Patents

Literature

165results about How to "Mix and disperse evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-nickel material coated with aluminum and lithium silicate on surface and doped with fluorine on surface layer and preparation method

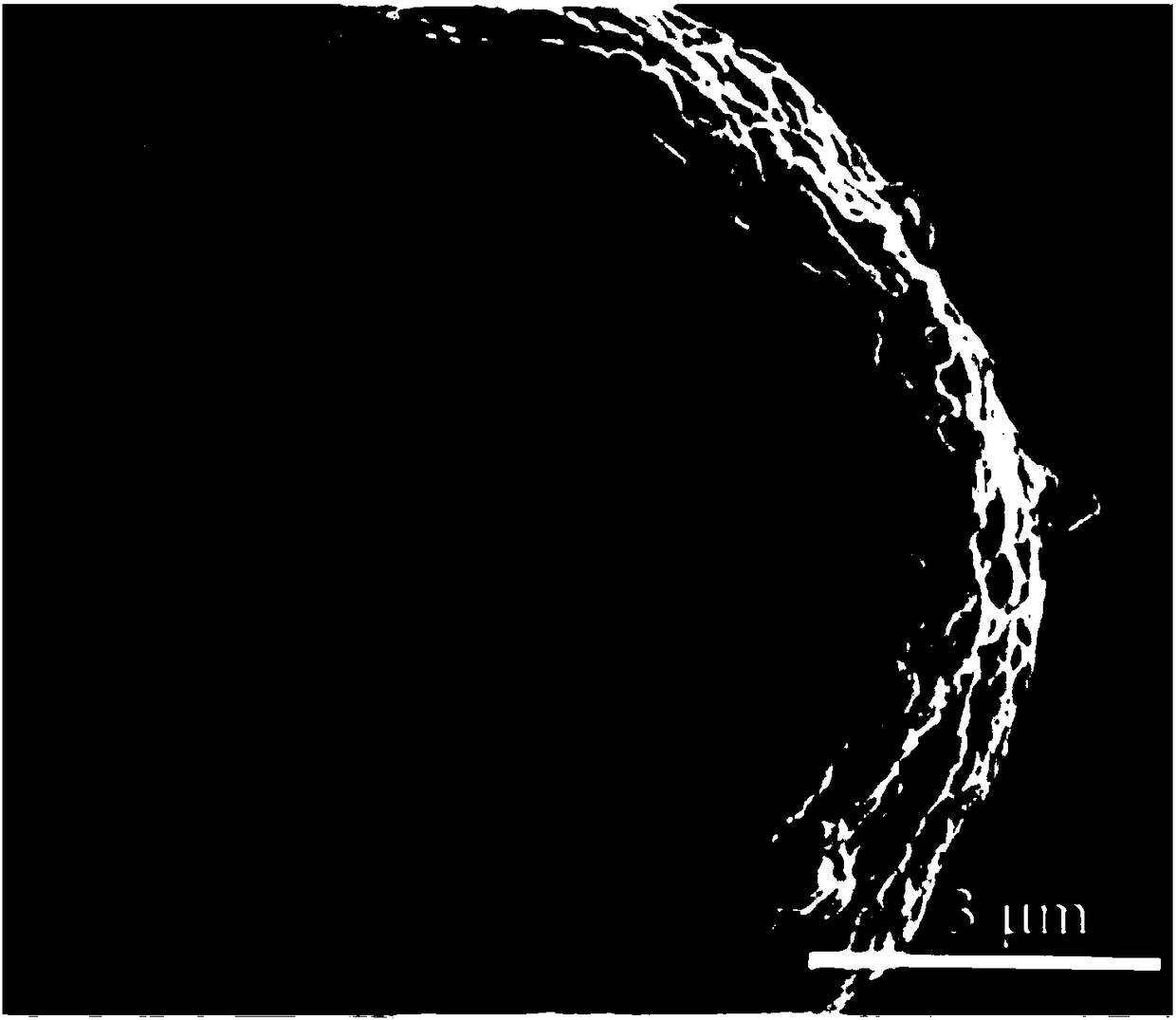

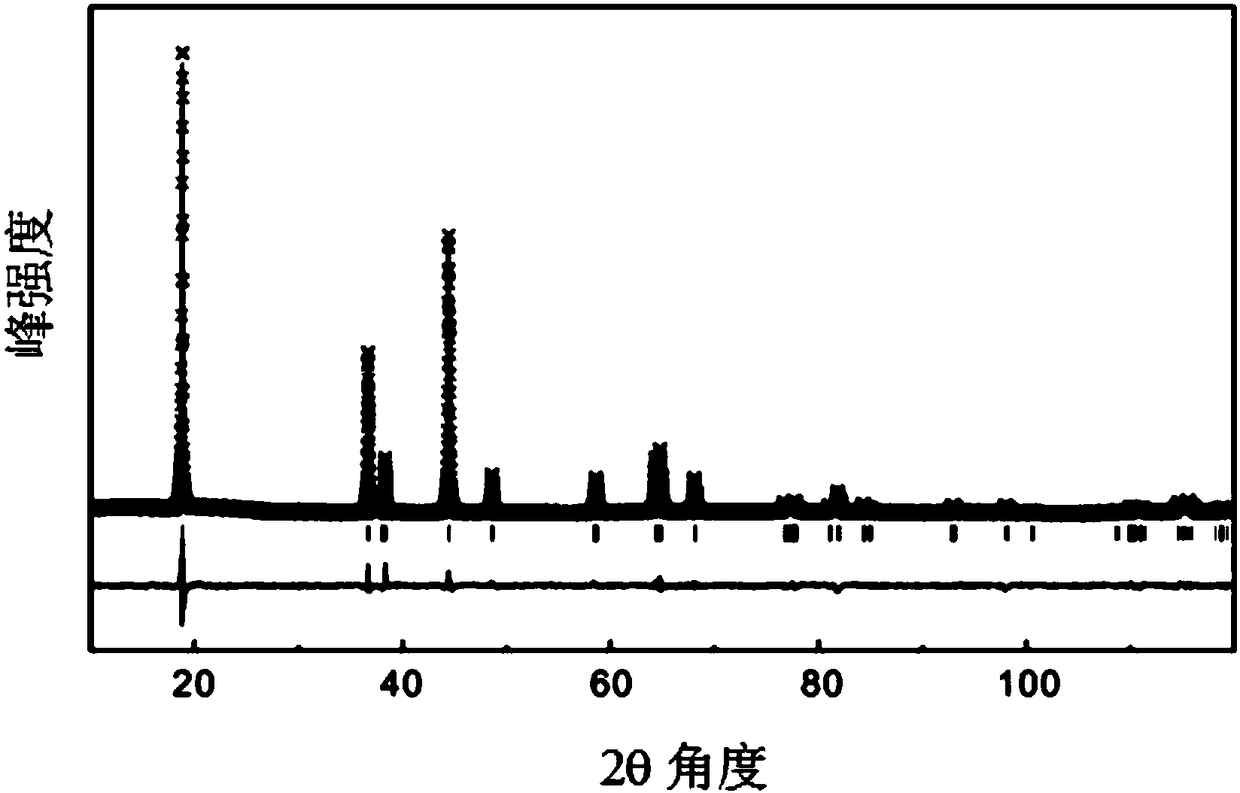

ActiveCN108807931AImprove electronic conductivityReduce residual alkaliCell electrodesElectrical conductorOxygen

The invention discloses a high-nickel material coated with aluminum and lithium silicate on the surface and doped with fluorine on a surface layer. The high-nickel material comprises an aluminum and lithium silicate coating layer and a high-nickel ternary material central layer, wherein the thickness of the coating layer is 1-200 nm, and the coating layer is doped with a fluorine element. In addition, the invention discloses a preparation method of the high-nickel material. The preparation method comprises the steps of mixing, drying and screening, lithium-adding sintering and fluorine-addingthermal treatment. The aluminum and lithium silicate fast-ion conductor material coating layer has good lithium-ion conducting performance, doped fluorine ions replace oxygen in the coating layer or the high-nickel material, accordingly the electronic conductivity of the material is improved, finally the surface of the high-nickel material has better lithium-ion and electronic conductivity properties, and playing of the rate capability of an anode material for lithium ion batteries is facilitated. The preparation method of the high-nickel material is low in cost, the process is simple, and industrialization is easy to achieve.

Owner:余姚市海泰贸易有限公司

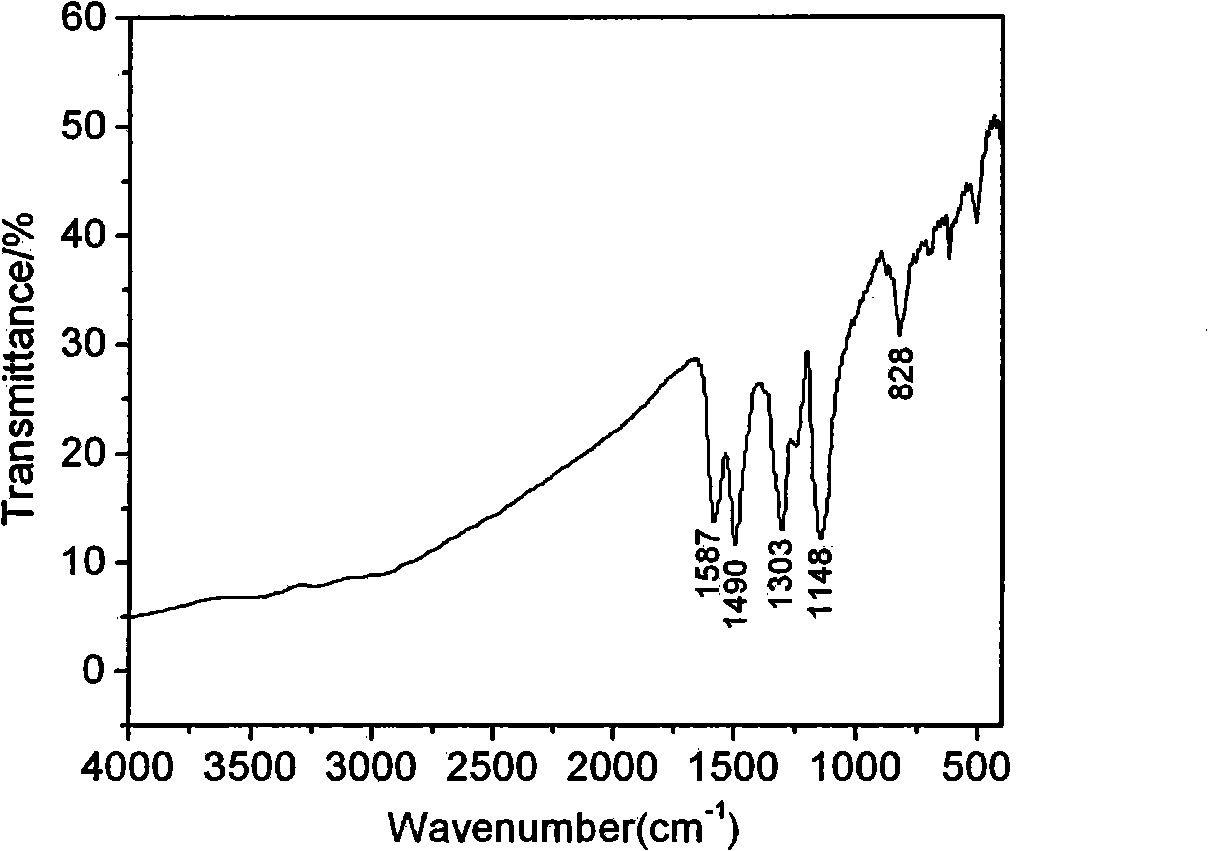

Method for preparing polyanionic lithium ion battery anode material

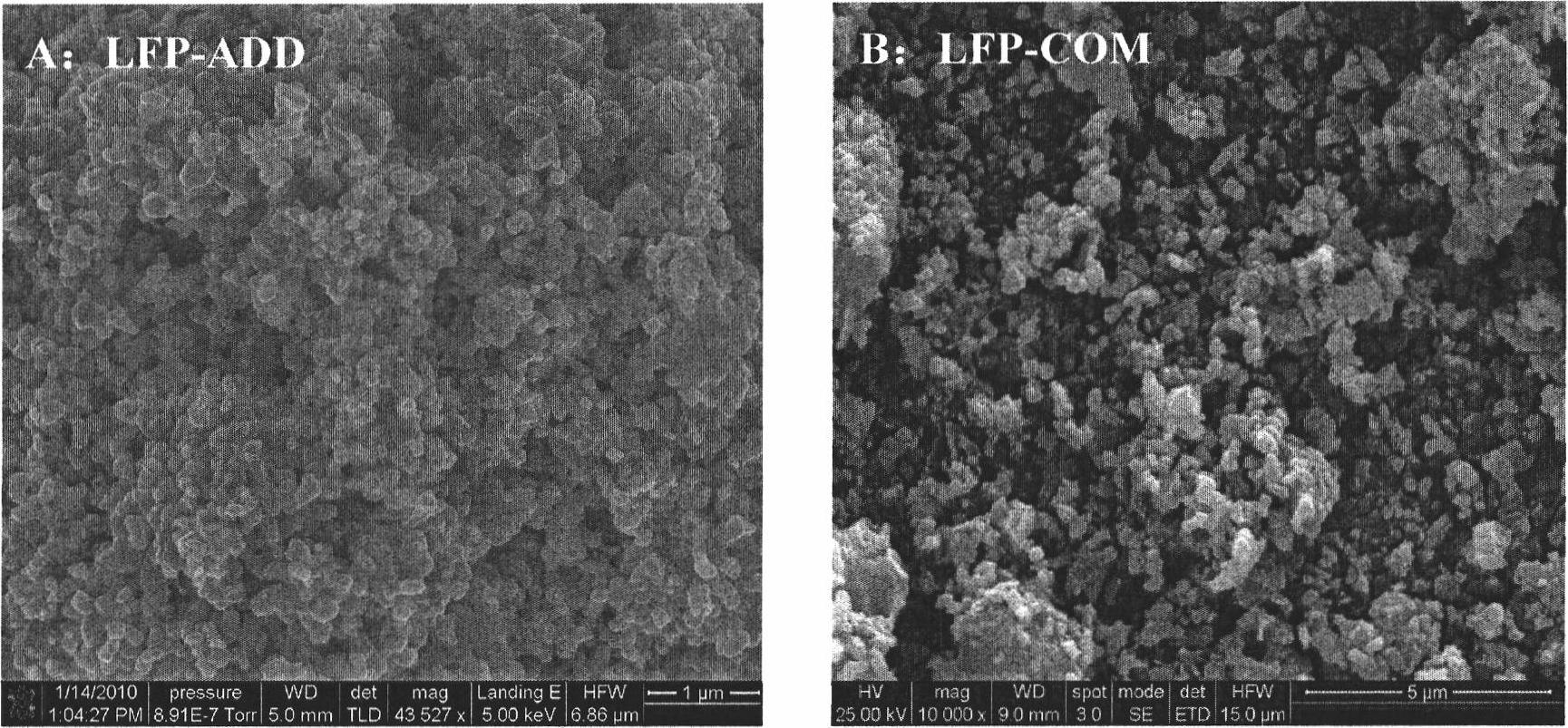

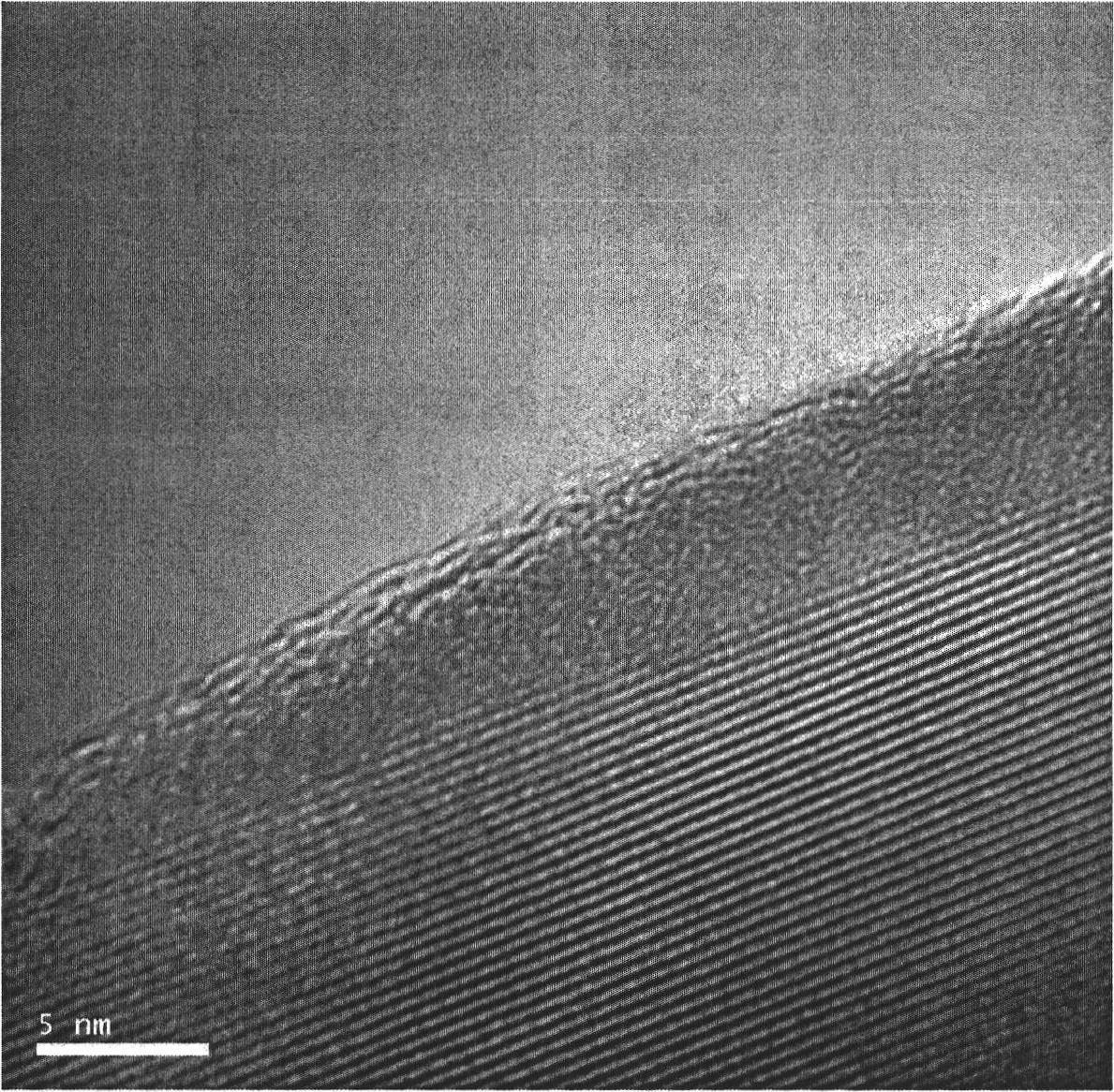

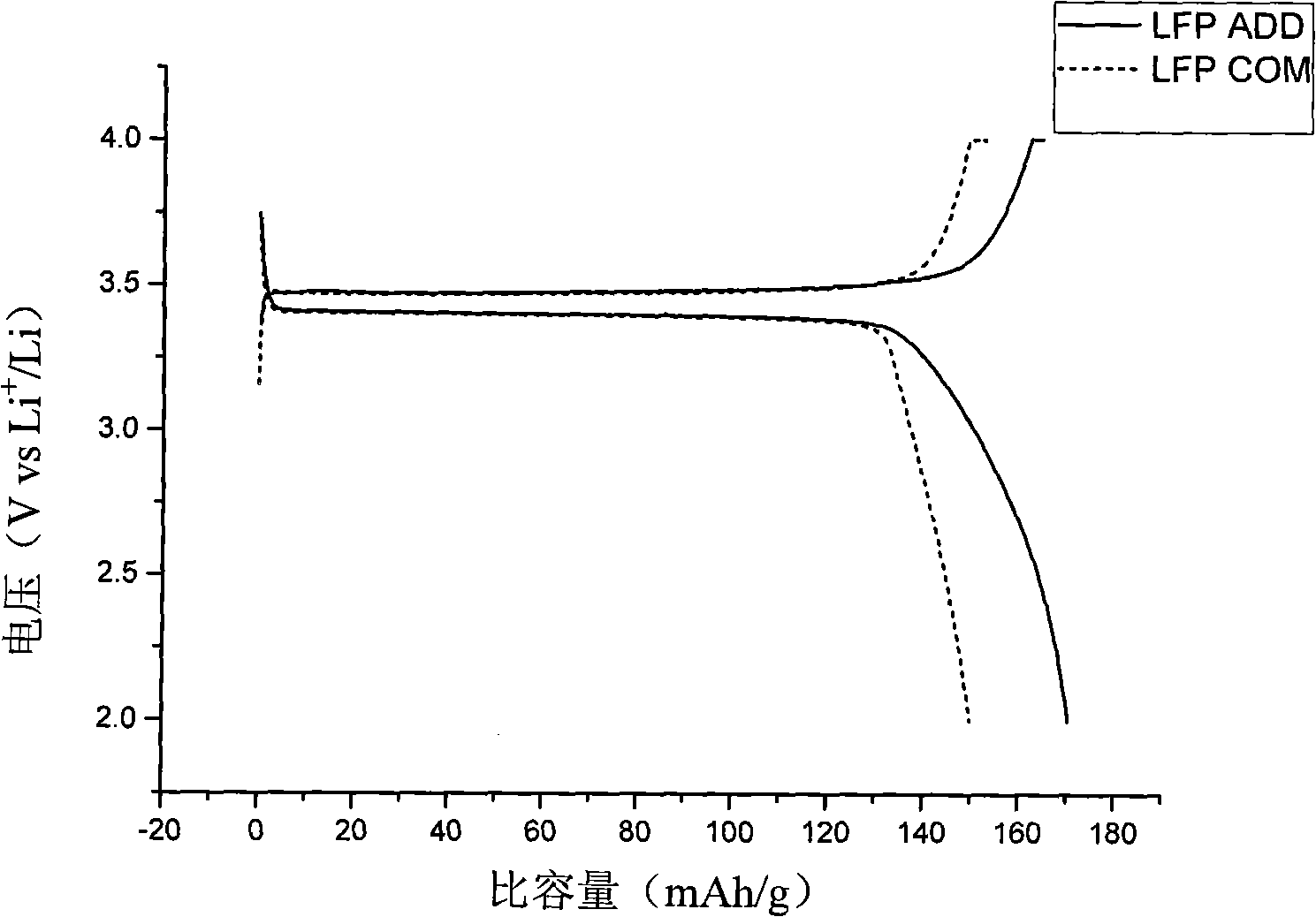

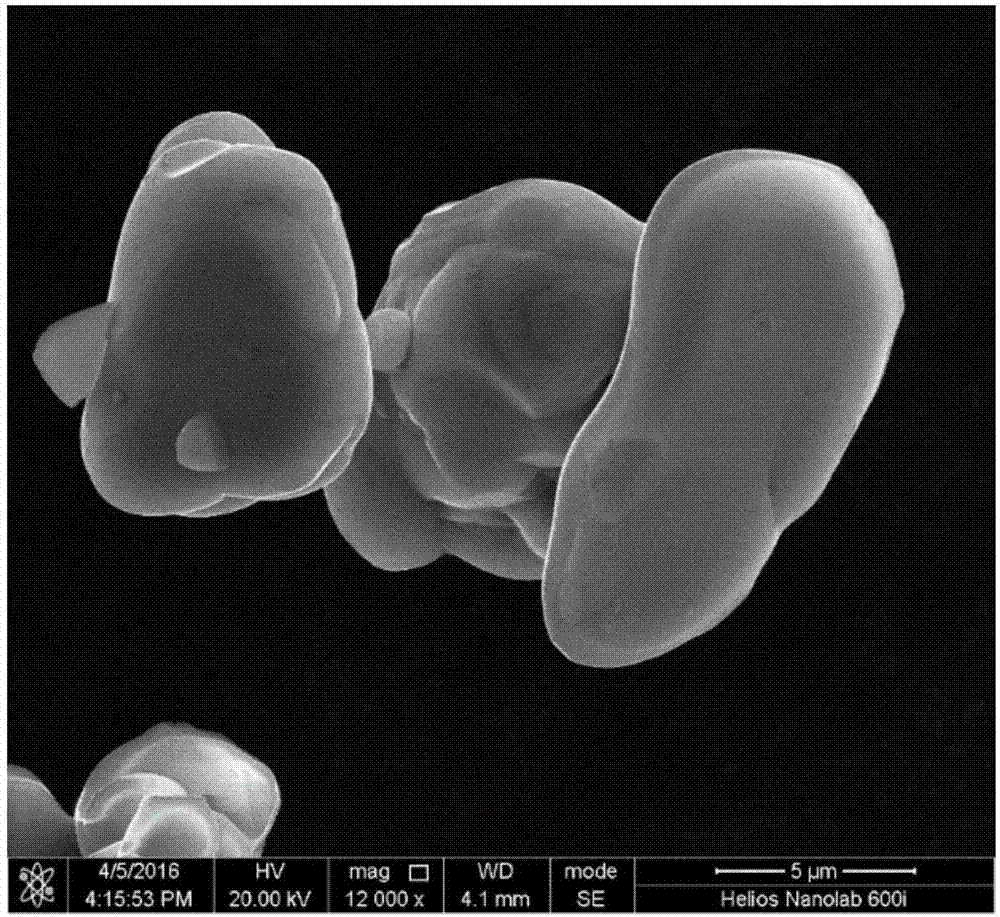

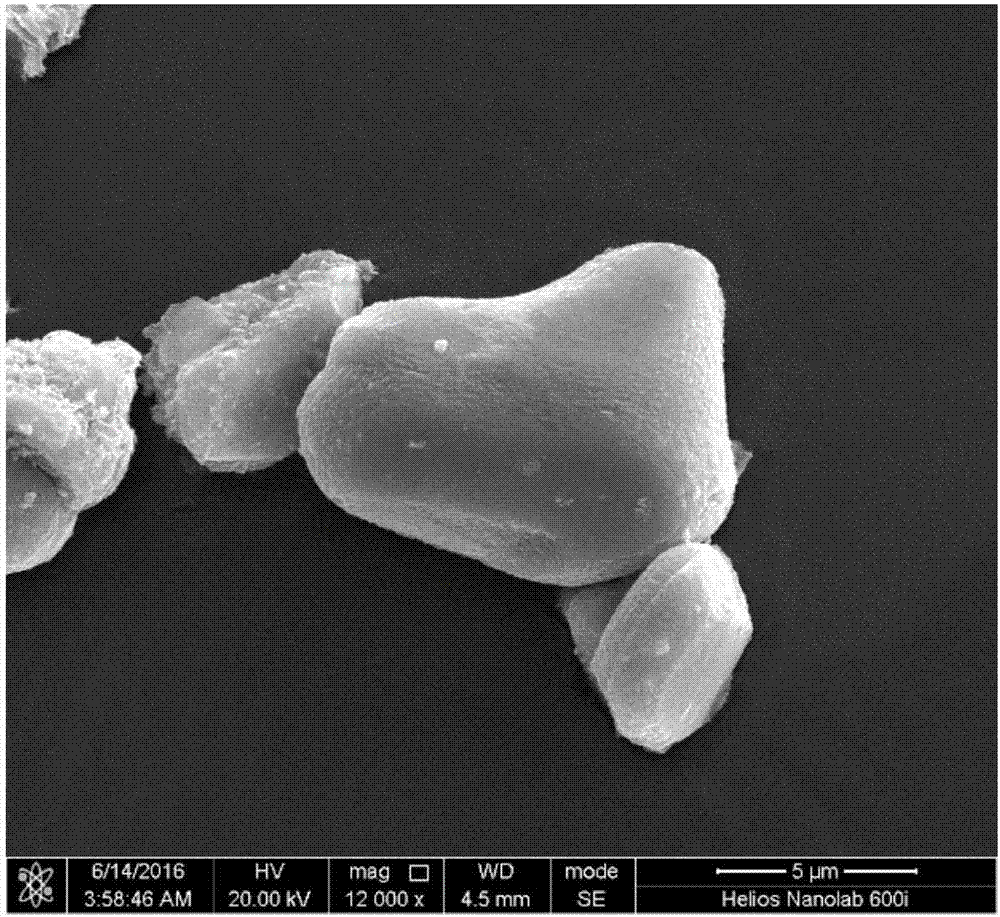

InactiveCN101794878AMixed changeChange the physical and chemical properties of the surfaceCell electrodesDispersityCalcination

The invention discloses a method for preparing a polyanionic lithium ion battery anode material. The anode material is LixMXO4 / C compound, wherein M denotes a transition metal element and X denotes phosphorus, silicon or sulfur. Solid-liquid mixed dispersing agent is added in the material mixing of solid-phase synthesis to change the surface physical and chemical properties of the materials and to enable the dispersity of material particles to be good. The solid-liquid mixed dispersing agent can effectively inhibit the growth of the particles and the conglobation among particles in the process of high-temperature calcinations. The distribution of the grain size of the prepared anode material particles is even, carbon is evenly coated on the surface of the LixMXO4 particles, the electron and ion conductivity is high, the specific capacity is close to the theoretical capacity of the compound and the rate discharge performance is excellent.

Owner:PULEAD TECH IND

Fluorophosphate lithium ion-electron mixed conductor modified lithium cobaltate composite material and preparation method thereof

ActiveCN106920947AAvoid decompositionReduce erosionCell electrodesSecondary cellsPhosphoric acidSlurry

The invention discloses a fluorophosphate lithium ion-electron mixed conductor modified lithium cobaltate composite material and a preparation method thereof, and relates to the fields of lithium ion battery positive electrode materials and preparation methods thereof. The technical problems to be solved in the invention are poor cycle performance, poor rate performance and poor compatibility with an electrolyte of lithium cobaltate positive electrode materials under a high voltage of 4.55V. The composite material is a lithium cobaltate positive electrode material coated with a layer of lithium-containing fluorophosphate, wherein the coated lithium cobaltate positive electrode material is a layered material and has chemical formula is LiCo1-xMxO2, x is not less than 0 and not more than 0.2, the chemical formula of the coating layer material is LiM'PO4-yF1+y, and y is not less than 0 and not more than 1.2. The method comprises the following steps: 1, preparation of a coating layer material solution; 2, preparation of a slurry; 3, drying; and 4, sintering. The preparation method has the advantages of simplicity, low cost, and easiness in industrialization realization. The fluorophosphate lithium ion-electron mixed conductor modified lithium cobaltate composite material is used for making lithium ion secondary batteries.

Owner:HARBIN INST OF TECH

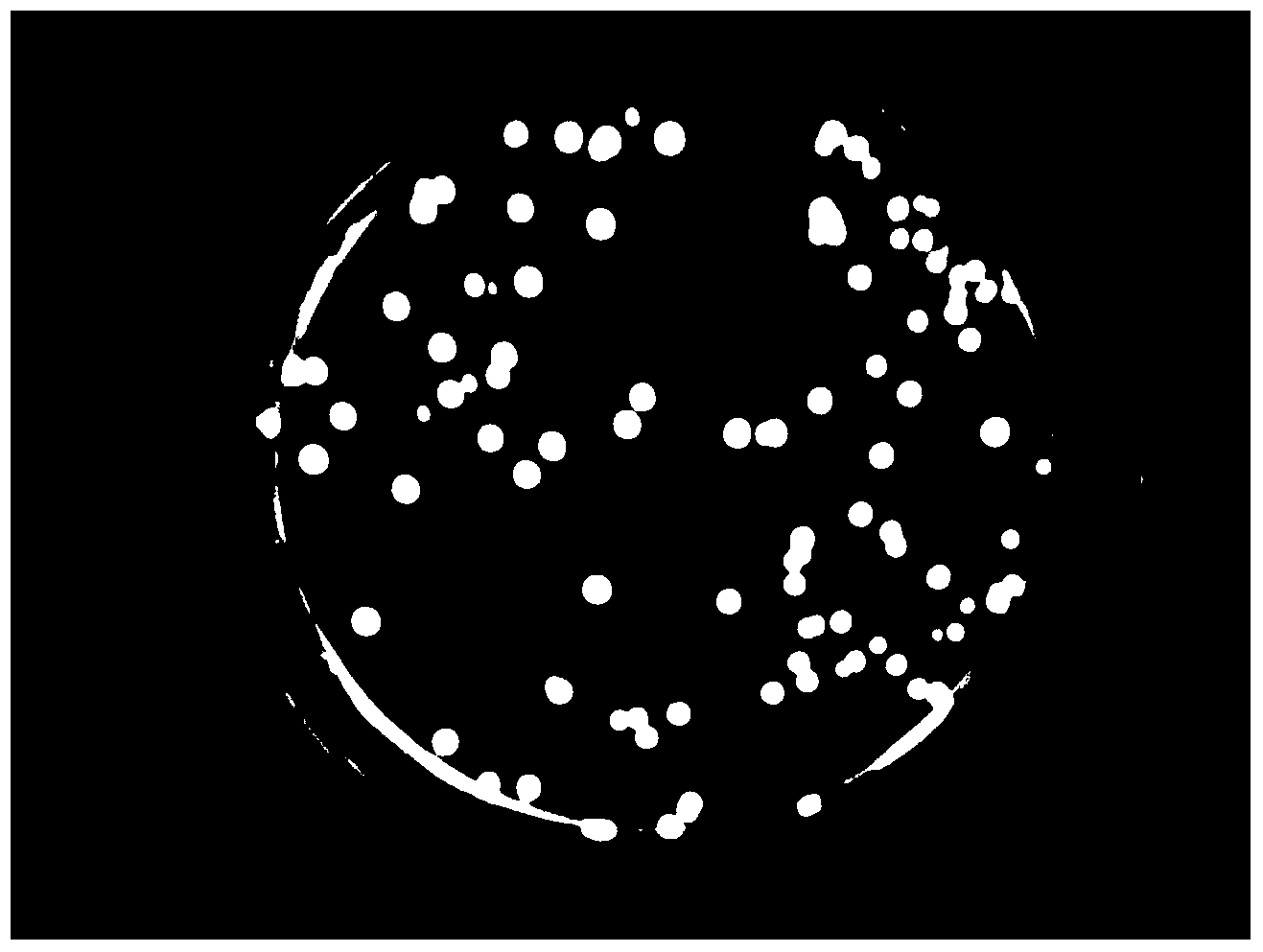

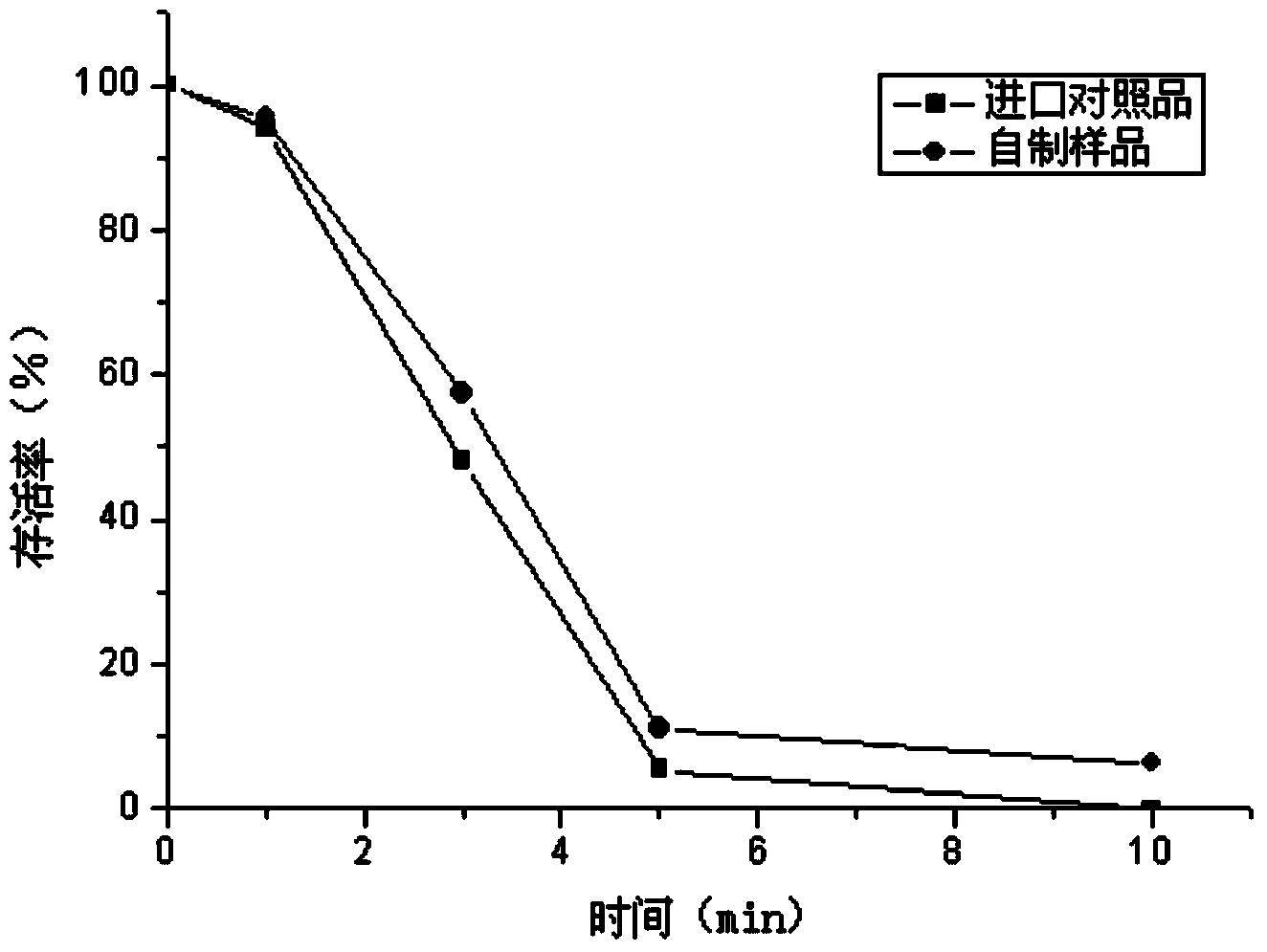

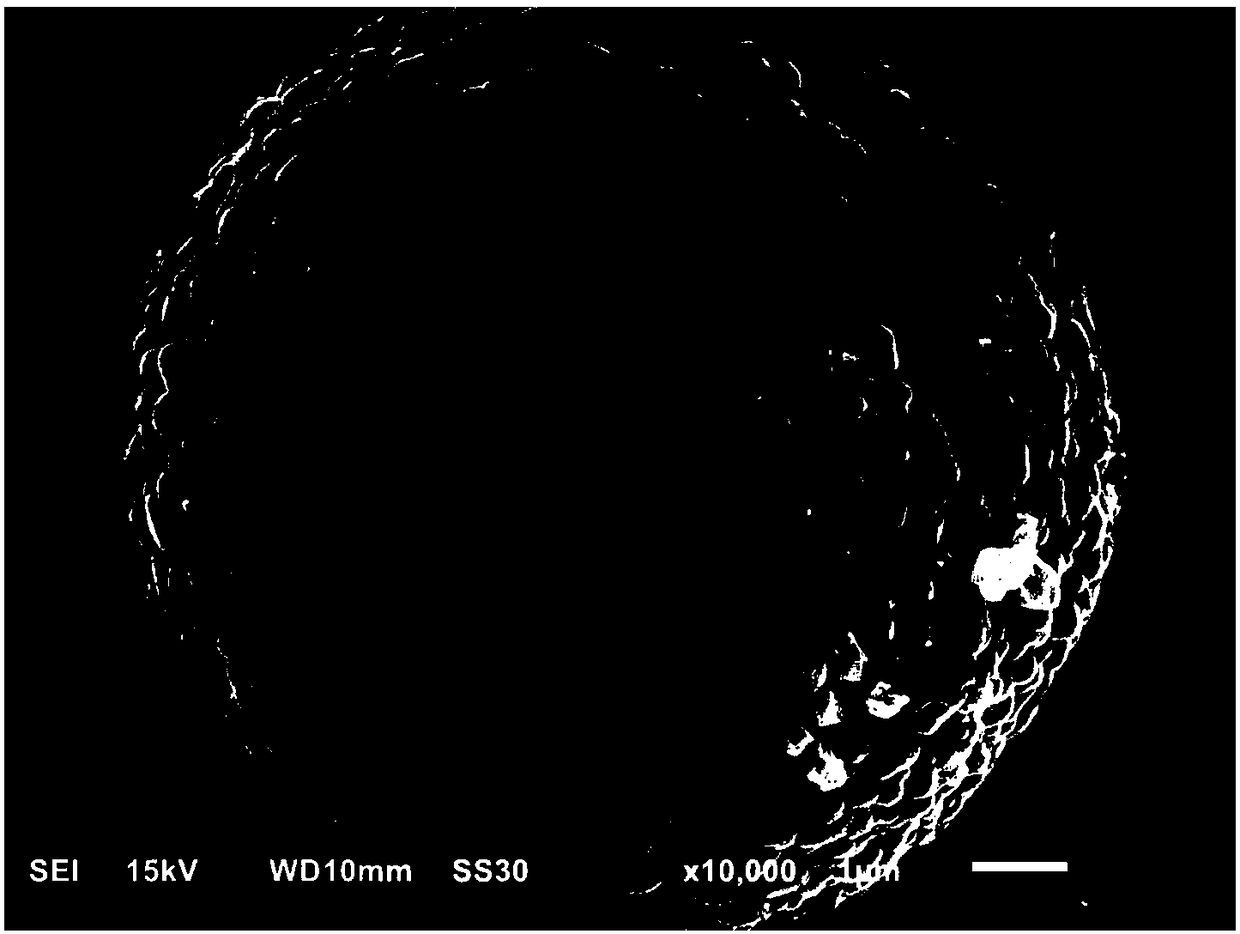

Feeding high temperature-resistant microcapsule yeast probiotics preparation as well as preparation method and application thereof

The invention discloses a feeding high temperature-resistant microcapsule yeast probiotics preparation as well as a preparation method and application thereof, and belongs to the technical field of feed additives. The feeding high temperature-resistant microcapsule yeast probiotics preparation is prepared by the steps such as fermenting, centrifuging, cleaning, carrier and protective agent adding, extruding, rolling and pelletizing, drying and the like. The feeding high temperature-resistant microcapsule yeast probiotics preparation prepared by the method disclosed by the invention is more uniform in particle size and good in storage stability, has better heat resistance, can tolerate processing conditions such as high temperature and high humidity in a feed pelletizing process, has a higher rate of survival. The rate of survival is kept over 90%, and viable count of probiotics is over 5*10<9>cfu / g.

Owner:翁源县新南都饲料科技有限公司

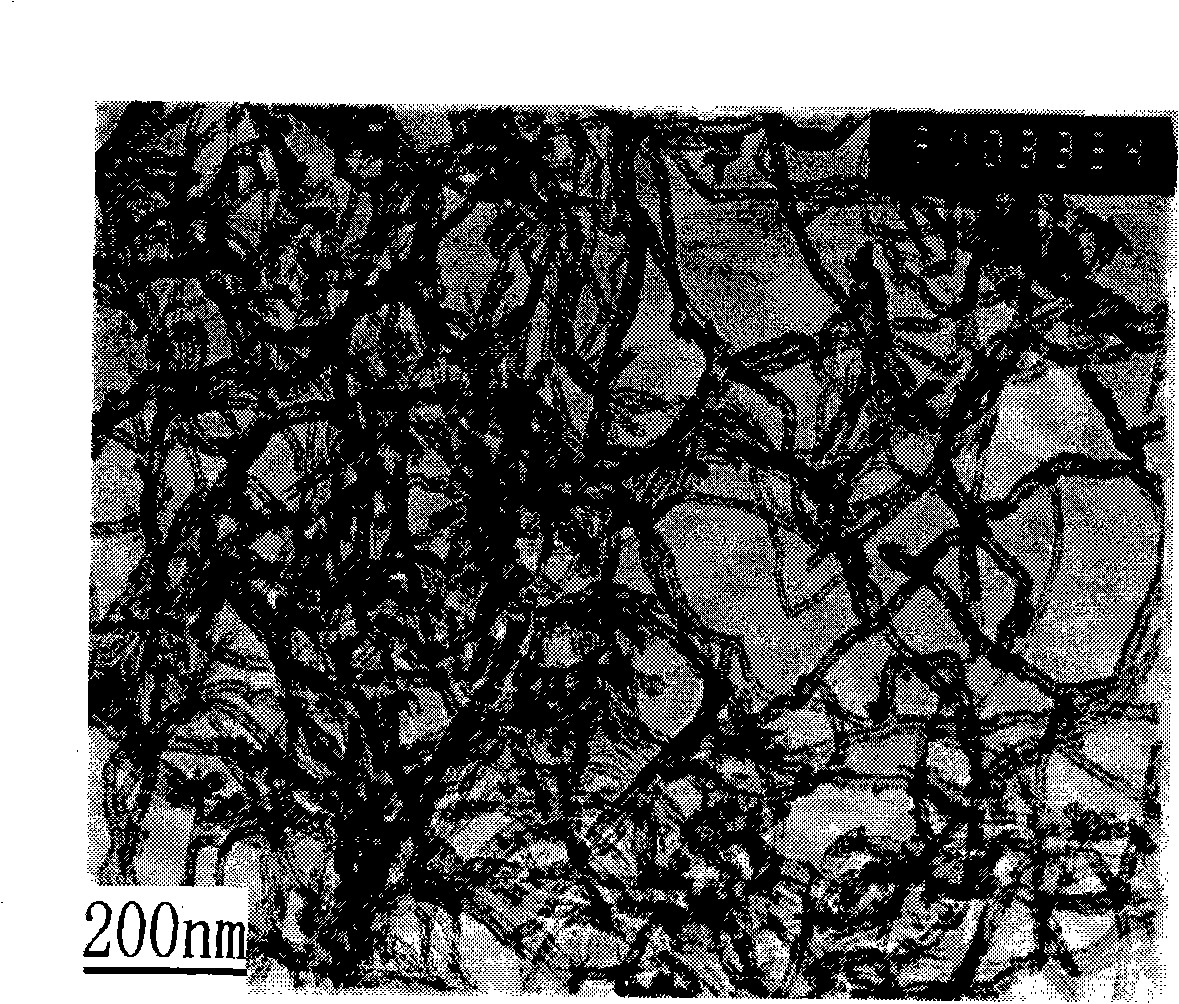

Preparation of carbonaceous inorganic material-polymer composite material

Disclosed is a method for preparing carbon-containing inorganic materials-polymer composite materials, which has the following steps: a. preparation of organic phase, 0.01-100 portions of polymer monomers by weight are added into organic solvent to form the organic solution of polymer monomers; b. preparation of inorganic phase, 1 portion of carbon-containing inorganic material is dispersed or dissolved in water to form aqueous solution, and then the polymerization agent of polymer monomers in step a is added into the aqueous solution to form inorganic solution; the polymerization agent is non-reactive with water and the addition amount of the agent enables full polymerization of the polymer monomers in step a; c. the inorganic solution in step b is slowly added to the organic solution in step a, and the two solutions are fully mixed and reacted to generate complex colloid; the colloid is then filtered, washed and dried so as to get the polymer composite materials. The method is simple to operate and has high yield, which is suitable for large-scale industrial production; the prepared composite materials are of good performance.

Owner:SOUTHWEST JIAOTONG UNIV

Lithium ion-electron mixed conductor modified ternary anode material and preparation method

InactiveCN108091857ALithium ion conductivity is goodImprove electronic conductivityPhosphatesCell electrodesElectrical conductorPhosphate

The invention discloses a lithium ion-electron mixed conductor modified ternary anode material and a preparation method. A layer of lithium-containing phosphate is arranged on the surface of the ternary anode material, a main ingredient magnesium lithium phosphate of the coating layer serves as a lithium ion conductor material and has better lithium ion electric conductive performance, and electronic conductivity of the coating layer can be improved by doping trivalent and tetravalent metal ions or F ions; thus, the coating layer has better lithium ion and electron conduction performance at the same time. The modified ternary anode material can work under higher voltage and remarkably improve battery capacity; furthermore, cycle performance, rate capability, overcharging performance and safety performance of the modified ternary anode material are greatly improved.

Owner:桑顿新能源科技(长沙)有限公司

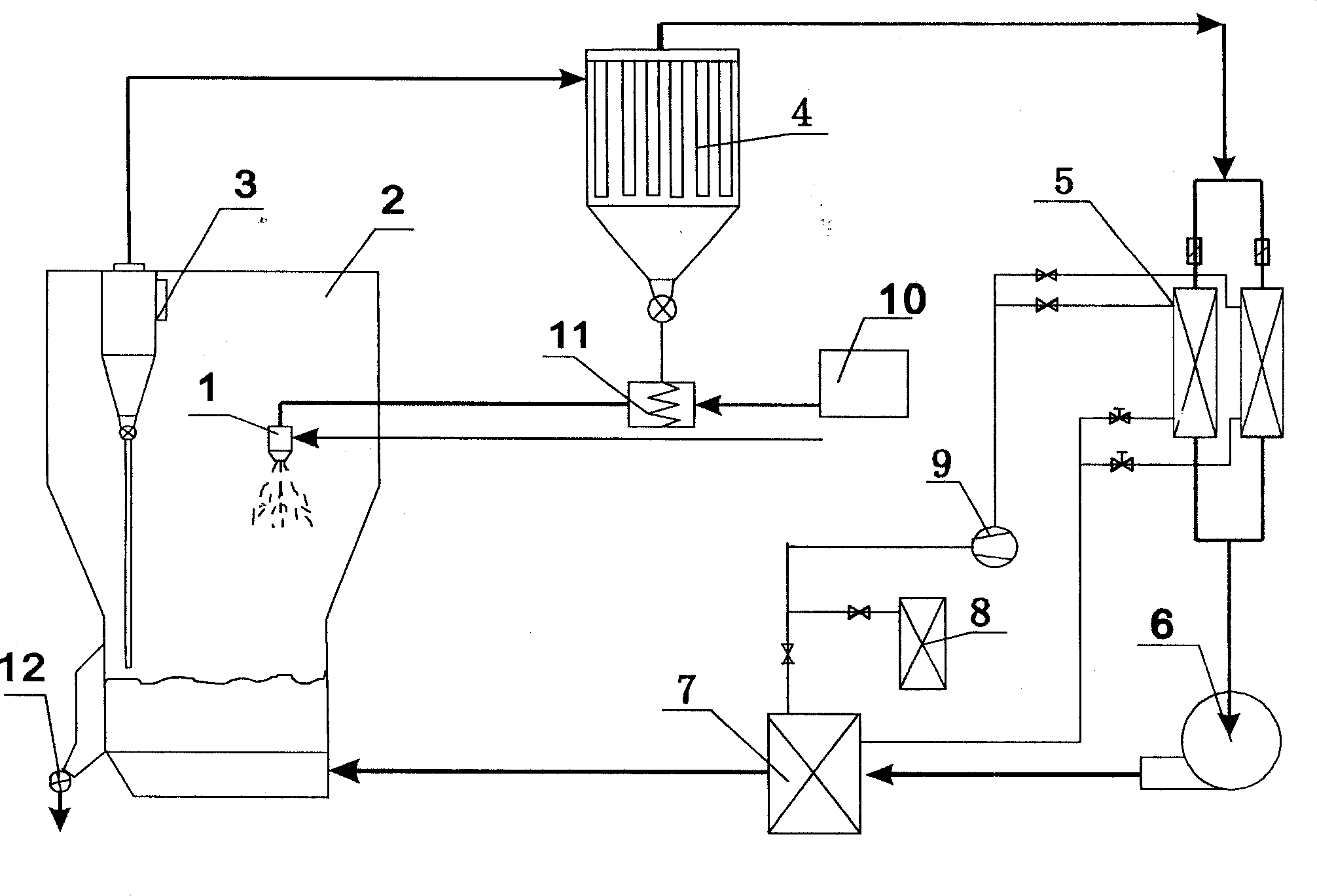

Fluidized-bed normal pressure spray-freezing drying method and device

InactiveCN101191693ANo need to shred againAvoid damageDrying solid materials without heatVoid ratioWater vapor

The present invention relates to a fluidized bed atmospheric spray freeze drying method and a device thereof, and is mainly used for dehydration and preservation of liquid food, medicine, biological products and other products with high added-value; the method is formed by combining a low temperature spray freeze granulating technique and a fluidized bed atmospheric freeze drying technique. Liquid material is atomized and frozen by two liquid atomizers which operate in a low temperature; the fine freezing particles are achieved and collected in the fluidized bed layer of the bottom of the device; then the atmospheric freeze drying medium is used to have partial pressure on the low vapour to satisfy the condition of water sublimation; through the fluidization technology, the freezing particles made by spray freezing are dried in the same device to a high quality qualified powdery product which has high void rate and fluidness and can adjust the granularity distribution; the system is a continuous closed operation; the cost of equipment investment and operation expense is lower than that of vacuum freeze drying; the invention has no pollution on environment.

Owner:李胜

Oil-resistant irradiation-crosslinking low-smoke halogen-free flame-retardant polyolefin material for locomotive wires and cables

ActiveCN105504480AMeet the needs of useMeet the needs of normal useLinear low-density polyethylenePolyolefin

The invention relates to an oil-resistant irradiation-crosslinking low-smoke halogen-free flame-retardant polyolefin material for locomotive wires and cables, belonging to the technical field of high-polymer materials for wires and cables. The oil-resistant irradiation-crosslinking low-smoke halogen-free flame-retardant polyolefin material for locomotive wires and cables is prepared from the following raw materials in parts by weight: 50-80 parts of ethylene-vinyl acetate copolymer, 15-30 parts of high-polymer compatilizer, 5-25 parts of metallocene linear low density polyethylene, 120-150 parts of inorganic flame retardant, no more than 10 parts of flame-retardant synergist, 5-25 parts of electric property modifier, 2-5 parts of crosslinking assistant, 2-3 parts of antioxidant, no more than 1 part of copper inhibitor and 2-3 parts of lubricant. The polyolefin material has the advantages of low smoke, no halogen, environment friendliness, favorable oil corrosion resistance and favorable thermal aging resistance, is beneficial to ensuring excellent mechanical properties, electric properties and light transmittance, is beneficial to embodying ideal extrudability, and can enable the prepared wire and cable to satisfy the single vertical burning test or bunched cable burning test according to the standard requirements.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF

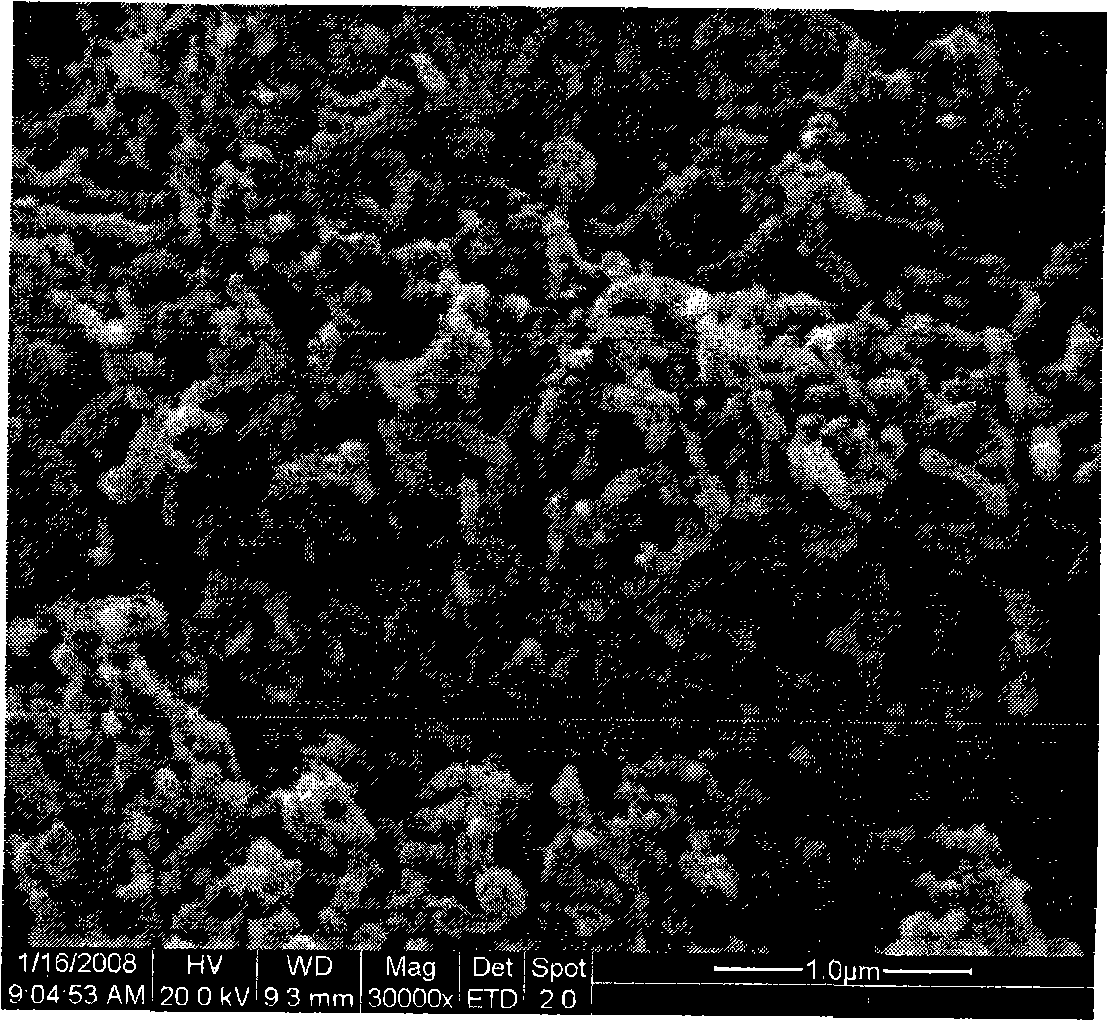

Titanium dioxide binary Na crystal porous membrane and preparation method thereof

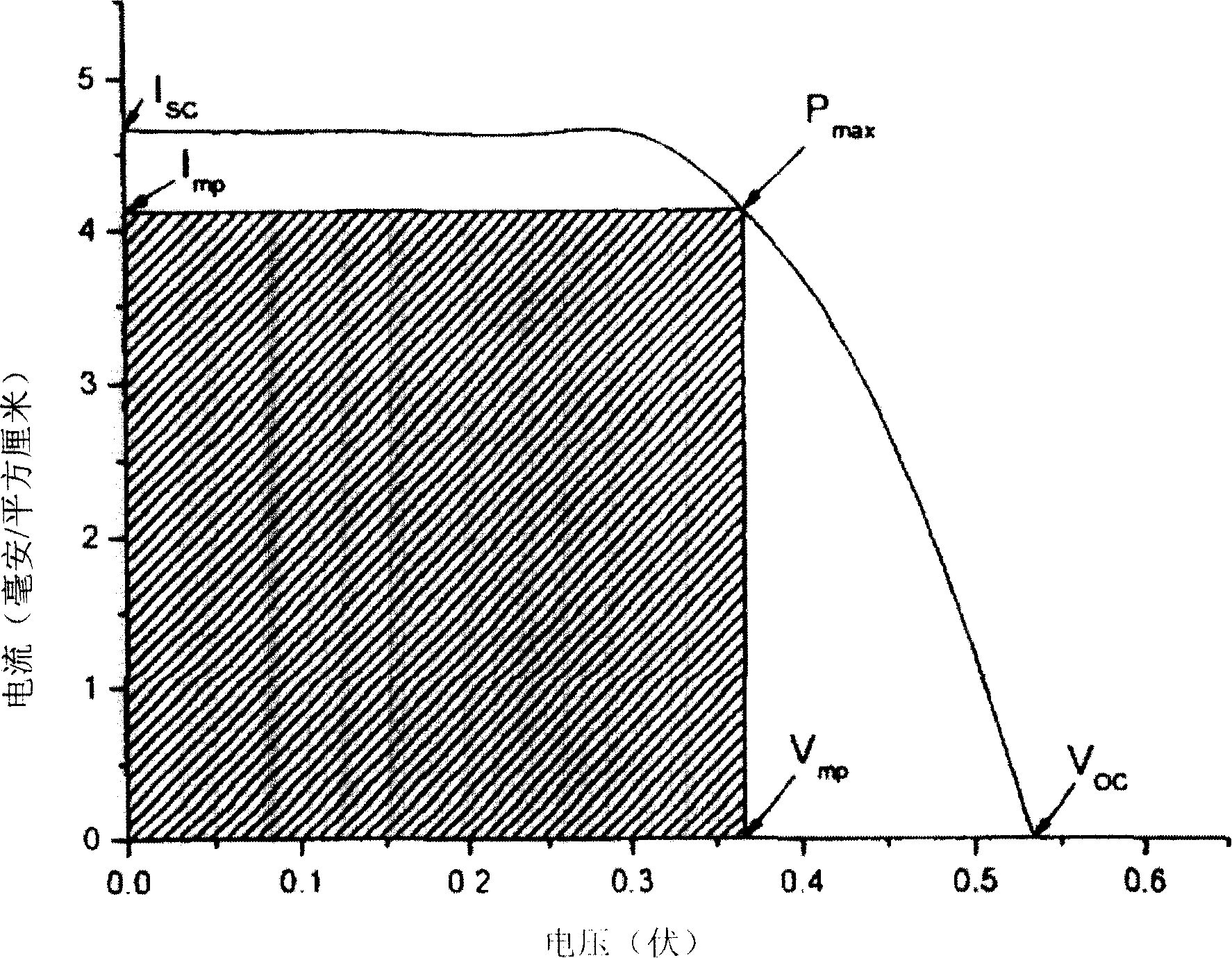

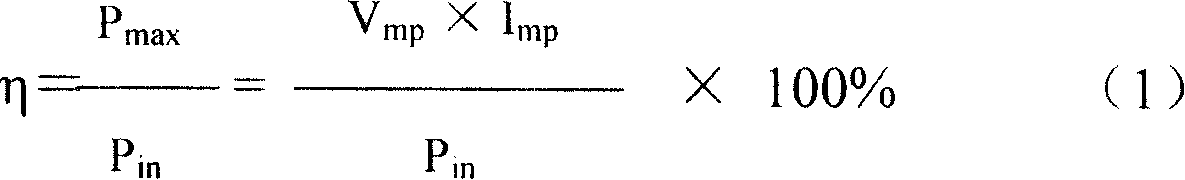

InactiveCN101207159AExtended service lifeGood photoelectric conversion rateFrom gel statePolycrystalline material growthPorous membraneTitanium

The invention relates to a titanium dioxide binary nanocrystalline film, which comprises large particle size titanium dioxide and small particle size titanium dioxide, wherein, the particle diameter of the large particle size titanium dioxide is 60-95 nometer, and the particle diameter of the small particle size titanium dioxide is not more than 40 nanometer. The titanium dioxide binary nanocrystalline film provided bythe invention not only is provided with better photoelectric transformation rate, but also is provided with outstanding binding force with the condustive bottom layer, hence when the titanium dioxide binary nanocrystalline film is used for a dye-sensitized solarcell , the service life of the dye-sensitized solar cell can be prolonged greatly. The preparation method of the titanium dioxide binary nanocrystalline film provided by the invention comprises the following steps; after the titanium dioxides with different particle sizes are manufactured into the collosol and then the collosol is mixed, to cause the mixed titanium dioxide of two different particle sizesto be dispersed more uniformly, thereby to cause the binding force of the obtained binary nanocrystalline film with the conduative bottom layer to be stronger when the obtained binary nanocrystalline film is used for dye-sensitized solar cell , and the service life of the dye-sensitized solar cell can be prolonged greatly.

Owner:BYD CO LTD

Low-smoke fireproofing cable material without halide and its preparation method

InactiveCN1951993AAdd lessHigh flame retardant efficiencyInsulated cablesInsulated conductorsAmmonium polyphosphateSmoke

The invention discloses a low-smoke flame-proof non-halogen cable material and preparing method, which comprises the following steps: blending polyphosphoric ammonia and zinc boride evenly; spraying and cladding the composite material through coupler; adding middle-density polyethylene, copolymer, functional nylon, compatible agent, anti-oxidant and lubricant to stir evenly; transmitting composite material into concurrent twin-screw extruder to fuse; graining after winding to obtain the product.

Owner:YUNNAN CHEM RES INST

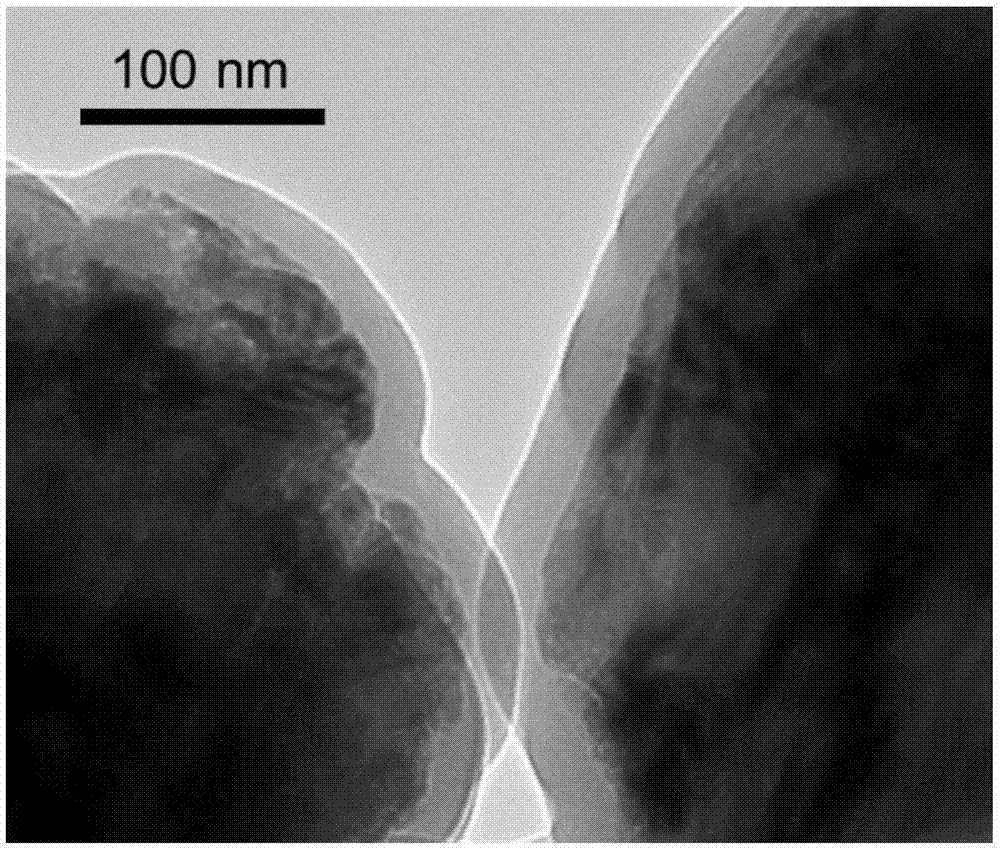

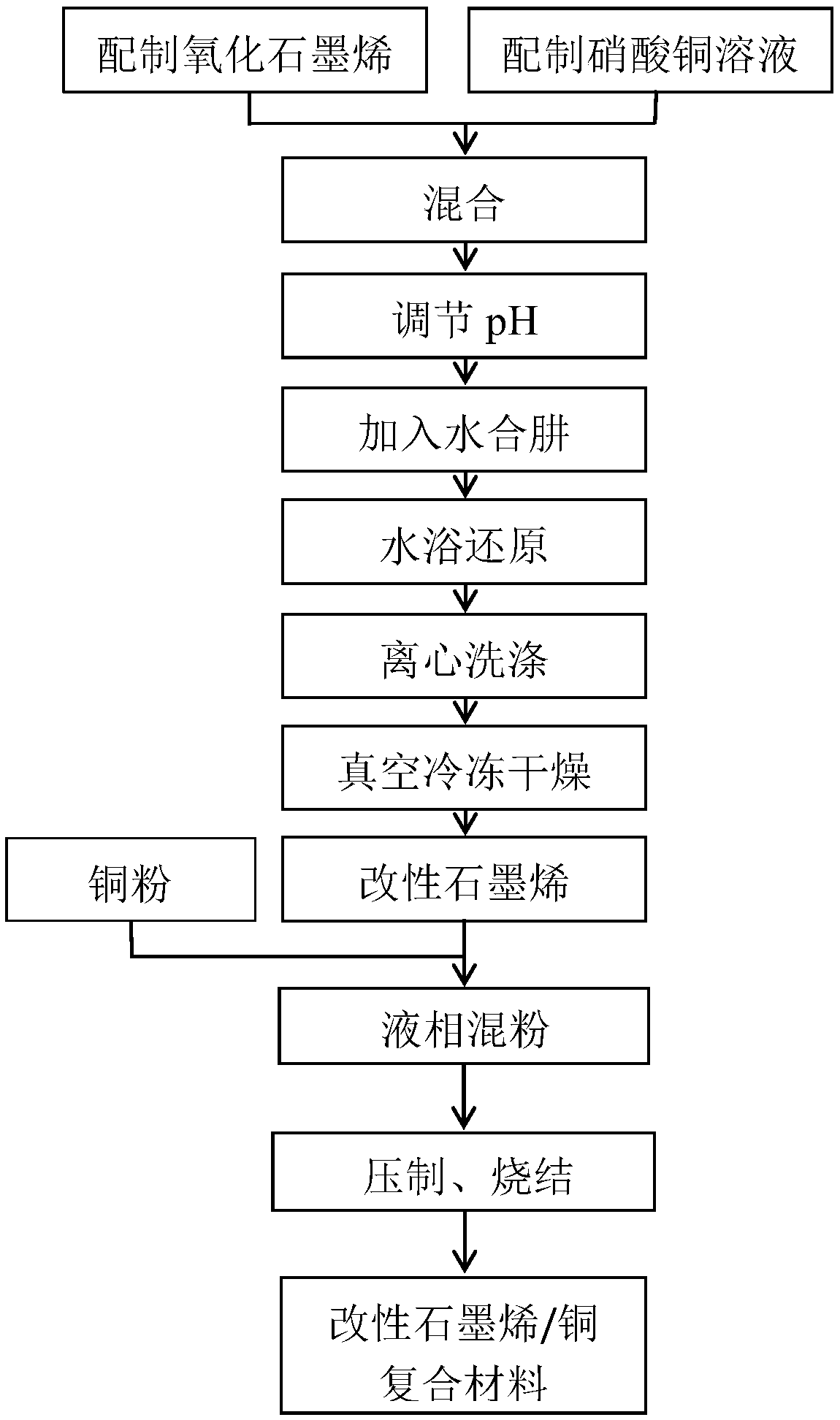

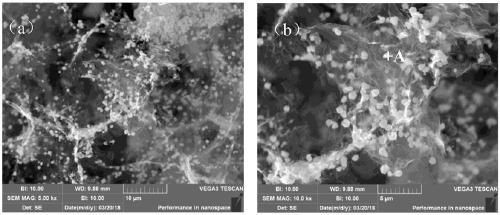

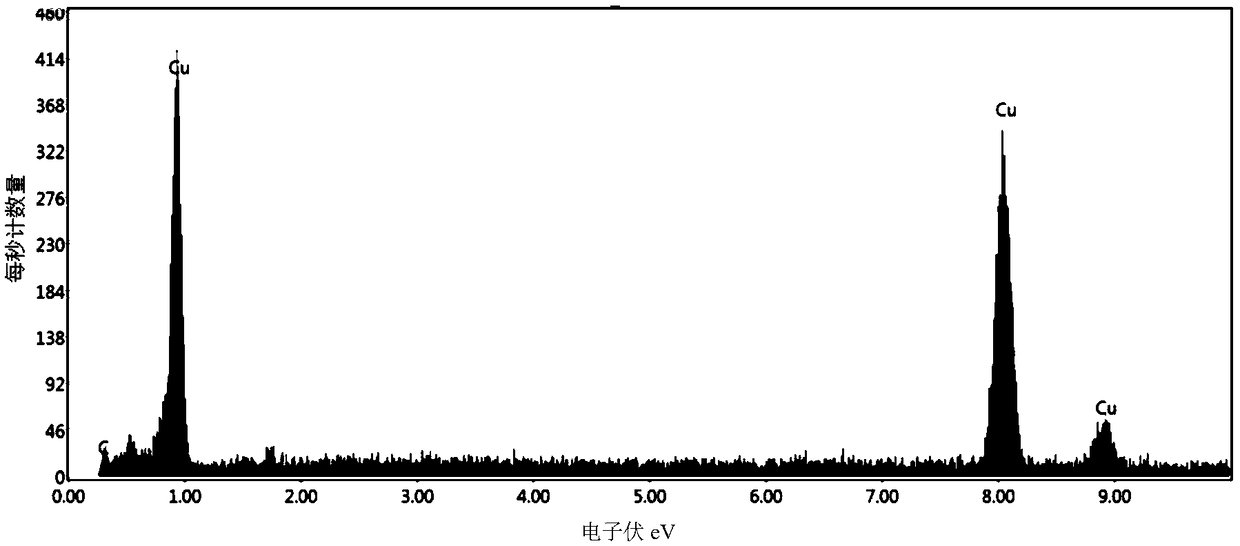

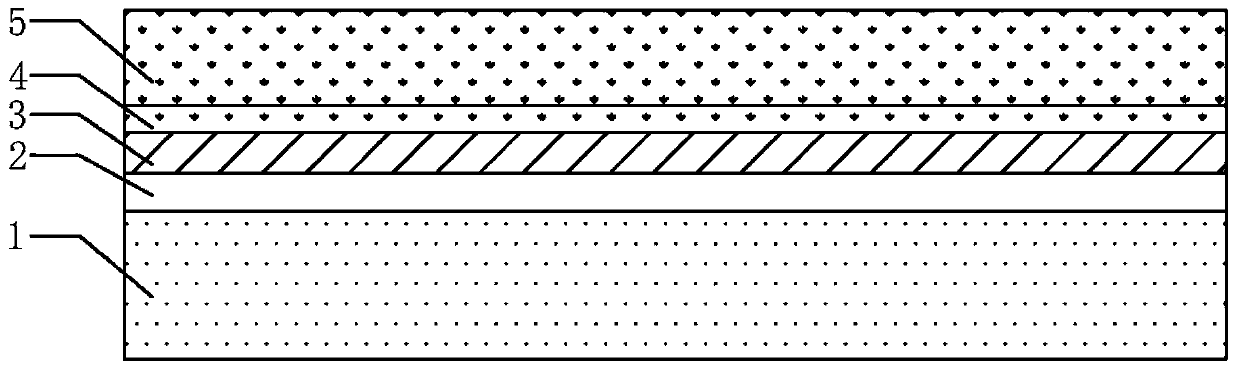

Method for preparing modified graphene reinforced copper-based composite material

The invention discloses a method for preparing modified graphene reinforced copper-based composite material. The method specifically comprises the following steps: uniformly mixing a copper nitrate solution with a graphene oxide solution, and then adding hydrazine hydrate for carrying out reduction reaction; then cleaning a mixed solution after reaction, and drying precipitate, thus obtaining modified graphene composite powder; then carrying out liquid-phase powder mixing on the modified graphene composite powder and copper powder, drying by evaporating, cold-pressing and sintering, thus obtaining the modified graphene reinforced copper-based composite material. According to the method disclosed by the invention, surface modification is carried out on graphene, and copper particles are inserted between graphene sheet layers, so that the graphene is not easy to generate an aggregation phenomenon when the graphene is mixed with matrix copper powder; during a sintering process, a sintering neck can be formed by the copper particles of the graphene sheet layers and matrix copper, so that strong graphene / copper interface bonding strength can be favorably obtained; the modified graphenereinforced copper-based composite material prepared by adopting the method disclosed by the invention is uniform in organization and higher in strength and electrical conductivity.

Owner:XIAN UNIV OF TECH

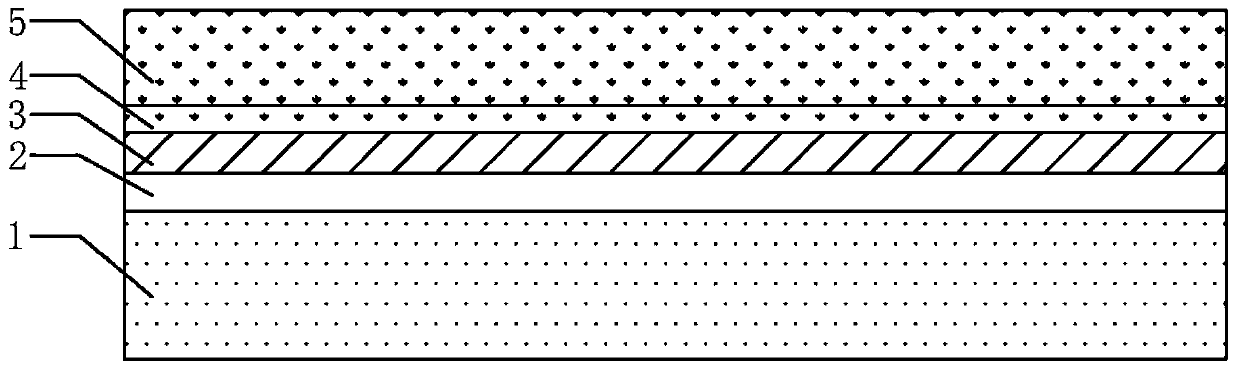

Three-dimensional glazed tile made of scraping waste and manufacturing method thereof

ActiveCN109849163AEasy to operateEasy to controlCovering/liningsCeramic shaping apparatusCeramic glazeScrap

The invention relates to the technical field of ceramic tiles, in particular to a three-dimensional glazed tile made of scraping waste and a manufacturing method thereof. The manufacturing method includes the following steps of A, drying a green body, specifically, the temperature of the green body is raised to 130-160 DEG C for drying; B, applying engobe, specifically, the engobe is performed onthe surface of the dried green body; C, carrying out pattern decoration, specifically, the pattern decoration is carried out on the surface, coated with the engobe, of the green body, and the green body is then dried; D, spraying transparent glaze slip, specifically, the transparent glaze slip is sprayed on the surface of the dried green body; and E, spreading ceramic particles, specifically, theceramic particles are spread on the surface, sprayed with the transparent glaze slip, of the green body, and then, the green body is fired to manufacture the three-dimensional glazed tile, and the rawmaterials for manufacturing the ceramic particles include scraping recovery materials. According to the method, the operation steps are easy to control, the production efficiency is high, the production cost is low, and the energy consumption is saved; the recycling rate of the waste raw materials is increased, no solid waste is generated, and the three-dimensional glazed tile is environmentallyfriendly; and the manufactured three-dimensional glazed tile has distinct layers, obvious dry granular feeling and good three-dimensional effect.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +3

Blended non-woven fabric and preparation technology thereof

InactiveCN105908371ABeneficial elasticityBeneficial water absorptionSolvent-treatmentSucessive textile treatmentsRespiratorVegetable fibers

The invention discloses blended non-woven fabric and a preparation technology thereof. The blended non-woven fabric comprises the preparation raw materials of degummed silk protein fiber and degummed natural vegetable fiber, wherein the mass ratio of the degummed silk protein fiber to the degummed natural vegetable fiber is (20:80) to (80:20). The blended non-woven fabric not only has the advantages of softness, skin protection and skin favorableness of silk, but also has the elasticity and water absorption of fiber. The blended non-woven fabric is simple in preparation technology, and can be widely applied to industrials of facial masks, sanitary towels, sanitary pads, paper diapers, cosmetics, respirators, hygienic products and medical supplies.

Owner:SUZHOU YAZHOU COMMODITY TECH CO LTD

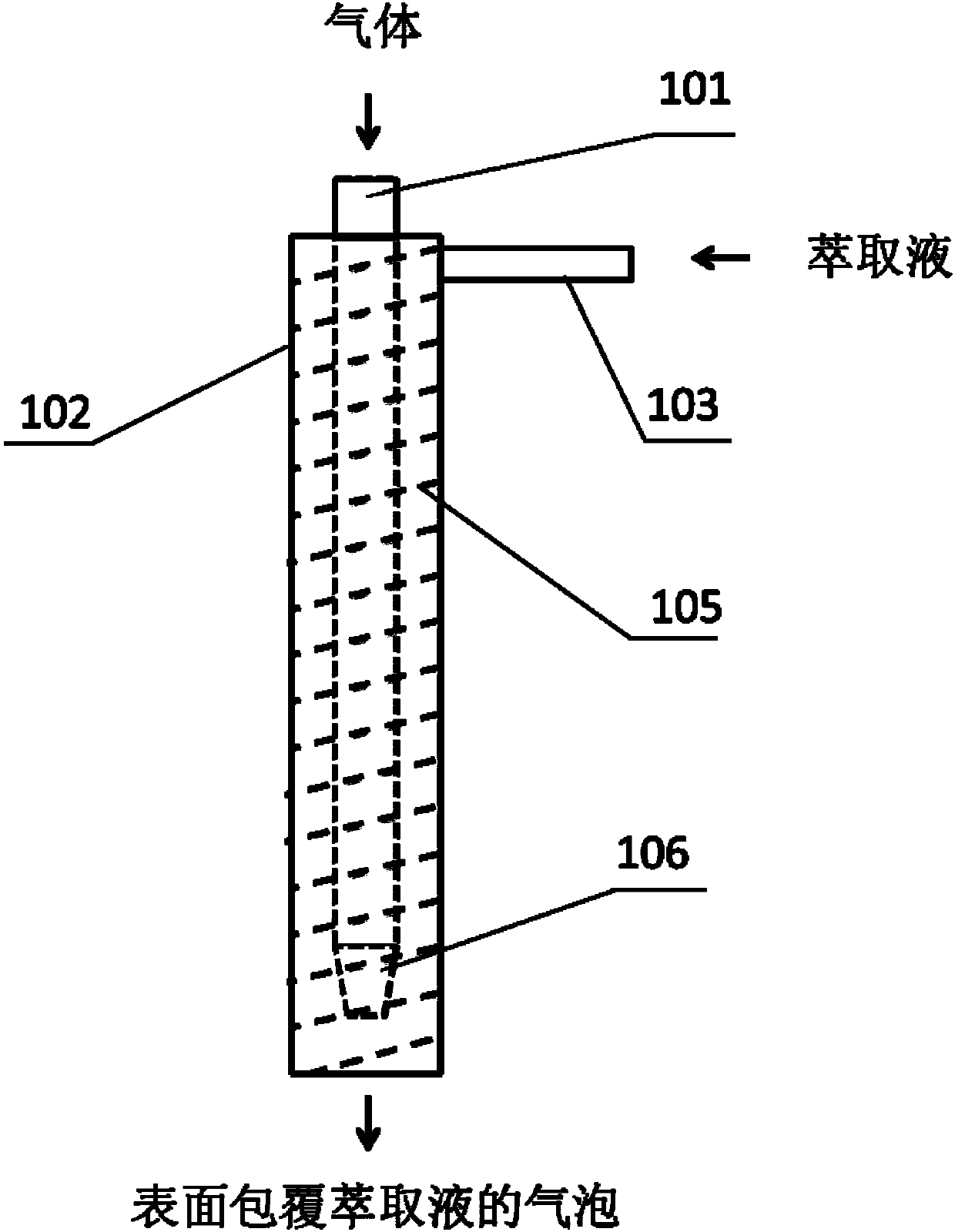

Rare earth element ion extraction method and obtained rare earth enrichment liquid

PendingCN107828961AHigh extraction rateDoes not affect extraction capacityProcess efficiency improvementRare-earth elementRare earth ions

The invention relates to a rare earth element ion extraction method. The rare earth element ion extraction method comprises the following steps that bubbles of which the surfaces are coated with extraction liquid are added into a water solution containing rare earth ions, the bubbles break after floating, and reversed-phase extraction is performed on an organic phase to obtain rare earth enrichment liquid. As the extraction liquid is dispersed on the surfaces of the bubbles with extremely small sizes and led into a rare earth ion solution, the rare earth solution and an organic extracting agent are in two-phase contact under the condition of an extremely large volume ratio, efficient extraction of low-concentration rare earth ions can be realized on the premise of not performing saponification pretreatment on the extraction liquid, and nitrogenous or concentrated salt wastewater cannot be produced; the original extracting agent can be recycled after reversed-phase extraction is performed on the organic phase; and the rare earth element ion extraction method has the advantages of saving energy, protecting the environment and being simple in process and economical in product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Anti-flaming aging-resistant rubber material

The invention discloses an anti-flaming aging-resistant rubber material which comprises the following constituents in parts by weight: 40 parts to 45 parts of butadiene styrene rubber, 30 parts to 36 parts of polyurethane elastomer, 10 parts to 15 parts of chlorinated butyl rubber, 2 parts to 3 parts of vulcanizing agent BPO, 1.2 parts to 1.8 parts of sulphur, 2 parts to 4 parts of divinyl carboxylic acid sodium, 20 parts to 30 parts of calcite powder, 9 parts to 11 parts of kieselguhr, 5 parts to 7 parts of aluminum silicate, 14 parts to 15 parts of carbon black N660, 14 parts to 15 parts of carbon black N330, 10 parts to 12 parts of magnesium hydroxide, 3 parts to 5 parts of quartz powder, 5 parts to 7 parts of zinc oxide, 2 parts to 4 parts of calcium stearate, 5 parts to 8 parts of barium stearate, 5 parts to 7 parts of diphenyl phosphate ester, 2 parts to 4 parts of melamine, and 1.5 parts to 2.5 parts of silane coupling agent KH450. The anti-flaming aging-resistant rubber material has an excellent anti-flaming aging-resistant performance, so that smog is effectively prevented from generating during a combustion process; besides, the ozone resistance and the weather resistance of the anti-flaming aging-resistant rubber material are excellent; moreover, the anti-flaming aging-resistant rubber material further has the advantages of high elasticity, high hardness and high strength.

Owner:南通鹏达体育用品有限公司

Nano-polymer compound modified asphalt and preparation method thereof

InactiveCN104277464AImprove high temperature performanceImprove low temperature performanceBuilding insulationsNano sio2Butadiene-styrene rubber

The invention discloses nano-polymer compound modified asphalt. The nano-polymer compound modified asphalt comprises a nanomaterial, a polymer and matrix asphalt, wherein the nanomaterial is one or two of nano SiO2 particles and bentonite, and the polymer is one or two of styrene-butadiene-styrene block copolymer and butadiene styrene rubber. The invention further discloses a preparation method of the nano-polymer compound modified asphalt. The prepared compound modified asphalt is obviously improved in high-temperature performance and low-temperature performance compared with the matrix asphalt.

Owner:上海频谱顿交通科技有限公司

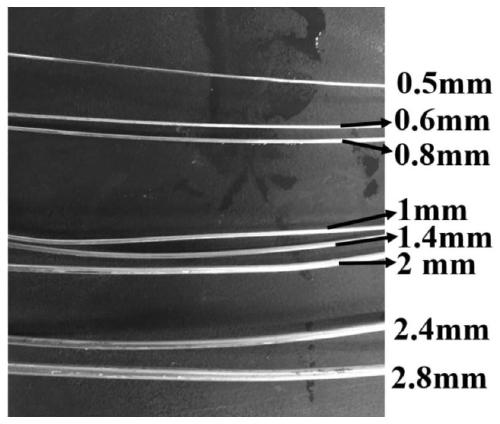

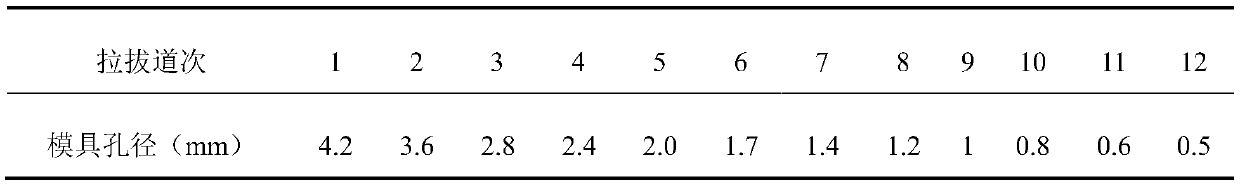

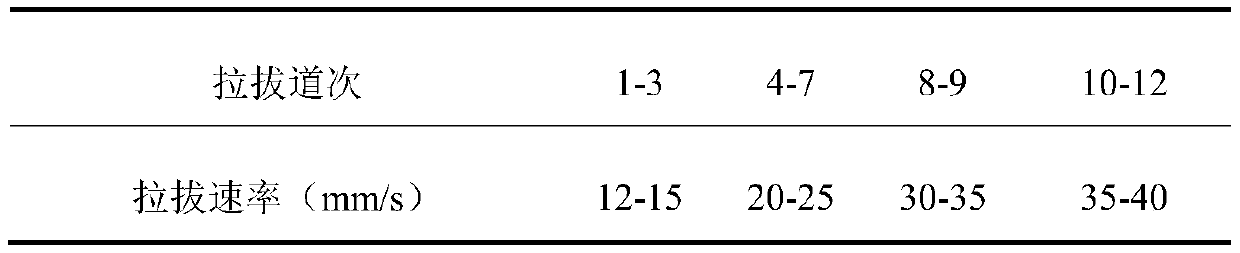

Preparation method of grapheme/aluminum composite material monofilament for cables

The invention discloses the preparation method of grapheme / aluminum composite material monofilament for cables. The preparation method comprises the following steps of preparing a graphene dispersionliquid and a nano aluminum powder dispersion liquid; mixing the nano aluminum powder dispersion liquid and the graphene dispersion liquid, and pressing into a plurality of nano aluminum powder-graphene prefabricated blocks; putting pure aluminum into an induction furnace, pressing the nano aluminum powder-graphene prefabricated blocks into an aluminum melt by using a graphite cover, then cooling the graphene aluminum melt, and pouring the graphene aluminum melt into a metal mold; heating the obtained grapheme / the aluminum composite material ingot, and carrying out extrusion deformation treatment to obtain a grapheme / aluminum composite material rod piece; annealing the grapheme / aluminum composite material rod piece, then carrying out 12 times of room-temperature drawing deformation to obtain the grapheme / aluminum composite material monofilaments, and finally annealing to obtain the grapheme / aluminum composite material monofilaments for the cables. The preparation method solves the problem that the conductivity of the graphene / aluminum composite material is reduced due to graphene agglomeration.

Owner:CHINA UNIV OF MINING & TECH

Super clean odor interior wall latex paint and production method thereof

The invention relates to a super clean odor interior wall latex paint which mainly consists of titanium pigment, superfine coarse whiting, 3131 lotion, Unihub E and the like, and components of dispersing agent, thickening agent, wetting agent, mold preventing agent, flatting agent, antifoaming agent, multifunctional addition agent, and the like are also added. The super clean odor interior wall latex paint adopts materials which accord with latest environmental protection standards and are mixed under strict and sufficient stirring condition to ensure that the elements are scattered and mixedequably, and no odor harmful to health exists, thereby ensuring the safety of use. The invention has the advantages of simple manufacturing technique, less used equipment, low product cost and high quality.

Owner:山西晋明涂料有限公司

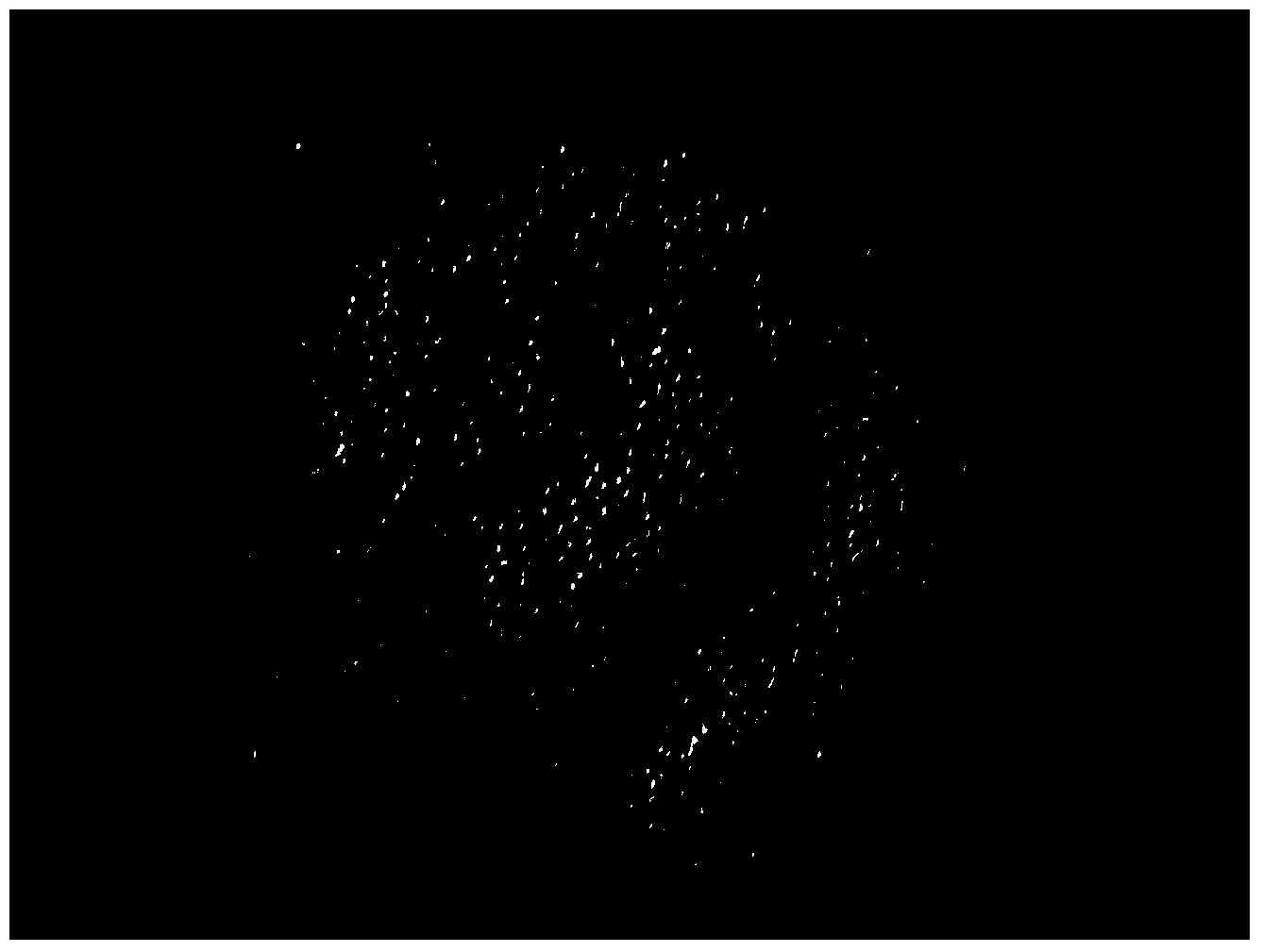

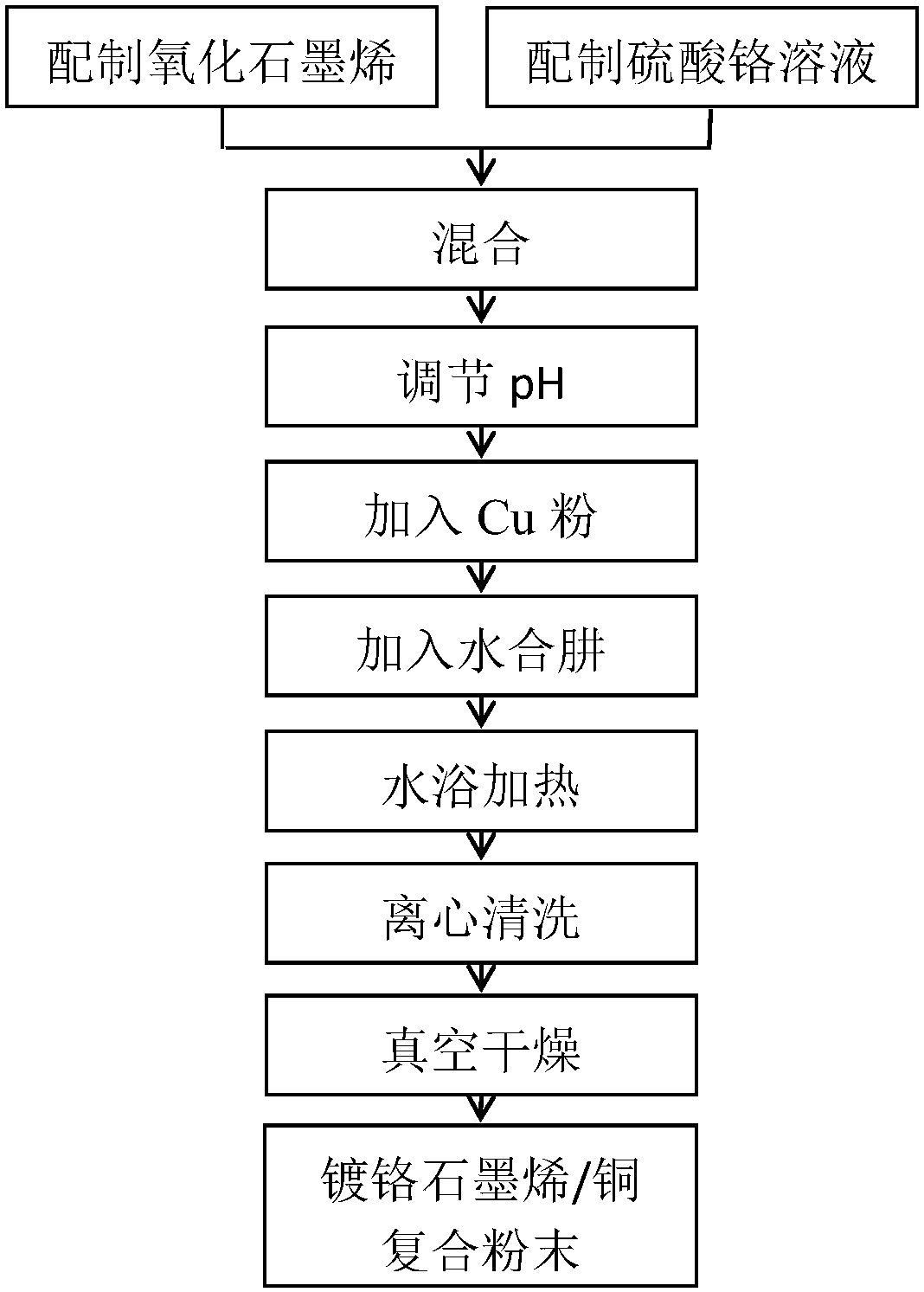

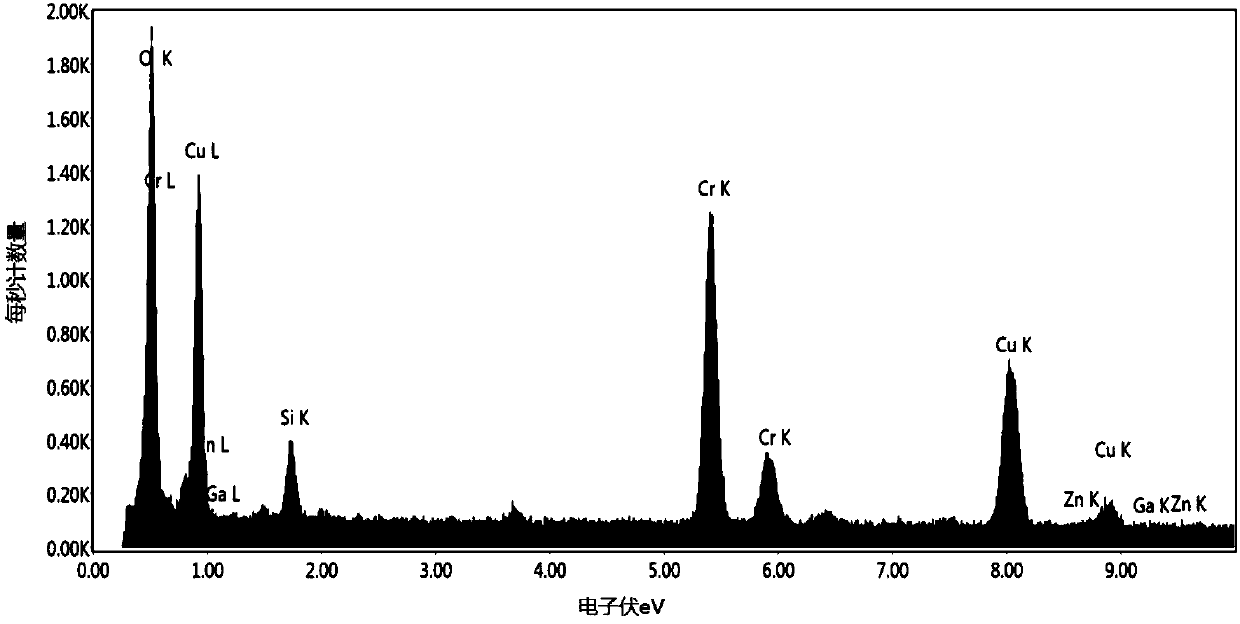

Method for preparing chrome plated graphene/copper composite powder

ActiveCN108031837ANot easy to agglomerateMix and disperse evenlyTransportation and packagingMetal-working apparatusCentrifugationSulfate

The invention discloses a method for preparing chrome plated graphene / copper composite powder. The method particularly includes the steps that a chromium sulfate solution is added into a graphene oxide solution, chemical chrome plating is carried out, and a chrome plated graphene mixed solution is obtained; copper powder is added into the chrome plated graphene mixed solution to be evenly scattered, hydrazine hydrate is added, and a reduction reaction is made; and a mixed solution obtained after reaction is subject to centrifugation and washing, precipitates are dried, and the chrome plated graphene / copper composite powder is obtained. According to the method, surface modification is carried out through chemical chrome plating on graphene, chrome particles are inserted into graphene layers, and therefore the graphene is not prone to agglomeration when the graphene and the copper powder are mixed. The chrome plated graphene / copper composite powder is prepared through the chrome plated graphene, mixing and scattering are more even, and a graphene enhanced copper-based composite material with even texture and higher strength and conductivity is better obtained.

Owner:XIAN UNIV OF TECH

Special emulsion paint for spraying and production method thereof

The invention discloses a special emulsion paint for spraying, comprising the following ingredients in parts by weight: 280-310 parts of water, 5-6 parts of sodium salt dispersing agent, 0.5-1.5 parts of wetting agent, 2.5-4.5 parts of high polymer defoaming agent, 160-190 parts of anatase titanium dioxide, 90-110 parts of calcined kaolin, 70-80 parts of light calcium carbonate, 90-110 parts of heavy calcium carbonate, 45-55 parts of talcum powder, 2.5-3.5 parts of hydroxyethylcellulose, 1.5-2.5 parts of multifunctional additive, 140-160 parts of styrene-acrylic emulsion, 7.5-9.5 parts of film forming additive, 14-16 parts of propylene glycol, 1-2 parts of preservative, 2-4 parts of mildew preventive, 9-11 parts of leveling agent and 2-4 parts of thickener. The special emulsion paint disclosed by the invention has the advantages of low viscosity, strong adhesion, spraying availability, convenience for construction, improved construction efficiency, good leveling property and better using effect.

Owner:杭州法莱利涂料有限公司

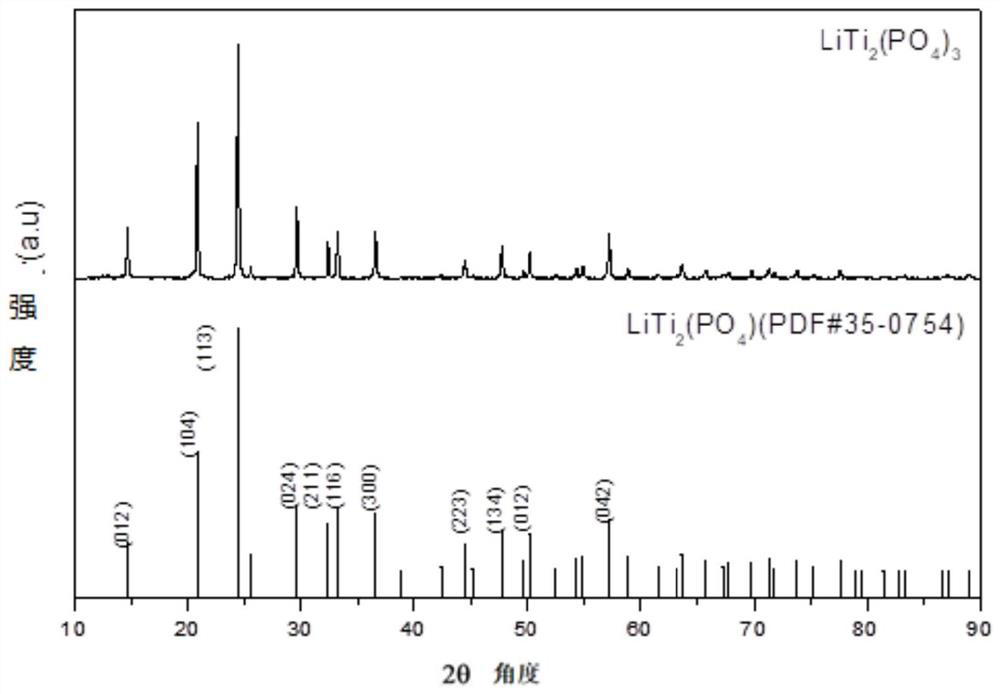

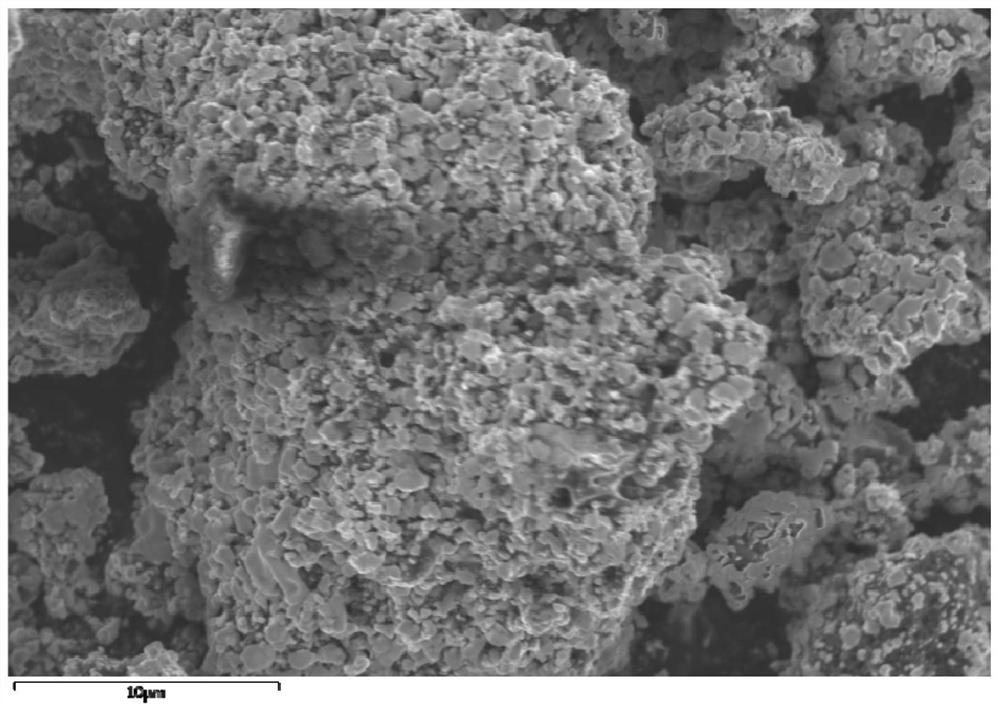

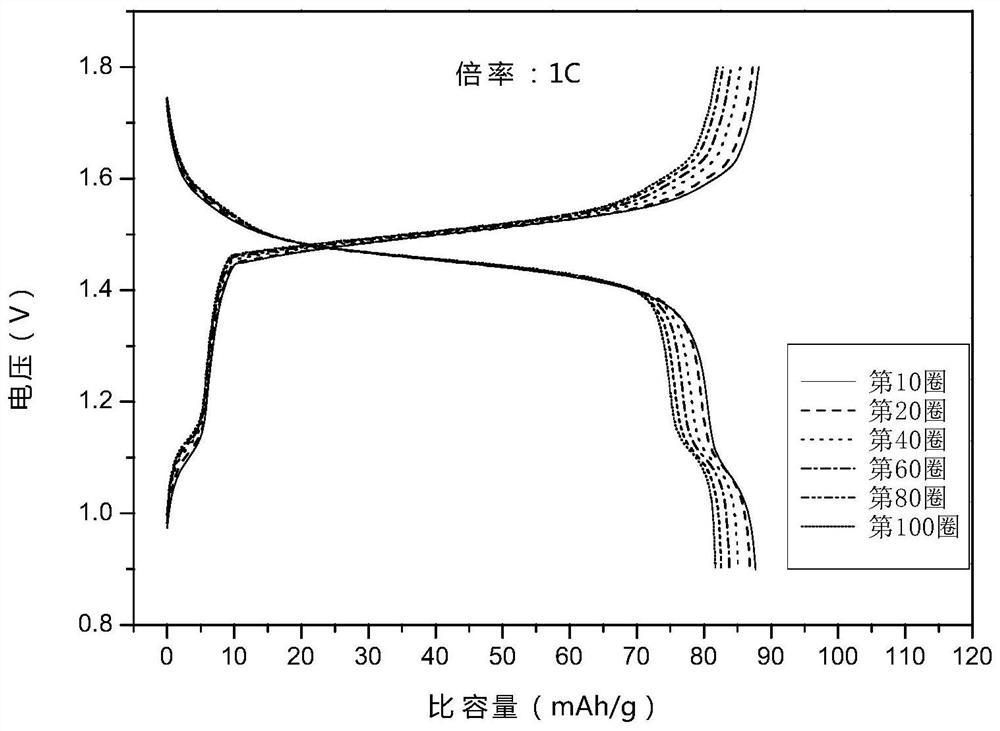

Titanium phosphate composite material and preparation method and application thereof

ActiveCN111755694AEvenly dispersedEasy post-processingNegative electrodesSecondary cellsTitanium phosphateElectrical battery

The invention discloses a titanium phosphate composite material and a preparation method and application thereof. The method comprises the steps of: enabling a lithium source, a titanium source, a phosphorus source and a carbon source to be subjected to dry ball milling I, and obtaining mixed powder I; mixing the mixed powder I with an additive aqueous solution, and drying to obtain a mixed material; carrying out dry ball milling II on the mixed material to obtain mixed powder II; and sintering the mixed powder II to obtain the carbon / titanium phosphate composite material. The method is simplein process and easy to operate, uniform dispersion of the raw materials during mixing can be guaranteed through dispersion of the additive aqueous solution in the method, the hardness of dried material particles can be reduced, and the whole preparation process is green, environmentally friendly and free of pollution; and when the titanium phosphate composite material prepared by adopting the method is used as a negative electrode of an aqueous lithium ion battery, the specific capacity of a half battery is close to 88mAh / g, and obvious attenuation is avoided after 100 cycles.

Owner:NINGBO FENGCHENG ADVANCED ENERGY MATERIALS RES INST

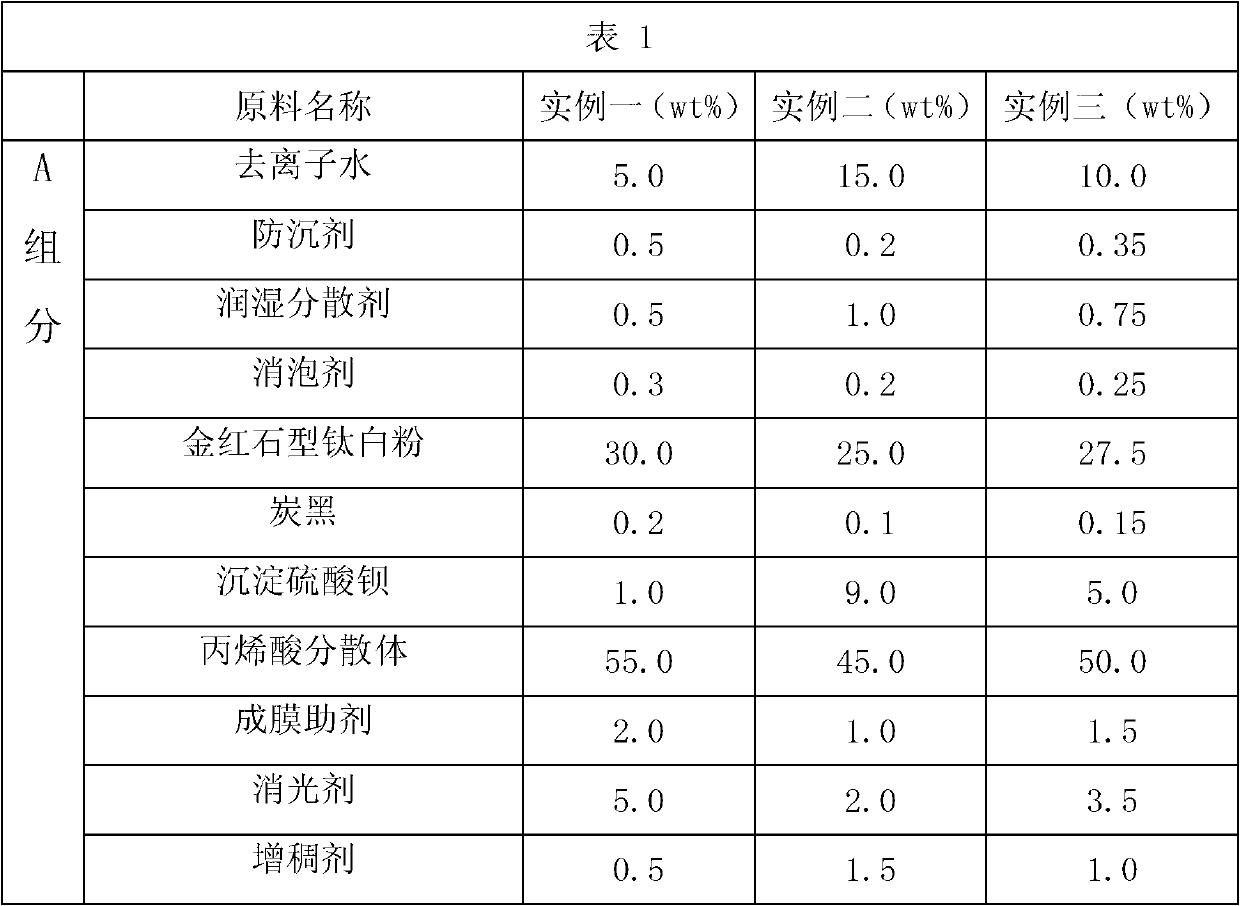

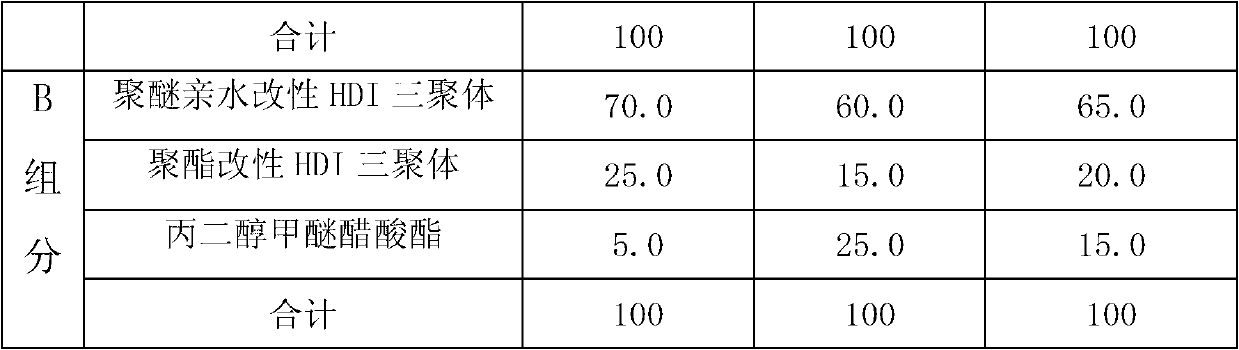

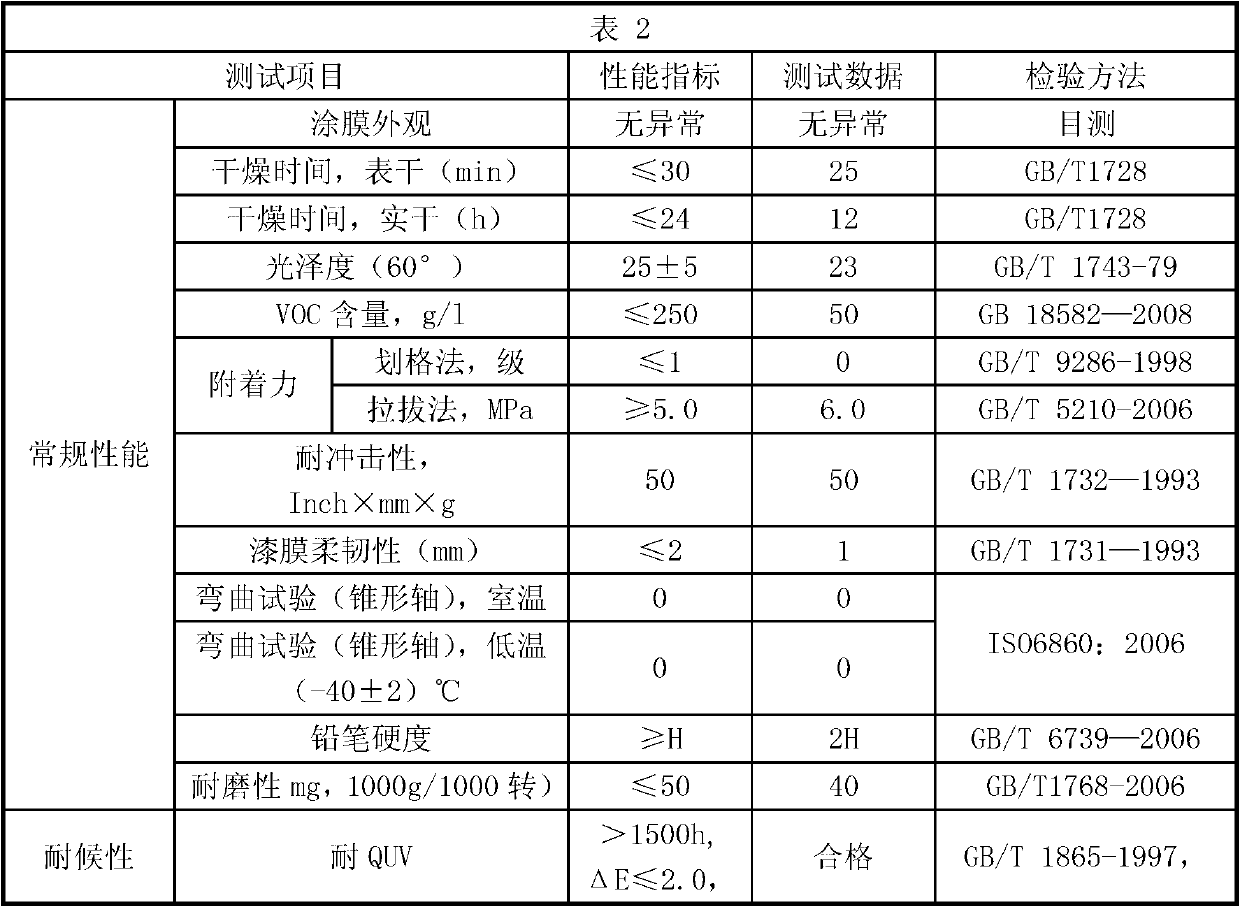

Water-base polyurethane coating for fan blades and preparation method thereof

ActiveCN102863892AGood weather resistanceImprove wear resistancePolyurea/polyurethane coatingsPolyesterWater based

The invention relates to water-base polyurethane coating for fan blades and a preparation method thereof. The water-base polyurethane coating comprises component A and component B by weight proportion of 5:1. The component A comprises deionized water, anti-settling agents, wetting dispersant, defoaming agents, rutile type titanium dioxide powder, carbon black, precipitated barium sulphate, acrylic dispersion, filming auxiliary, flatting agents and thickeners, and the component B comprises hydrophilic modified polyether HDI (hexamethylene diisocyanate) trimer, modified polyester HDI trimer and propylene glycol methyl ether acetate. By taking water as a main dispersion medium, the water-base polyurethane coating for the fan blades has the advantages of low VOC (volatile organic compounds) release, light smell, low harms on human bodies, non-combustible property, unique safety in storage, transport and use, excellent performance and the like, and further, safety potential hazards caused by accumulation of a great quantity of harmful solvents can be eliminated, and physical and psychological health of constructors are benefited greatly.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

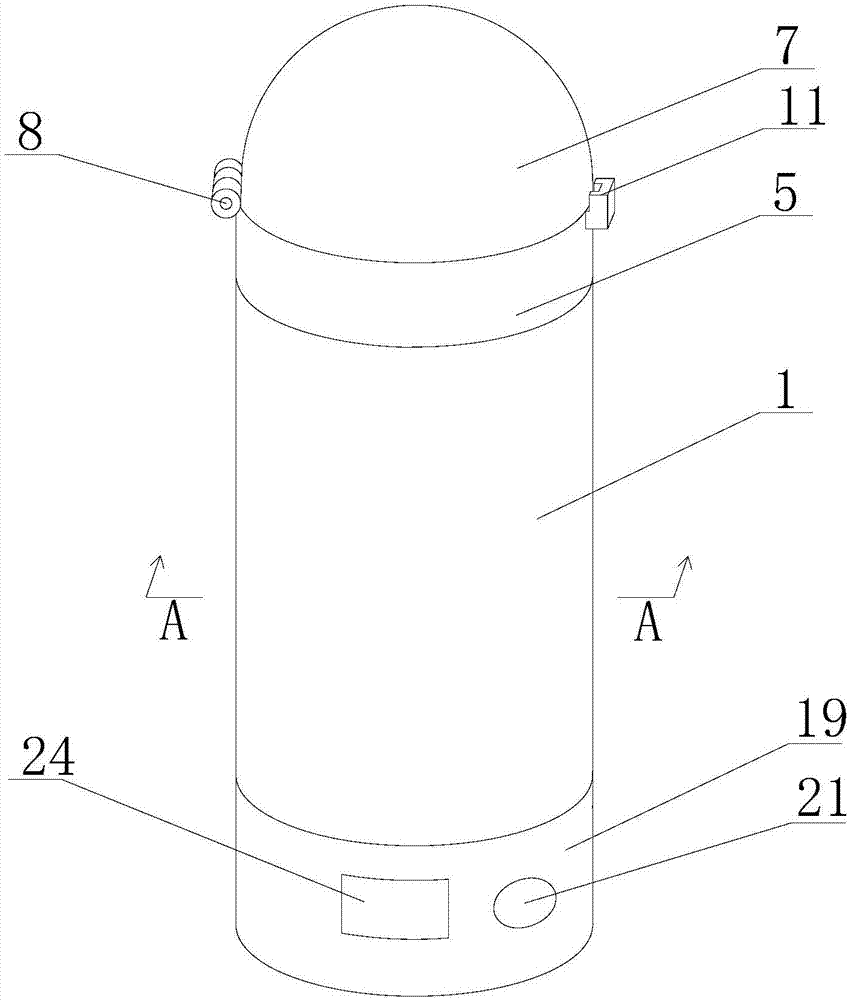

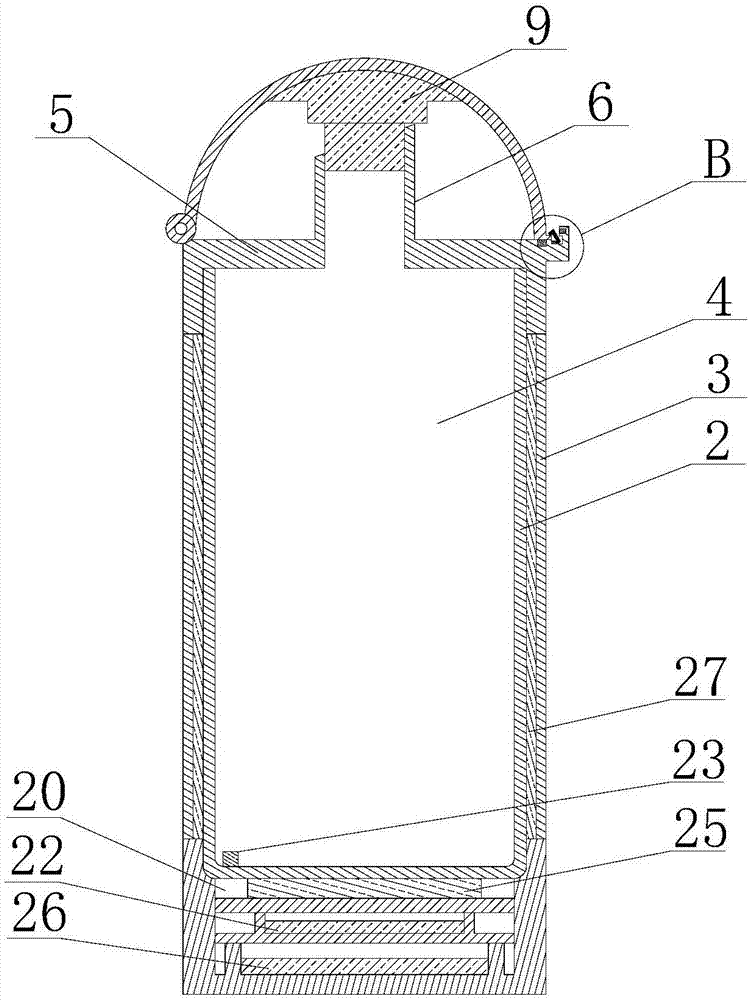

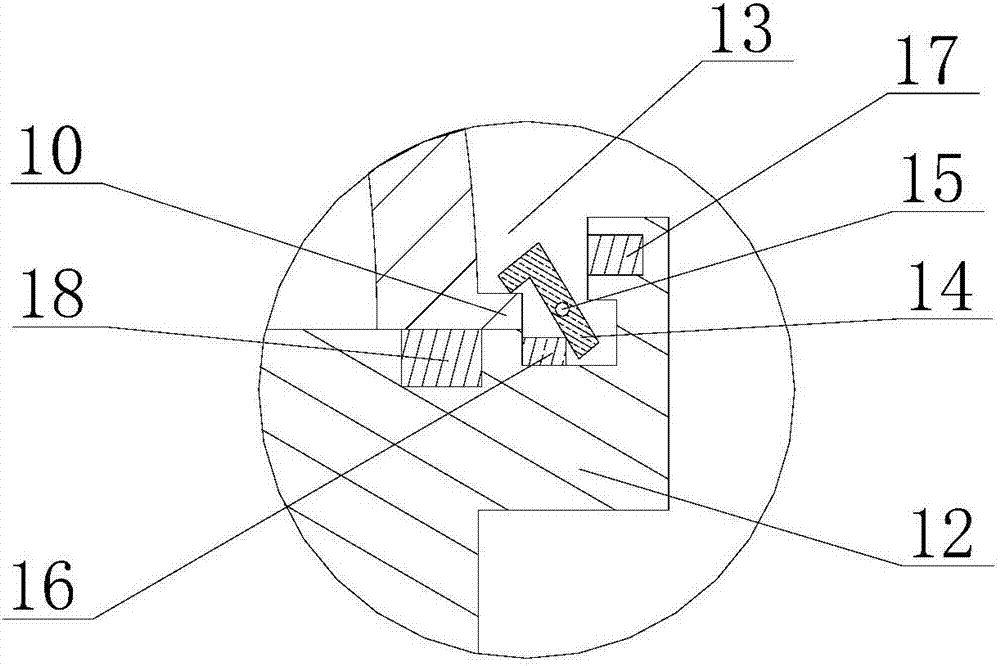

Portable thermal-insulation cup

ActiveCN107468016AAvoid pollutionAvoid automatic openingTravelling sacksDrinking vesselsThermal insulationEngineering

The invention discloses a portable thermal-insulation cup, and belongs to the technical field of articles of daily use. The portable thermal-insulation cup comprises a cup body, an inner cup lid, an outer cup lid, a locking device, a detection device, a base, an infrared sensing switch and a controller; the cup body is internally provided with an inner cavity, the inner cup lid is arranged at the upper portion of the cup body, and the outer cup lid is hinged to the upper portion of the inner cup lid, and is provided with a first lug which is matched with the locking device to lock the outer cup lid; the locking device comprises a second lug, a pressing rod, an electromagnet, an elastic part and a second overturn shaft; the detection device is inset at the upper edge of the inner cup lid; the base is arranged at the bottom of the cup body, and is provided with an electric appliance mounting cavity; the infrared sensing switch is arranged at the outer circumference surface of the base; the controller is arranged in the electric appliance mounting cavity. According to the portable thermal-insulation cup, automatic opening and locking of the outer cup lid are achieved, and the problem that the cup opening is easily contaminated when a lid of a traditional thermal-insulation cup needs to be unscrewed with hands is solved.

Owner:南丹县产品质量检验所

Spherical styrene-butadiene rubber for 3D printing and preparation method thereof

ActiveCN105504174AFulfil requirementsNarrow particle size distributionAdditive manufacturing apparatusRubber materialPolymer science

The invention relates to a spherical styrene-butadiene rubber material for 3D printing. The material is characterized in that a structural core is polystyrene microspheres; the material is prepared from, by weight, 5-20 parts of polystyrene microspheres, 60-80 parts of butadiene monomers, 20-30 parts of styrene monomers, 0.2-1 part of an emulsifying agent, 0.02-0.5 part of an initiator, 0.02-0.1 part of a terminating agent and 80-120 parts of a filling material. Styrene-butadiene rubber latex is prepared through a seeding emulsion polymerization method in which the polystyrene microspheres serve as the core and the polystyrene microspheres, the butadiene monomers and the styrene monomers are grafted and copolymerized, the styrene-butadiene rubber latex and the filling materials are coagulated into powder, the particle size is 10-100 micrometers, particle size distribution is narrow, performance is uniform and stable, and the spherical styrene-butadiene rubber material can be directly applied as a 3D printing material.

Owner:台州科金中高技术转移有限公司

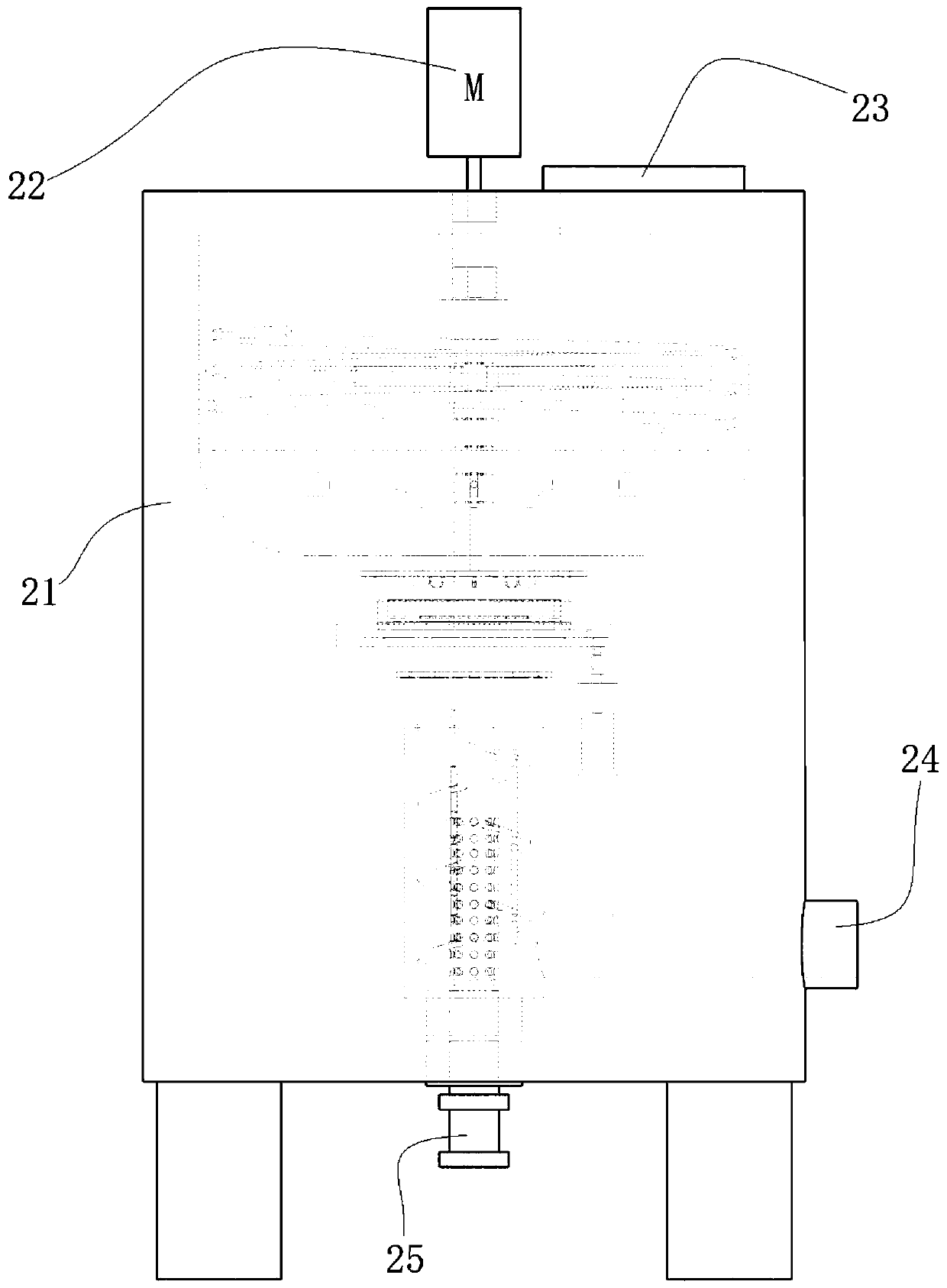

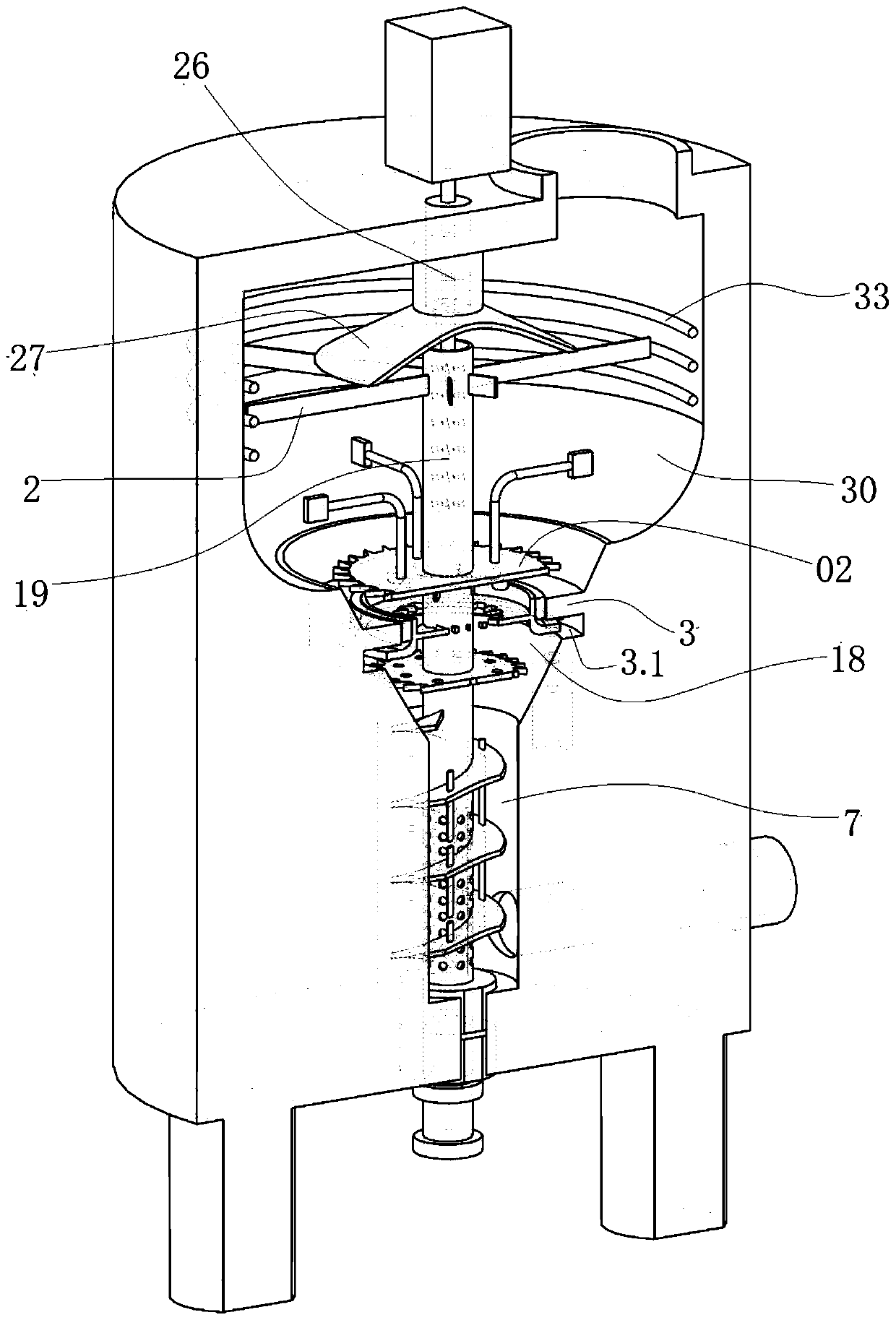

Low-VOC (volatile organic compound) high-strength preservative-containing oil-resistant paint process system, process and formula

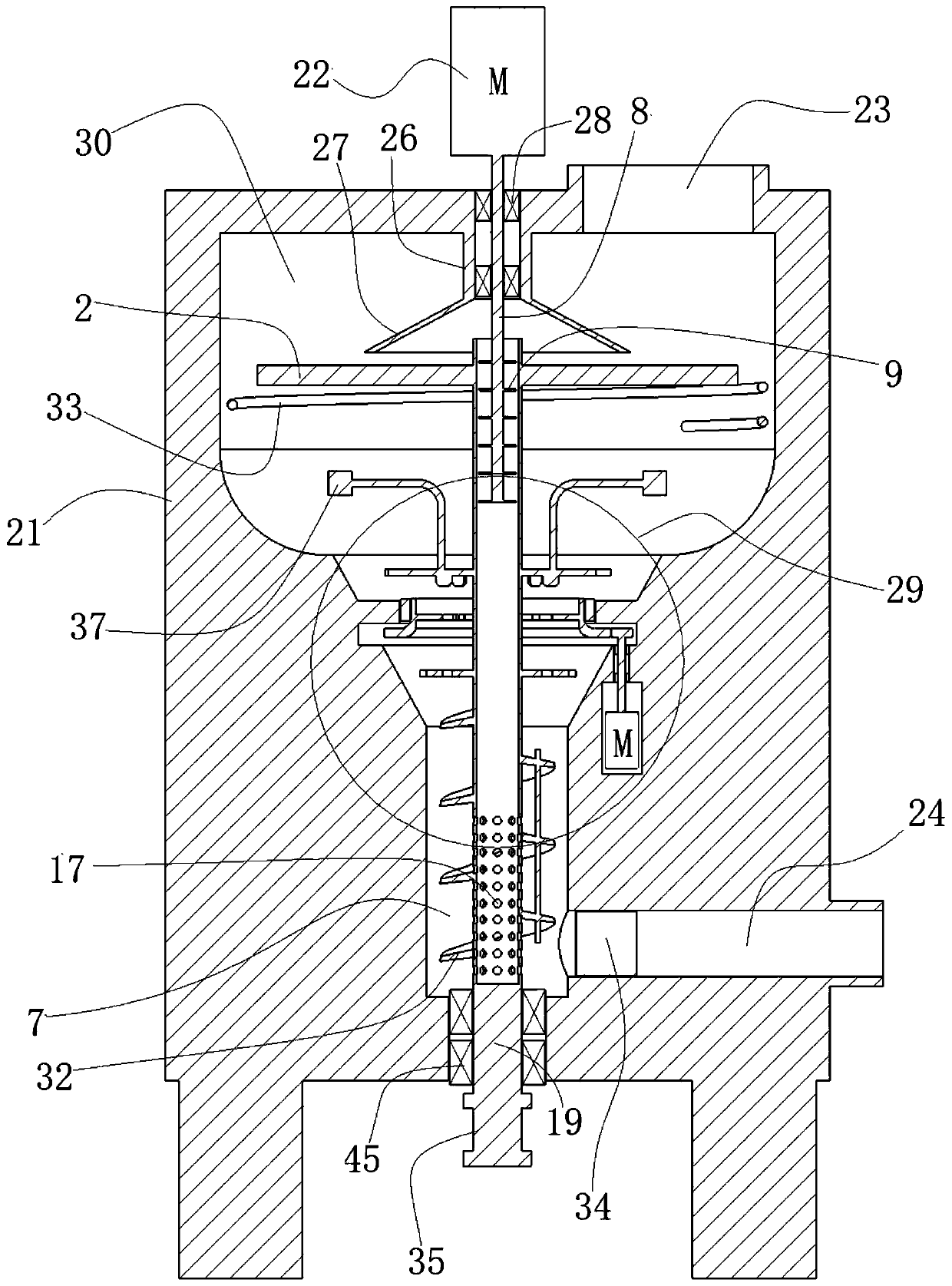

ActiveCN110052191AMix and disperse evenlyFully dispersedFlow mixersRotary stirring mixersVolatile organic compoundProcess systems

The invention discloses a low-VOC (volatile organic compound) high-strength preservative-containing oil-resistant paint process system which comprises a vertical paint dispersion tank. A coarse mixingcavity is concentrically formed in the inner upper portion of the paint dispersion tank, a columnar conveying cavity is concentrically formed in the inner lower portion of the paint dispersion tank,a tapered dispersion conical cavity is concentrically formed in the inner middle of the paint dispersion tank, the coarse mixing cavity is concentrically communicated with the upper end of the dispersion conical cavity, and the lower end of the dispersion conical cavity is concentrically communicated with the upper end of the conveying cavity. The system is simple in structure, and paint in the paint dispersion tank is more uniformly dispersed and mixed by an internal circulation stirring refined system.

Owner:无锡市英波化工有限公司

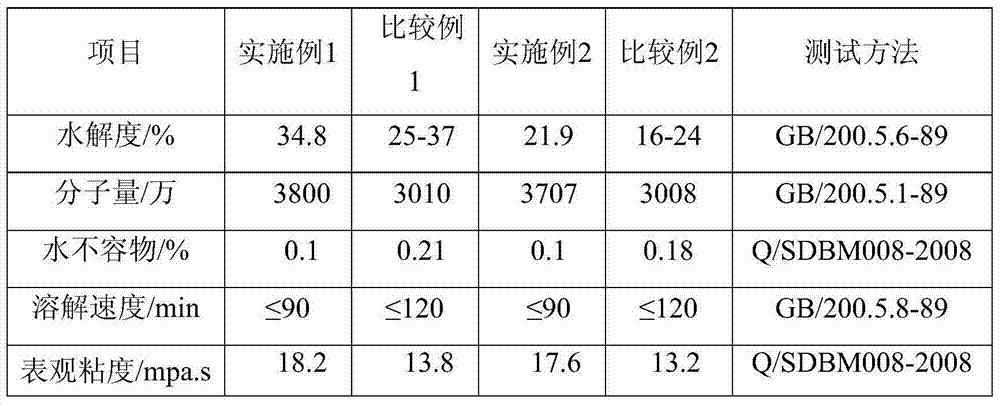

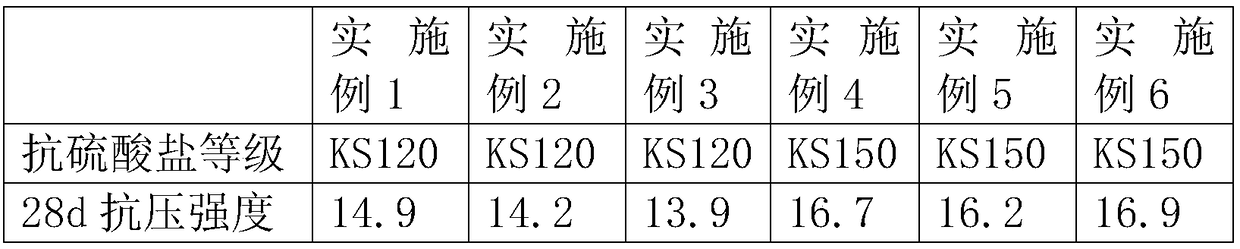

Continuous posthydrolysis method for polyacrylamide

The invention relates to a continuous posthydrolysis method for polyacrylamide. The continuous posthydrolysis method comprises the following steps: homopolymerizing aqueous solution of the acrylamide to obtain high molecular weight polyacrylamide gel blocks; after one-time granulation, adding a dispersing agent I accounting for 1-1.5 percent of the total weight of the gel blocks during passing through a double-ribbon hydrolyzer and uniformly mixing; then adding alkaline as a hydrolytic agent and uniformly mixing the alkaline and colloidal particles; after uniformly mixing, adding a dispersing agent II accounting for 0.8-1.2 percent of the total weight of the gel blocks and uniformly dispersing; finally, enabling the mixture to enter a hydrolysis tank for hydrolysis; besides, keeping the hydrolysis tank at a certain material level for avoiding the influence on continuous operation of the granulation on the next station. With the addition of the dispersing agent I, the colloidal particles are prevented from being easily bonded and aggregated; the dispersion is uniform, so that the resistance for uniform mixing of the colloid and the hydrolytic agent is reduced, and the uniform mixing time of the colloid and the hydrolytic agent is shortened; with the addition of the dispersing agent II, the colloid and the hydrolytic agent can be mixed more sufficiently, and a hydrolysis reaction is realized more thoroughly. The amount of residual monomers and the content of water insoluble matters are effectively reduced, the molecular weight and the solubility of products are improved, and the viscosity of the products is improved.

Owner:DONGYING BAOMO ENVIRONMENT ENG CO LTD

Bare concrete

InactiveCN109503071ASoft on the outside and rigid on the insideImprove corrosion resistanceFiberEmulsion

The invention relates to the field of building materials, aims at solving the problem that bare concrete is prone to be corroded by rainwater and provides bare concrete. The bare concrete is preparedfrom the following ingredients in parts by mass: 7.5 to 10 parts of water, 15 to 20 parts of Portland cement, 45 to 60 parts of sand, 60 to 80 parts of stone, 0.75 to 1 part of a water reducing agent,3 to 4 parts of carbon fiber, 10.5 to 14 parts of rubber emulsion and 3.75 to 5 parts of a silane coupling agent. The carbon fiber is added into the bare concrete; the carbon fiber has the characteristics of soft outside and rigid inside, and the carbon fiber further has outstanding corrosion resistance; thus, corrosion resistance of the bare concrete is improved, and prolongation of service lifeof the bare concrete is facilitated.

Owner:武汉城开新兴建材有限责任公司

Sound-insulation and vibration-absorption damping slurry and production method

The invention discloses sound-insulation and vibration-absorption damping slurry which comprises the following raw materials in parts by weight: 20-30 parts of water, 0.1-0.5 parts of cellulose, 0.1-0.2 parts of AMP-95 (2-amino-2-methyl-1-propanol), 0.5-2 parts of dispersing agent, 0.05-0.2 parts of wetting agent, 0.1-0.5 parts of defoaming agent, 5-10 parts of titanium dioxide, 10-20 parts of calcium carbonate, 10-20 parts of mica powder, 5-10 parts of vermiculite powder, 1-2 parts of film formation aid, 1-2 parts of glycol, 30-40 parts of styrene-acrylic emulsion, 0.05-0.2 parts of preserving agent, and 0.5-1 part of alkali swelling thickener. The sound-insulation and vibration-absorption damping slurry is lower in production cost, better in vibration-reduction effect and better in noise-reduction effect.

Owner:HUZHOU YIHUAN ENVIRONMENTAL PROTECTION

Preparation method of conductive polymer composite material possessing positive temperature coefficient characteristics

InactiveCN1556137AIncreased positive temperature coefficient strengthImprove toughnessEpoxyConductive polymer composite

An electrically conductive high-molecular composition with positive temp coefficient is prepared through treating the surface of carbon black by the epoxy modified aqueous emulsion of polyisoprene rubber, drying, high-temp plasticizing of polyethene, high-temp pugging of said carbon black and polyethene, and granulating. It has the improved electric property and toughness.

Owner:SICHUAN UNIV

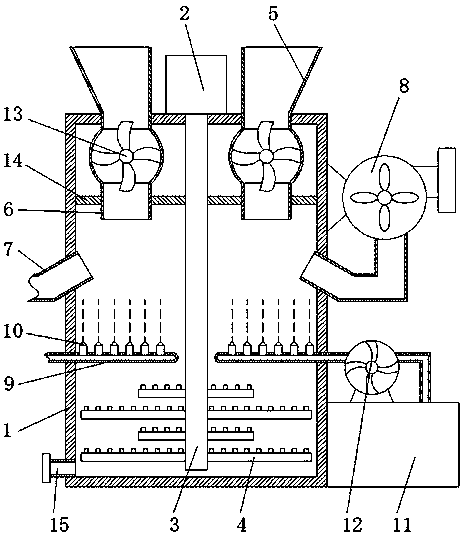

Stirring device for buildings and working method thereof

PendingCN110450281APrecise control of weight ratioMix and disperse evenlyMixing operation control apparatusIngredients proportioning apparatusPulp and paper industryAir blower

The invention discloses a stirring device for buildings and a working method thereof. The stirring device comprises a stirring barrel, wherein a stirring motor is arranged at the center of the top surface of the stirring barrel; an output end of the stirring motor is connected with a stirring shaft; the bottom end of the stirring shaft penetrates to the position above the bottom surface in the stirring barrel; stirring blades are arranged at the bottom section of the stirring shaft; a plurality of feeding hoppers distributed in an array are embedded in the top surface of the stirring barrel; the bottom ends of the feeding hoppers are connected with a feeding device positioned in the stirring barrel; an output end of the bottom of the feeding device is connected with a discharging pipe; a plurality of air inlet pipes distributed in an array are connected to the side wall of the stirring barrel in a penetrating mode; one ends, in the stirring barrel, of the air inlet pipes are positionedbelow the discharging pipe; and an air blower is arranged on the outer side wall of the stirring barrel. According to the stirring device and the working method, continuous feeding, blowing, water replenishing and stirring of concrete ingredients can be achieved, and the stirring device is simple to use, high in working efficiency and better in stirring quality.

Owner:陕西闹闹馨馨知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com