Aluminum foil double-face fast coating device and method

A technology of coating and aluminum foil, which is applied to the device for coating liquid on the surface, coating, pretreatment surface, etc., to achieve the effect of fast coating, convenient operation and saving oven space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

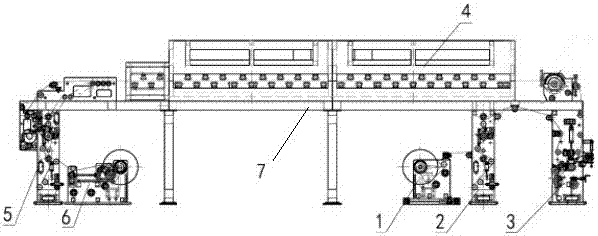

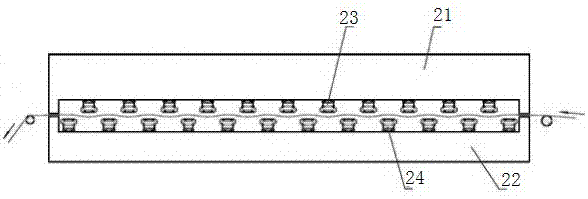

[0036] This embodiment provides a figure 1 The device for rapid coating on both sides of aluminum foil, a device for rapid coating on both sides of aluminum foil, includes a frame body 7 and an unwinding mechanism 1 arranged on the frame body 1 7, a feeding pulling mechanism 2, coating Mechanism 3, oven 4, discharge traction mechanism 5 and winding mechanism 6, characterized in that: the coating mechanism 3 is a double-sided ladder coating mechanism, and the double-sided ladder coating mechanism includes a front coating mechanism And the reverse coating mechanism, the oven 4 is a suspension type oven, and the aluminum foil passes through the unwinding mechanism 1, the feeding traction mechanism 2, the coating mechanism 3, the oven 4, the discharging traction mechanism 5 and the winding mechanism 6 to complete the double-sided operation. coating.

[0037] The aluminum foil is coated sequentially through the unwinding mechanism 1, the feeding traction mechanism 2, the coating m...

Embodiment 2

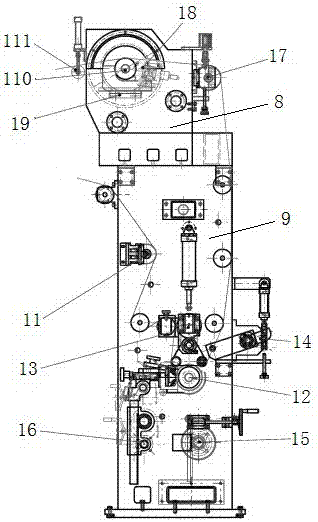

[0039] On the basis of Embodiment 1, this embodiment provides a device for double-sided rapid coating of aluminum foil, such as figure 2 As shown, the front coating mechanism is arranged below the reverse coating mechanism. The aluminum foil is front-coated and then reverse-coated upwards.

Embodiment 3

[0041] On the basis of Embodiment 1 or Embodiment 2, this embodiment provides a device for rapid coating on both sides of aluminum foil, such as figure 2As shown, the front coating mechanism includes a frame body 2, and the frame body 2 8 is provided with a tension floating roller 11, a front gravure coating roller 12, a rubber pressing roller 13, a smoothing roller 14, an ink cartridge 15 and a scraper One 16, the tension floating roller 11 is arranged on the upper part of the frame body 2, the gravure coating roller 12 is arranged in the middle of the frame body 2, the rubber pressing roller 13 is arranged above the gravure coating roller 12, and is driven by Press the aluminum foil on the gravure coating roll 12, the smoothing roll 14 is tangent to the gravure coating roll 12, the oil outlet of the ink cartridge 15 is aligned with the gravure coating roll 12, and the scraper 1 16 is tangent to the side surface of the gravure coating roll 12, and the tension dancer roll 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com