Machine oil supply module

A supply module, oil technology, applied in the installation/connection of lubricant purification device, adding/discharging lubricant, lubricating parts, etc., can solve the problem that the engine oil cannot be completely discharged, and achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

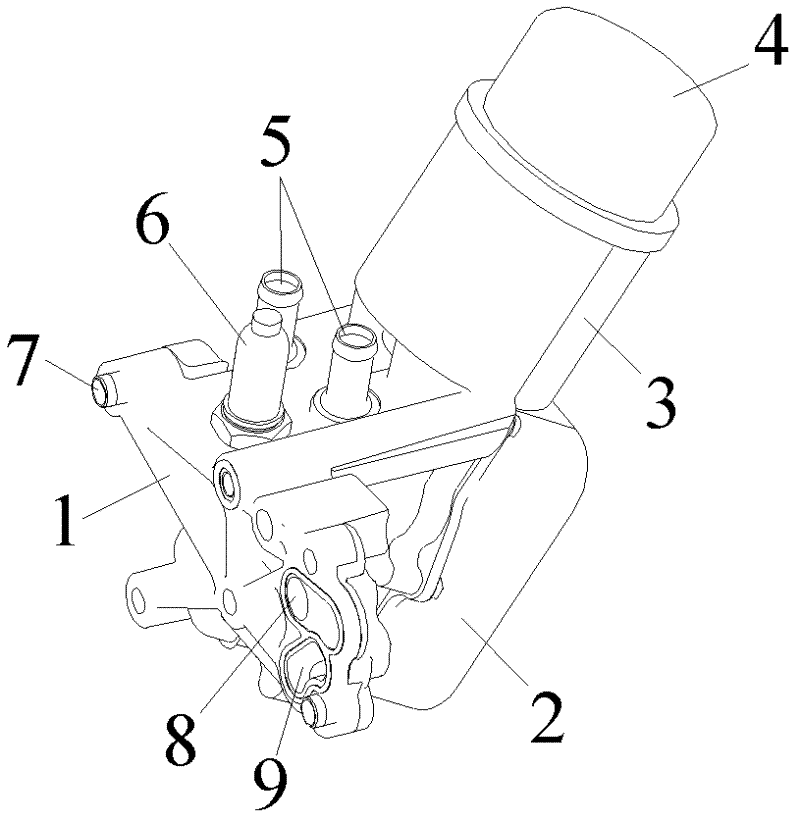

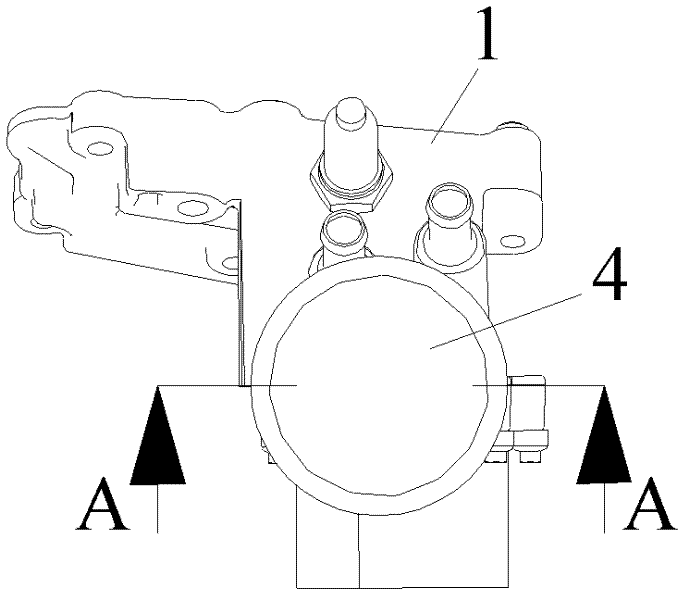

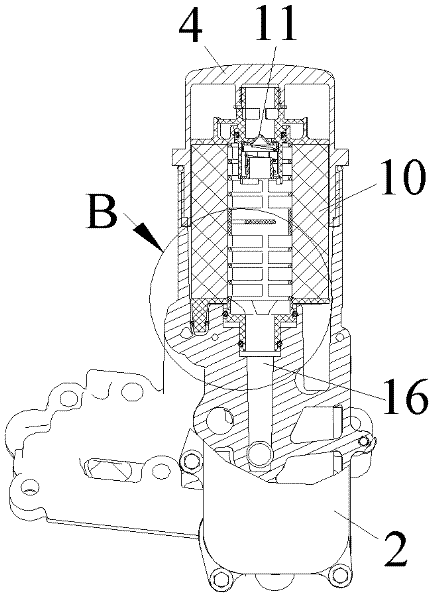

[0018] like figure 1 and figure 2 As shown, an engine oil supply module includes a module body 1 and an oil filter 3 and an oil cooler 2 integrated on the module body 1 . The module body 1 is provided with an inlet and outlet water pipe joint 5 connected with the module external water inlet and outlet pipe, and the inlet and outlet water pipe joint 5 is connected with the cooling water pipe in the oil cooler to form a cooling circuit. An oil outlet 8 and an oil inlet 9 are provided on the side of the module body 1, and the unfiltered engine oil first enters the oil cooler in the module through the oil inlet 9 of the oil supply module, and cools the unfiltered engine oil. The finished machine oil enters the machine oil filter 3 to filter again, and the machine oil after the filter flows back in the engine through the oil outlet 8 again. A positioning sleeve 7 and bolt connection holes for positioning and fixing the oil supply module are also provided on the side of the modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com