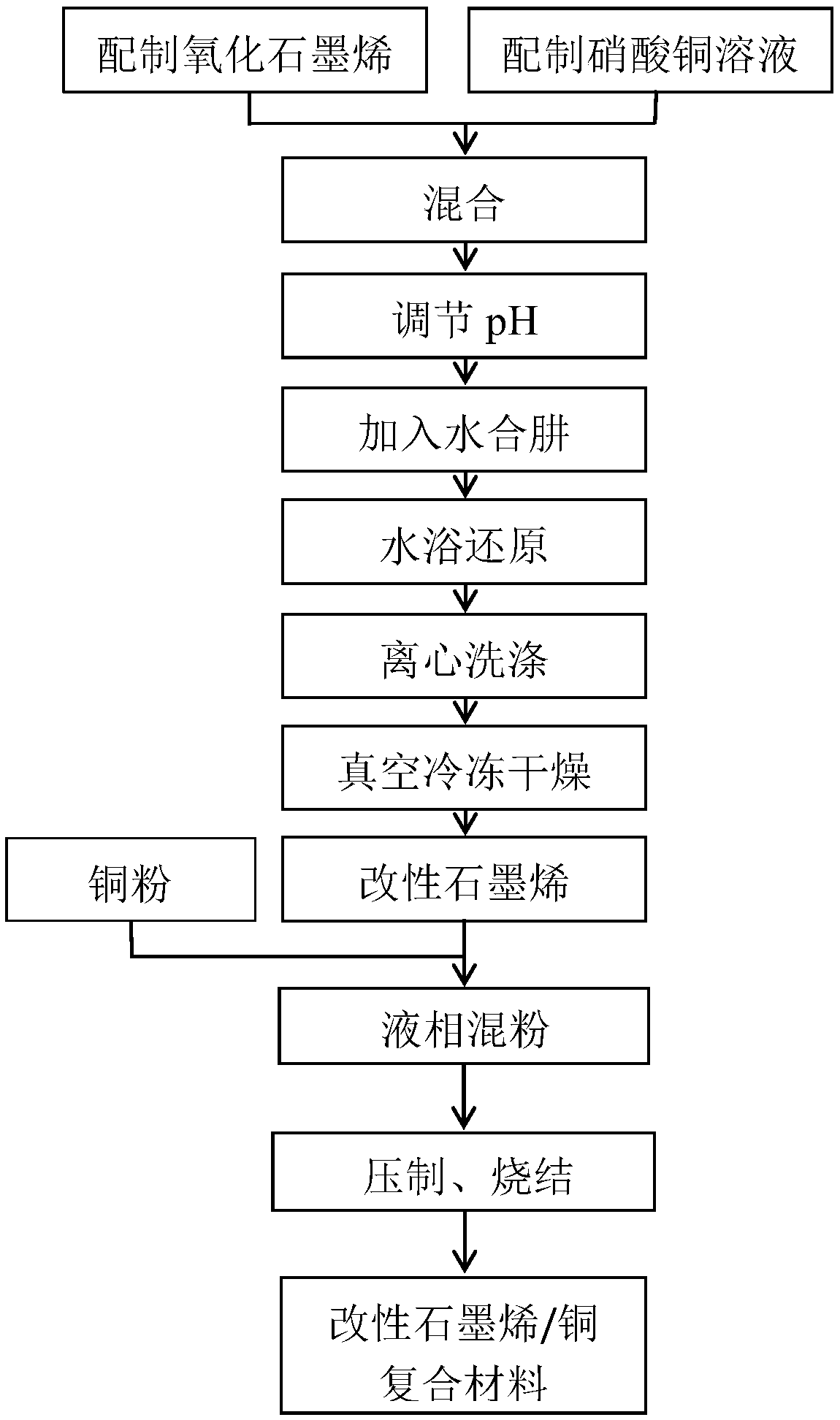

Method for preparing modified graphene reinforced copper-based composite material

A copper-based composite material and graphene composite technology, which is applied in the field of metal-based composite material preparation, can solve the problems of difficulty in preparing density, poor graphene/copper composite powder phase interface bonding, etc., and achieves high strength and electrical conductivity. The effect of uniform organization, uniform mixing and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

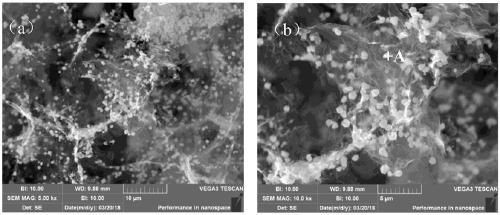

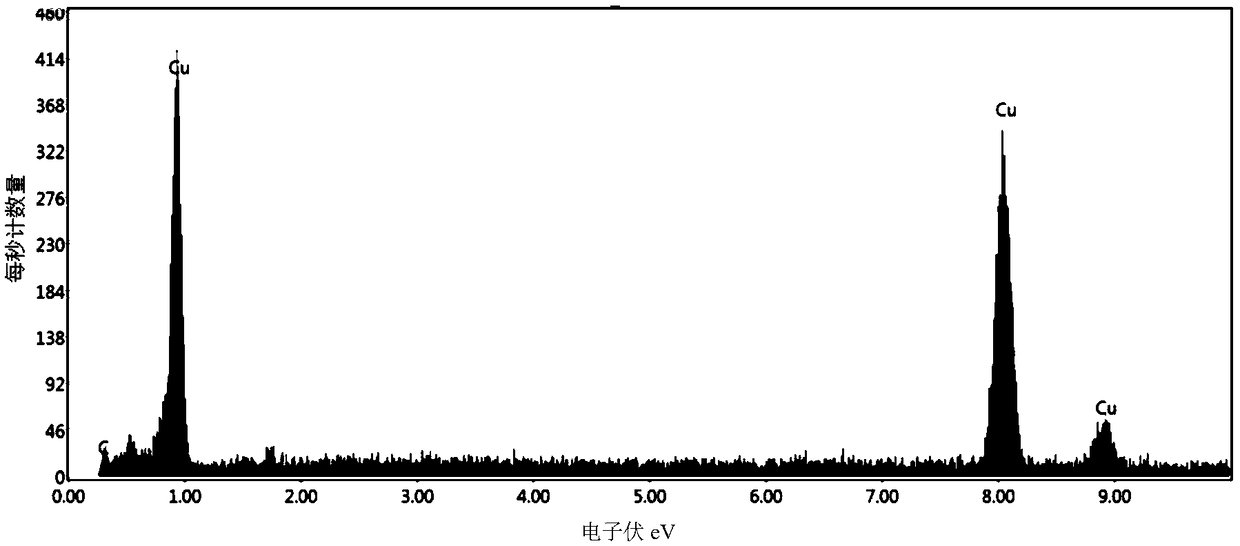

Image

Examples

Embodiment 1

[0050]Weigh graphene oxide dissolved in deionized water and ultrasonically disperse for 1 h to obtain a graphene oxide solution with a concentration of 0.2 g / L; weigh copper nitrate dissolved in deionized water and magnetically stir for 20 min to obtain a copper nitrate solution with a concentration of 5 g / L . According to the volume ratio of 5:1, the prepared copper nitrate solution was added to the graphene oxide solution at a rate of 1 drop / s, and the process was accompanied by magnetic stirring; then the beaker was sealed, magnetically stirred for 20 minutes, and then ultrasonically dispersed for 20 minutes.

[0051] NaOH solution (2mol / L) was added dropwise to the mixed solution to adjust the pH value to 8. The process was accompanied by magnetic stirring, then magnetic stirring for 20 minutes, and ultrasonic dispersion for 20 minutes. Under ventilated conditions, according to the volume ratio of the mixed solution to hydrazine hydrate is 6:1, add hydrazine hydrate dropwi...

Embodiment 2

[0054] Graphene oxide was dissolved in deionized water and ultrasonically dispersed for 5 hours to obtain a graphene oxide solution with a concentration of 1 g / L; copper nitrate was dissolved in deionized water and magnetically stirred for 60 minutes to obtain a copper nitrate solution with a concentration of 25 g / L. According to the volume ratio of 20:1, the prepared copper nitrate solution was added to the graphene oxide solution at a rate of 3 drops / s, and the process was accompanied by magnetic stirring; the beaker was sealed, first magnetically stirred for 60 minutes, and then ultrasonically dispersed for 60 minutes.

[0055] NaOH solution (2mol / L) was added dropwise to the mixed solution to adjust the pH value to 12. The process was accompanied by magnetic stirring for 60 minutes, followed by ultrasonic dispersion for 60 minutes. Under ventilated conditions, according to the volume ratio of the mixed solution to hydrazine hydrate is 30:1, add hydrazine hydrate dropwise to...

Embodiment 3

[0059] Weigh graphene oxide dissolved in deionized water and ultrasonically disperse for 3 hours to obtain a graphene oxide solution with a concentration of 0.6g / L; weigh copper nitrate dissolved in deionized water and magnetically stir for 40min to obtain a copper nitrate solution with a concentration of 15g / L . According to the volume ratio of 10:1, the prepared copper nitrate solution was added to the graphene oxide solution at a rate of 2 drops / s, and the process was accompanied by magnetic stirring; then the beaker was sealed, magnetically stirred for 40 minutes, and then ultrasonically dispersed for 40 minutes.

[0060] NaOH solution (2mol / L) was added dropwise to the mixed solution to adjust the pH value to 10. The process was accompanied by magnetic stirring, then magnetic stirring for 40 minutes, and ultrasonic dispersion for 40 minutes. Under ventilated conditions, according to the volume ratio of the mixed solution to hydrazine hydrate is 18:1, add hydrazine hydrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com