Warp-overlapping-structure carbon cloth gas diffusion layer for fuel cell

A gas diffusion layer and fuel cell technology, applied to electrical components, battery electrodes, structural parts, etc., to achieve the effects of resistance to changes in environmental conditions, long-term stable and reliable performance, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

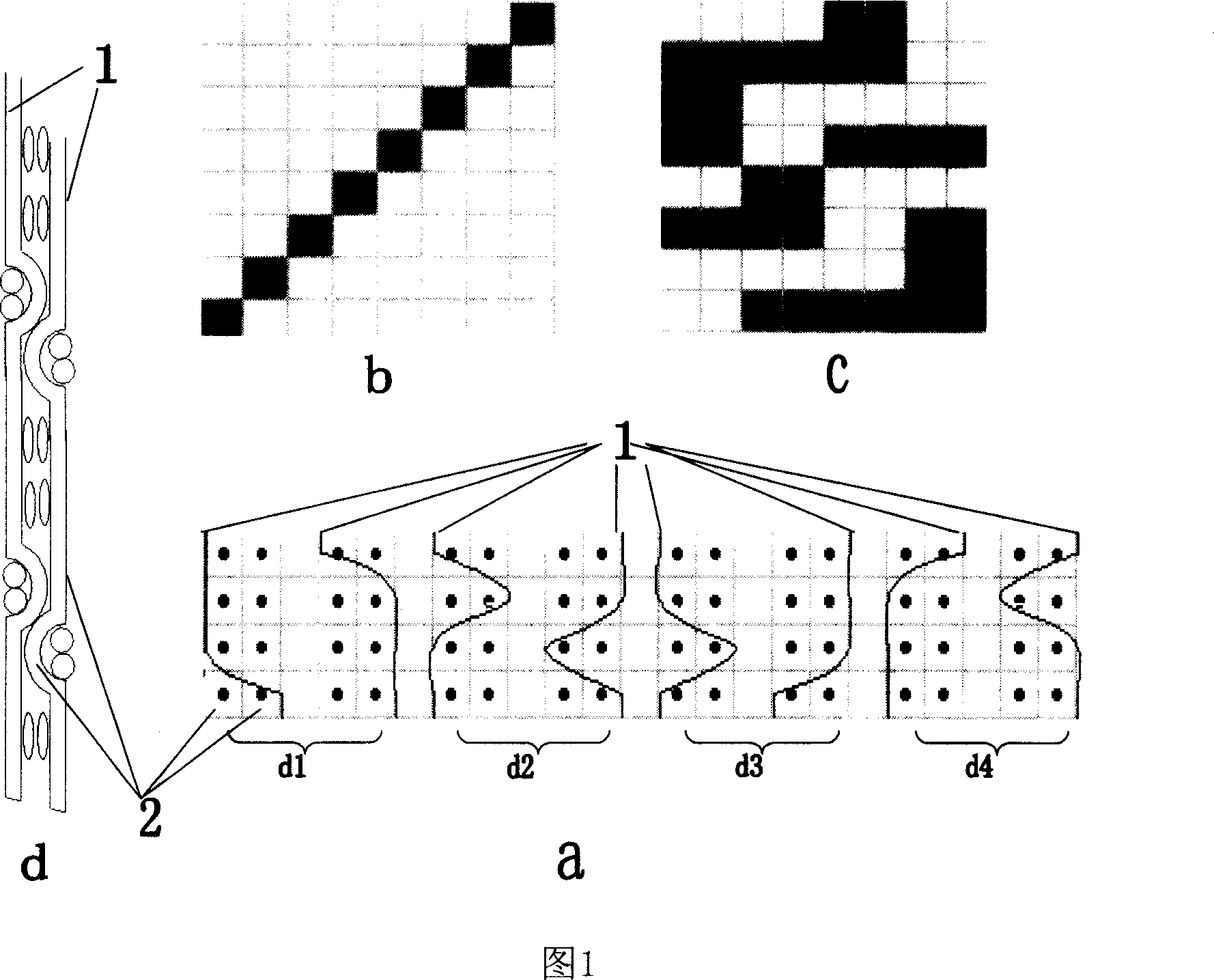

[0023] In Fig. 1, figure a is a diagram of warp yarn combination state and weaving movement, which is shown as the ups and downs and ups and downs of carbon fiber warp yarn 1 (a total of 8, represented by a curve) relative to carbon fiber weft yarn 2 (represented by a dot) in a complete structure. Movement, there are four groups of double-weave (d1, d2, d3, d4) in the fabric from left to right, and the cross-section of each group of double-weave structure is the longitudinal cross-section of the fabric in Figure d shown. Figure b and Figure c are the weaving process diagrams used when the carbon cloth of this embodiment is weaved on the upper machine, Figure b represents the drafting diagram, and Figure c is the pattern diagram.

[0024] It can be seen and deduced from the structure of the longitudinal cross-sectional view d of the carbon cloth in the embodiment:

[0025] 1. Both sides of the carbon cloth are composed of warp yarns with 3 floating and 1 sinking long warp floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com