Medium trace element mixture and preparation method of medium trace element-wrapped fertilizer

A technology of medium and trace elements and mixtures, applied in urea compound fertilizers, layered/coated fertilizers, inorganic fertilizers, etc., can solve the problems of difficult to evenly disperse crops, large particle size of massive sulfur, and speeding up the sulfur film layer, etc. To achieve the effect of flexible addition, controllable content, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0029] (1) Preparation of medium and trace element mixture. The composition of the mixture was as follows: 75% sulfur, 10% zinc oxide, 5% zinc sulfate (without water) and 10% sodium polyacrylate with a molecular weight of 5000. The sulfur is heated to a liquid state, and medium zinc oxide, zinc sulfate and sodium polyacrylate are added to the liquid sulfur and mixed uniformly to prepare a medium and trace element mixture.

[0030] (2) Prepare a novel fertilizer of trace elements in the package. Add diammonium phosphate (DAP: 18-46-0) to the wrapping drum and preheat to 60°C. Addition ratio of medium and trace element mixture: 1 ton of diammonium phosphate wraps 120kg of medium and trace element mixture, and the wrapped granular fertilizer is cooled and packaged.

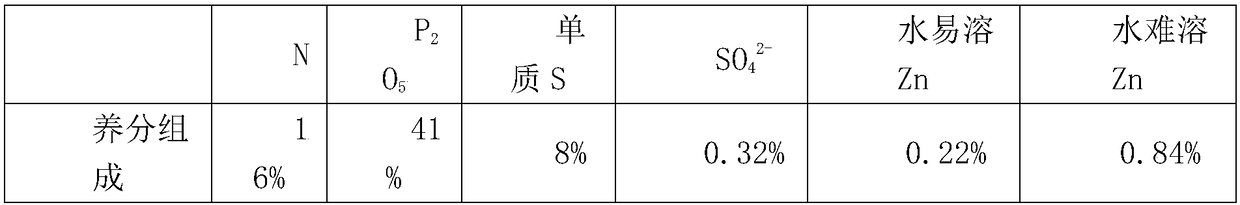

[0031] (3) The novel middle and trace element fertilizer nutrient that finally prepares is as follows:

[0032]

[0033] Zinc is one of the essential trace elements for plants. It is an activator of various enz...

Embodiment example 2

[0036] (1) Preparation of medium and trace element mixture. The composition of the mixture is as follows: 50% sulfur, 15% magnesium oxide, 10% zinc oxide, 10% anhydrous copper sulfate, 10% boric acid and 5% chitosan with a molecular weight of 50000. The sulfur is heated to a liquid state, and medium magnesium oxide, zinc oxide, anhydrous copper sulfate, boric acid and chitosan are added to the liquid sulfur and mixed uniformly to prepare a medium and trace element mixture.

[0037] (2) Prepare a novel fertilizer of trace elements in the package. Add compound fertilizer (NPK: 15-15-15) into the disc with heating function and preheat to 40°C. Addition ratio of medium and trace element mixture: 1 ton of compound fertilizer is wrapped with 150kg of medium and trace element mixture, and the wrapped granular fertilizer is cooled and packaged.

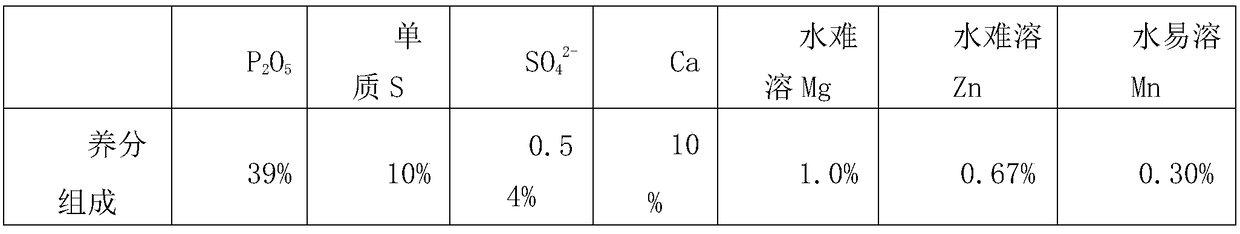

[0038] (3) The novel middle and trace element fertilizer nutrient that finally prepares is as follows:

[0039]

[0040] After ...

Embodiment example 3

[0042] (1) Preparation of medium and trace element mixture. The composition of the mixture is as follows: 90% sulfur, 5% boric acid and 5% cellulose with a molecular weight of 60000. The sulfur is heated to a liquid state, and medium boric acid and cellulose are added to the liquid sulfur and mixed evenly to prepare a medium and trace element mixture.

[0043] (2) Prepare a novel fertilizer of trace elements in the package. Add urea (46-0-0) into the bottom spray fluidized bed equipment and preheat to 55°C. Addition ratio of medium and trace element mixture: 1 ton of urea is wrapped with 200kg of medium and trace element mixture, and the wrapped granular fertilizer is cooled and packaged.

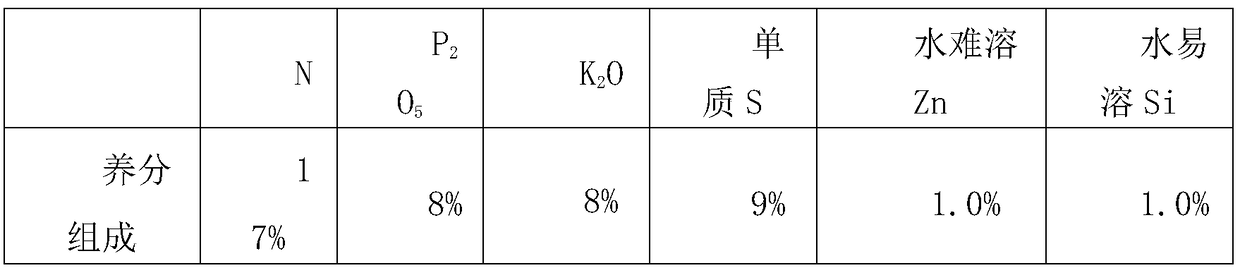

[0044] (3) The novel middle and trace element fertilizer nutrient that finally prepares is as follows:

[0045]

[0046] Urea is upgraded to urea containing sulfur and boron through this technology. Boron can promote the absorption of nitrogen and can improve the utilization ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com