Method for finely preparing iminodiacetic acid

A technology of iminodiacetic acid and iminodiacetonitrile, which is applied in the field of refined iminodiacetic acid preparation, can solve the problems of long process, high cost, difficult handling of mother liquor, etc., and achieves the effects of avoiding material flushing, softening reaction and easy handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

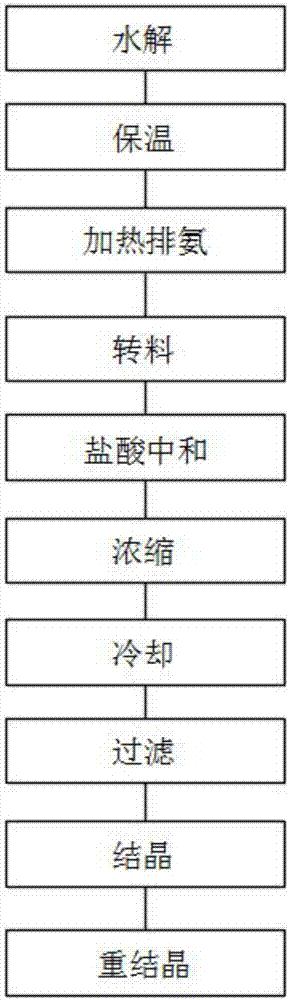

[0023] see figure 1 , a refined preparation method of iminodiacetic acid, the innovation of which is that iminodiacetic acid is prepared through the following steps:

[0024] Hydrolysis: Divide the weighed iminodiacetonitrile into 5-10 equal parts and put them into the liquid caustic soda solution in batches, and the temperature during the addition process is 40°C-50°C; Effectively avoid the occurrence of material flushing. If the temperature rises too fast during the feeding process, the condensate water should be passed in time to cool down. When the temperature exceeds 50°C, the amount of cooling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com