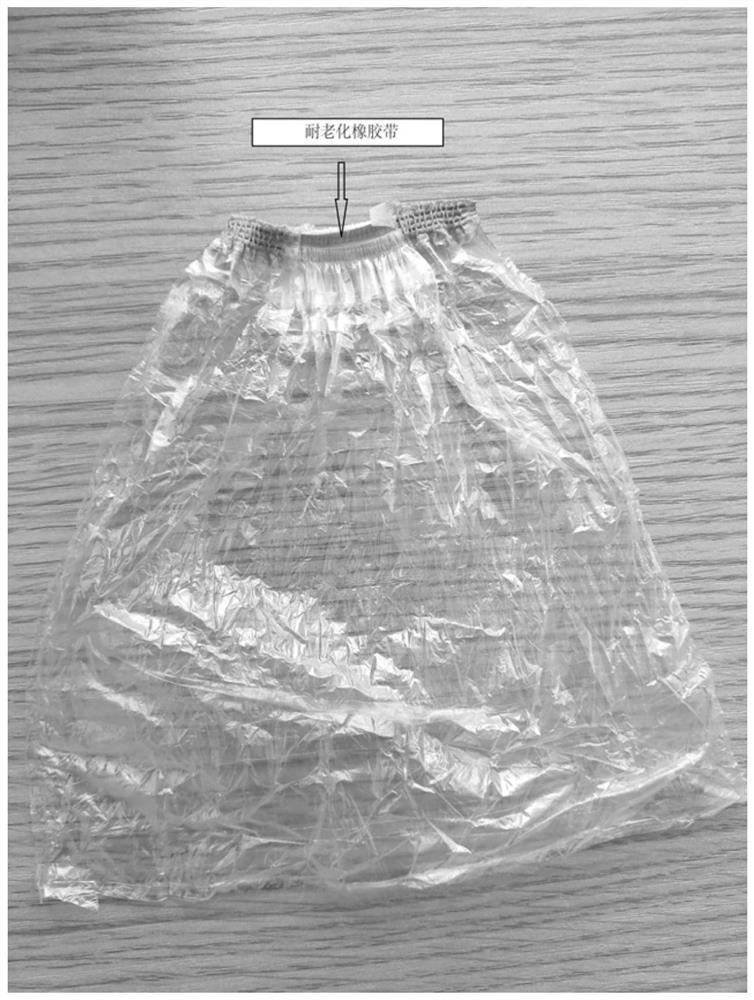

Anti-aging rubber belt and preparation method thereof

A rubber belt and anti-aging technology, applied in the field of rubber products, can solve the problems of high labor cost and material cost, complicated operation process, labor and time-consuming, etc., and achieve the effect of low preparation cost, simple operation process and uniform product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An embodiment of the aging-resistant rubber belt of the present invention includes the following raw materials in parts by weight: 70 parts of natural rubber, 30 parts of EPDM rubber, 2 parts of sulfur, and 1.0 part of tetramethylthiuram monosulfide accelerator , 1.0 parts of dithiocarbamate accelerator, 1.5 parts of thiazole accelerator, 5 parts of nano-zinc oxide, 2 parts of stearic acid, 2 parts of styrenated phenol, 2.5 parts of 2-mercaptobenzimidazole, protective 1.5 parts of paraffin, 15 parts of reinforcing silica, 10 parts of calcium carbonate, 1 part of antioxidant and 5 parts of softener.

[0035] The preparation method of described aging-resistant rubber belt comprises the following steps:

[0036] (1) After mixing natural rubber and propylene diene rubber, put them into an internal mixer, add accelerators, active agents, antiaging agents, reinforcing silica, fillers and softeners in turn, mix and disperse them, and then knead them. Automatic de-glue after g...

Embodiment 2

[0042] An embodiment of the aging-resistant rubber belt of the present invention includes the following raw materials in parts by weight: 60 parts of natural rubber, 40 parts of EPDM rubber, 2.5 parts of sulfur, and 1.5 parts of tetramethylthiuram monosulfide accelerator , 1.5 parts of dithiocarbamate accelerator, 2 parts of thiazole accelerator, 4 parts of nano-zinc oxide, 3 parts of stearic acid, 3 parts of styrenated phenol, 3 parts of 2-mercaptobenzimidazole, protective 2 parts of paraffin, 20 parts of reinforcing silica, 15 parts of calcium carbonate, 2 parts of antioxidant and 10 parts of softener.

[0043] The preparation method of the aging-resistant rubber belt described in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0045] An embodiment of the aging-resistant rubber belt of the present invention includes the following raw materials in parts by weight: 65 parts of natural rubber, 35 parts of EPDM rubber, 2.5 parts of sulfur, and 1.0 part of tetramethylthiuram monosulfide accelerator , 1.0 parts of dithiocarbamate accelerator, 1.5 parts of thiazole accelerator, 6 parts of nano zinc oxide, 1 part of stearic acid, 2 parts of styrenated phenol, 2 parts of 2-mercaptobenzimidazole, protective 1.5 parts of paraffin, 18 parts of reinforcing silica, 18 parts of calcium carbonate, 1.5 parts of antioxidant and 8 parts of softener.

[0046] The preparation method of the aging-resistant rubber belt described in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com