machine with prestressed frame is composed of enclosed frame-type main body, main cylinder assembly and bottom cylinder assembly. Said main cylinder assembly installed at upper part of main body consists of main cylinder, and nested cylinder fixed to the top of piston rod of main cylinder. Its advantages are less tensional deformation, high rigidity, and high machining accuracy. It is suitable for shaping the workpiece with complex shape and central hole.

Owner:SOUTH CHINA UNIV OF TECH

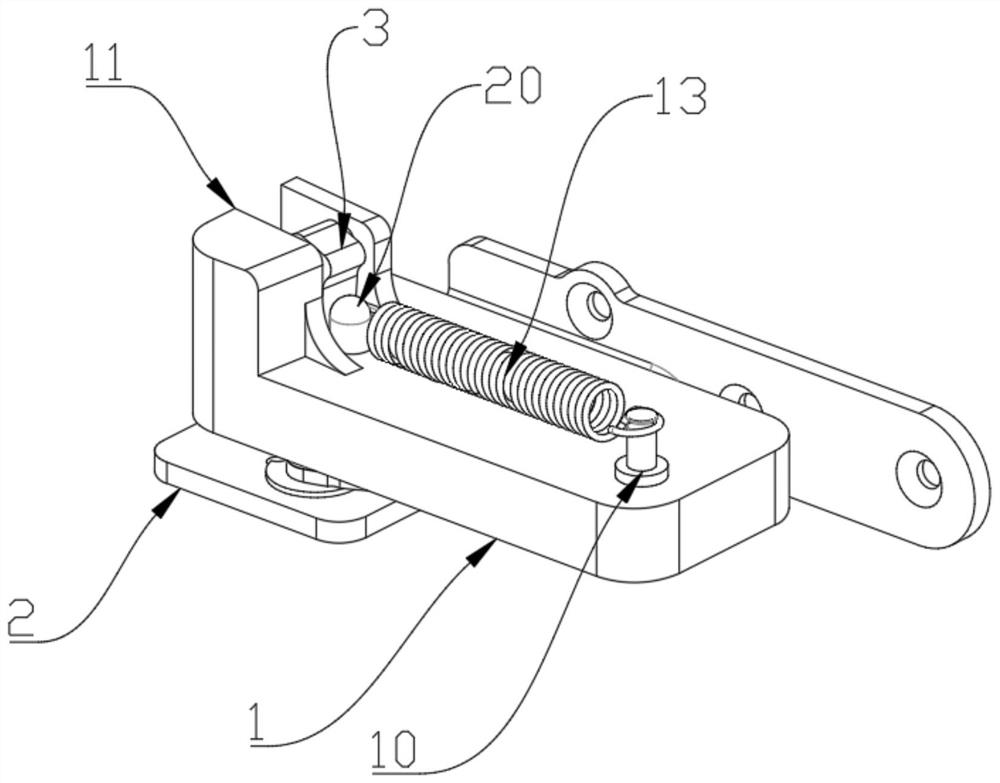

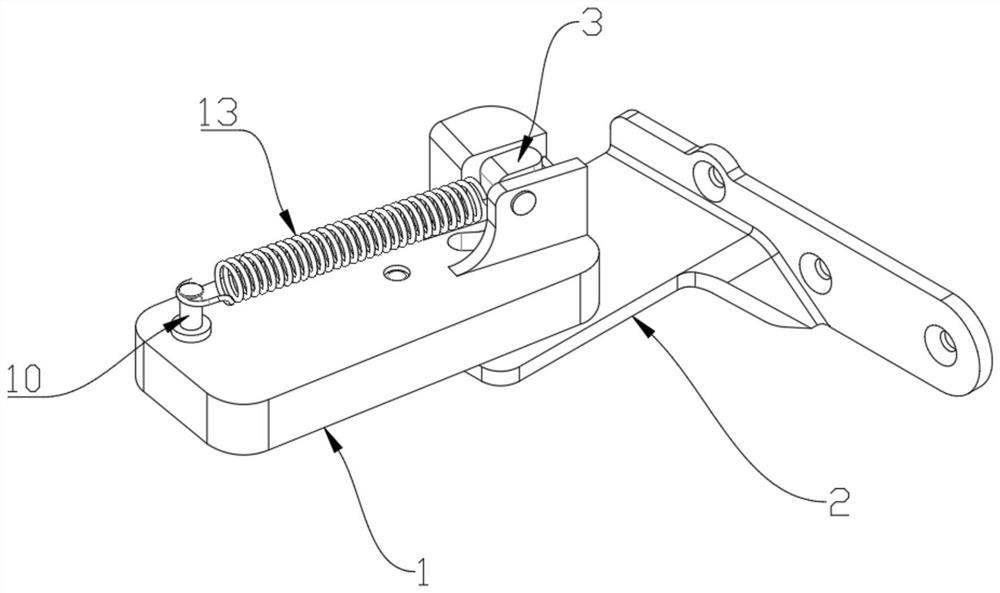

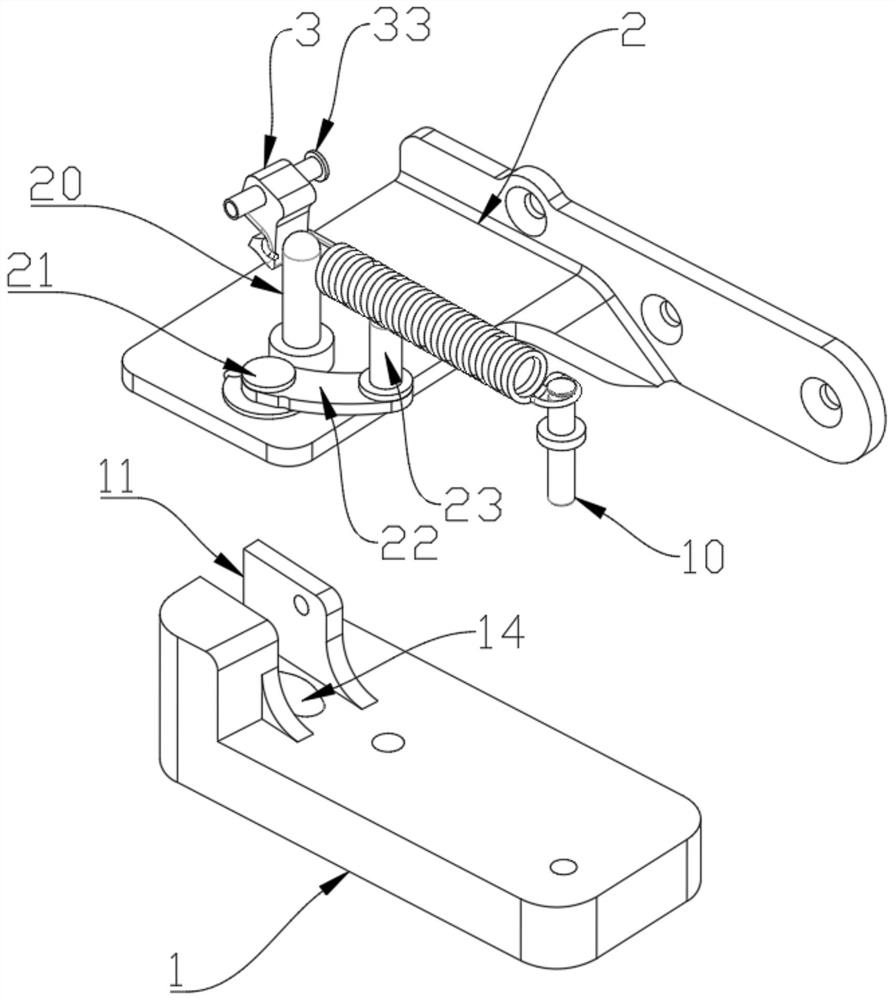

Single-rail embedded hinge automatic door closing mechanism

PendingCN114016839AEven by forceStress smoothHingesWing openersStructural engineeringMechanical engineering

A single-rail embedded hinge automatic door closing mechanism comprises a door mounting block single-guide-rail mechanism, a connecting rod and a cabinet mounting plate, a spring mounting rod is fixed to a door mounting block, an angle keeping block is rotationally fixed to the portion, on the opposite side of the spring mounting rod, of a panel of the door mounting block, and the outer wall of the angle keeping block is slidably connected with the top end of a sliding groove rod; when the sliding groove rod moves in the guide sliding groove, the top end of the sliding groove rod drives the angle keeping block to rotate, and a reset spring is installed between the angle keeping block and the spring installation rod. The angle keeping block and the sliding groove rod used for guiding rail transfer act in a matched mode, under the condition that other components are reduced, the automatic door closing action can be achieved, the overall elastic reset state is well combined with the rail transfer action, the spring stretching amount is reduced, the reset spring is evenly stressed in the automatic door closing process, the door closing action is smoother and quieter, the service life of the spring is prolonged.

Owner:JIANGSU SACA PRECISION TECH CO LTD

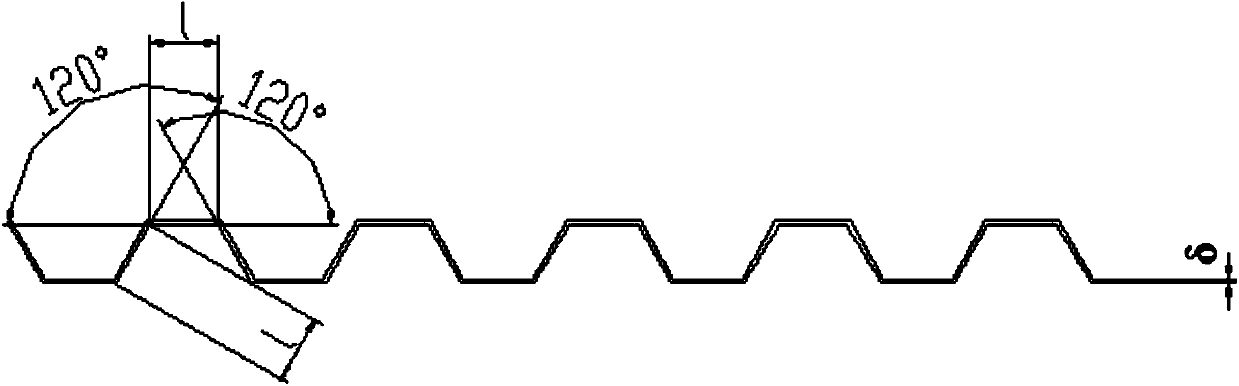

Semi-honeycomb steel belt hobbing machine for ensuring uniform forced convection flow field

ActiveCN104259355AReduce stretch deformationAddressing OversqueezeMetal rollingDistortionForced convection

The invention discloses a semi-honeycomb steel belt hobbing machine for ensuring a uniform forced convection flow field. The machine comprises a feeder and a discharger, and further comprises two toothed trapezoidal gears having the same number of teeth, wherein the trapezoidal gears are mounted on a driving shaft and a driven shaft respectively; the driving shaft is connected with a spindle of a reducer motor via a coupler; the two trapezoidal gears are mounted in an engaged manner; and a clearance between tooth faces of the trapezoidal gears is the thickness of a steel belt. With the adoption of the technical scheme, the steel belt is extruded into a semi-hexagonal semi-honeycomb steel belt when the steel belt participates in an engagement process by using a gear engagement principle; the dimensional uniformity of the sides of a semi-hexagon is good; tensile deformation of the steel belt is small; production efficiency is high; a fine adjustment mechanism of a driven gear shaft is designed; the problems of excessive extrusion and tension of the steel belt due to fine change in the thickness of a steel sheet are solved by finely adjusting a distance between a driving gear and a driven gear; the problem of great arc distortion of the semi-honeycomb steel belt is solved by finely adjusting the parallelism of the driving gear and the driven gear; and the machine is simple in structure and convenient to use and adjust.

Owner:南通利联机床制造有限公司

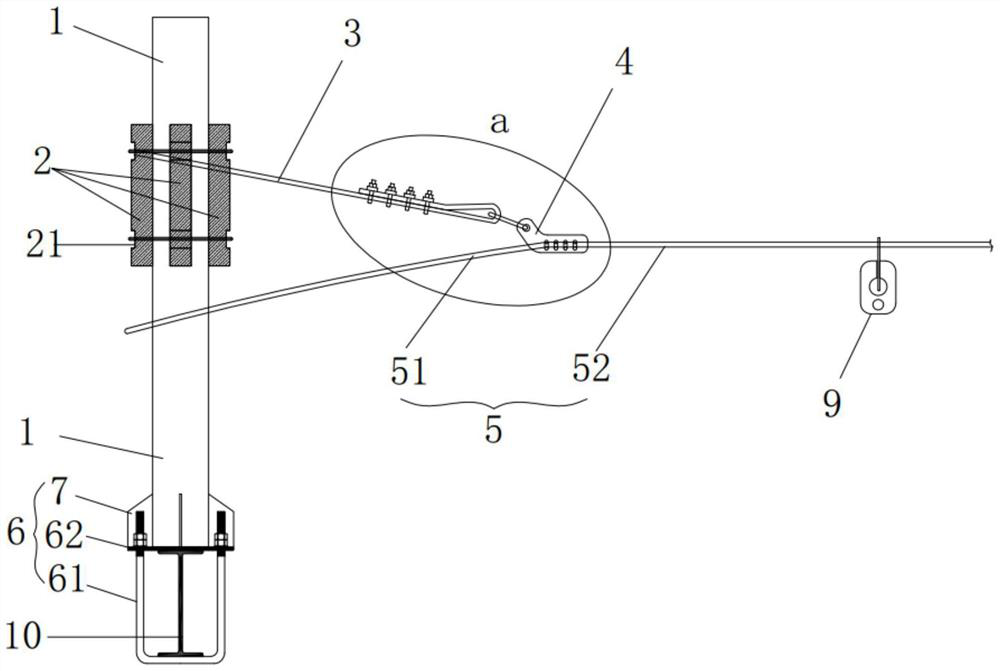

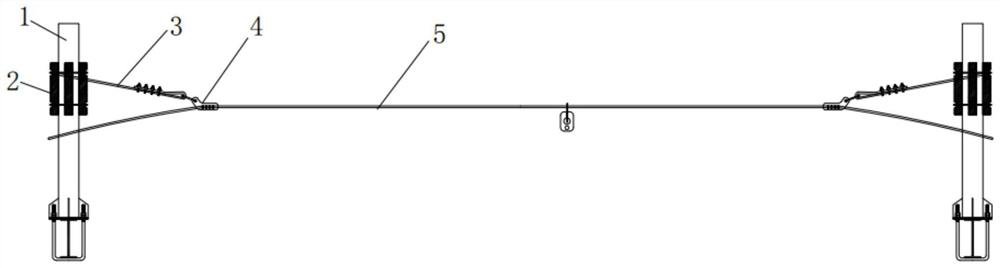

Anchoring stand column unit and anchoring stand column protection system

PendingCN114033201AIngenious ideaWarranty ExtensionBuilding material handlingSafe operationWire rope

The invention provides an anchoring stand column unit and an anchoring stand column protection system. The anchoring stand column unit comprises an anchoring stand column body arranged on a building beam, at least one square column block sequentially arranged along the periphery of the anchoring stand column body, an auxiliary steel wire rope in hasp connection with the square column block, a connecting device and a main steel wire rope; wherein a hasp groove is concavely formed in the square column block in the direction close to the central axis of the anchoring stand column body; one end of the auxiliary steel wire rope is fixedly sleeved with the hasp groove, and the other end of the auxiliary steel wire rope is in transition connection with the main steel wire rope through the connecting device. The main steel wire rope is locked with the connecting device, and the two ends of the main steel wire rope extend outwards. The anchoring stand column protection system comprises a plurality of anchoring stand column units. The anchoring stand column unit is ingenious in conception, and safe operation of a single person or multiple persons during construction of structural beams in a high narrow area is guaranteed.

Owner:友谊国际工程咨询股份有限公司

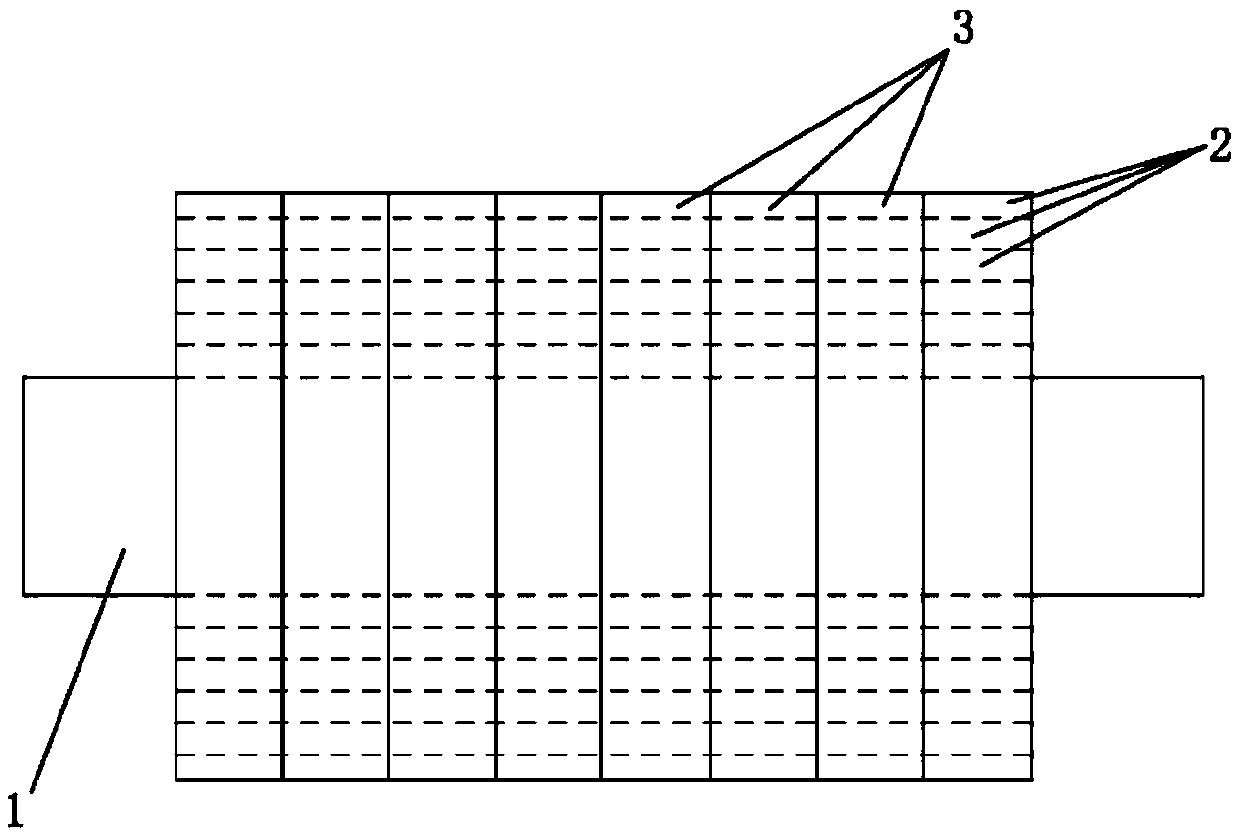

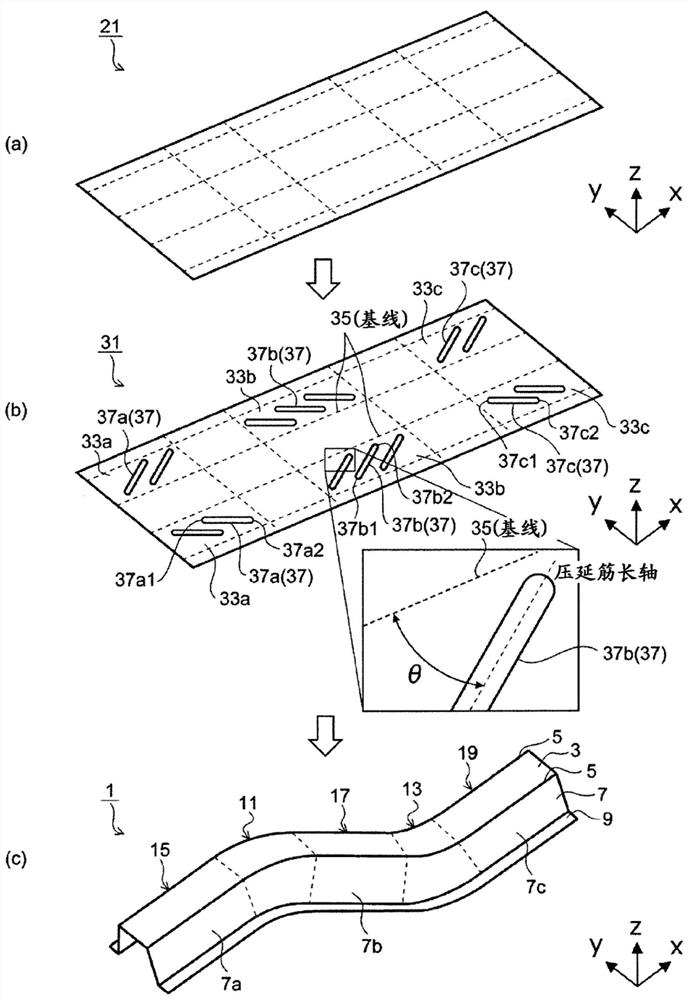

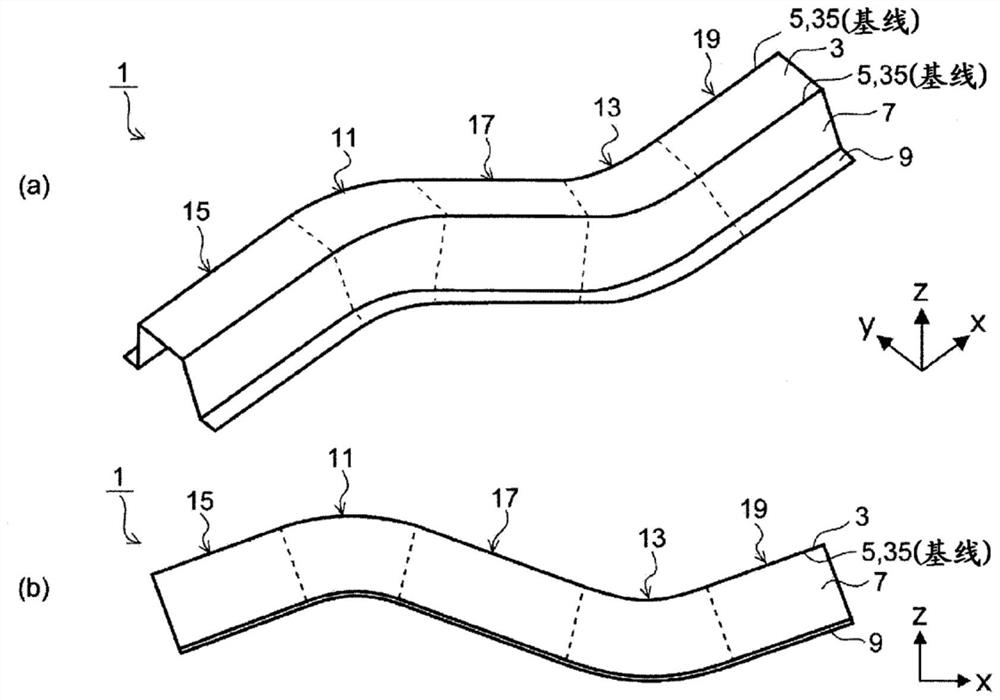

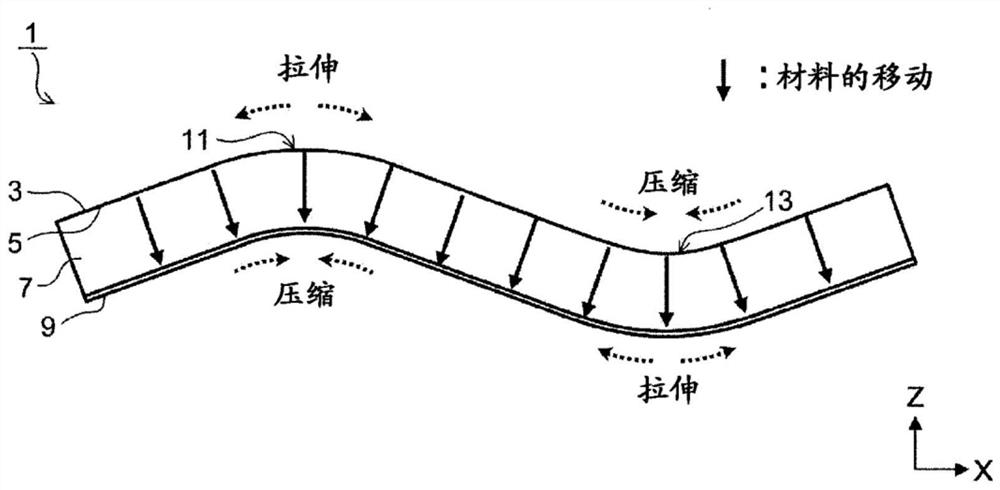

Press forming method

ActiveCN113226584AReduce stretch deformationNo crackVehicle componentsStructural engineeringShearing deformation

A press forming method according to the present invention is a method for forming a press formed product (1) having a top plate section (3), vertical wall sections (7), flange sections (9), and a protruding curved site (11 curved in a protruding manner and a recessed curved site (13) curved in a recessed manner in the height direction. The method includes: a preforming step for forming an intermediate formed product (31) having bead parts (37) formed in a vertical wall-corresponding surface section (33) corresponding to the vertical wall sections (7) on both sides in the longitudinal direction of each of the protruding curved site (11) and the recessed curved site (13); and a main forming step for forming the press formed product (1) by crushing the bead parts (37) of the intermediate formed product (31) and thereby inducing pseudo shearing deformation in the vertical wall-corresponding surface section (33). In the preforming step, the bead parts (37) are slanted such that an end section of each bead part (37) on the protruding curved site (11) side is spaced apart from a baseline (35) corresponding to a top-plate side ridge line section (5) between the top plate section (3) and the vertical wall section (7), and such that an end section of the bead part (37) on the opposite side is closer to the baseline (35).

Owner:JFE STEEL CORP

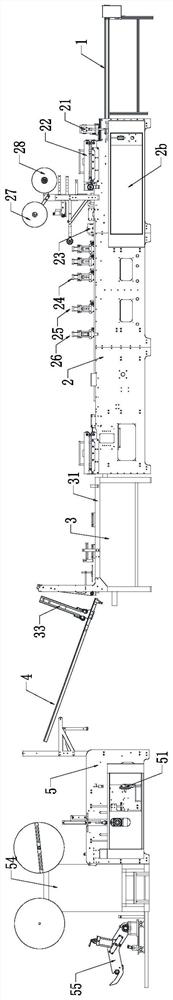

New high-speed full-automatic bag making machine

ActiveCN109760368BQuick resizeReduce labor costsBag making operationsPaper-makingMechanical equipmentConveyor belt

The present invention is applicable to the technical field of mechanical equipment, and provides a novel high-speed full-automatic edge-pressing bag-making machine, which includes: a conveyor belt, a front frame, a middle frame and a rear frame. From the input end to the output end, there are cutting devices, intermittent positioning feeding devices, color-tracking electric eye movable devices, and hot-pressing knife edge-sealing devices in sequence. Roller etc. The new high-speed full-automatic edge-pressing bag making machine provided by the present invention can automatically adjust the position of the edge-pressing in real time through the transmission device after running and middle-heating, and can quickly adjust the position of the edge-sealing of the product size, reduce labor costs, increase production capacity, and thereby reduce costs , greatly reducing product scrapping, and can automatically adjust the position of the press knife and cutter in real time according to the stretching length of the printed product, greatly reducing scrapping. The folding position can be corrected in both directions by the correction device to improve product quality. There is a pressing glue stick at the film covering position, which can minimize the stretching deformation of the product.

Owner:深圳市创信自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com