Combined shear wall with steel plates concealed in internal prestressed tendon CFST (concrete filled steel tube) frame and manufacturing method

A technology of concrete-filled steel tube and steel plate shear wall, applied in the direction of walls, building components, buildings, etc., can solve the problems of non-recoverable shear wall bearing capacity, insufficient seismic energy dissipation capacity, etc., achieve easy recovery function, reduce tensile deformation, etc. Small, the effect of improving the tensile strength of the rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments:

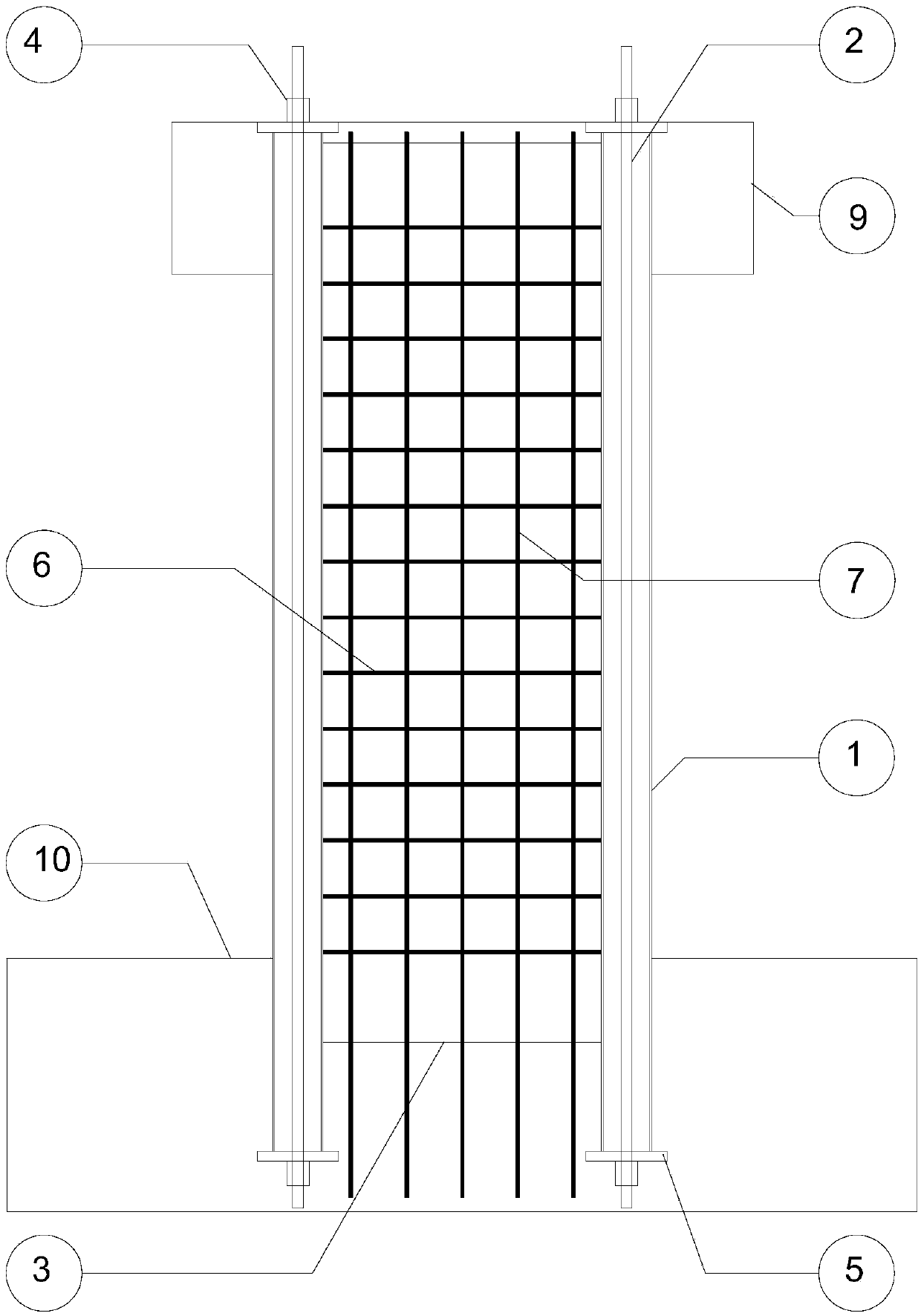

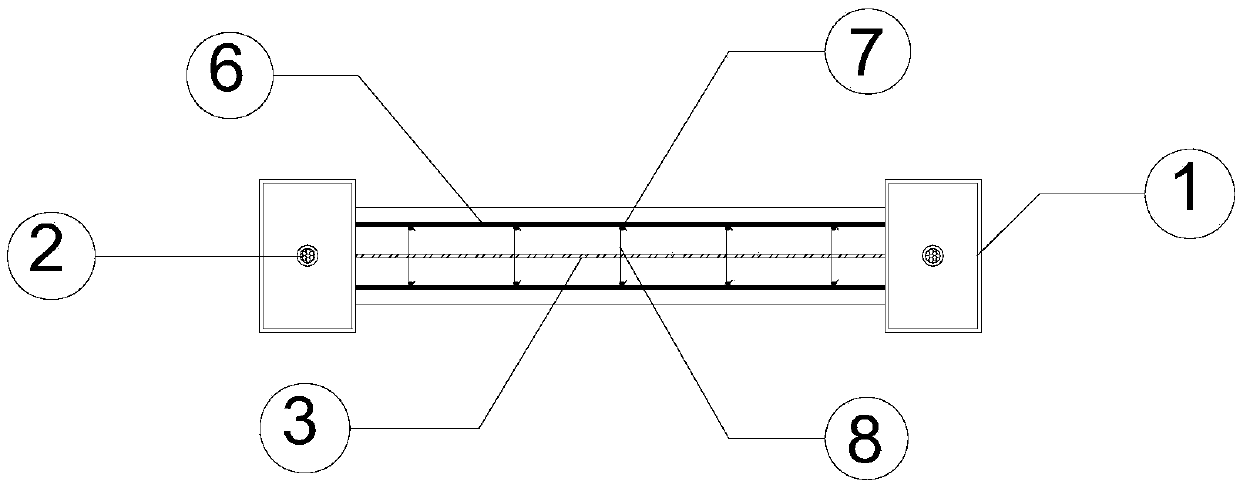

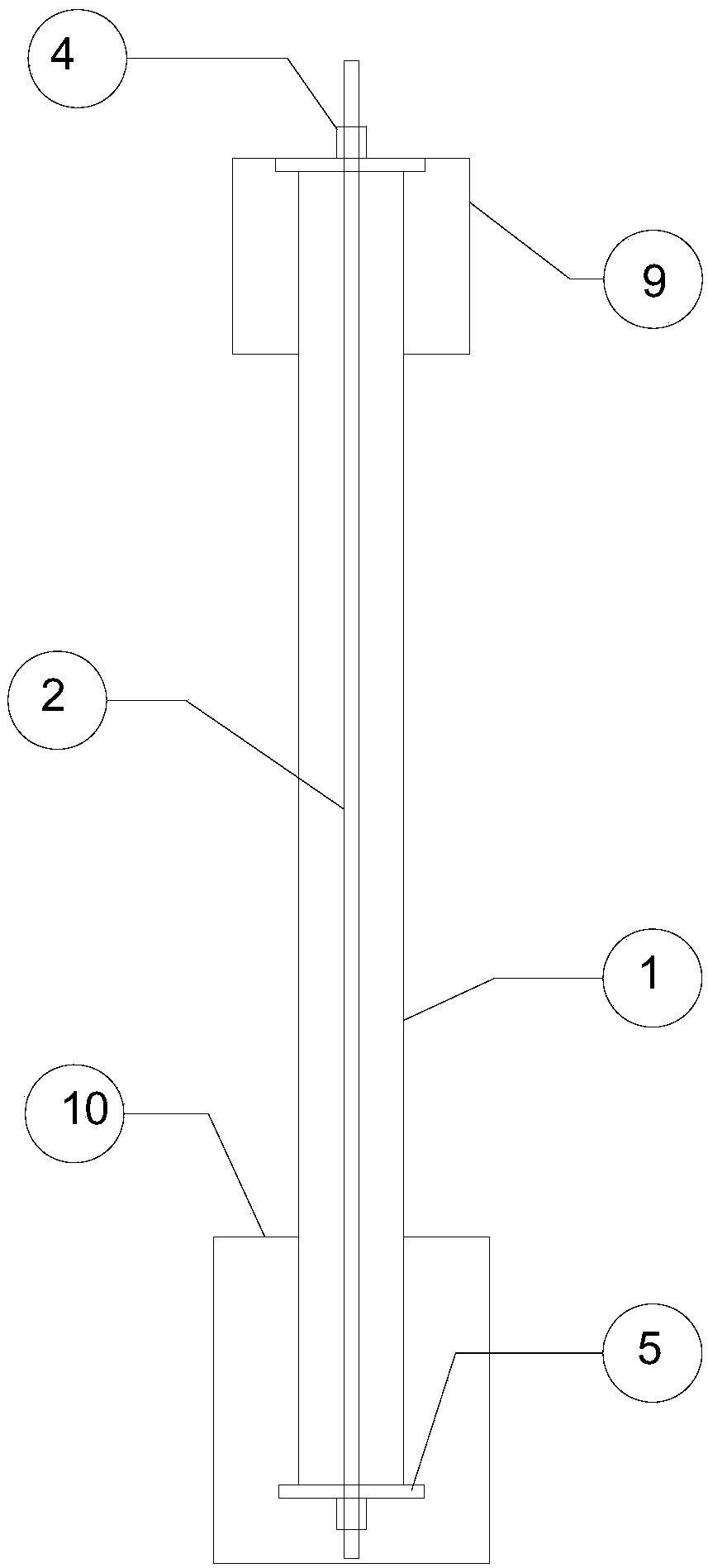

[0034] The structural diagram of a structural unit of the steel plate composite shear wall with the built-in prestressed steel tube concrete frame is as follows figure 1 , figure 2 , image 3 and Figure 4 Shown.

[0035] The built-in pre-stressed steel tube concrete frame contains steel plate shear wall, which is composed of steel tube concrete frame column 1, pre-stressed steel bar 2, steel plate 3 and reinforced concrete shear wall. The main features are: the wall section is I-shaped, and the prestressed tendons are built into the frame column of the steel plate composite shear wall embedded in the steel tube concrete frame.

[0036] The “combined shear force of steel plate embedded in the concrete-filled steel tube frame” refers to a steel-concrete composite shear wall composed of a steel-tube concrete frame column 1, a steel plate 3, a horizontal steel bar 6 and a longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com