New high-speed full-automatic bag making machine

A fully automatic, bag-making machine technology, applied in bag-making operations, flexible container manufacturing, paper/cardboard containers, etc., can solve problems such as increased production costs, longer film stretches, and increased bag-making difficulty. The effect of reducing product scrap, reducing labor costs and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

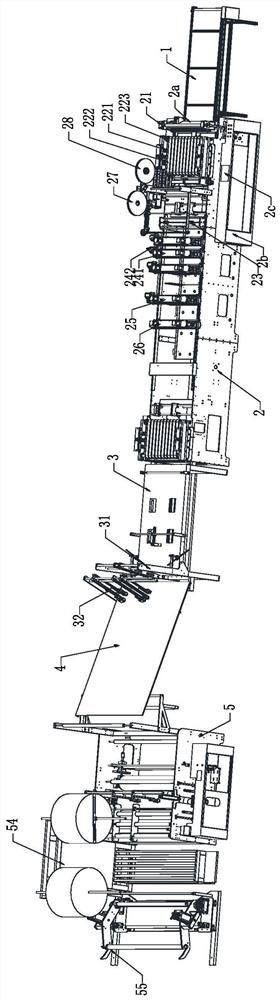

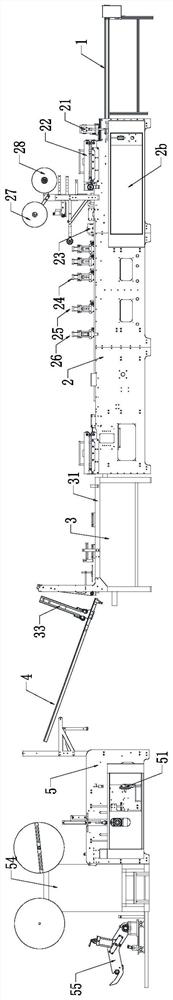

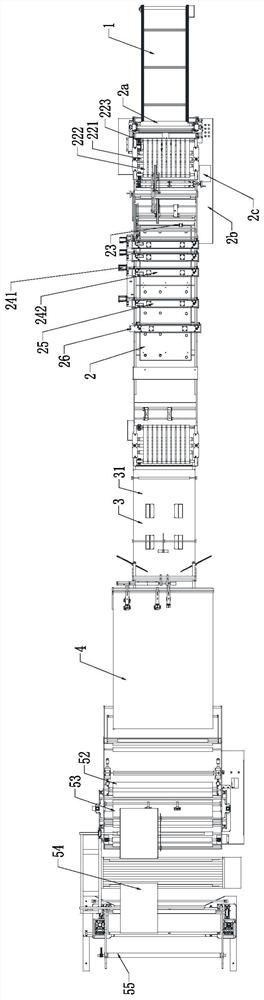

[0032] see Figure 1-Figure 3 , the present embodiment provides a novel high-speed full-automatic edge-pressing bag-making machine, which includes:

[0033] conveyor belt 1;

[0034] The front frame 2, its input end is close to the output end of the conveyor belt 1, and it is sequentially provided with a cutting device 21, an intermittent positioning feeding device 22, a color-tracking electric eye movable device 23, and a hot-press knife seal from the input end to the output end. Edge device 24, upper and lower hot press knife edge sealing device 25 and sealing deflation device 26 (can realize deflation at the air bubble seal), and the front frame 2 is also provided with release film storage device 27 and hot melt adhesive Applicator 28;

[0035] The middle frame 3 has its input end connected to the output end of the front frame 2, and it is provided with a platform retaining device 31, a folding device 32, and a correction device 33 in sequence from the input end to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com