Self-adaptive buckling-preventing support

An anti-buckling bracing and self-adaptive technology, applied in earthquake resistance, building maintenance, building components, etc., can solve the problems of single application scenario, poor self-reset bracing energy dissipation capacity, etc., to increase the shear area and reduce the structural efficiency. Deformation, effect of large self-resetting restoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

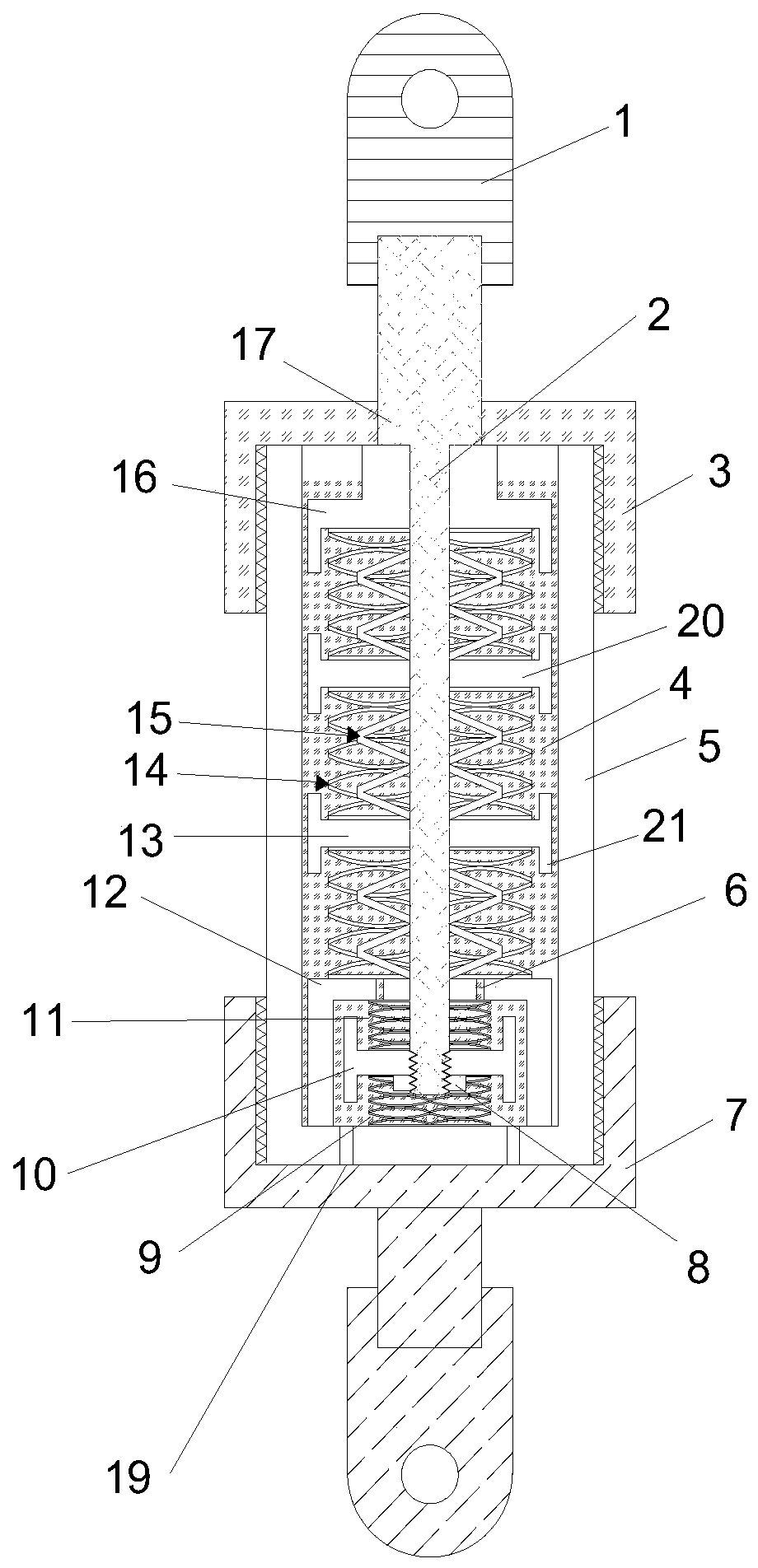

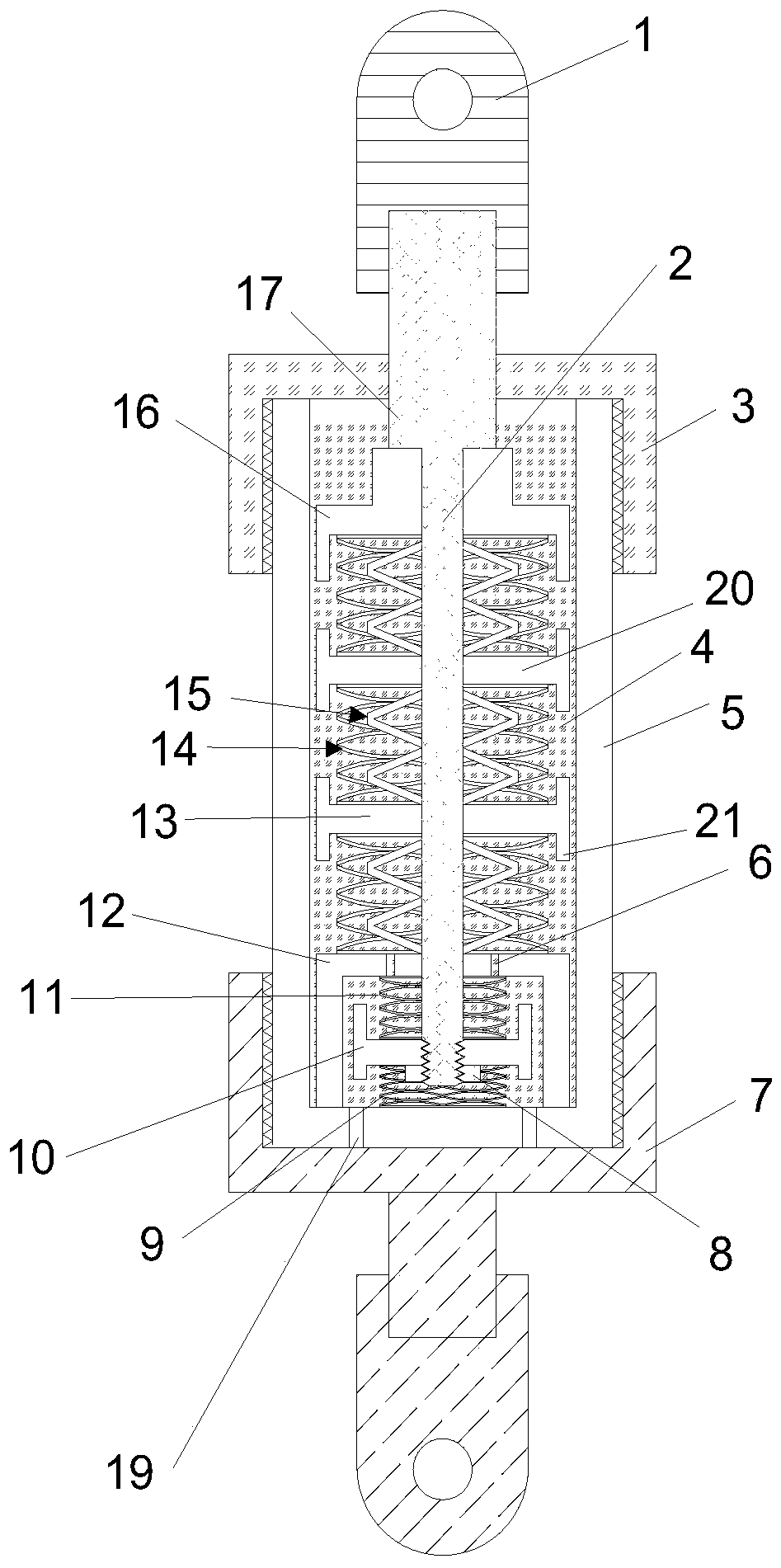

[0066] The second embodiment differs from the first embodiment in that (refer to Image 6 ), there is a gap between the primary spring 14 and the built-in upper oil storage tank cylinder 16, and the multi-objective self-adaptive high-efficiency energy-consuming self-resetting anti-buckling support is divided into three different working stages according to the external excitation and deformation of the structure , and can be automatically adjusted according to the change of external excitation, so that the performance of multi-objective self-adaptive high-efficiency energy-consuming self-resetting anti-buckling support adapts to the current external excitation conditions. In the first stage, when the structure is subjected to environmental vibration (wind vibration, machine vibration, subway vibration, etc.), the multi-objective adaptive high-efficiency energy-consuming self-resetting anti-buckling support deforms very little, and does not need to provide self-resetting force f...

no. 3 example

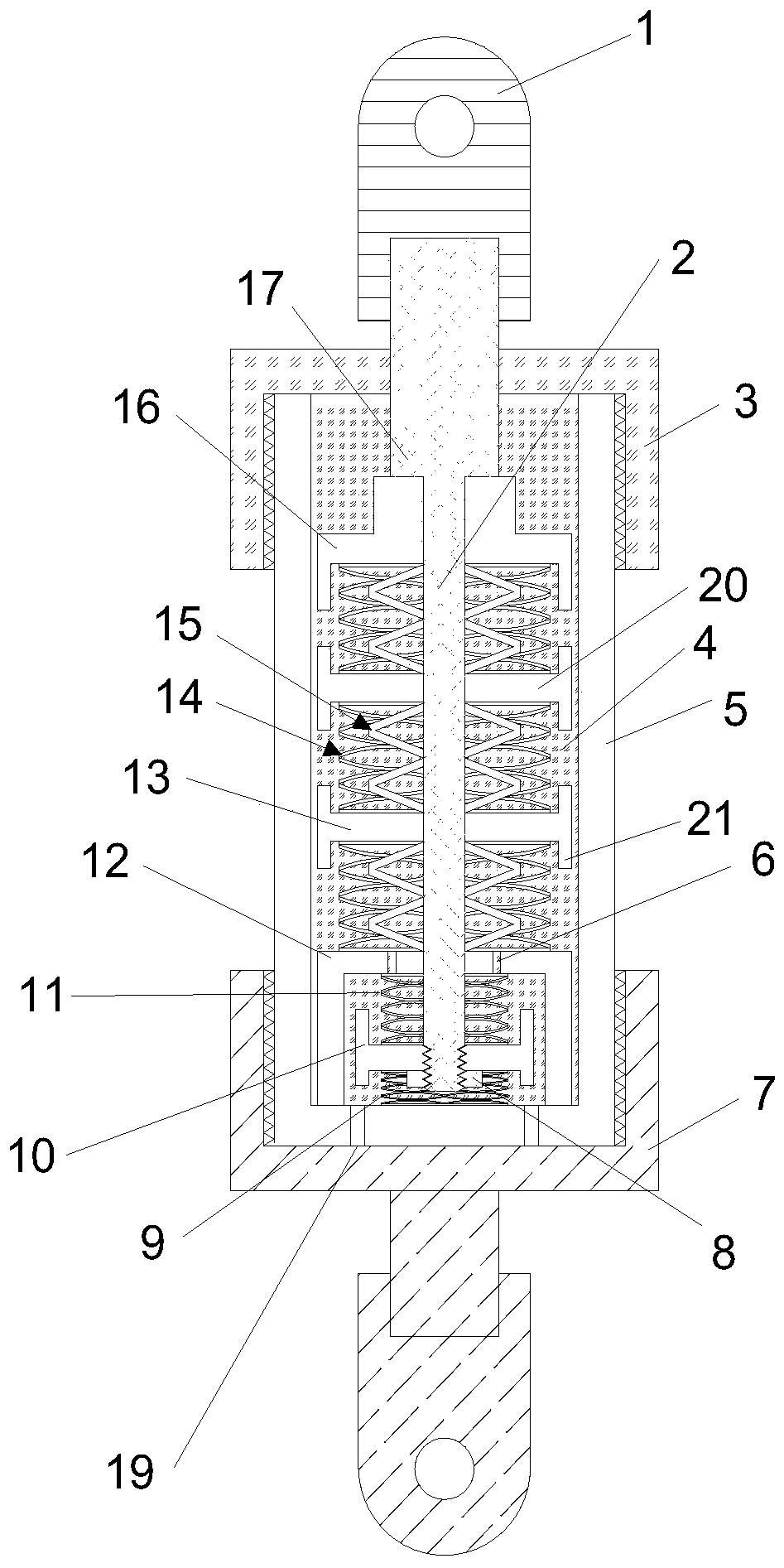

[0067] The third embodiment differs from the first embodiment in that (refer to Figure 7 ), the built-in upper oil storage tank cylinder 16, the first energy-dissipating fixed partition 20 and the second energy-consuming fixed partition 13 and the built-in lower oil storage tank limit cylinder 12 are provided with a damping hole 18 for the circulation of the damping fluid 4 , the built-in upper oil storage tank cylinder 16, the first energy-consuming fixed partition 20, the second energy-consuming fixed partition 13, and the built-in lower oil storage tank limit cylinder 12 are attached to the inner wall of the sealed cylinder cavity 5 or are in contact with A gap is left between the inner walls of the sealed cylinder cavity 5 . Through the damping hole 18, the damping fluid 4 can circulate among the built-in upper oil storage tank cylinder 16, the first energy-dissipating fixed partition 20, the second energy-consuming fixed partition 13 and the built-in lower oil storage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com