Hydro-entangled non-woven fabric containing X-ray developer and its producing method

A technology of spunlace non-woven fabrics and production methods, which is applied in non-woven fabrics, textiles, papermaking, fiber processing, etc., can solve the problems of being difficult to be inspected, patient's condition deterioration, death, etc. The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

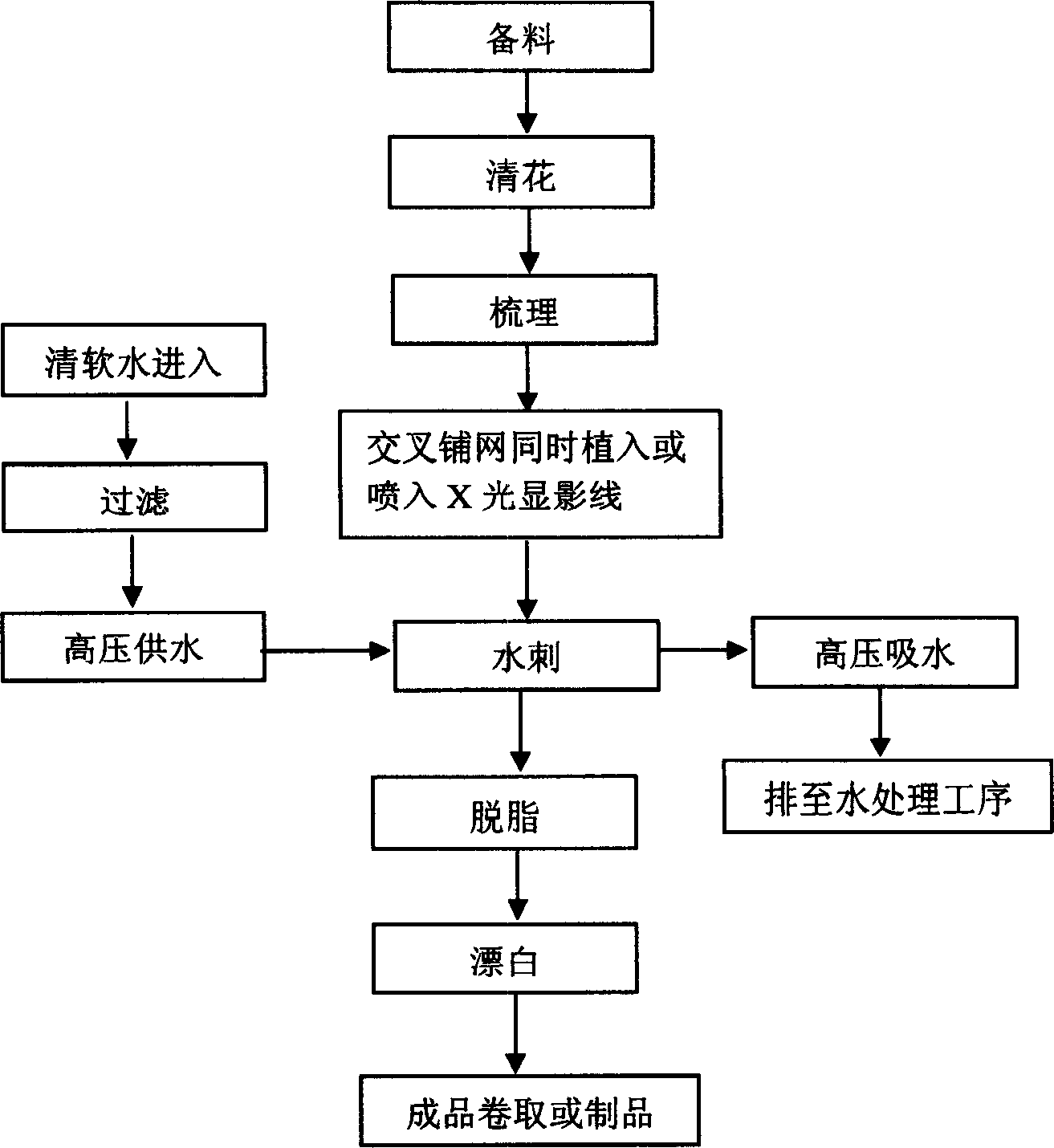

[0016] Embodiment 1, this embodiment is also the best embodiment of the present invention, as figure 1 As shown, the production process of spunlace nonwovens containing X-ray imaging includes the following steps:

[0017] 1) Prepare materials: prepare raw materials, namely 100% pure natural cotton or a small part of synthetic fibers plus pure natural cotton;

[0018] 2) Flower cleaning: first, the raw materials are removed by a flower cleaning machine, the foreign matter in the raw materials is screened out, and the raw materials are opened. This step is a known technology and is the same as the prior art;

[0019] 3) Carding: use a carding machine to loosen and comb the raw cotton after cleaning;

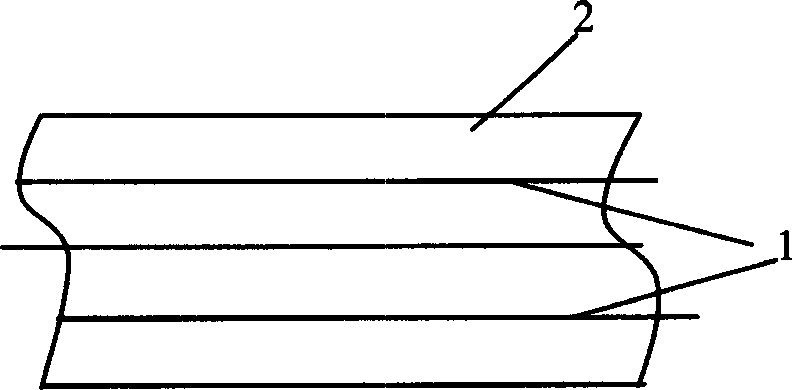

[0020] 4) Cross-lapping: the X-ray developing line is evenly implanted or sprayed into the net-laying stroke in the form of a solid state with compressed gas; or the liquid X-ray absorbing material is sprayed into the net-laying stroke, Frozen into X-ray imaging lines. At the sa...

Embodiment 2

[0030] Embodiment 2. The difference from Embodiment 1 is that the spunlace process is designed after the degreasing and bleaching processes. Compared with Embodiment 1, this embodiment has lower yield and higher production cost.

Embodiment 3

[0031] Embodiment 3. In addition to adding the X-ray developing line in the cross-lapping process, it can also be added after spunlace, including the following steps:

[0032] 1) material preparation; same as embodiment one

[0033] 2) cleaning flowers; same as embodiment one

[0034] 3) carding; same as embodiment one

[0035] 4) net laying; Same as embodiment one

[0036] 5) spunlace; same as embodiment one

[0037] 6) Composite the X-ray developing line on the surface of the non-woven fabric. Compounding refers to pasting the X-ray developing line on the surface of the non-woven fabric through heat sealing, hot pressing and ultrasonic treatment;

[0038] 7) degreasing; same as embodiment one

[0039] 8) bleaching; same as Example 1

[0040] 9) Finished product coiling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com