Viscoelastic friction type energy dissipation self-resetting buckling-restrained brace

An anti-buckling support and self-resetting technology, which is applied in the field of shock absorption and anti-seismic, can solve the problems of self-resetting device energy consumption capacity and poor stability of self-resetting ability, and achieve the effect of enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

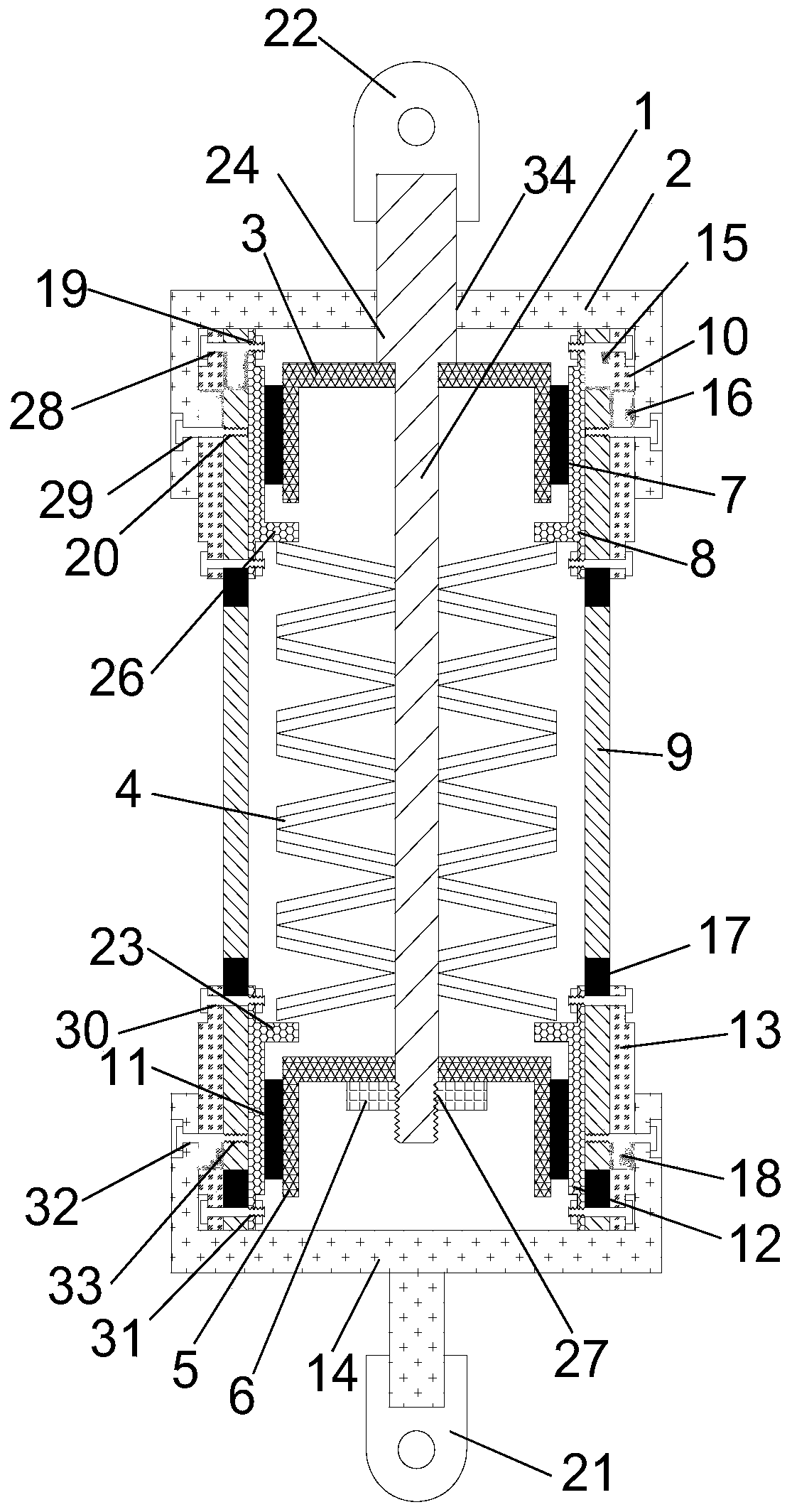

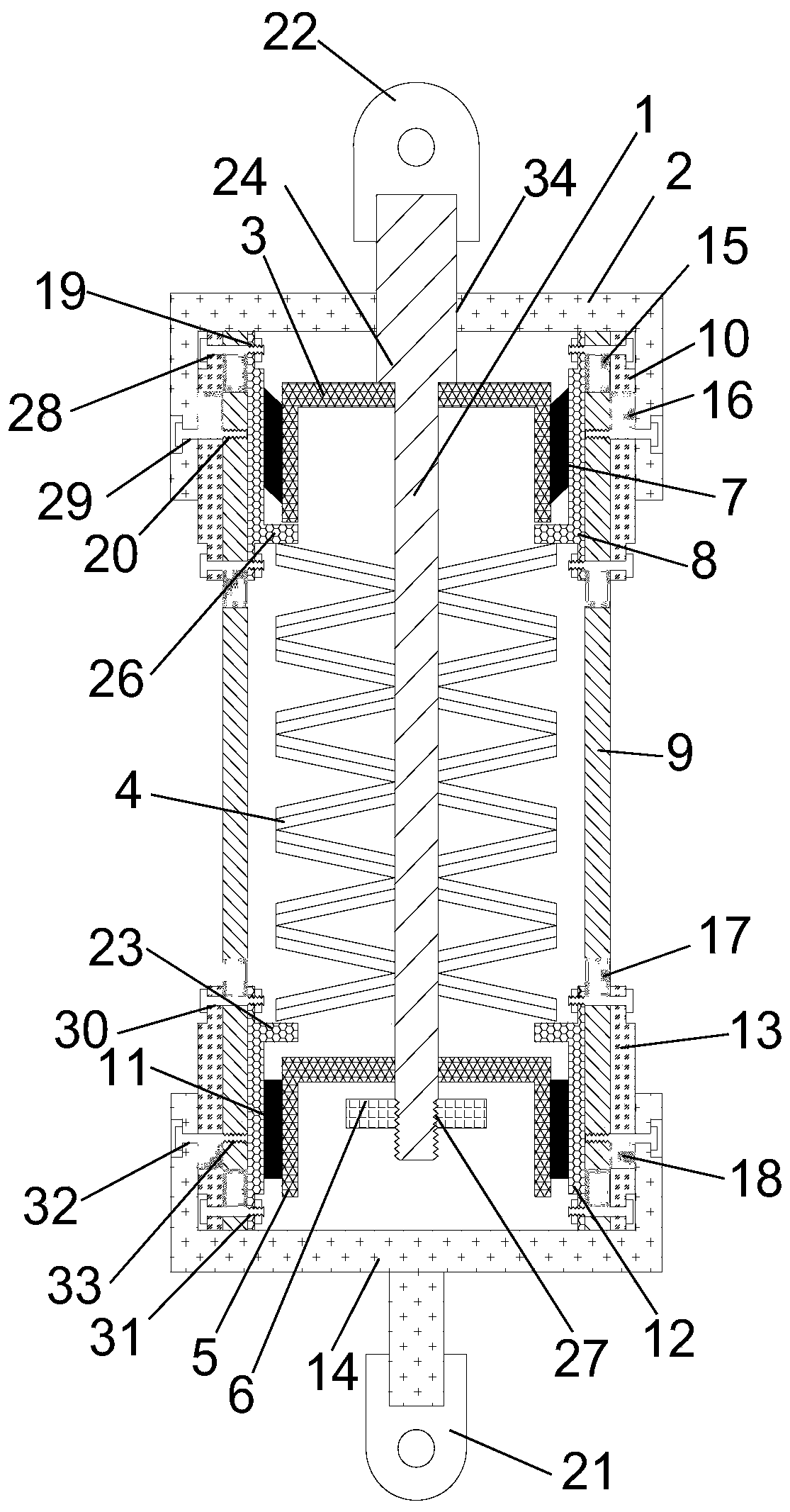

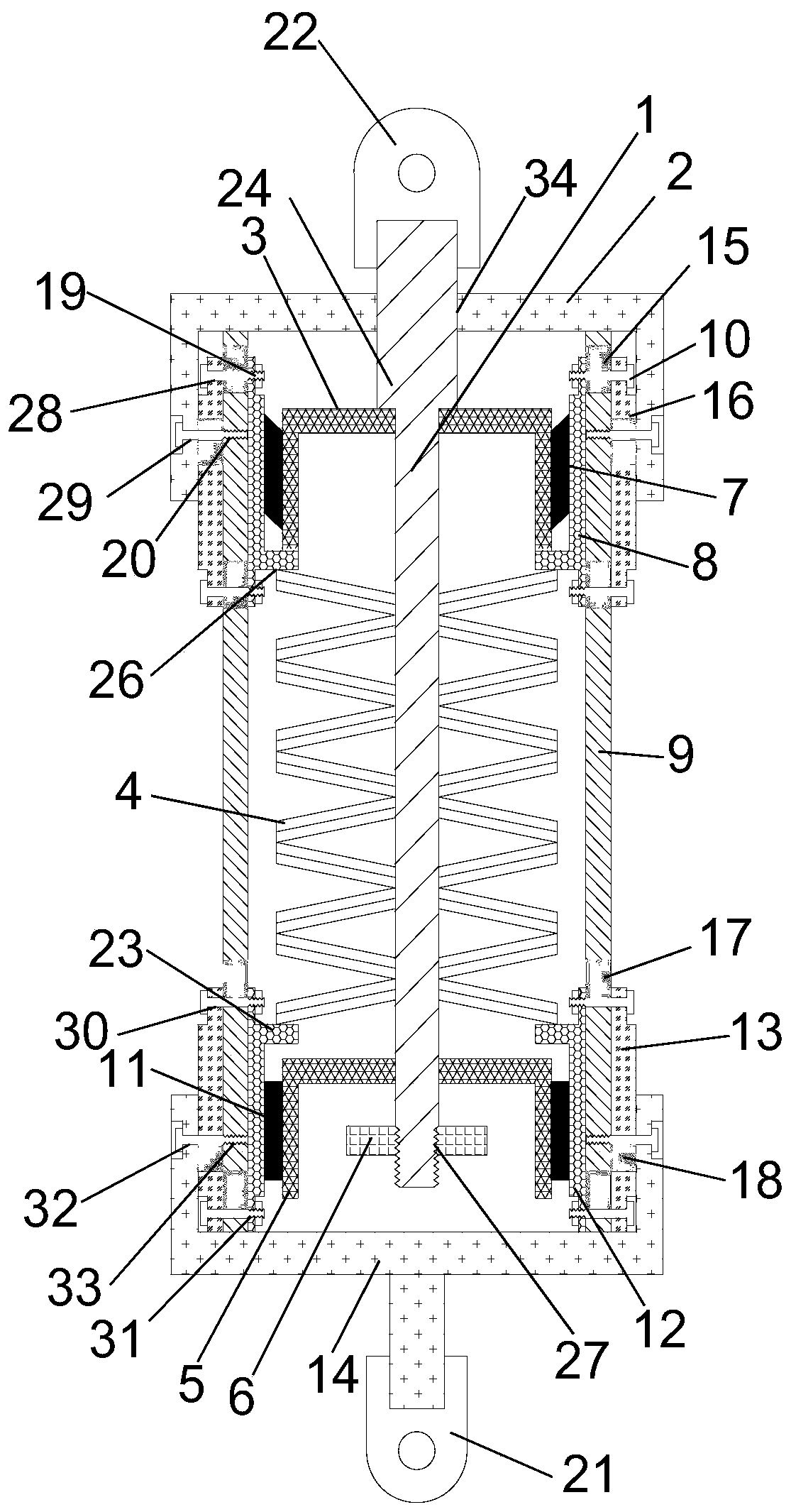

[0039] According to the attached Figure 1~6 , Give the preferred embodiments of the present invention and describe them in detail, so as to better understand the functions and characteristics of the present invention.

[0040] See figure 1 , A viscoelastic friction type energy-consuming self-resetting anti-buckling support according to an embodiment of the present invention includes: an upper fixed cylinder 2, a lower fixed cylinder 14, at least one fixed guide plate 9, a piston rod 1, a fixed end plate 6, At least one spring 4, a first viscoelastic energy dissipation component, a second viscoelastic energy dissipation component, at least one first friction structure, at least one second friction structure, at least one third friction structure, and at least one fourth friction structure 1. An upper connecting piece 22 and a lower connecting piece 21; a first through hole 34 is opened in the middle of the top surface of the upper fixing cylinder 2, and both ends of the fixing gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com