Patents

Literature

149results about How to "Avoid flushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

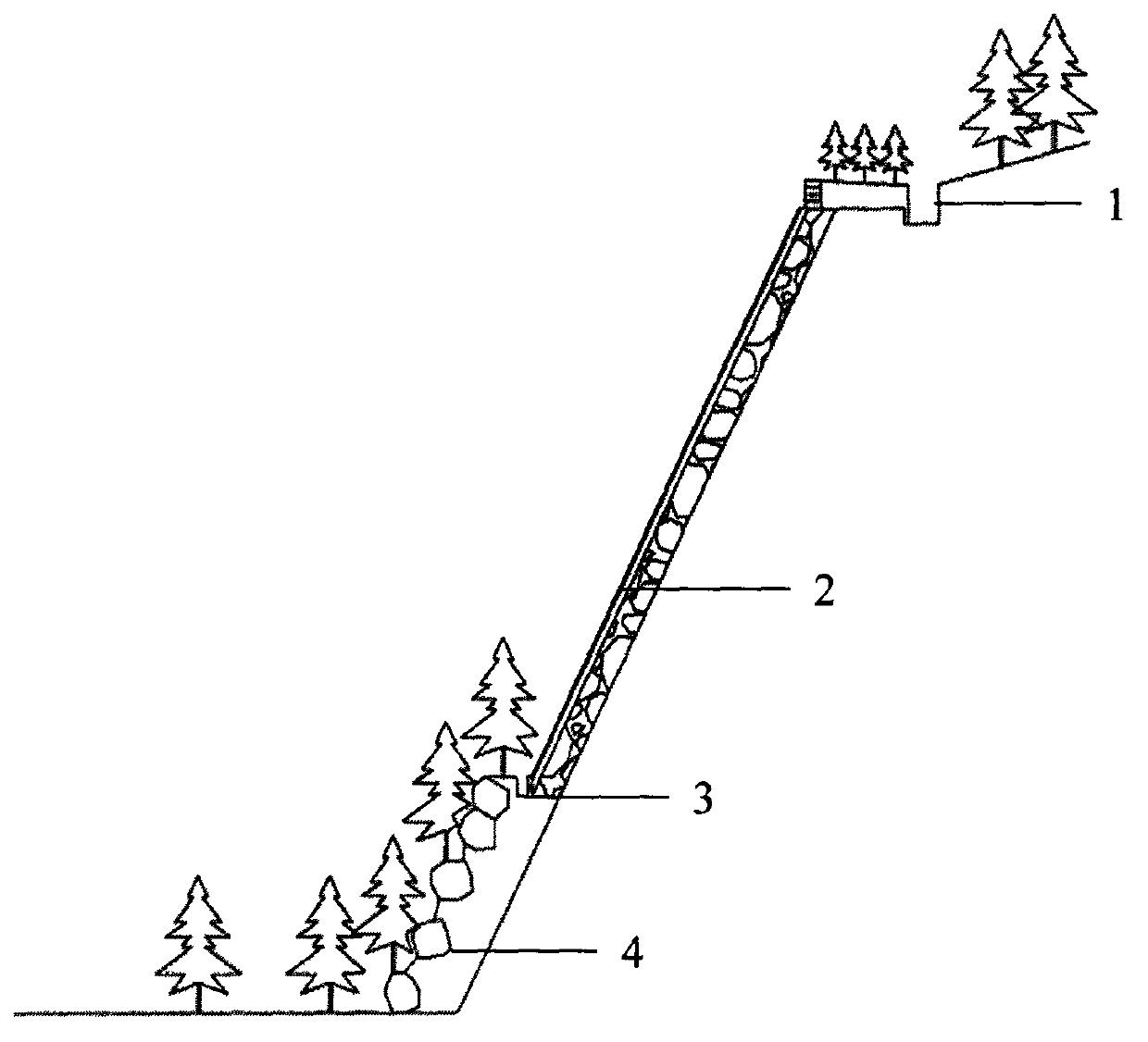

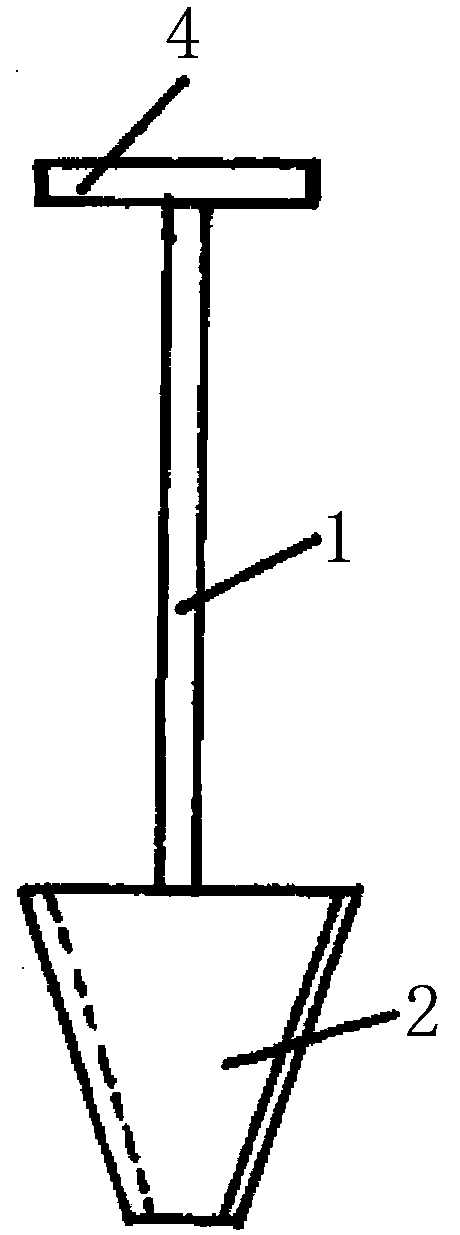

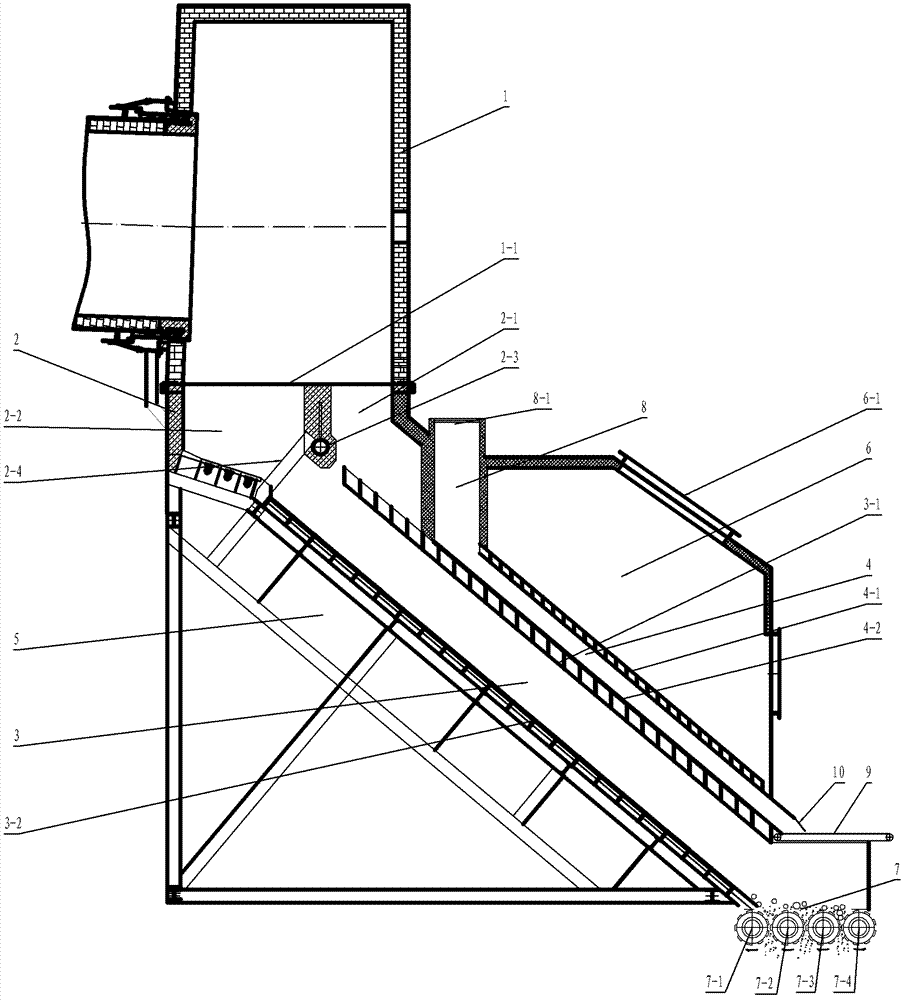

Slope reinforced structure and reinforcing method thereof

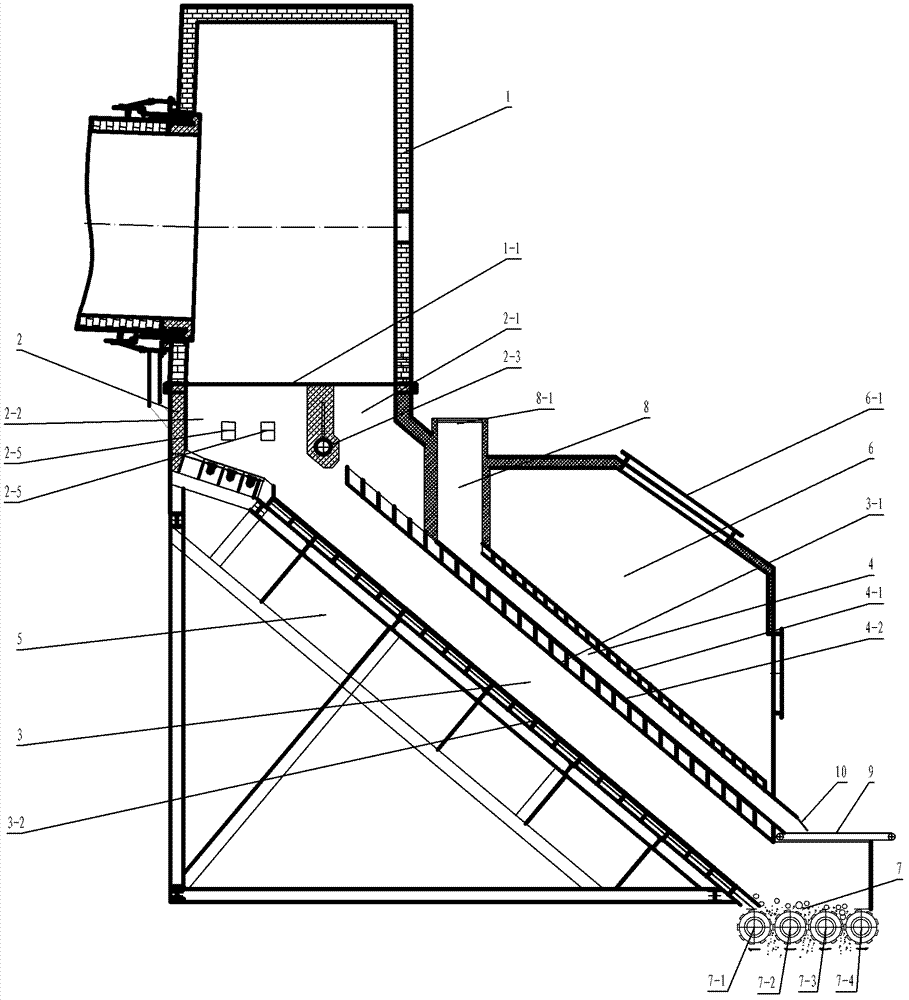

The invention discloses a slope reinforced structure and a reinforcing method thereof. An intercepting drain (1) is arranged at the top of a slope. A drainage ditch (2) is formed in the surface of the slope. A drainage ditch (3) is formed in the bottom of the slope. A stone laying retaining wall (4) is arranged at a slope toe. The intercepting drain (1) is built by rubble. A C15 concrete cushion is arranged at the bottom of the intercepting drain (1). The slope reinforced structure relates to soil dressing spray-seeding technology and is capable of effectively reducing corrosion of organic base materials caused by slope surface rainwash and slope top runoff.

Owner:陕西红叶园林绿化设计工程集团有限公司 +1

Method for preparing alpha-acetyl-gamma-butyrolactone

ActiveCN101768141AReduce pollutionQuick responseOrganic chemistryAlpha-acetyl-gamma-butyrolactoneEthyl fumarate

The invention provides a method for preparing alpha-acetyl-gamma-butyrolactone. In the method, gamma-butyrolactone and an acetylating agent (ethyl acetate and methyl acetate or a mixture of ethyl acetate and methyl acetate) are used as starting materials, metal sodium is used as a catalyst, and the product is obtained by acylation, neutralization and distillation. The method has the advantages that: the raw materials are used as the solvent at an initial stage of the reaction, so that the environmental pollution brought by the solvent is lowered, the material feeding amount is increased, the production efficiency is improved, and the production cost is lowered; the metal sodium is added into the reaction system continuously or for several times, so that potential safety risks such as outshoot and combustion caused by difficult control of the reaction speed can be effectively avoided when the sodium metal is reacted at a melting temperature; and by adopting the pressure-regulating distillation method, the byproducts are effectively recovered, the environmental pollution is lowered, and the comprehensive economic benefits are improved.

Owner:鞠彩霞

Preparation method for alpha-acetyl-gamma-butyrolactone

ActiveCN102229586AEfficient recyclingLow input costOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsReaction rateMethyl acetate

In order to solve the problems of a low safety factor, low yield, high cost, environmental pollution and the like existing in the prior art, the invention provides a preparation method for alpha-acetyl-gamma-butyrolactone. In the method, gamma-butyrolactone and methyl acetate are used as reaction raw materials and metallic sodium is used as a catalyst; the final product is prepared through the phases of reaction, separation, neutralization and extraction. According to the invention, methyl acetate is used as the reaction raw material and a reaction solvent, which on one hand enables production cost to be reduced, the reaction rate to be slowed and dashing out of reacting materials to be avoided, and on the other hand avoids environmental pollution and affection on product quality caused by utilization of benzene solvents; preparation of the catalyst into sodium sand can improve reaction efficiency; high purity alpha-acetyl-gamma-butyrolactone can be obtained through neutralization andextraction of the solid resultants alpha-acetyl-gamma-butyrolactone sodium salt of the reaction which have been subjected to solid-liquid separation without underpressure distillation, thereby effectively improving production efficiency and reducing production cost; the acidic neutral solution used in the invention can be used repeatedly, thereby avoiding environmental pollution by the solution.

Owner:山西三维华邦集团有限公司 +1

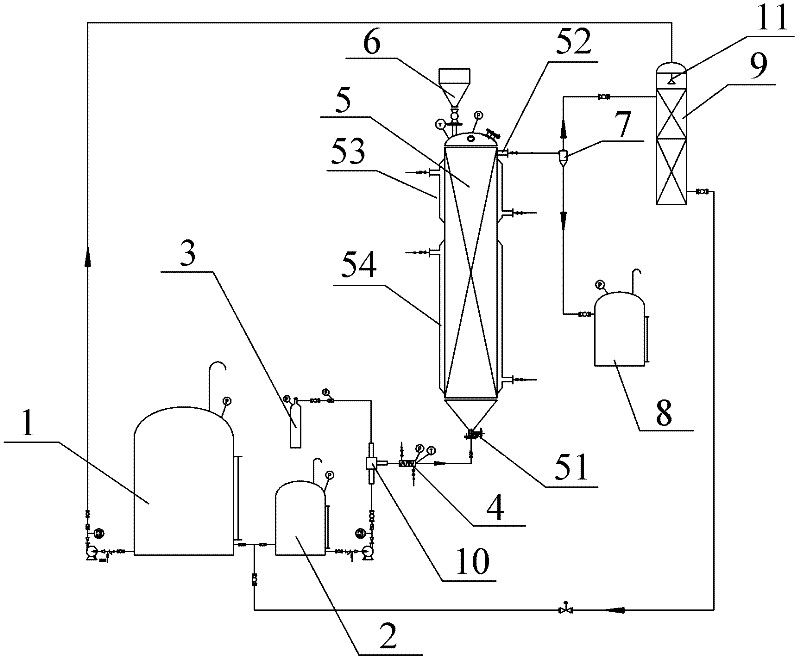

Device for continuous preparation of Grignard reagent and method for continuous preparation of Grignard reagent through using device

ActiveCN102603775ANot prone to valve cloggingLess prone to plumbing problemsMagnesium organic compoundsEnvironmental resistanceVapor–liquid separator

The invention discloses a device for the continuous preparation of a Grignard reagent and a method for the continuous preparation of the Grignard reagent through using the device. The device comprises a solvent storage container, a solvent-raw material mixing container, a raw gas storage container, a preheater, a reactor, a magnesium adding bin, a gas-liquid separator, a Grignard reagent reception container and a tail gas recovery apparatus, wherein the reactor adopts a three-phase bubble slurry column reactor. A purpose of the continuous preparation of the Grignard reagent can be realized through using the device of the invention, and initiation and heat radiation problems of a Grignard reaction can be effectively solved through adopting the three-phase bubble slurry column reactor, so potential safety hazards of material rush-out, explosion and the like caused by the severe temperature rise of the Grignard reaction can be effectively avoided, the obstruction of valves and pipelines by magnesium shreds can be prevented, and the high purity Grignard reagent can be obtained; and the tail gas recovery apparatus is arranged in the invention to absorb and recycle tail gases, so the cost is saved, and the environmental pollution is reduced, thereby cleaning and environmental protection requirements of the preparation of the Grignard reagent are realized.

Owner:SHANGHAI HEGNO PHARMA HLDG +1

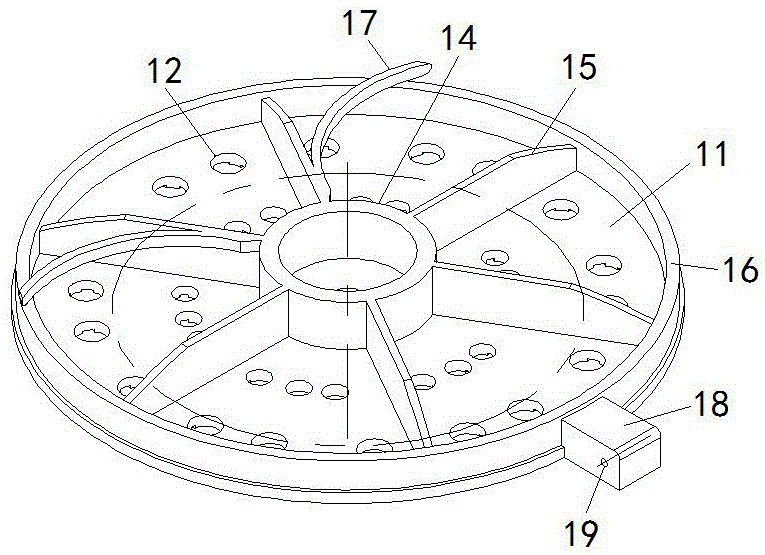

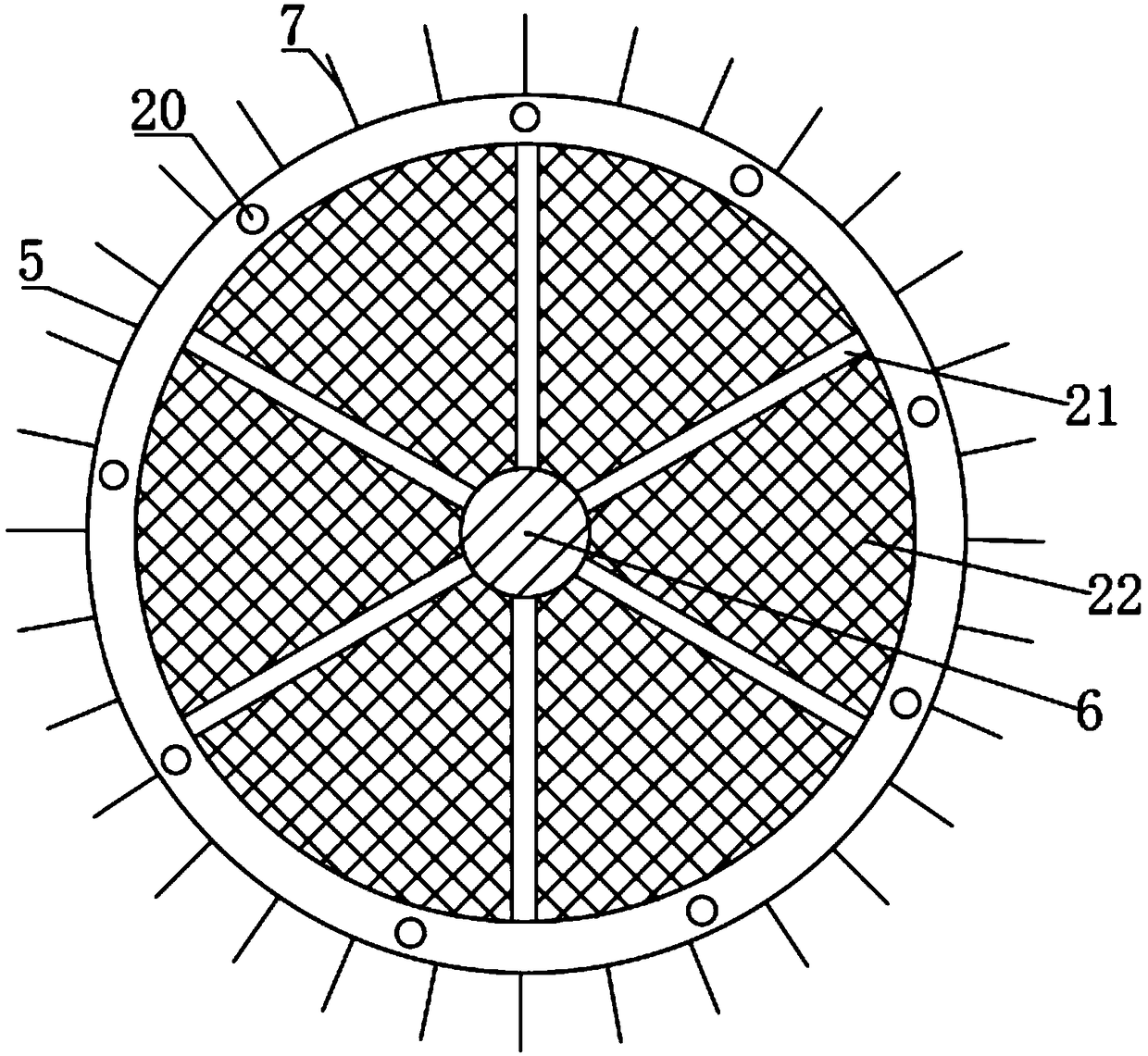

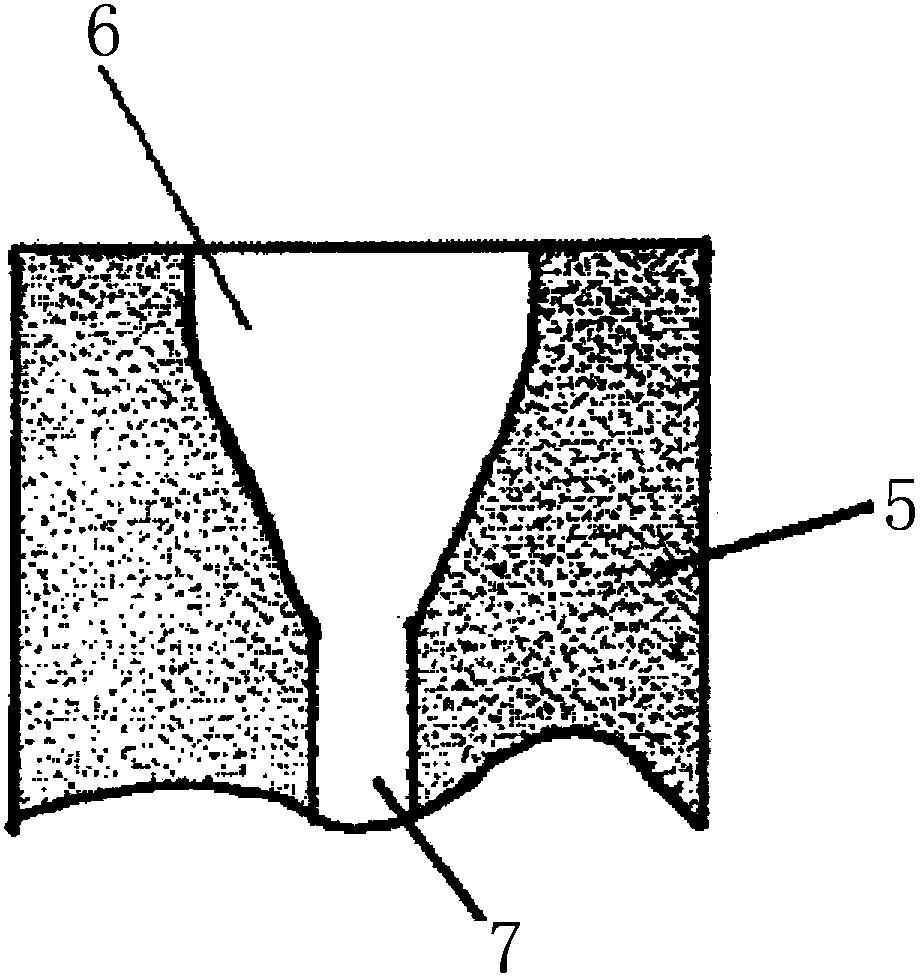

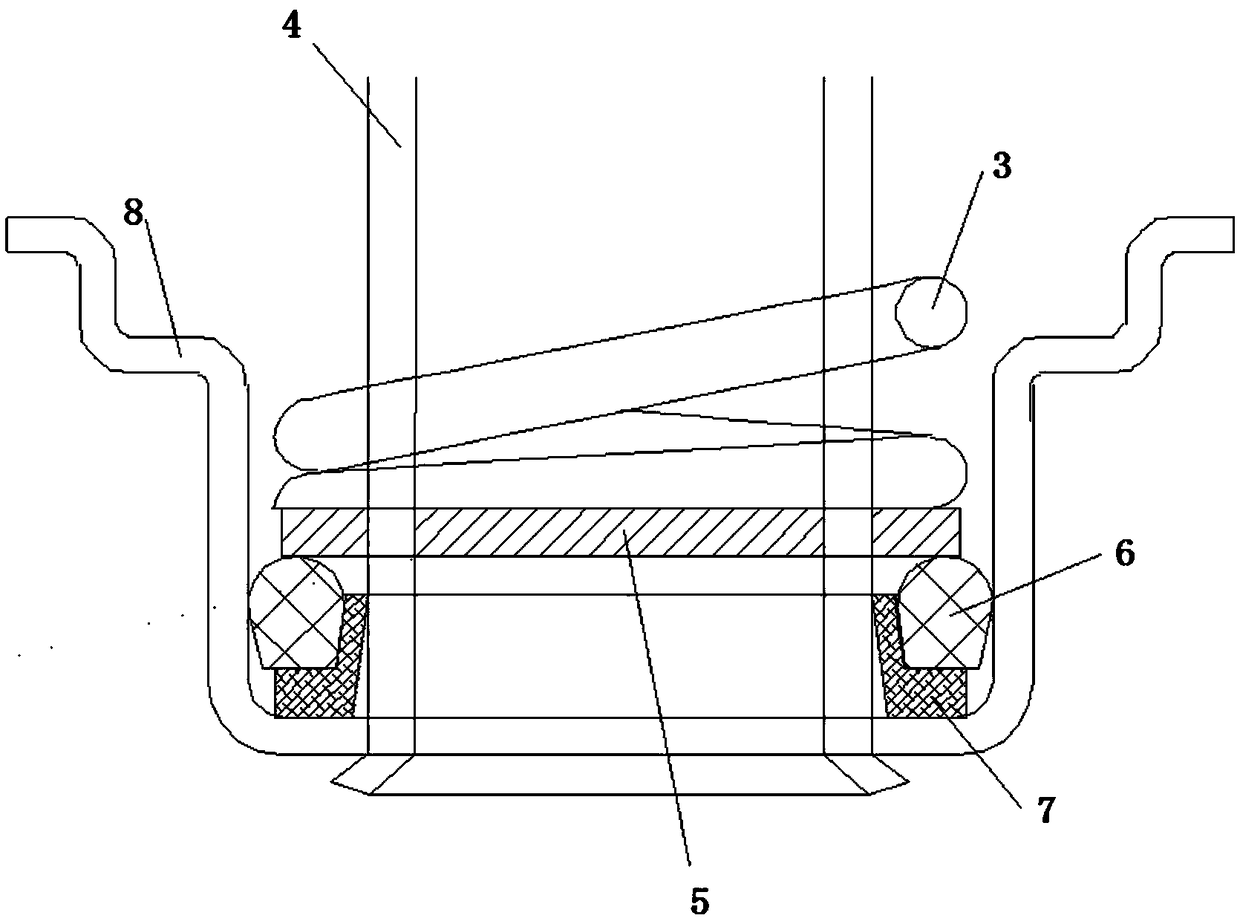

Safe sewer well lid

InactiveCN106592746AFix security issuesSolve practicalityFatty/oily/floating substances removal devicesSewerage structuresRoad surfaceRoad condition

The invention provides a safe sewer well lid. The safe sewer well lid is used for solving the problems of lower safety, poor practicability and lower reliability of a well lid in the prior art. According to the technical scheme provided by the invention, the safe sewer well lid comprises a cover plate, a well base and a foundation base, wherein the cover plate is moveably connected with the well base and the well base is arranged on the foundation base. The safe sewer well lid has the beneficial effects that the maintenance cost is lower than that of the traditional well lid; the well lid is fit with the pavement, so that the stress of the well lid can be shared by the pavement, the lower part of the support base of the well lid can be served as a support and the well lid is dually stressed; the antitheft property and the safety are promoted; the practicability is high and the safe sewer well lid is suitable for most road conditions; a filter screen is built-in, so that the dirt on the pavement can be effectively prevented from entering into a sewer, the sewer can be effectively prevented from being blocked and the filter screen can be conveniently exchanged and cleaned.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

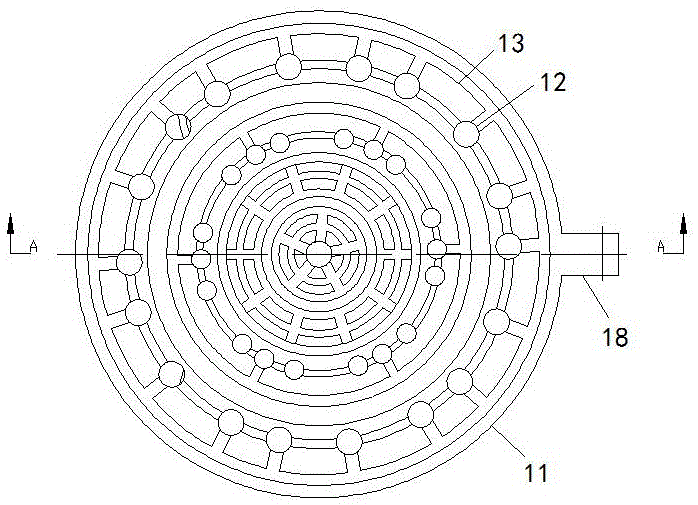

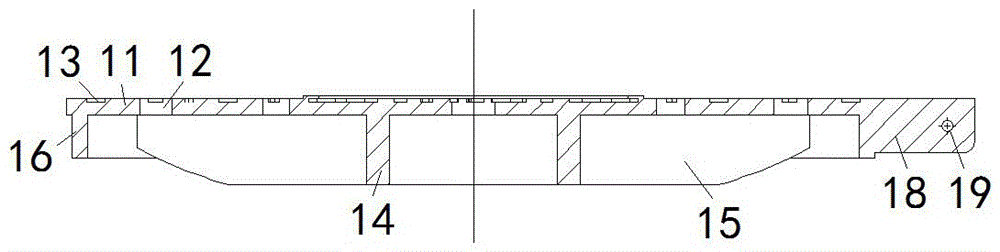

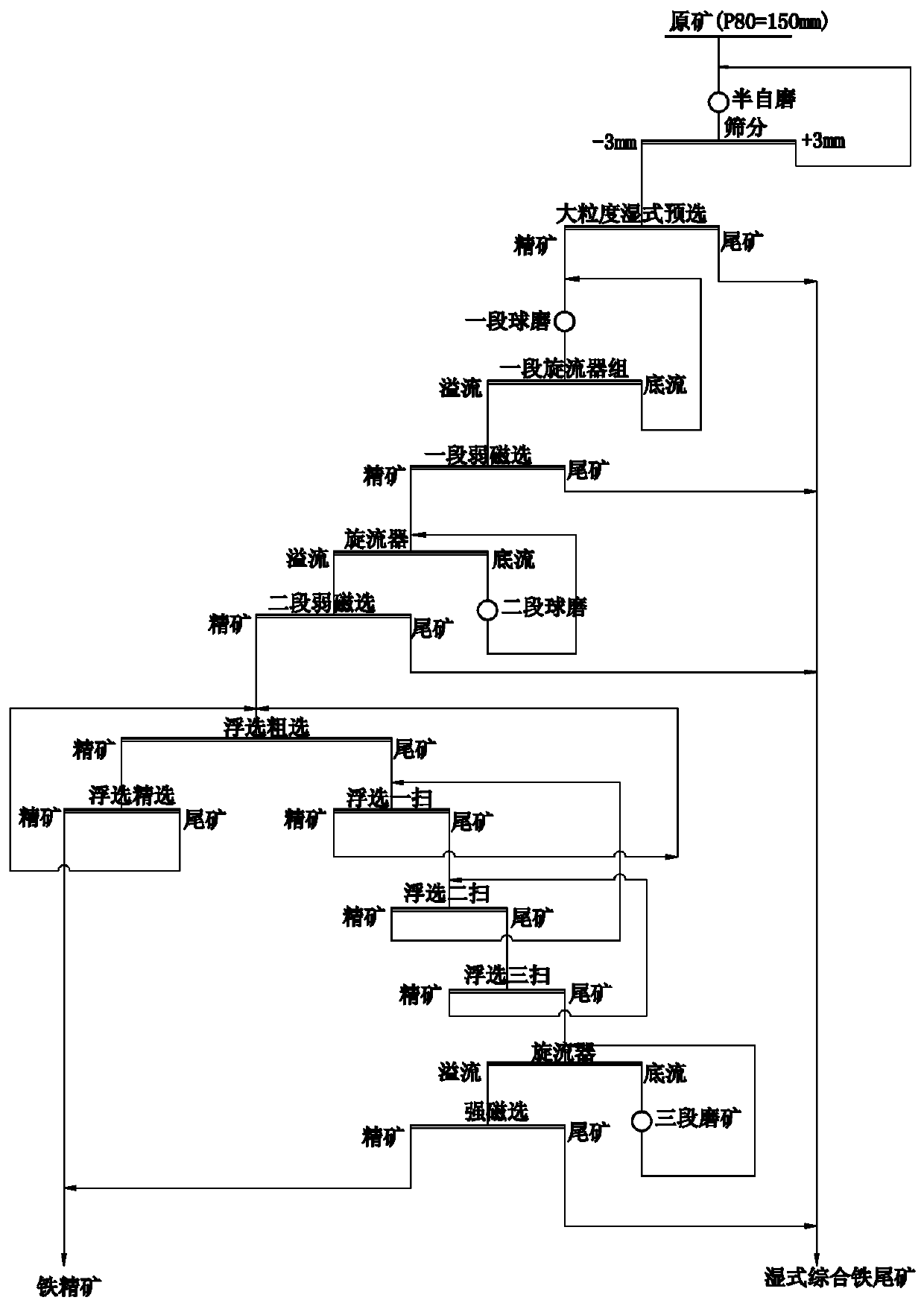

Amphibole type primary iron ore grading process

ActiveCN107790283AHigh recovery rateAvoid flushingHigh gradient magnetic separatorsFlotationIronstoneClosed loop

The invention relates to an amphibole type primary iron ore grading process. The amphibole type primary iron ore grading process comprises the steps that iron ore with iron mineral disseminated grainsize being P80=17 microns is subject to rough breaking and primary dry in-advance magnetic separation, primary dry in-advance magnetic separation concentrate with the grade being 28.62%, the recoveryrate being 98.51% and the particle size being P80=150 microns serves as raw materials; the process is characterized in that raw ore is subject to semi-automatic-grinding screening closed loop grinding, wet in-advance magnetic separation, two-stage stage grinding stage low intensity magnetic separation, one-roughing one-refined three-scavenging reverse flotation, three-stage closed loop superfine ore grinding and strong magnetic separation process grading, wherein the semi-automatic-grinding screening closed loop grinding product granularity is 0 mm-3 mm, the two-stage closed loop grinding product granularity is P80=30 microns, the three-stage closed loop grinding product granularity is P80=17 microns, and the good indexes with the final iron ore concentrate iron grade being 65.50%, the recovering rate being 76.00%, the comprehensive gangue iron grade being 11.30% and the recovery rate being 24.00% are finally obtained.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

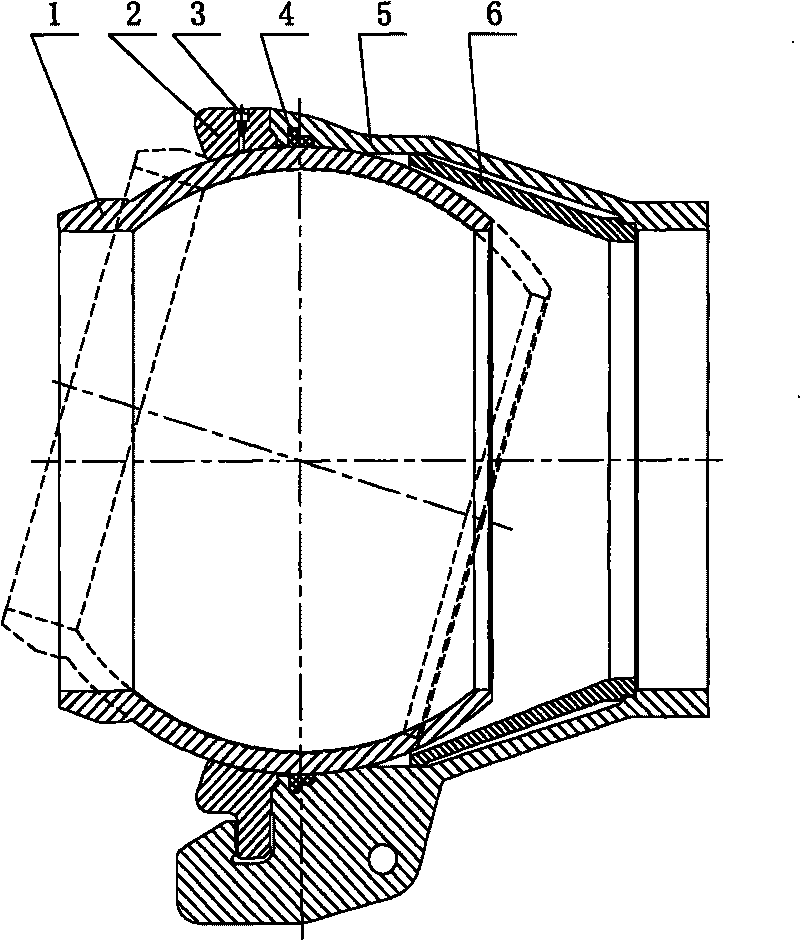

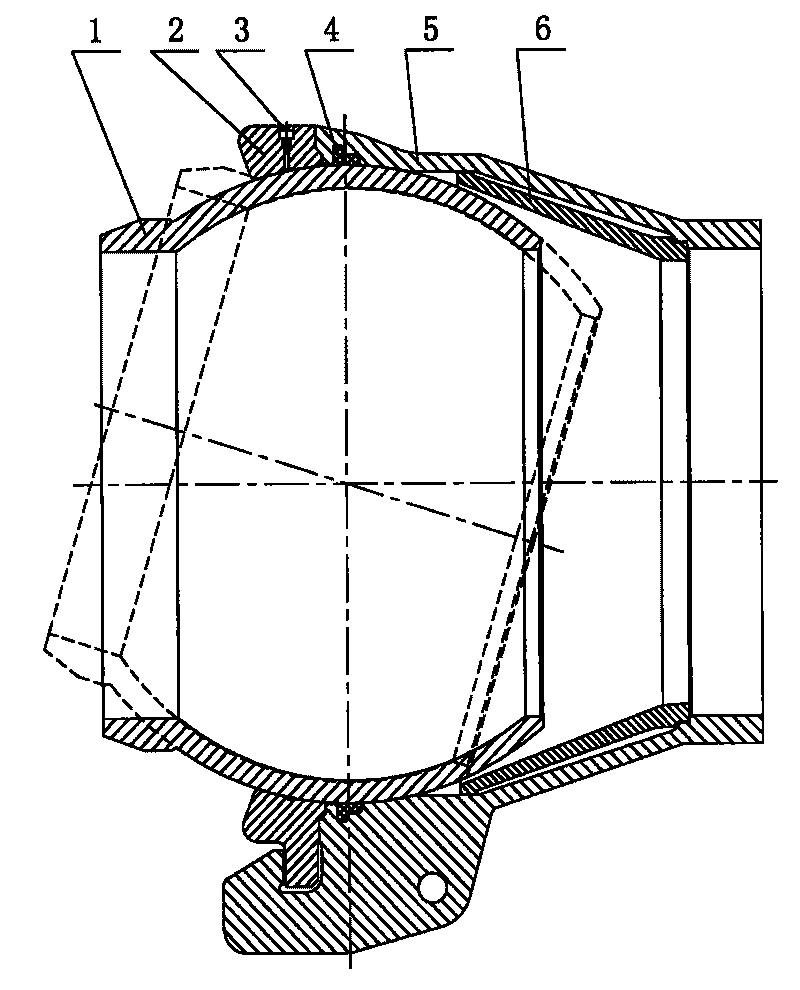

Quick ball joint

Disclosed is a quick ball joint which comprises a ball shell connected with a pipeline and a ball body connected with another pipeline. The ball body is spherical, the inner wall of the ball shell is also a spherical shape for being engaged with the ball body, the inner wall is provided with a sealing ring positioned on the inner side of a vertex of the ball body; the front end of the ball shell is connected with a pressure cover, the inner surface of the pressure cover is an arc-shaped surface, radian of the arc-shaped surface is same with that of the surface of the ball body. As the sealing ring is not positioned at the highest point of a spherical center but at a position deviating 5-7mm from the spherical center, tightness of the ball joint is not very effective when in the absence of an external pull force; the highest point of the ball body extrudes the sealing ring when stretched by an external force, thereby pressing the sealing ring tightly and being capable of bearing relatively high pressure and simultaneously bearing large enough pull force. When in installation, people only need to insert a ball body end into the ball shell, rotate the pressure cover to lead a flange portion of the pressure cover to be screwed at a fastening position of the ball shell, and then plug a pin shaft to prevent the pressure cover from rotating, thereby finishing installation. Accordingly, the ball joint achieves simple and convenient installation.

Owner:WUXI JINYANG PIPING FITTING

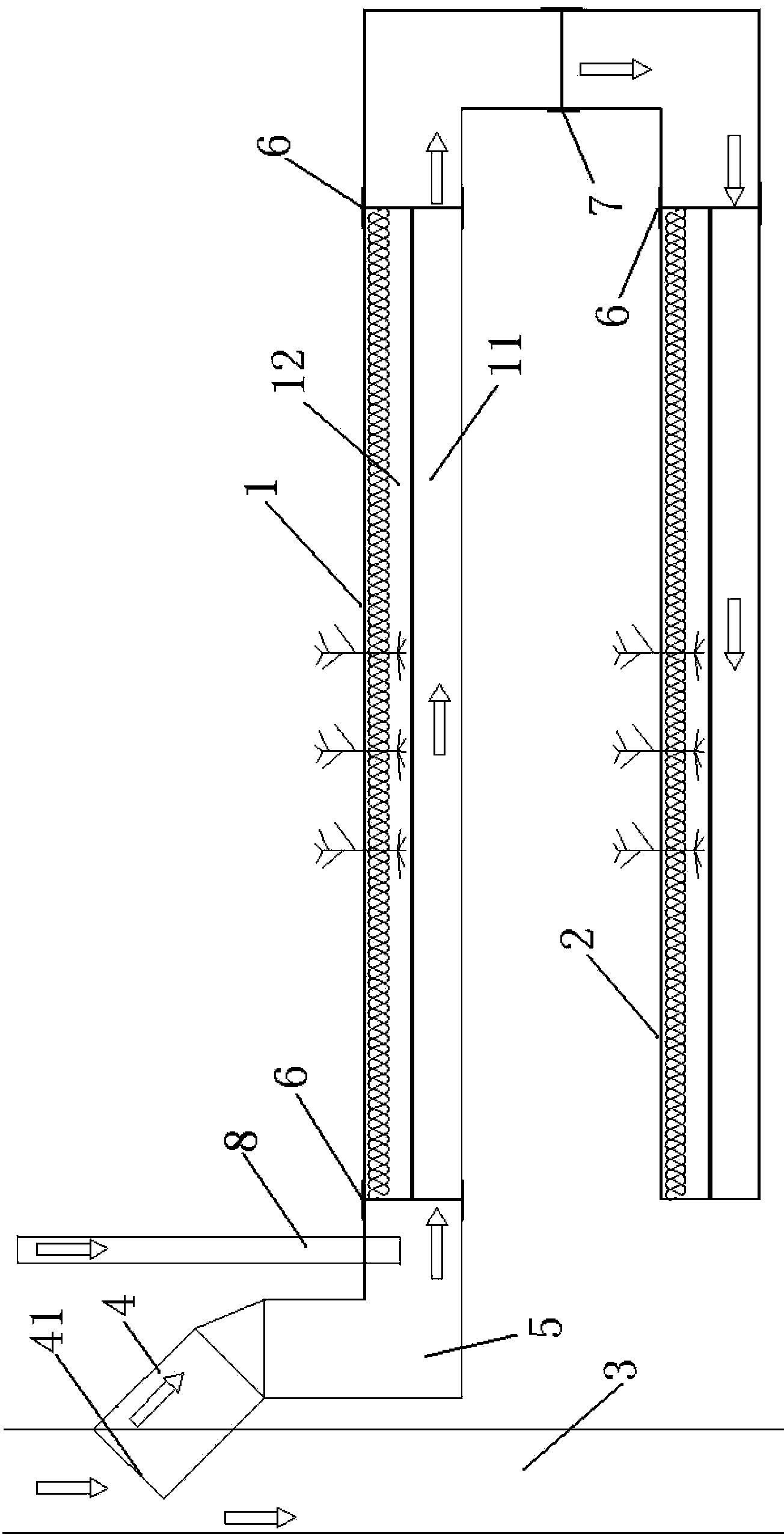

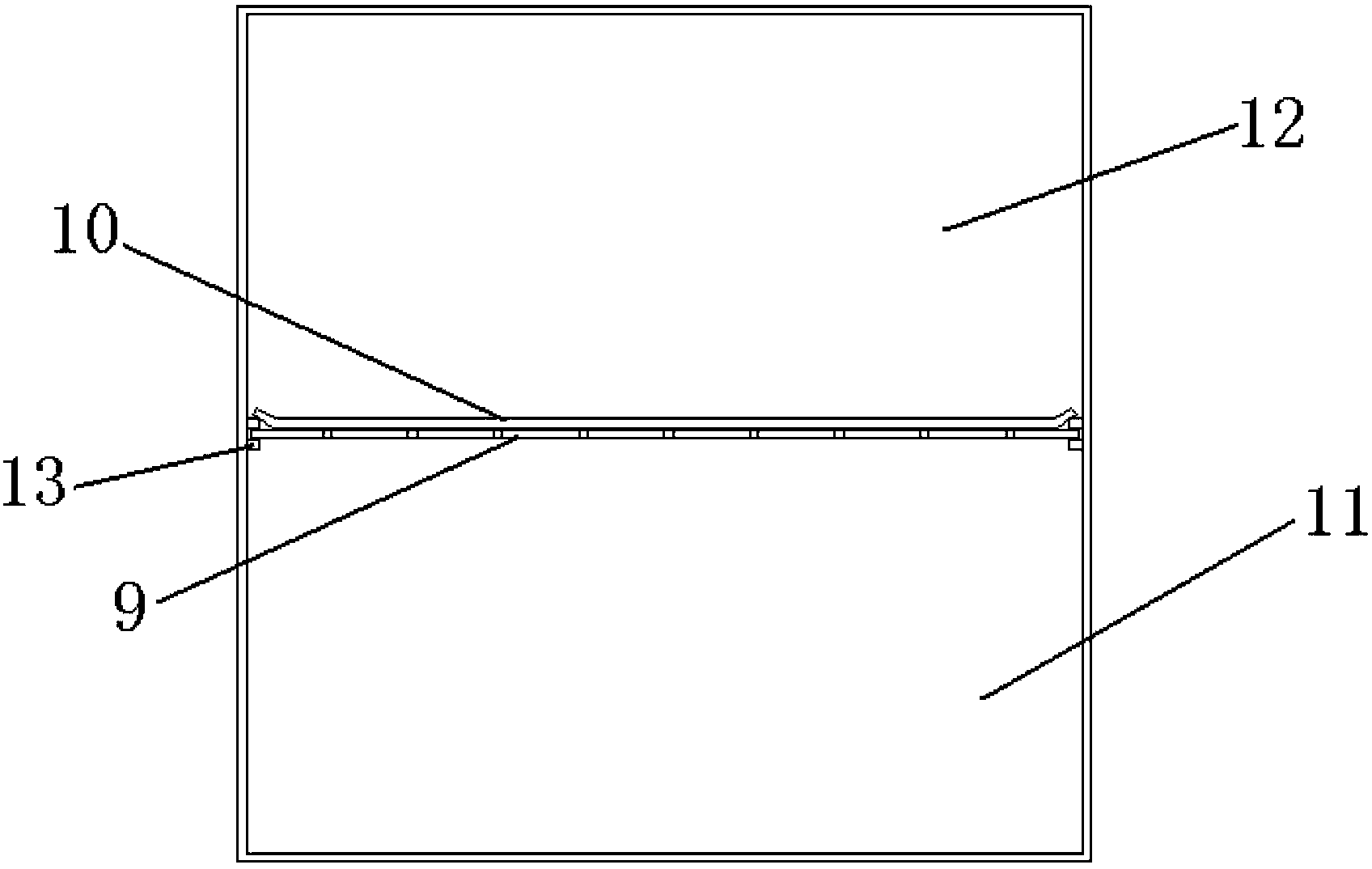

Wall greening system and installation method capable of using rain water efficiently

ActiveCN104221745AEfficient use ofWith shadeWatering devicesCultivating equipmentsWater savingPipeflow

The invention provides a wall greening system and installation method capable of using rain water efficiently. The wall greening system includes a first pipe, a rain riser and a filtering water diversion bend; The filtering water diversion bend-side filter is connected with the rain riser, the other end of the filtering water diversion bend is connected with the starting end of the first pipe through bend with opening holes, the first pipe is installed on the outer wall surface horizontally; the inside of the first pipe is provided with a horizontal middle partition board, the first pipe is divided into planting space and water space by the middle partition board, the planting space is above the water space, and geotextile is laid on the middle partition board; The pipe wall at top of the planting space has a plurality of opening holes for plant in the planting space growing. The invention provides a wall greening integrated system making efficient use of rain water through combining the rain water collection and utilization system with the wall greening system. The wall greening integrated system saves water, reduces sun exposure of the building outer wall, and decorates the outer wall.

Owner:中关村海绵城市工程研究院有限公司

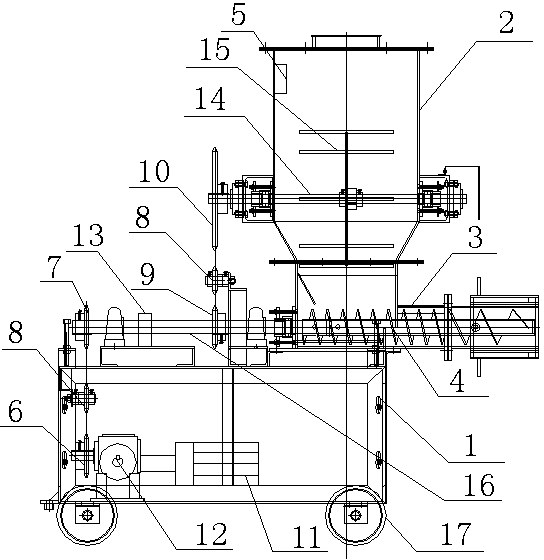

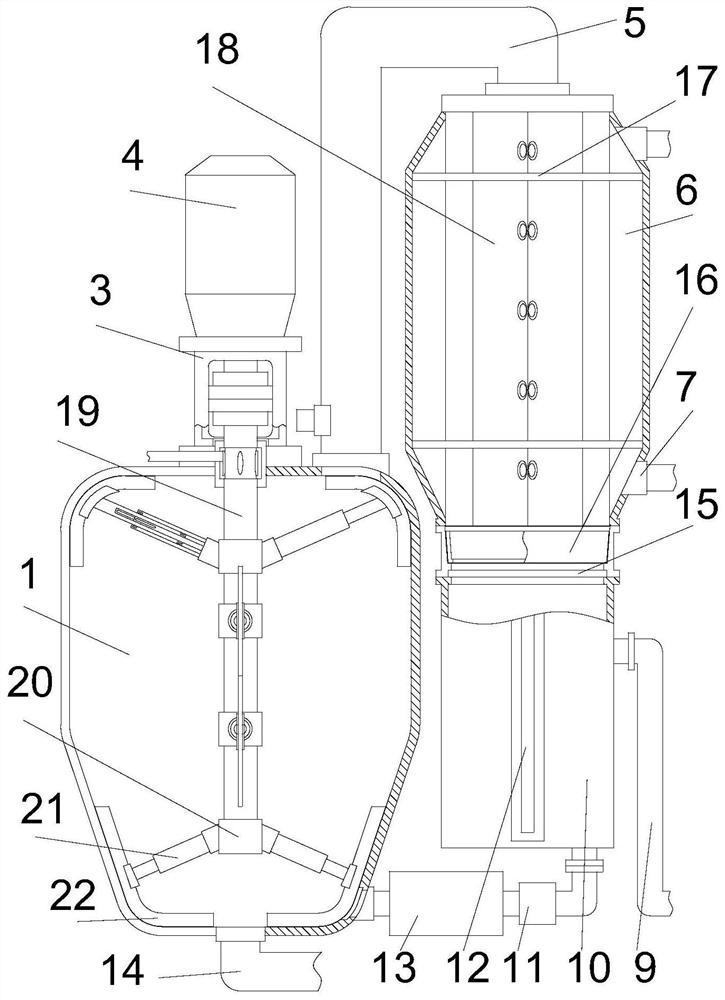

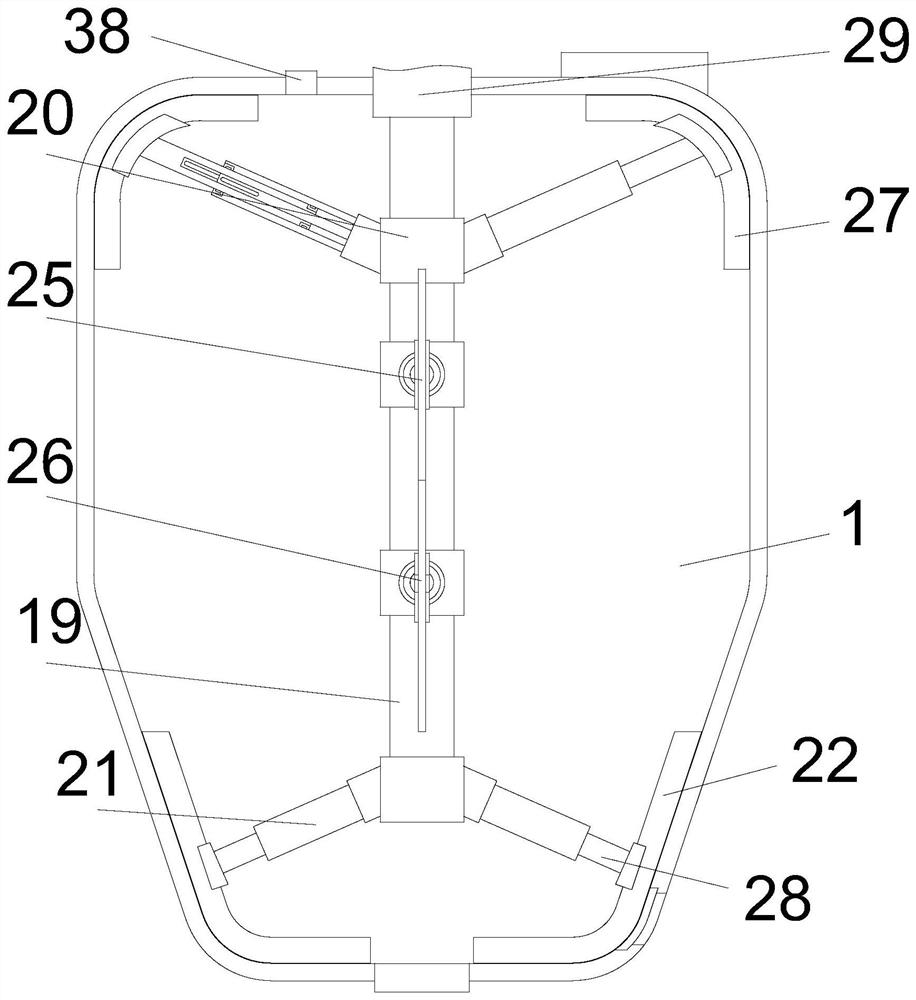

Feeder device of dissolving furnace for glass fiber production

The invention discloses a feeder device of a dissolving furnace for glass fiber production. The feeder device comprises a rack and a stock bin arranged on the rack. A discharging pipe is arranged at the lower end of the stock bin. A transmission device driving feeding is arranged at one side of the rack. The transmission device comprises a transmission shaft and a driving mechanism driving rotation of the transmission shaft. A helix tube is arranged at the inner side of the stock bin. The helix tube extends into the discharging pipe. The transmission shaft is connected with the helix tube, and drives rotation of the transmission shaft through the driving mechanism. Materials are rotated and discharged together with the helix tube under the normal thrust of the helix tube. Smooth transportation of materials is ensured, material clashing phenomenon is avoided, dust-free transportation is achieved and safe production is ensured. A detection device for detection of material level is arranged on the inner wall of the stock bin. Through arrangement of the detection device, real-time detection of the change of the material level in the stock bin can be achieved and the feeding amount of materials can be determined. The feeder is advantaged by simple structure, easy maintenance and low usage and maintenance cost.

Owner:TAIJIA GLASS FIBER

Carbon black dispersion, and preparation method and application thereof

ActiveCN113956686AImprove stabilityImprove adsorption capacityPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a carbon black dispersion and a preparation method thereof. The carbon black dispersion comprises, by mass, 10-40 parts of modified carbon black, 2-5 parts of a surfactant A, 2-5 parts of a surfactant B, 40-90 parts of a liquid dispersion medium and 0-0.1 part of an additive, wherein the modified carbon black is prepared by carrying out esterification reaction on a modified substance C and carbon black of which the surface contains hydroxyl. The invention also provides an application of the carbon black dispersion in polyester fiber stock solution coloring. The application specifically comprises the following steps: preheating the carbon black dispersion to 170-180 DEG C, and adding the carbon black dispersion into a polyester oligomer after an esterification reaction and before a polycondensation reaction in a polyester fiber production process. The carbon black dispersion has good compatibility with polyester, can be stably dispersed in the polyester, can improve the spinnability of the colored polyester fiber, and ensures that the polyester fiber has high elongation at break, high breaking strength, high soaping-resistant color fastness and high dry / wet rubbing fastness.

Owner:SUZHOU SUNMUN TECH CO LTD

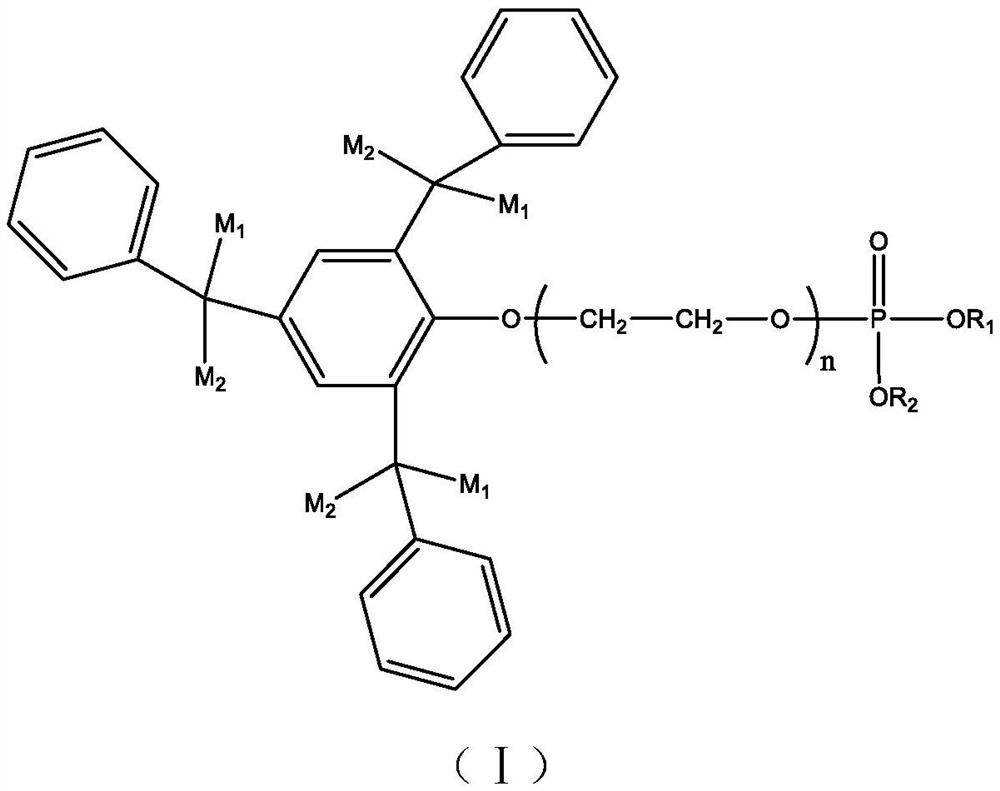

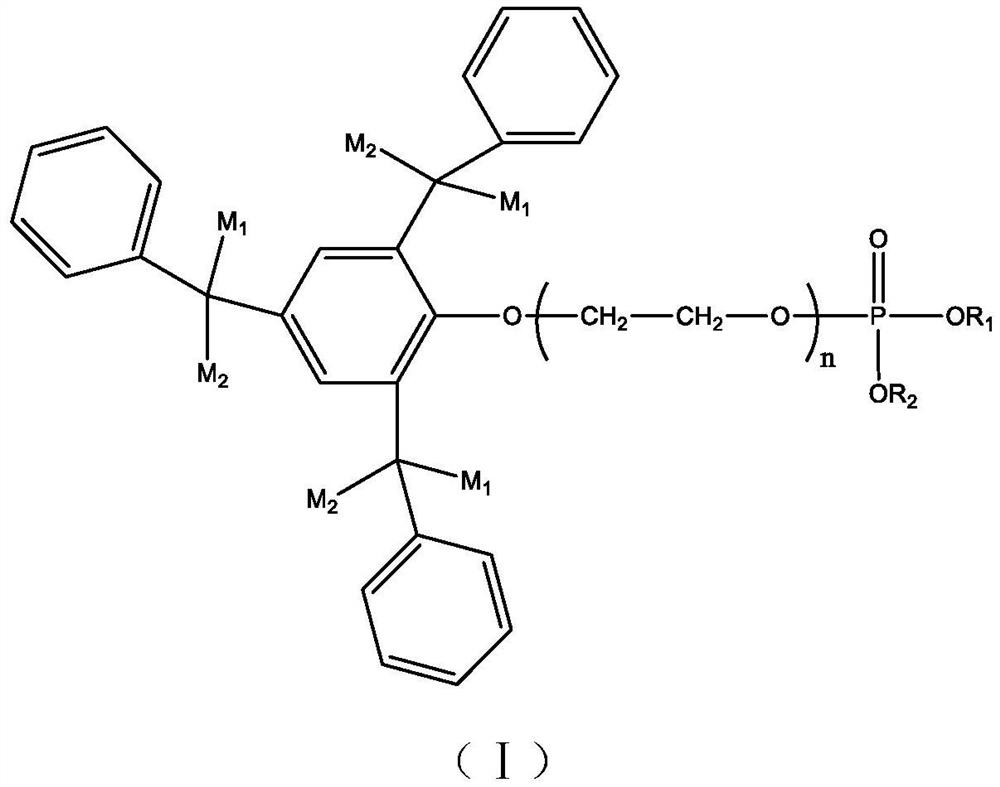

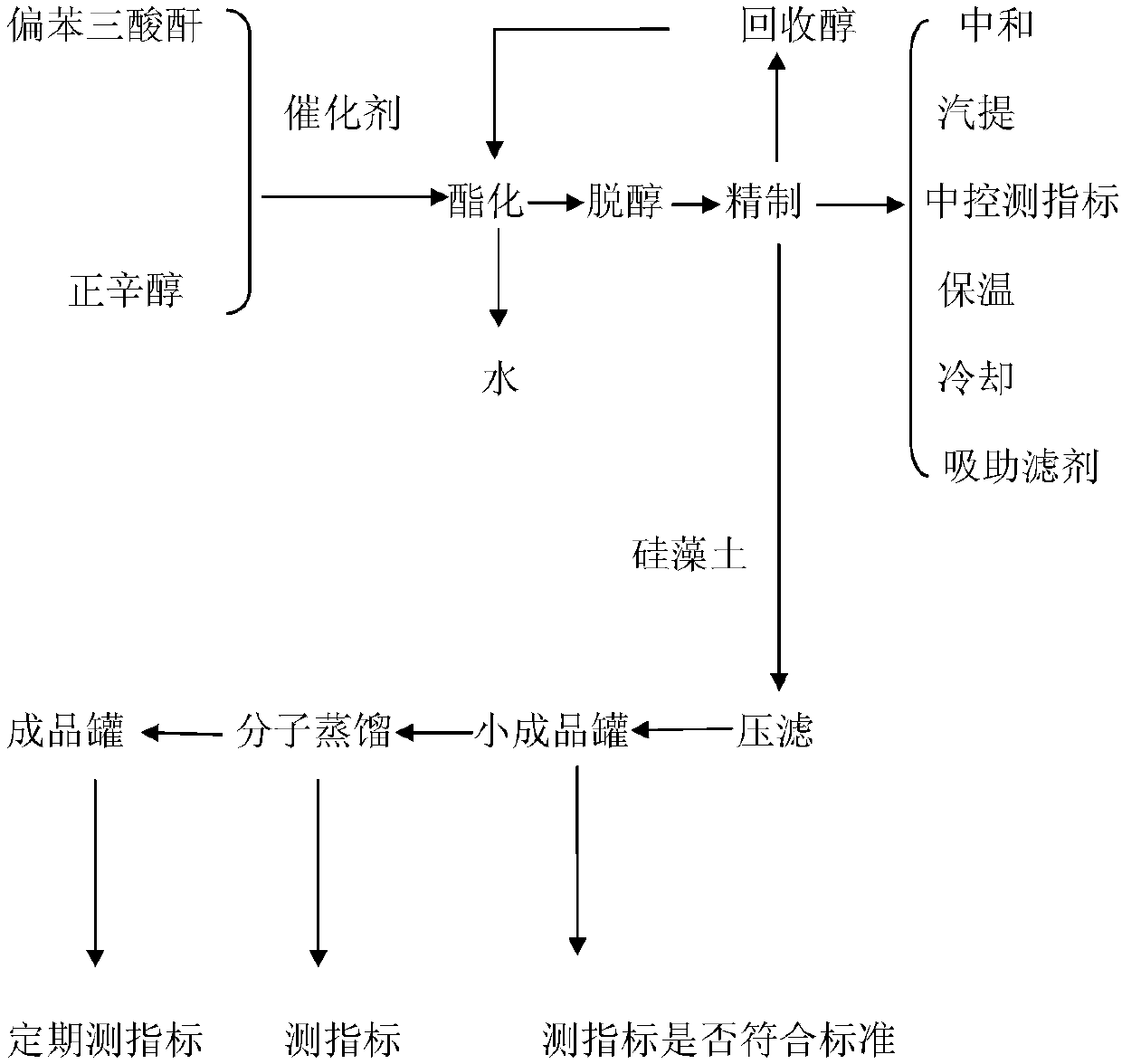

Special plasticizer TM8 for automobile interior parts

InactiveCN108218700AAvoid flushingAvoid cloggingOrganic compound preparationCarboxylic acid esters preparationAlcoholPlasticizer

The invention discloses a special plasticizer TM8 for automobile interior parts. Raw materials and auxiliary materials of the plasticizer TM8 comprise acid anhydride, alcohol, a catalyst, sodium carbonate and a filter aid. A process of the special plasticizer TM8 for the automobile interior parts comprises esterification, purification and filter press purification, and molecular distillation (short-path distillation). In esterification, alcohol is added first, after the temperature of a reactor is less than 80DEG C, 1,2,4-benzeneticarboxylic anhydride is added, then the catalyst is added, whenthe temperature of the material rises to 220DEG C, a negative pressure reaction starts, when an acid value is less than or equal to 0.1mgKOH / g, flash evaporation and dealcoholization start. In purification, steam stripping is performed while temperature rises to 215+ / -10DEG C, and the filter aid diatomite is added so as to purify and stir. In molecular distillation, the vacuum degree reaches lessthan 100pa, and the material inlet temperature is maintained at 215+ / -5DEG C. The raw materials are easy to obtain, the process is advanced, the equipment is simple, the plasticizer is environmentally friendly, has high plasticizing efficiency, resists high and low temperature, has low volatility, has small odor, and is highly stable.

Owner:JIANGSU SENHE CHEM TECH CO LTD

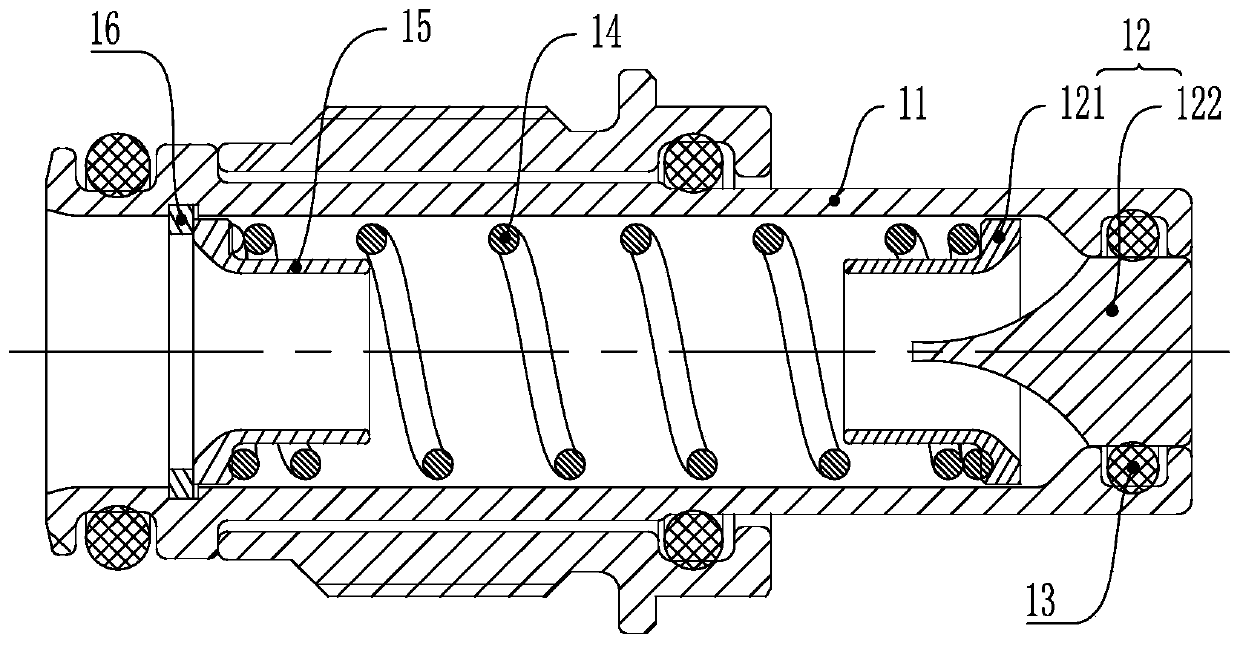

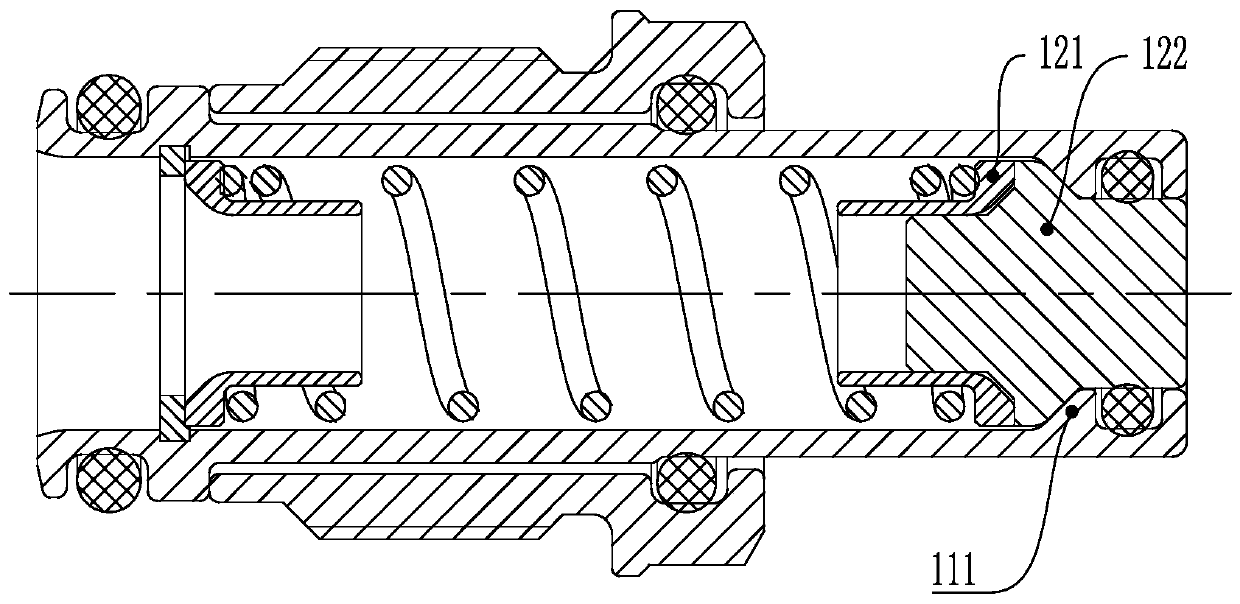

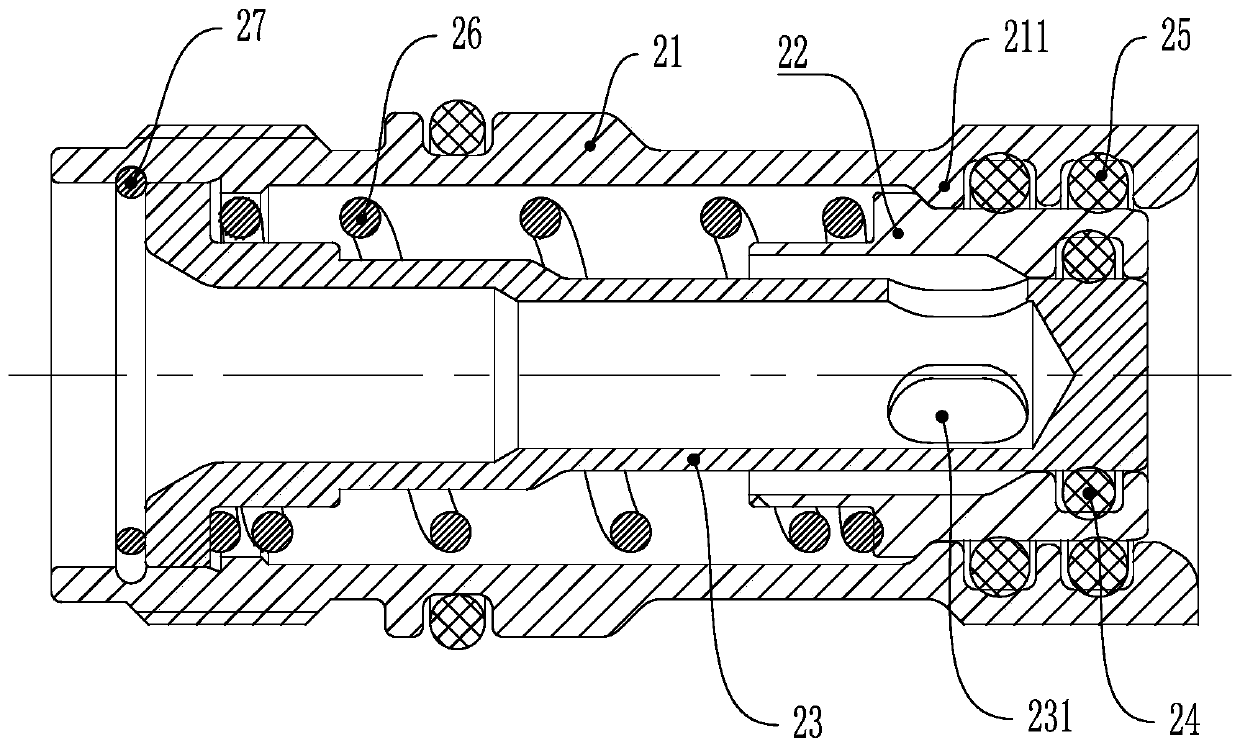

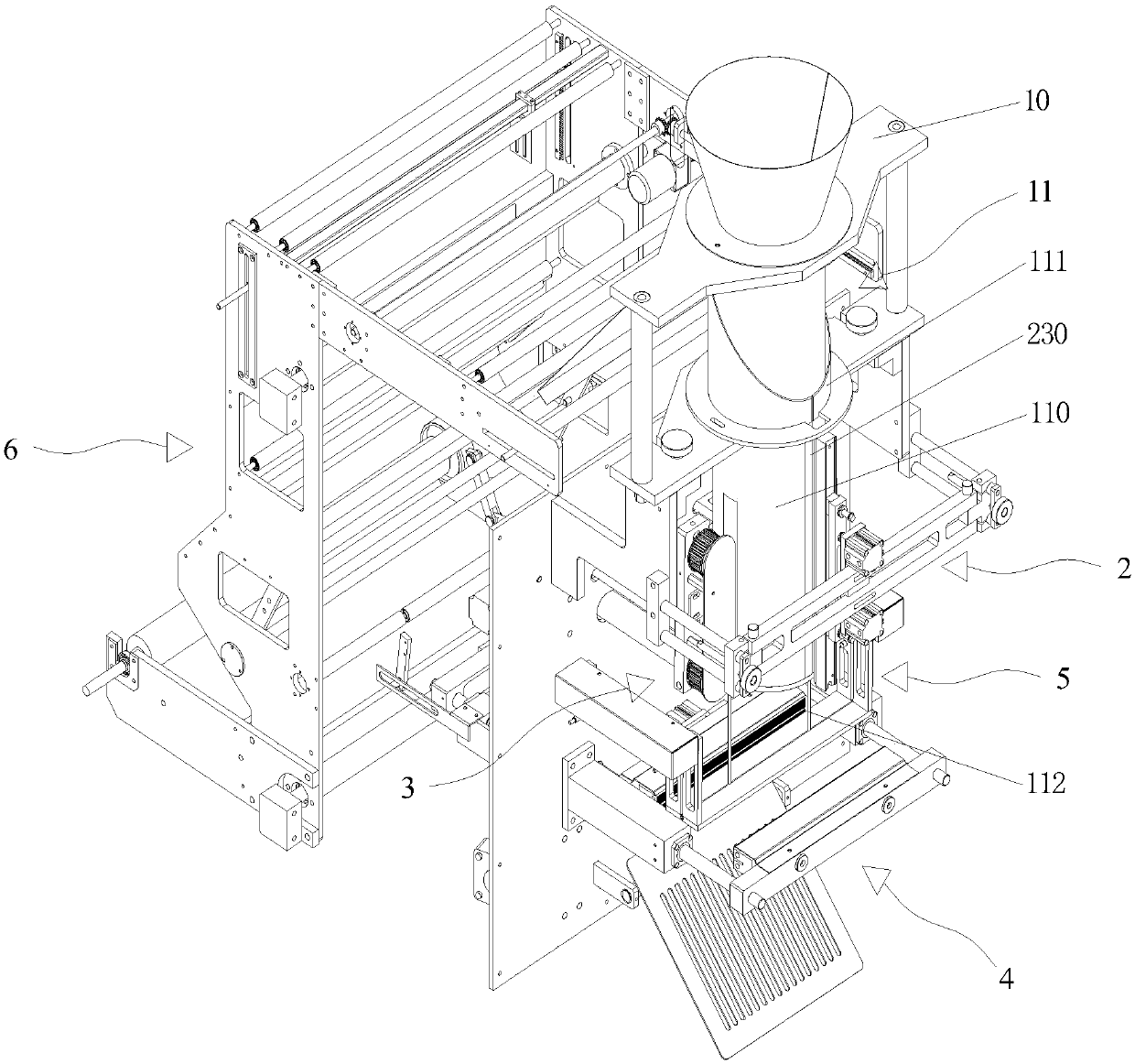

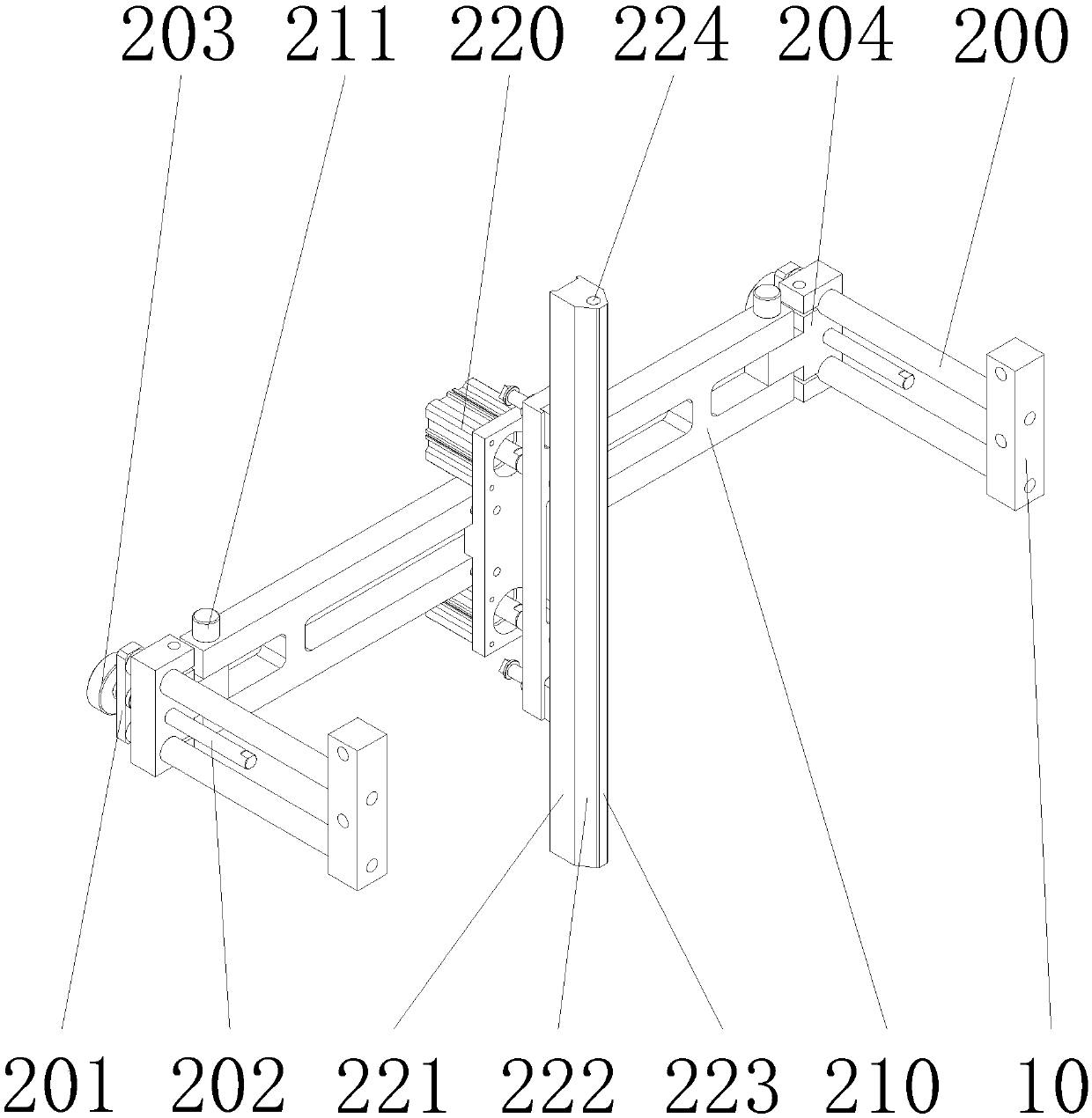

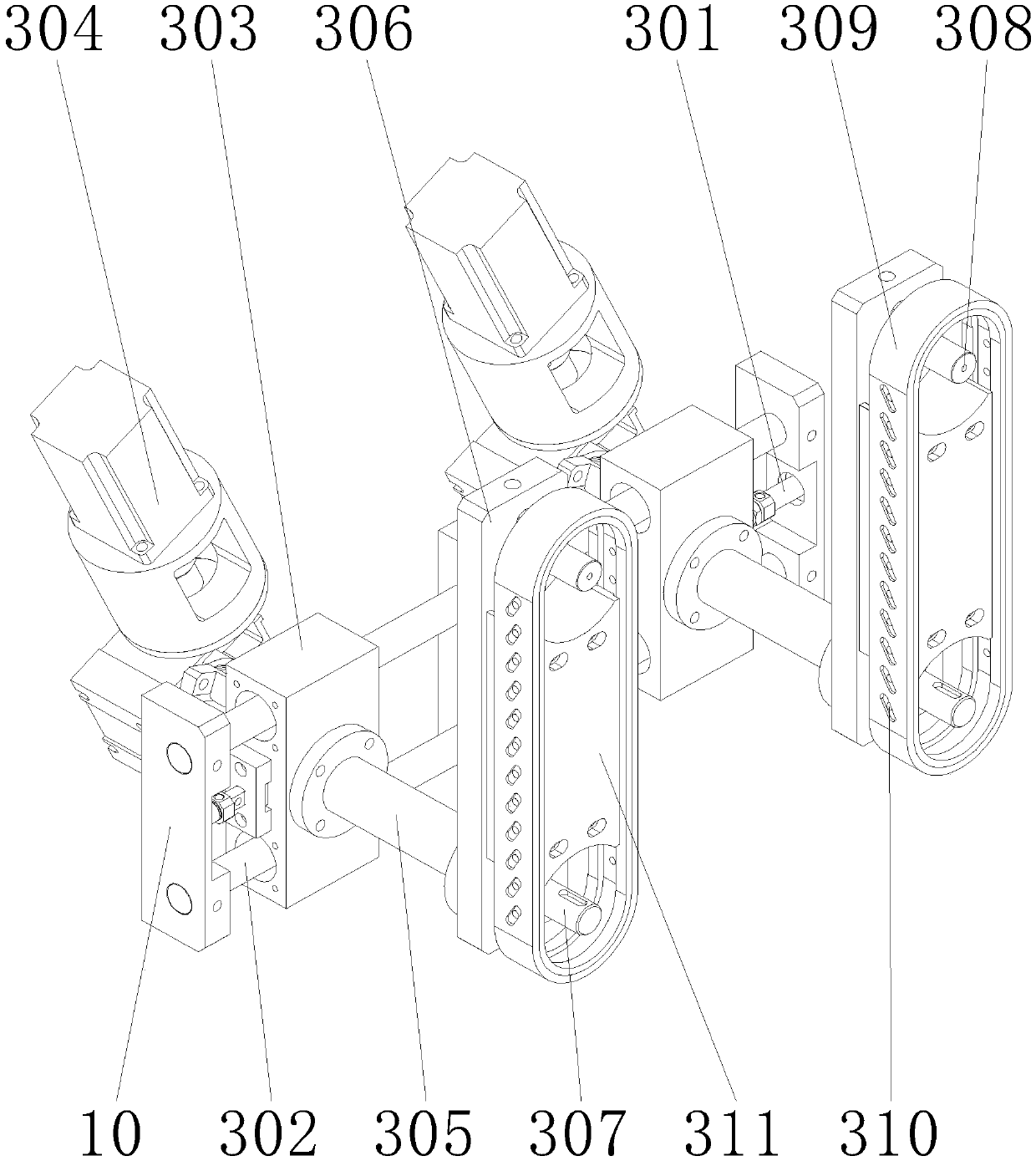

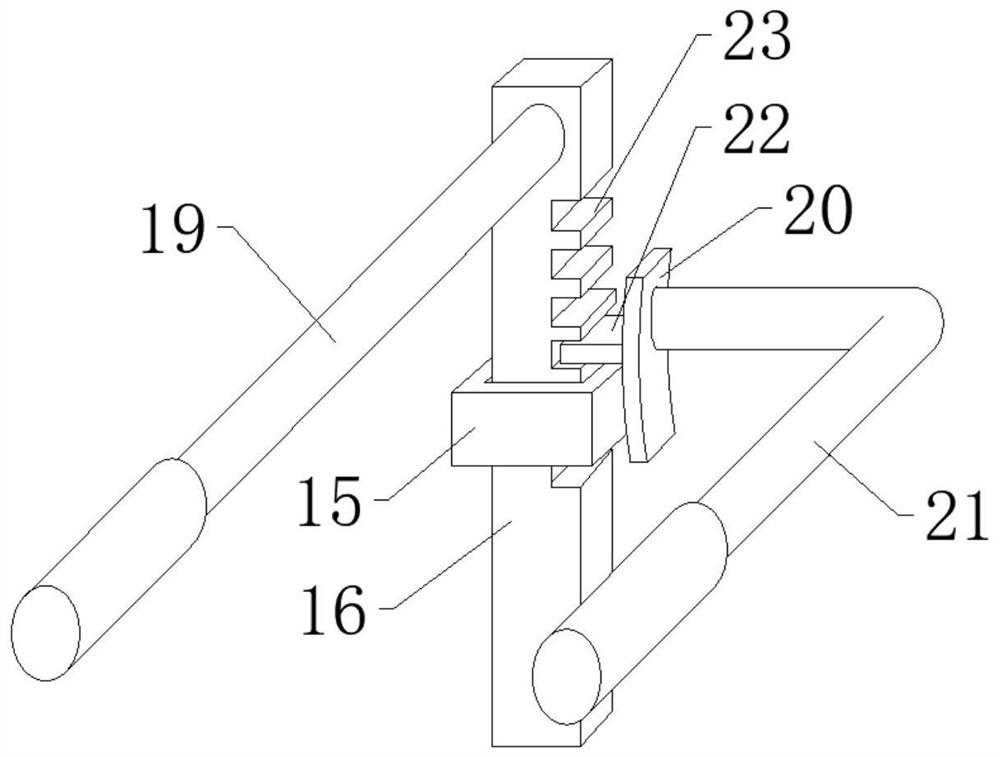

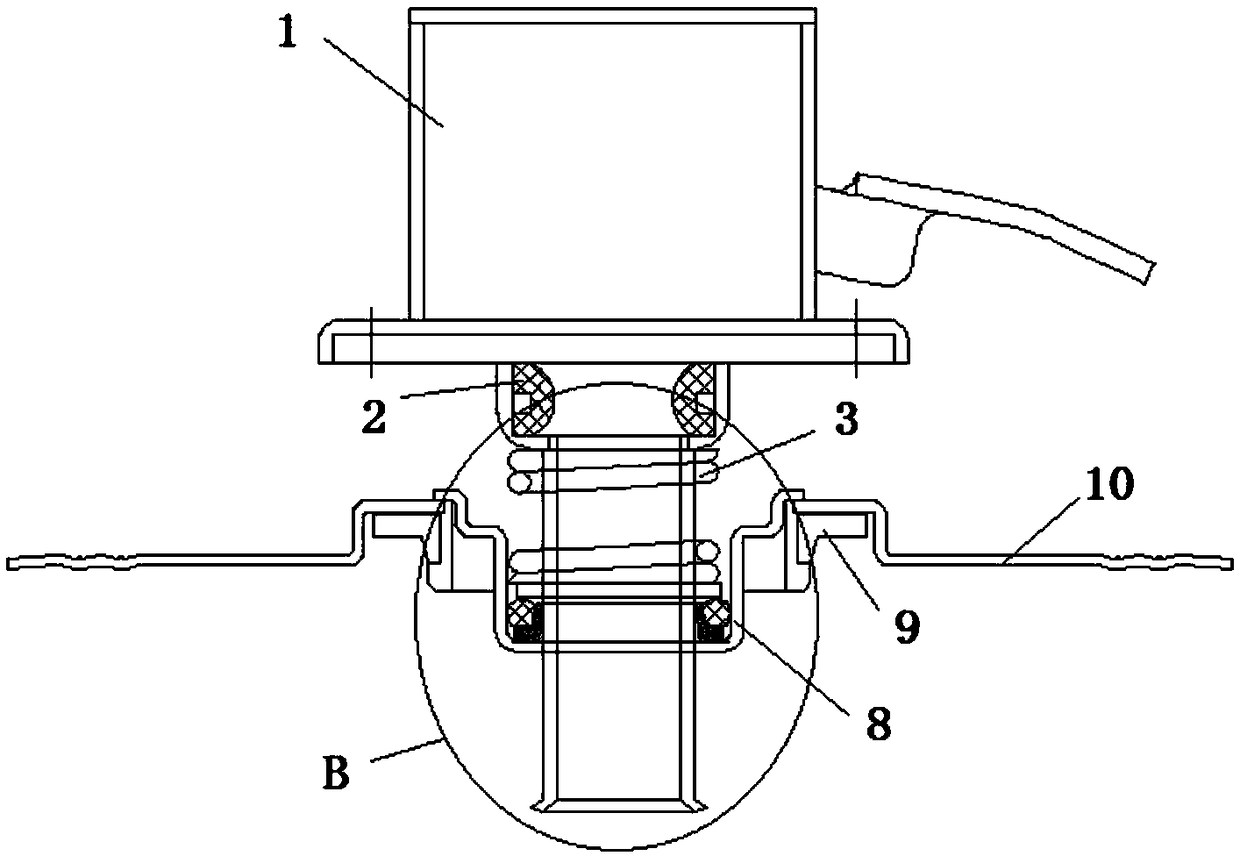

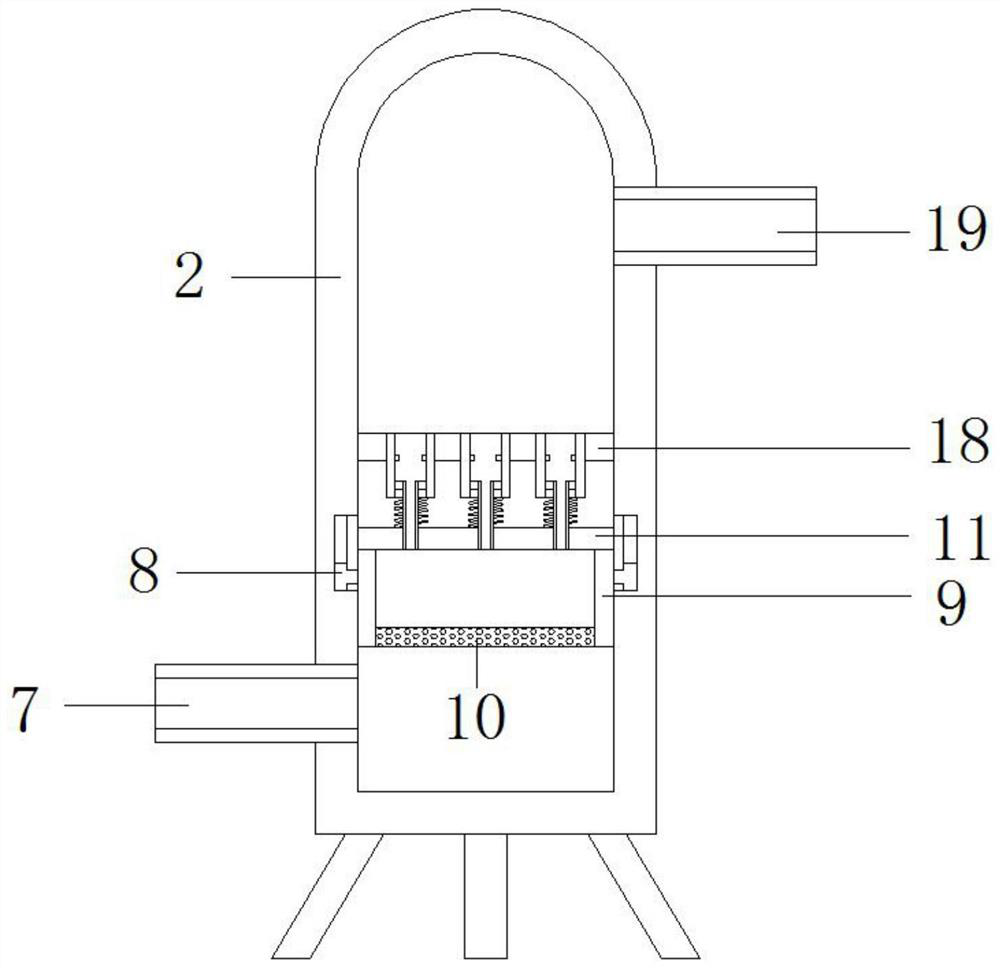

Micro-miniature under-pressure pluggable fluid connector

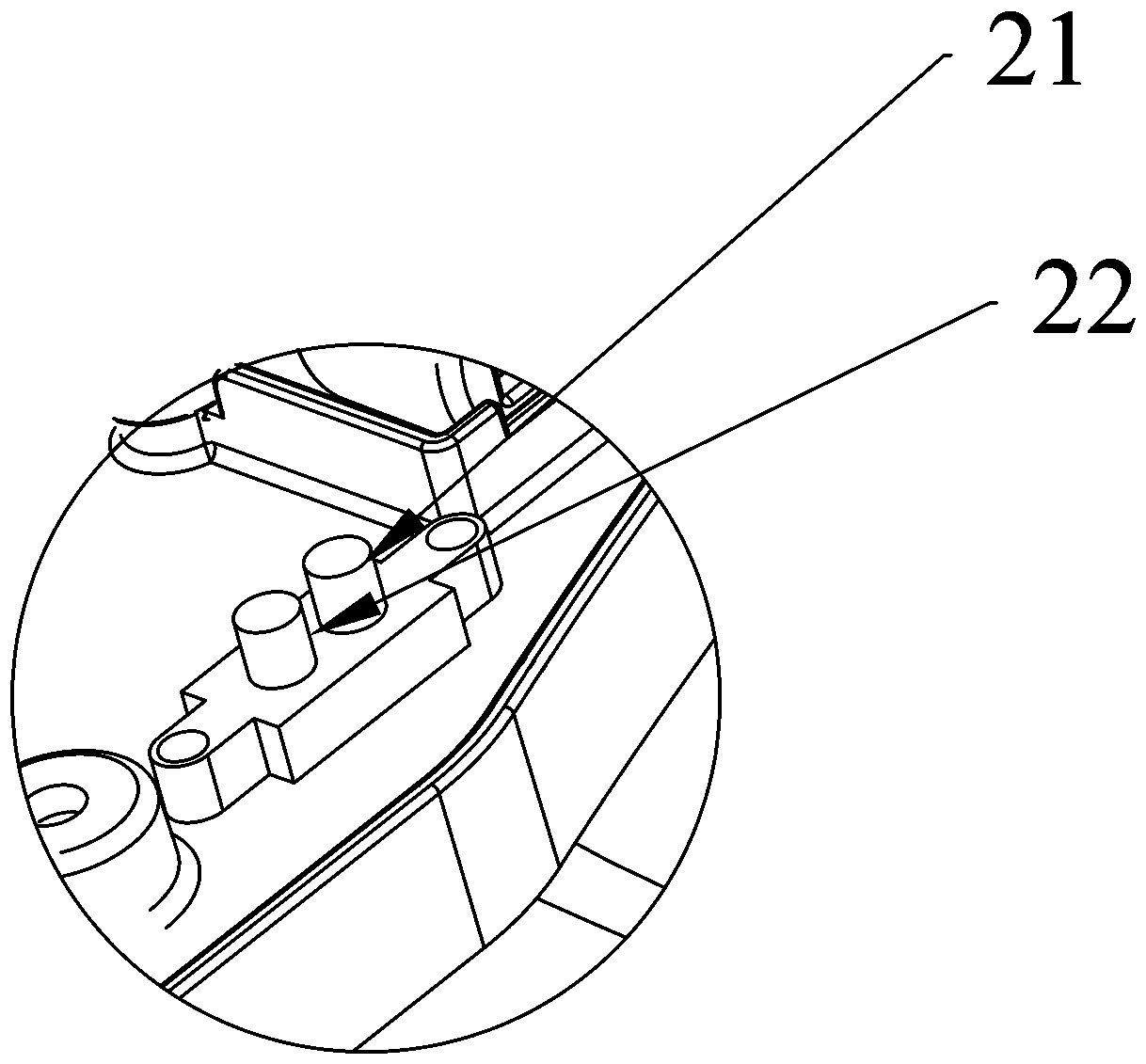

ActiveCN110671562AImprove stabilitySmall circulation resistanceCouplingsEngineeringMechanical engineering

The invention provides a micro-miniature under-pressure pluggable fluid connector. The micro-miniature under-pressure pluggable fluid connector comprises a plug and a socket. The plug comprises a plugshell and a sealing assembly. The sealing assembly comprises a sleeve and a sealing block. A locating sleeve is arranged at the rear end of the plug shell. The locating sleeve abuts against the sleeve through a first spring. The inner wall of the front end of the plug shell is provided with a first limiting part. A first seal ring is arranged between the sealing block and the plug shell. The socket comprises a socket shell and a sealing rod assembled in the socket shell. The sealing rod is sleeved with a second spring and a sealing ring. The front end of the second spring abuts against the sealing ring, and the rear end of the second spring abuts against the sealing rod. The inner wall of the front end of the socket shell is provided with a second limiting part. The inner side of the sealing ring and the sealing rod form sealing through a second seal ring. The front end of the sealing rod is provided with a plurality of through holes. During operation of the micro-miniature under-pressure pluggable fluid connector, no any seal ring is exposed in fluid, so that the seal rings are prevented from being washed away; and moreover, through the special sealing assembly, the stability ofthe connector is improved, the flow resistance of fluid is reduced, and the fluid flux is increased.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Sprouting vegetable culturing method

InactiveCN105875377AOmit the step of soaking the seedsSimple and fast operationGrowth substratesCulture mediaCell buddingBiology

The invention discloses a sprouting vegetable culturing method, belonging to the technical field of vegetable cultivating. The sprouting vegetable culturing method comprises the following steps: (1) seed selection: picking out injured seeds, and culturing uninjured seeds; (2) seeding: paving a matrix in a mesh disc, and flatly paving to-be-cultured seeds on the matrix; (3) buffing: wetting the seeds with mist, and keeping the seeds wet until budding; (4) growth: introducing flowing water from the lower part of the mesh disc, and enabling the water surface to be in contact with buds of the seeds until the buds grow to a harvesting height, wherein the seeds are not soaked in water; and (5) harvesting: harvesting the sprouting vegetables by cutting from the roots of the buds. The sprouting vegetable culturing method has the advantages that the operation is simple, the cost is low, and the cultured sprouting vegetables are healthy and free of pollution. The sprouting vegetable culturing method is particularly suitable for culturing the sprouting vegetables in families.

Owner:刘海瑞

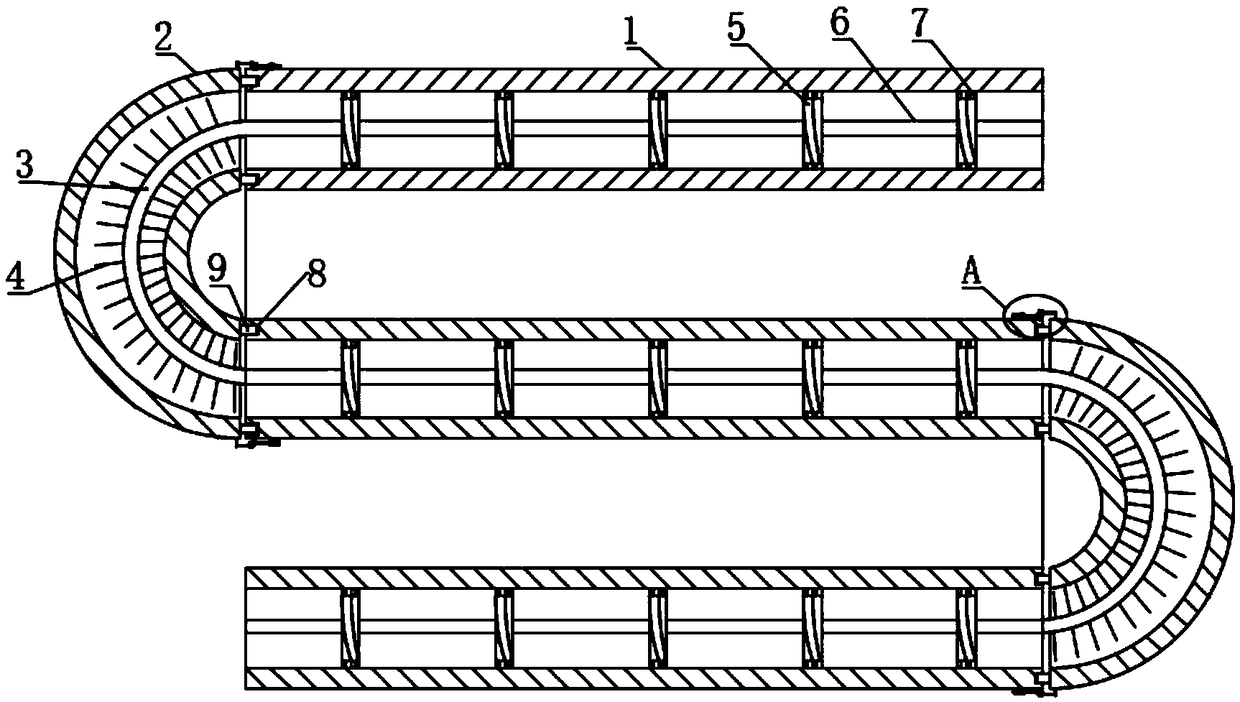

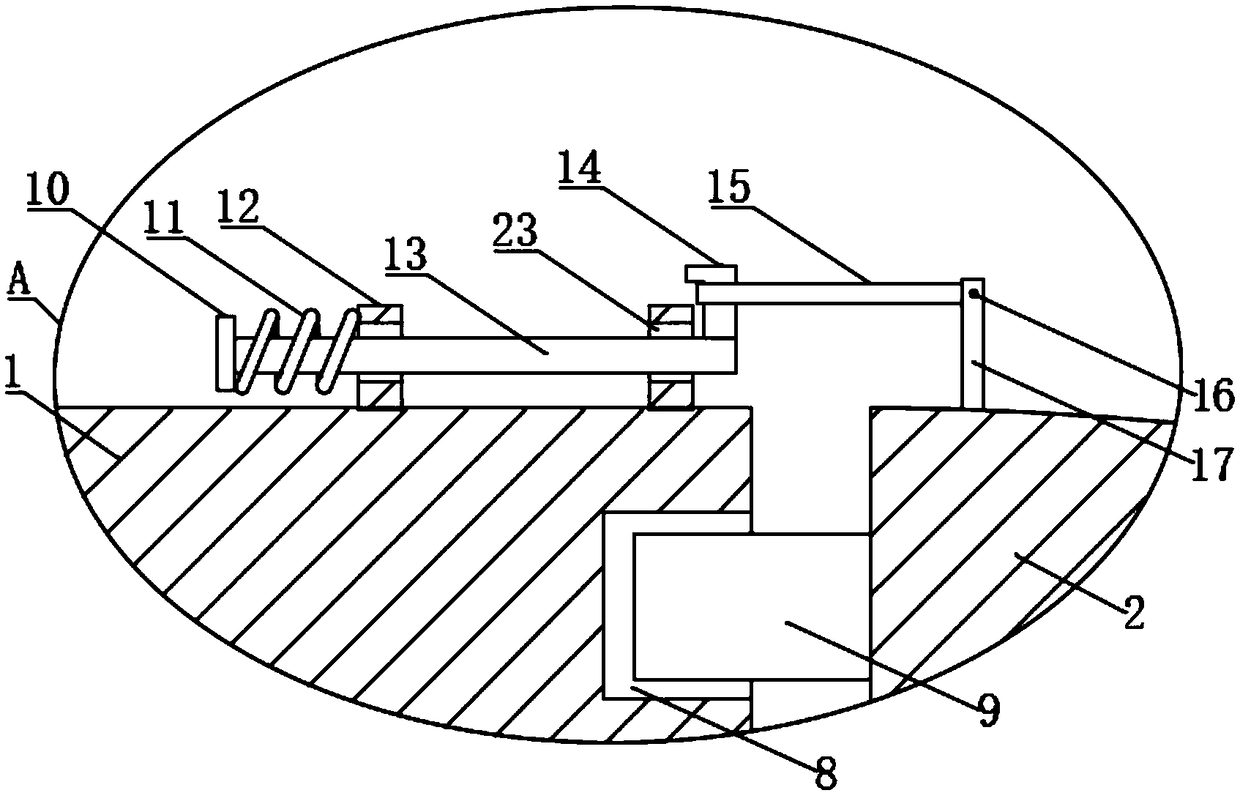

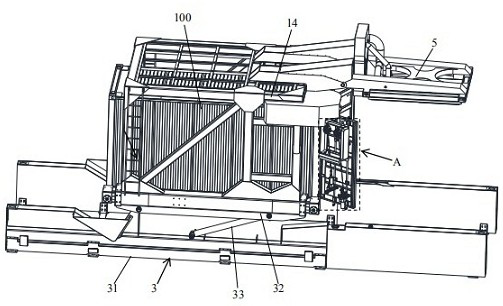

Packaging bag forming machine

InactiveCN109625371ANot easy to spillHigh degree of automationWrapper twisting/gatheringSuccessive articlesEngineeringMechanical engineering

The invention discloses a packaging bag forming machine. The packaging bag forming machine includes a rack, a feeding mechanism, a bag forming machine, a film pulling mechanism, a back sealing mechanism, a horizontal sealing mechanism and a buffer mechanism, wherein the feeding mechanism is arranged on the rack for precise releasing and conveying of packaging films, the bag forming machine folds the packaging films into a cylinder shape and fills goods, the film pulling mechanism is located at one side of the bag forming machine for pulling the packaging films folded into the cylinder shape forward, the back sealing mechanism is located at one side of the bag forming machine to seal the side edge of the cylindrical packaging films, the horizontal sealing mechanism is located on the lower part of the bag forming machine to seal the upper and lower ends of the cylindrical packaging films and cut the cylindrical packaging films into separate packaging bags, and the buffer mechanism is located between the bag forming machine and the horizontal sealing mechanism and can be clamped on the packaging films for packing buffer after horizontal sealing. According to the packaging bag formingmachine, the to-be-packaged goods can be automatically packaged into the package bags, the degree of automation is high, the manpower is saved, the goods after packaging is neat and attractive, the amount of the filled goods is accurate, and the filled goods is not prone to being spilled.

Owner:昆山迈格金相机械设备有限公司

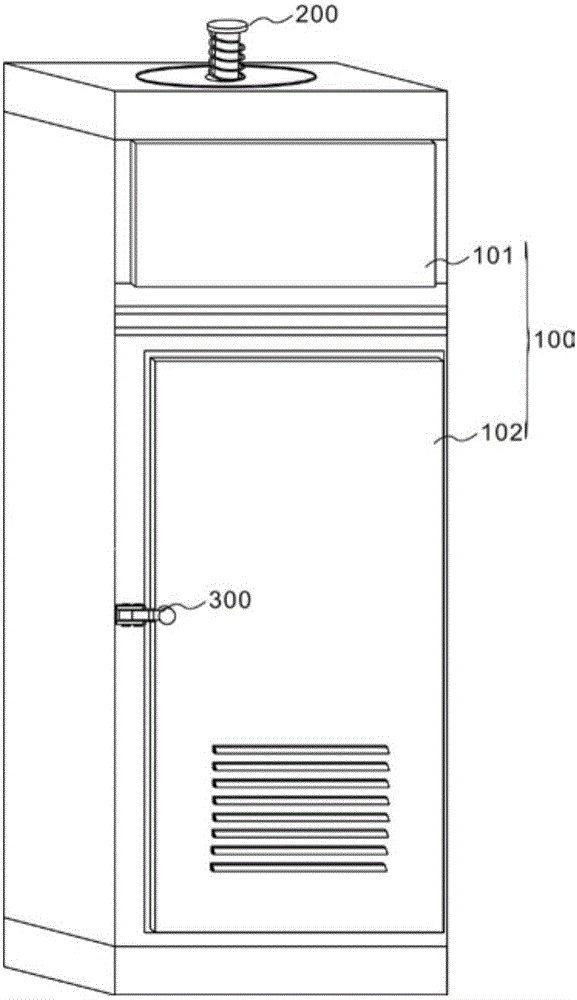

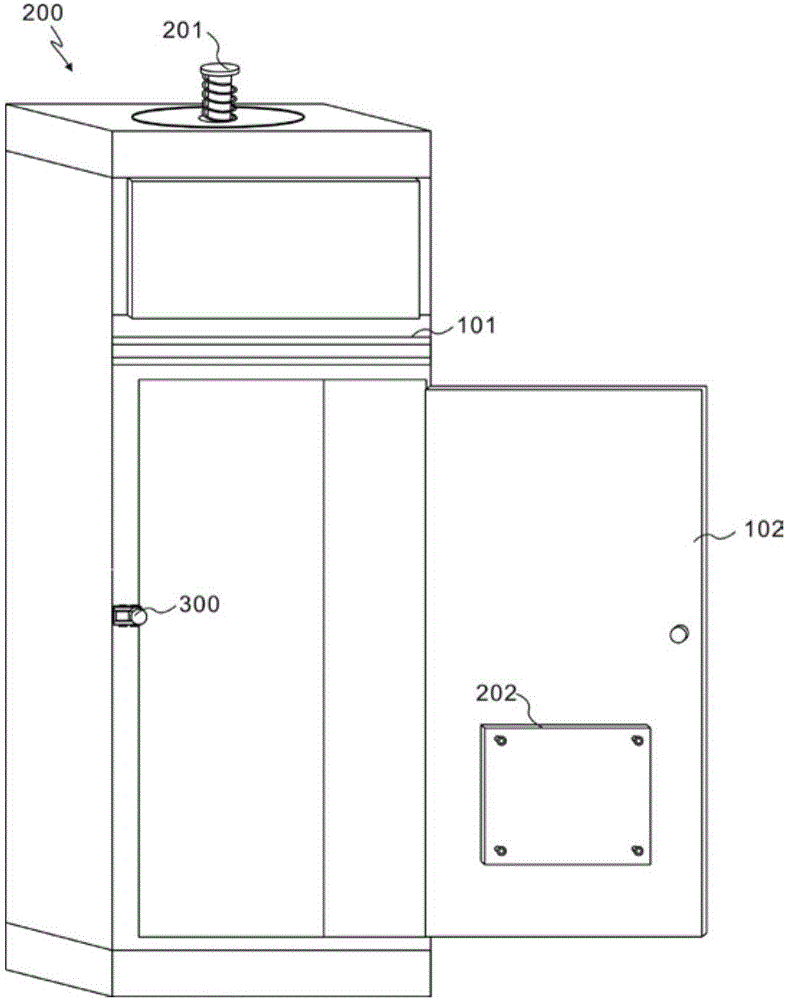

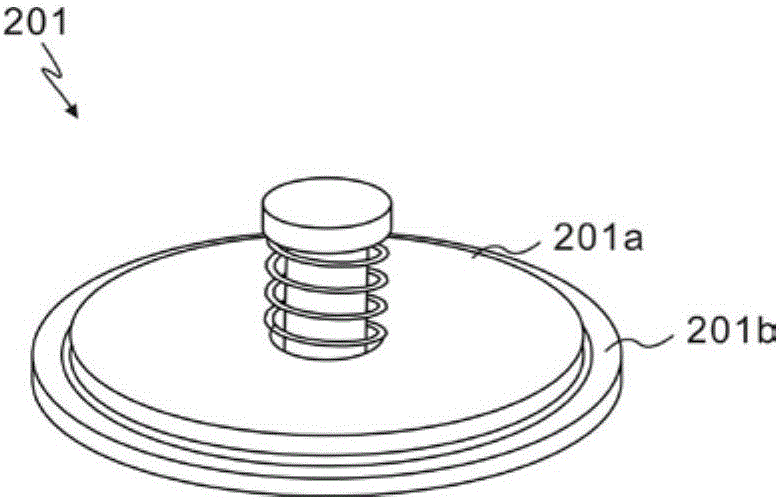

Protection structure of intelligent switch cabinet

InactiveCN107528237AEasy dischargeAvoid damageSwitchgear arrangementsSubstation/switching arrangement casingsSelf lockingHigh pressure

The invention discloses a protection structure of an intelligent switch cabinet, which includes a bearing assembly with accommodating space, the bearing assembly includes a cabinet body and a cabinet door, and one end of the cabinet door is arranged on the cabinet body through a hinge; and a protection device, It includes a venting unit and a blocking unit, the venting unit is arranged on the top of the cabinet body of the bearing assembly, and the blocking unit is arranged on the inner side of the cabinet door of the bearing assembly; the venting unit arranged on the cabinet body and the blocking unit installed on the inside of the cabinet door can be When the switchgear leaks, the high-temperature and high-pressure gas will be quickly discharged from the top of the cabinet, so as to avoid the explosion of the switchgear and damage to the adjacent switchgear. , which effectively improves the safety performance of the intelligent switchgear, and closes the cabinet door through the self-locking component, and can fasten the cabinet door to prevent it from blowing up when the air is deflated. It is convenient and reliable to use, and is easy to promote and use.

Owner:BAOHENG NEW ELECTRIC GRP

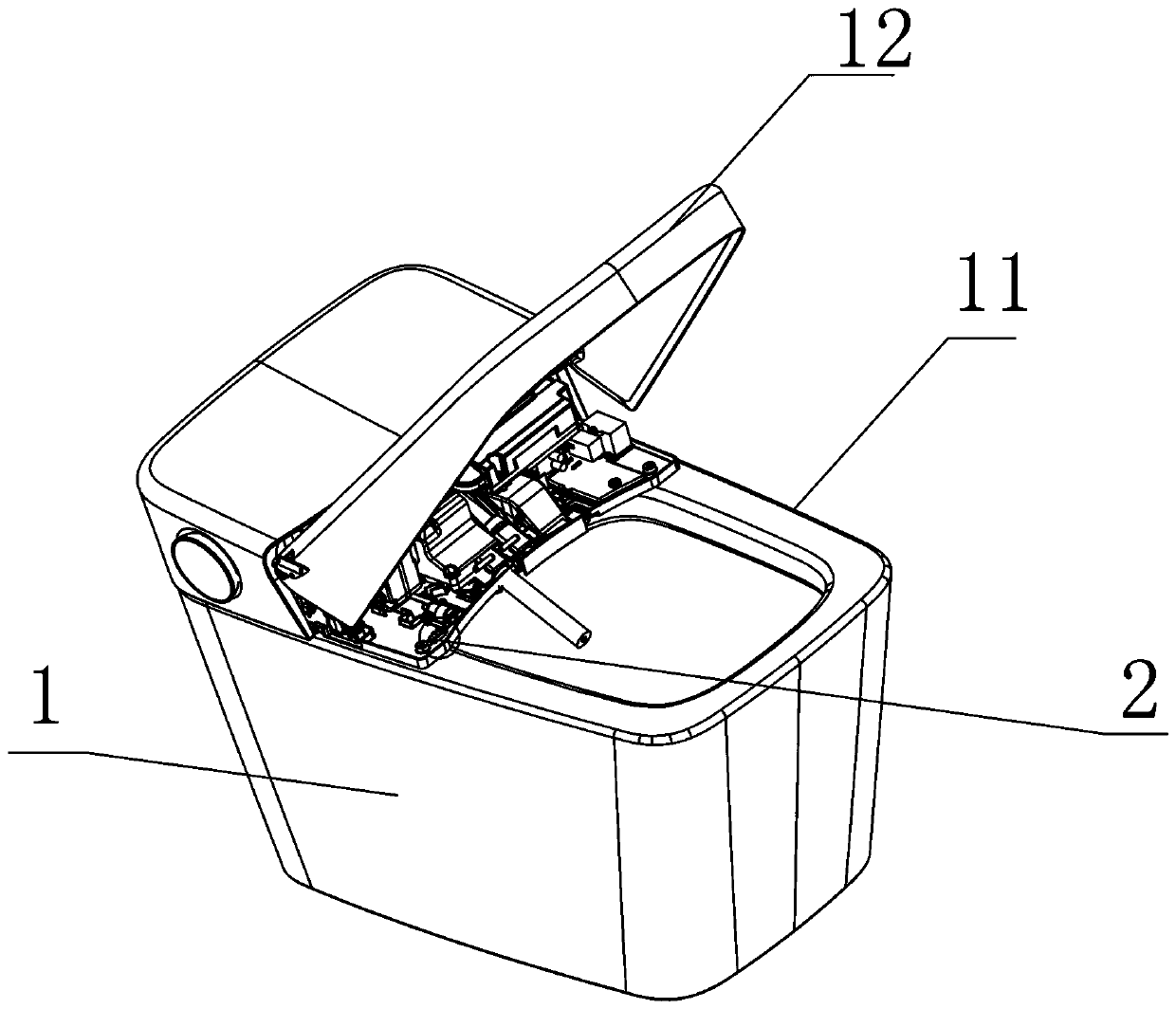

Intelligent closestool adaptive to excrements and urine and control method

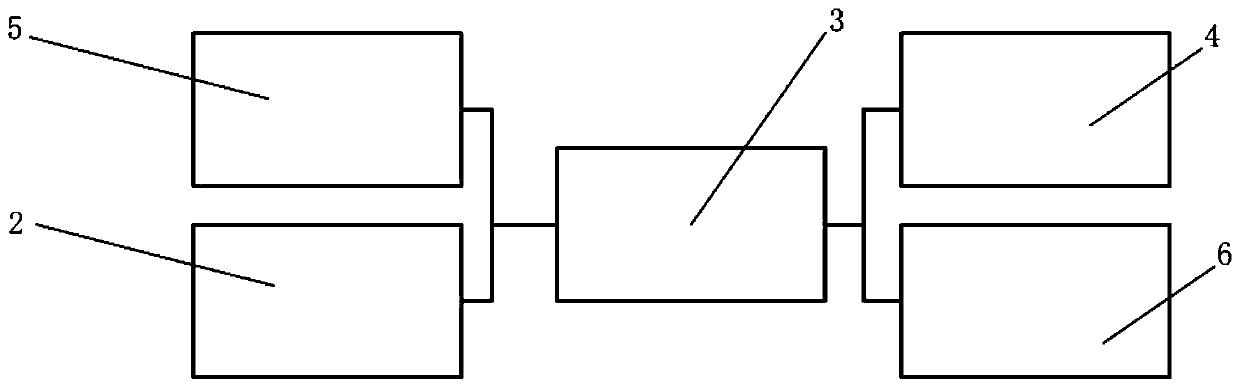

PendingCN107816099AReduce the possibility of bacterial infectionConserve waterFlushing devicesLavatory sanitoryControl cellEmergency medicine

The invention discloses an intelligent closestool adaptive to excrements and urine and a control method. The intelligent closestool comprises a closestool body, a gas detection unit, a control unit and a washing unit, wherein the gas detection unit and the washing unit are arranged in the closestool body and electrically connected with the control unit; the gas detection unit is used for measuringa urine identification gas concentration value and an excrement identification gas concentration value in the closestool body and transmitting the values to the control unit; and the control unit controls the washing unit to execute large flush or small flush according to a relationship between the urine identification gas concentration value and the excrement identification gas concentration value and a preset value. The invention further provides a control method for the intelligent closestool. According to the intelligent closestool and the control method disclosed by the invention, the function of executing the large flush when the excrement of a user is judged and executing the small flush when the urine of the user is judged can be realized, the water is saved, and the user experience is improved.

Owner:JOMOO KITCHEN & BATHROOM

Evaporator with heat exchange assembly convenient to clean

PendingCN109458769AReasonable structureFunctionalEvaporators/condensersNon-rotary device cleaningEngineeringEvaporator

The invention discloses an evaporator with a heat exchange assembly convenient to clean. The evaporator comprises straight pipes, elbow pipes, cleaning circular rings, horizontal rods and short brushes. The straight pipes and the elbow pipes can be disassembled. The two end faces of each elbow pipe are fixedly provided with rubber protrusions clamped to annular clamping grooves formed in the endsof the corresponding straight pipes. One elbow pipe and two straight pipes are integrally assembled to form a U-shaped structure. The horizontal rods penetrate through the straight pipes. The horizontal rods are sleeved with the cleaning circular rings. The outer edges of the cleaning circular rings are uniformly provided with the short brushes. In the evaporator provided by the invention, the straight pipes and the elbow pipes are detachably connected. When the elbow pipes are dismantled from the straight pipes, the inner walls of the elbow pipes are made to slide over the surfaces of long brushes, and the inner walls of the elbow pipes can be cleaned; the horizontal rods are made to move back and forth by pulling a flexible steel wire back and forth, so that the cleaning circular rings fixedly connected to the horizontal rods move back and forth on the inner walls of the straight pipes, and at the moment, the short brushes located on the edges of the cleaning circular rings can cleanthe inner walls of the straight pipes. The evaporator is convenient to use.

Owner:江苏世林博尔制冷设备有限公司

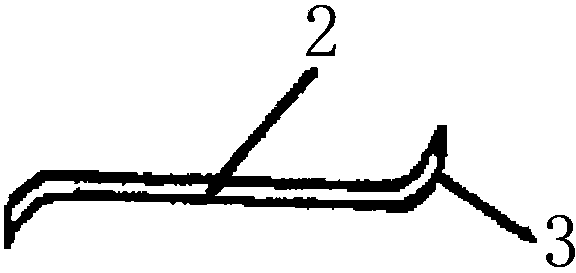

Milling device for foundry sand mould pouring gate

InactiveCN103350194AClean up and save effortInto a stableFoundry mouldsFoundry coresFoundryMilling cutter

The invention discloses a Milling device for a foundry sand mould pouring gate, which is characterized in that a ladder-shaped shovel head is connected with the lower end of a handle, bent milling cutters are respectively arranged on two side edges of the shovel head, and a rotary handle is arranged at the upper end of the handle. Through the arrangement, the milling device can clear up the connection part of a foundry sand mould pouring cup and a sprue quickly in a labor-saving manner, so that the pouring cup and the interior of the sprue are in smooth transition with each other, molten metal enters into a casting mold stably, the turbulence and the washing to the casting mold are avoided, no gas is involved in pouring, and the casting finished product rate is increased.

Owner:诸城市华欣铸造有限公司

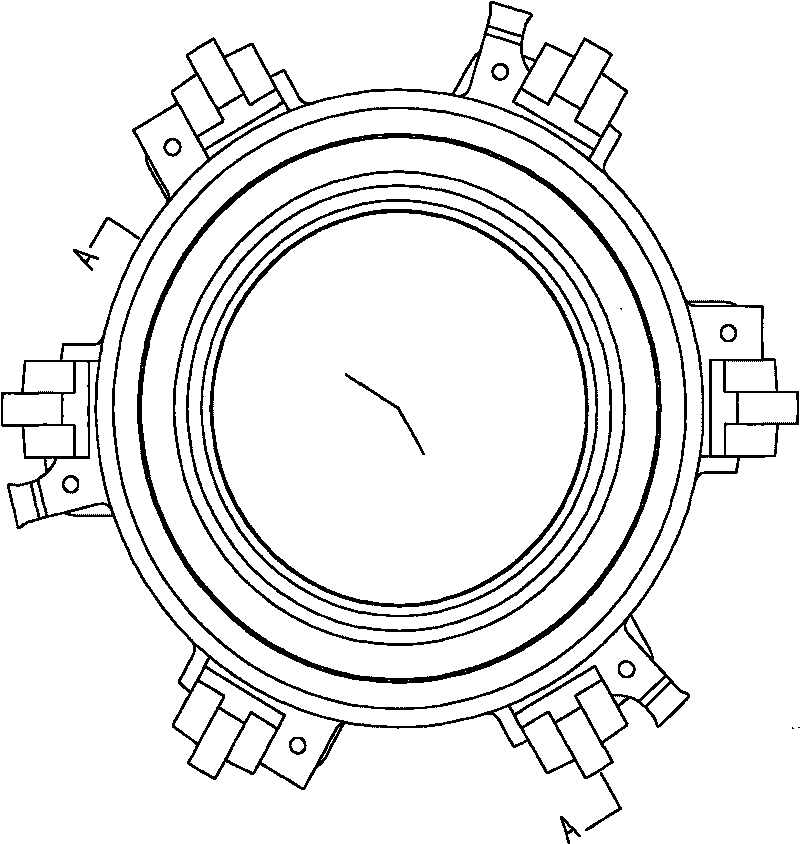

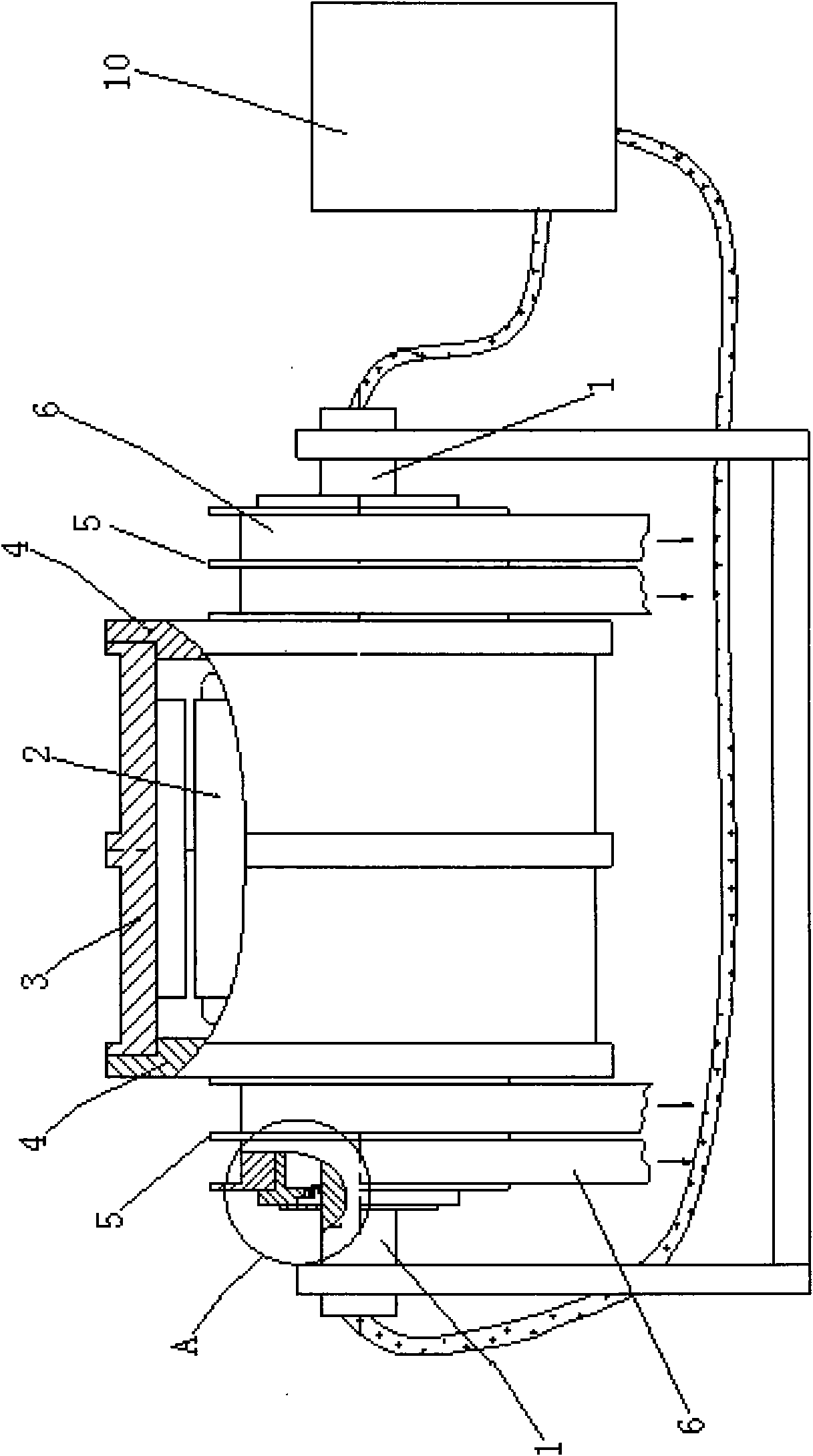

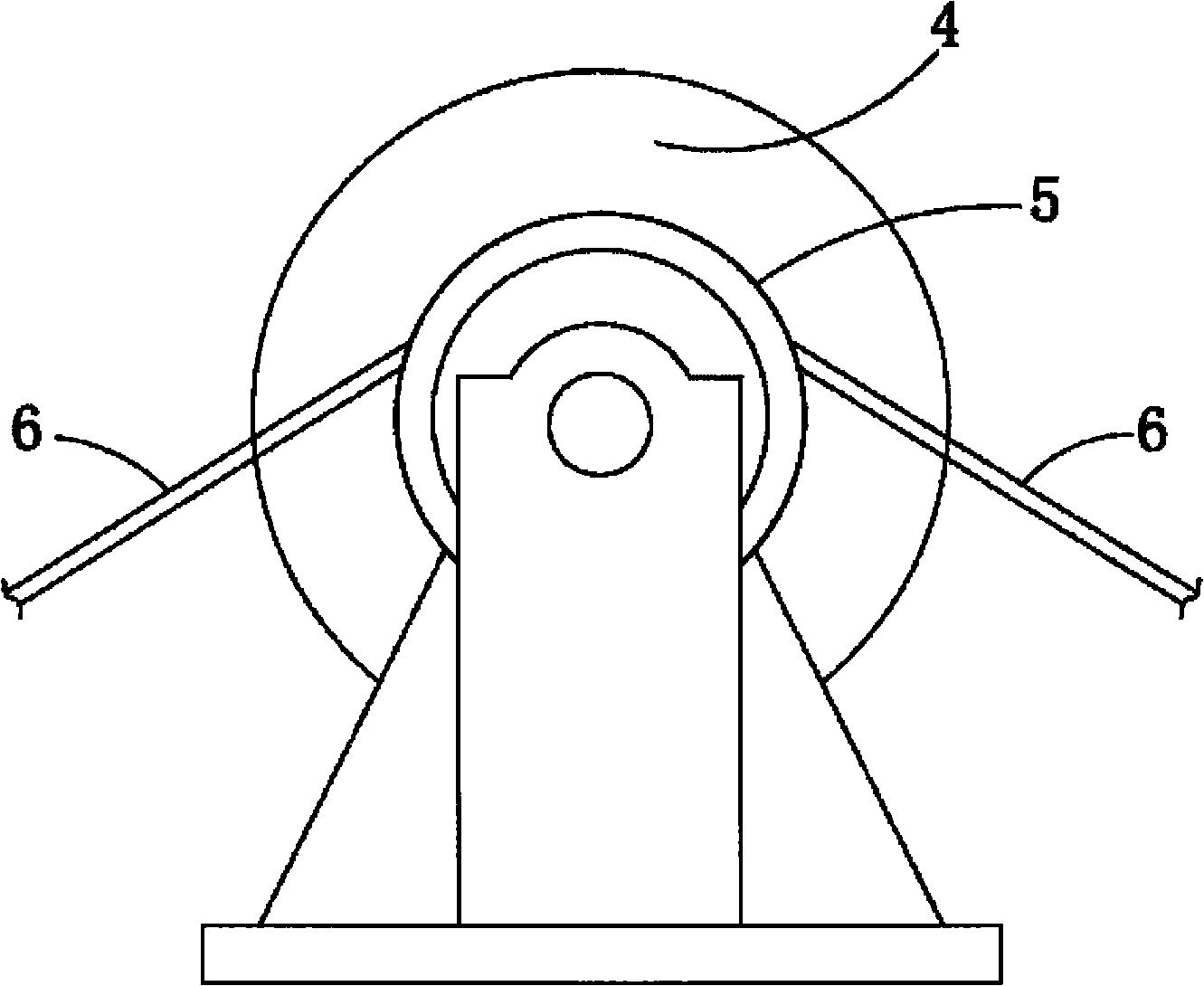

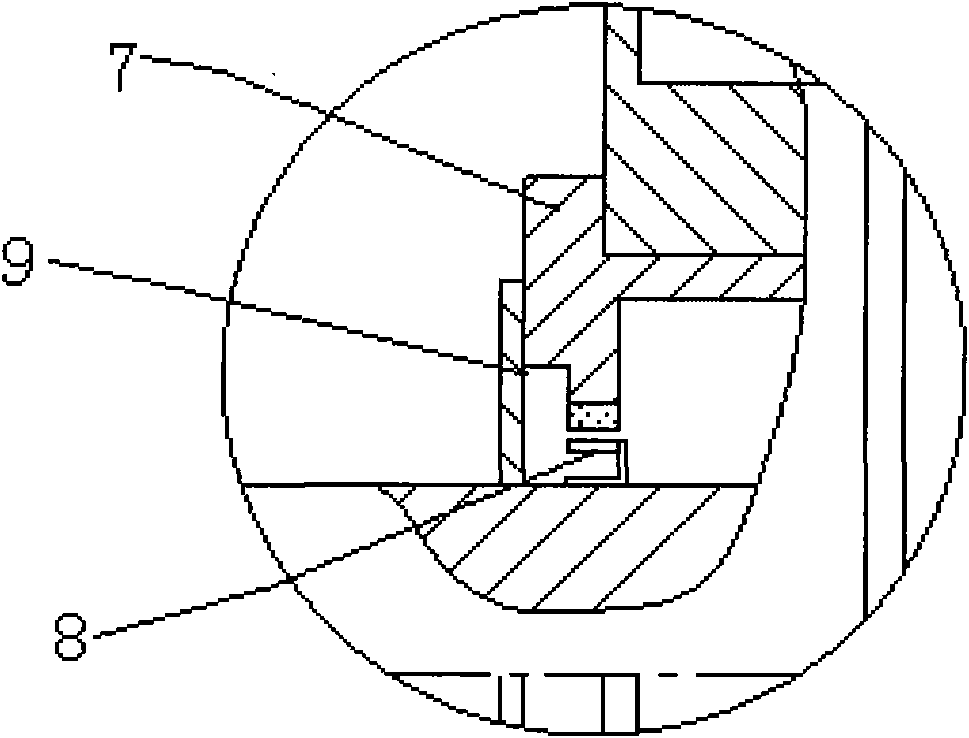

Brushless DC motor for energy-saving oil extractor

ActiveCN101854107AImprove work efficiencyReduce the possibilityMagnetic circuit rotating partsMechanical energy handlingStatorHigh torque

The invention discloses a brushless DC motor for an energy-saving oil extractor. As the brushless DC motor adopts a stator with a multilevel magnetic circuit and a barrel outer rotor covered with high performance NdFeB magnet, thus realizing the aims of low speed and high torque; as the structure that a belt is used to directly drive a sucker rod is adopted, the complicated drive mechanism of thecommon beam oil extractor can be omitted, the work efficiency of the oil extractor can be increased and the aim of saving energy can realized; as a Hall sensor with backup is adopted, the possibilityof changing the position sensor is greatly reduced; as the Hall sensor with backup is arranged in a bearing cap, when the sensor is replaced, a dust cap is only needed to remove without disassemblingthe electric motor and the detect of the traditional electric motor that when the position sensor is replaced, the electric motor is needed to disassemble can be avoided; and the stroke of oil extraction both adopts hardware limit and software limit so that the stroke control can be more effective and reliable and kicking can be effectively prevented.

Owner:苏州航天林泉电机有限公司

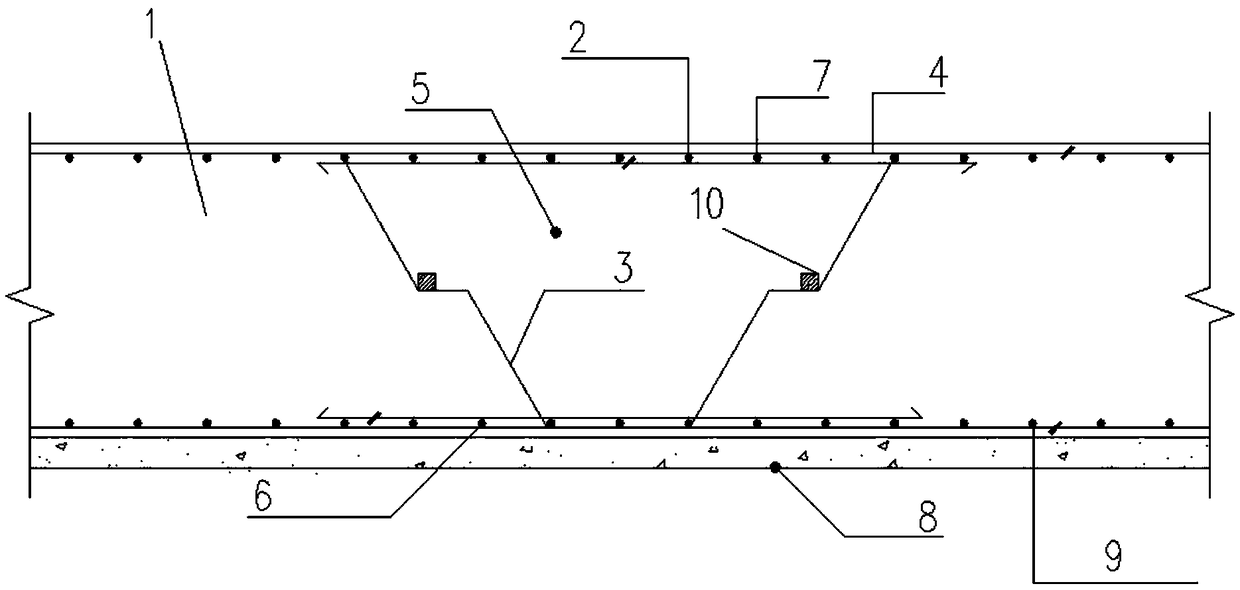

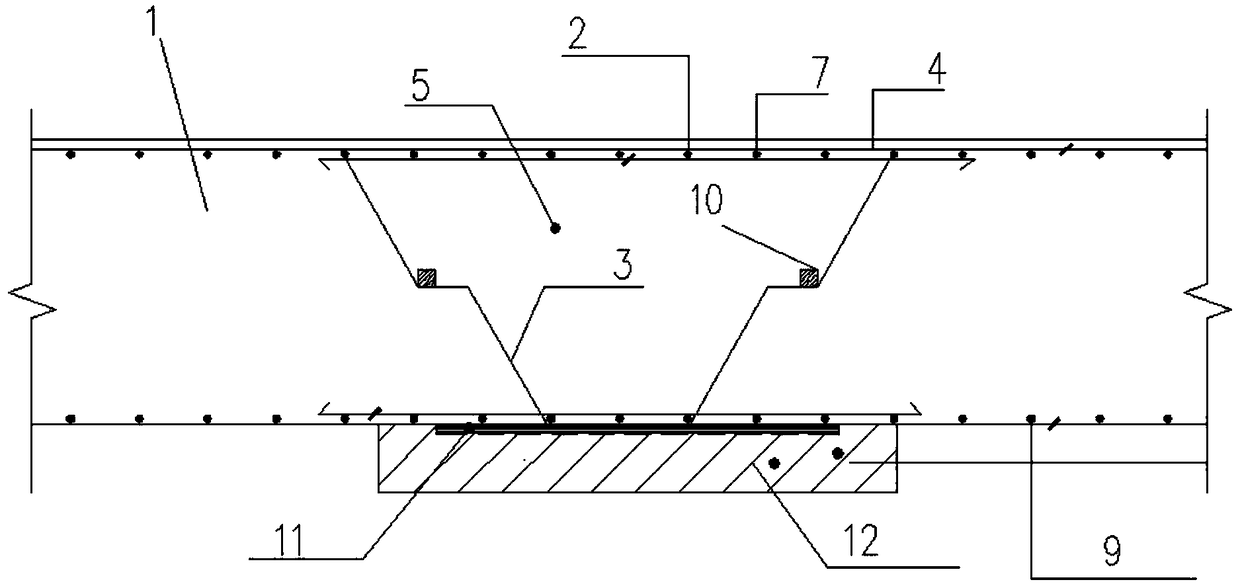

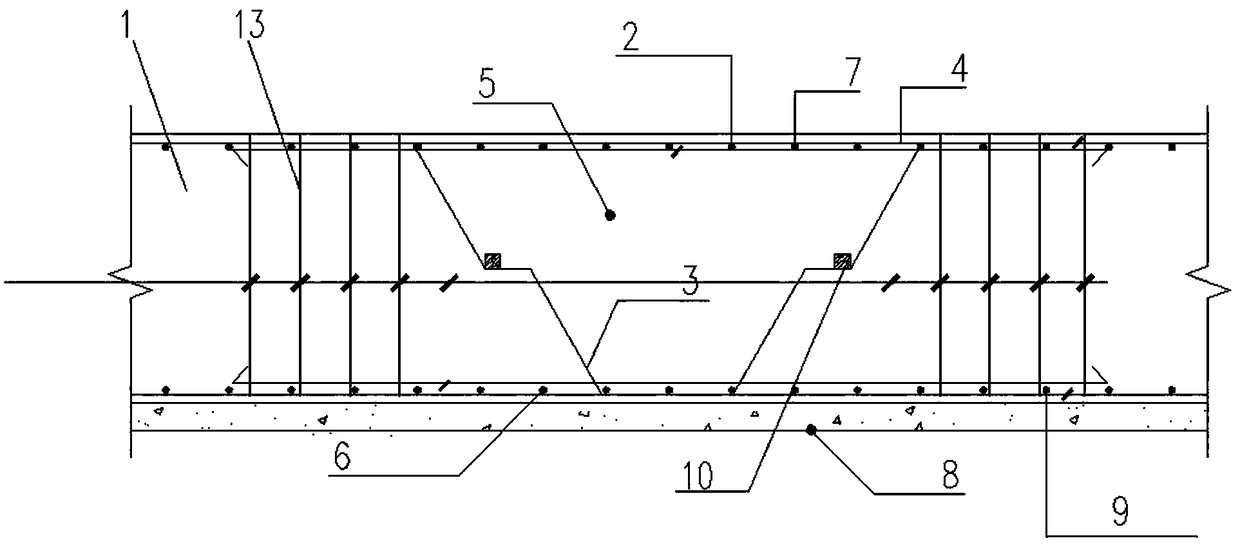

Stair type expansion reinforcing band system and construction method

InactiveCN109024704ASolve the problem of water seepageSimple structureArtificial islandsProtective foundationRebarWater seepage

The invention provides a stair type expansion reinforcing band system and a construction method. The system comprises a concrete bed die. A concrete base body is poured to the upper end of the concrete bed die. Upper run-through reinforcing steel bars and lower run-through reinforcing steel bars are embedded in the concrete base body. Expansion reinforcing bands are arranged in the concrete base body. Post-poured expansive concrete is poured in the expansion reinforcing bands. The section of each expansion reinforcing band is in a slope stair shape. Stair type steel wire nets are attached to the two side walls of each expansion reinforcing band. The steel wire net on each side is fixedly connected with a stair type vertical reinforcing steel bar. The system is simple in structure, the construction method is simple and clear, operation is convenient, the system can be effectively used for expansion post-cast strip pouring construction of most concrete pouring, the problems of ultra-longcomponent cracking and construction joint area water seepage are solved, the construction quality is guaranteed, meanwhile, later rework steps are avoided, engineering cost is saved, and the construction schedule is quickened.

Owner:CHINA MCC17 GRP

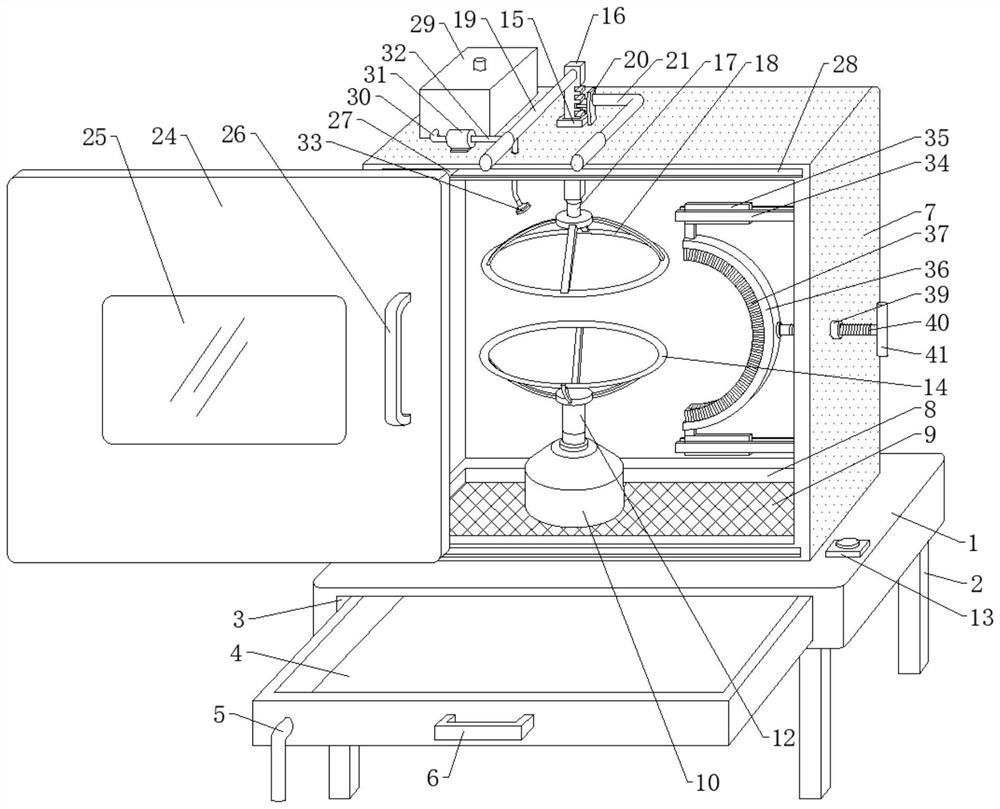

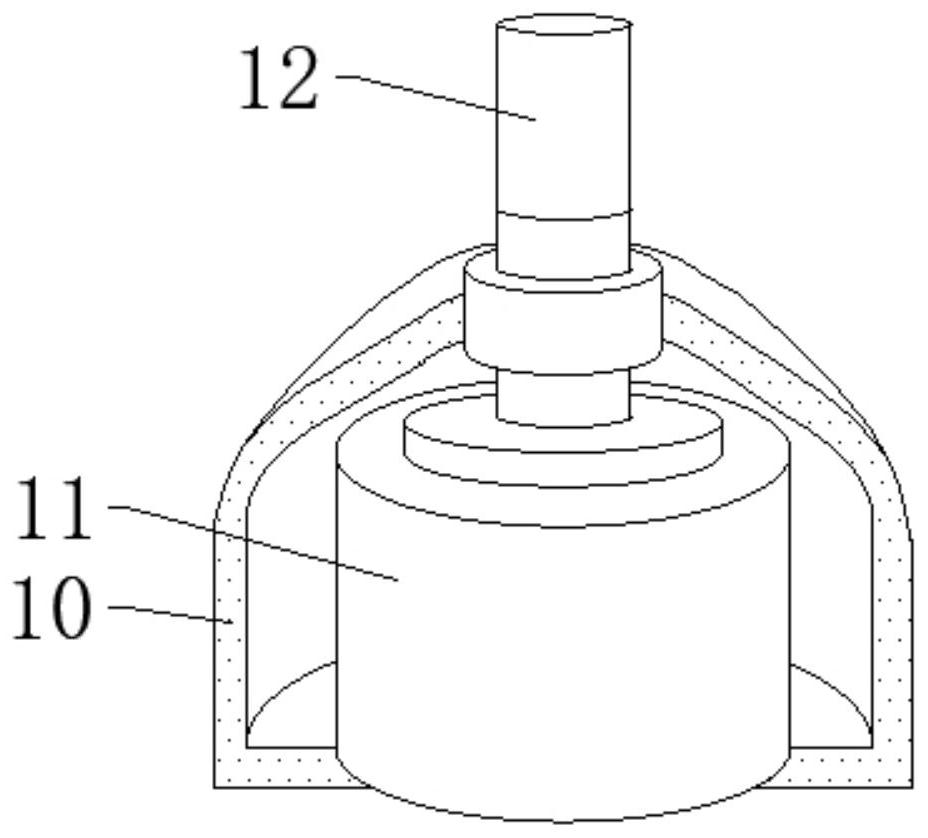

Rapid cleaning device for ball sports equipment

InactiveCN113426084AAchieve cleaningAvoid contaminationBall sportsWater storage tankSports equipment

The invention discloses a quick cleaning device for ball sports equipment, and relates to the technical field of cleaning devices, the quick cleaning device comprises a workbench, a cleaning box is fixedly arranged on the upper surface of the workbench, and a square groove is formed in the bottom side wall of the cleaning box. According to the quick cleaning device for the ball sports equipment, through cooperation of the motor protection box, the driving motor, the first rotating shaft, the control switch and the lower supporting sleeve and cooperation of the square sliding sleeve, the square sliding rod, the second rotating shaft and the upper supporting sleeve, after balls needing to be cleaned are placed into the lower supporting sleeve, a square sliding rod slides in a square sliding sleeve, an upper supporting sleeve can be driven to descend, then a ball can be fixed, basketballs, footballs, volleyballs and the like with different diameters can be clamped and fixed, then water can be directly sprayed to the clamped and fixed balls through cooperation of a water storage tank, a water pumping pipe, a water pump, a water conveying pipe and a spray head, and cleaning of the ball is achieved.

Owner:YANTAI UNIV

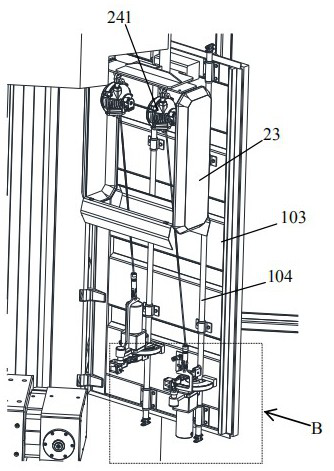

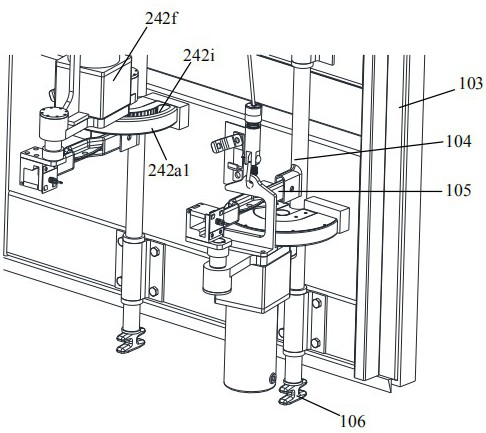

Container packing device

ActiveCN114104764ARealize automatic switchingImprove efficiencyLoading/unloadingStructural engineeringMechanical engineering

The invention discloses a container encasement device which comprises a container supporting seat, a frame, a folding sealing door and a door opening and closing assembly, the container supporting seat is used for supporting and fixing a container, the frame is arranged on the container supporting seat, the folding sealing door is arranged at the top of the frame, and the door opening and closing assembly is arranged on the frame. A filling opening is formed in the folding sealing door; the door opening and closing assembly comprises a rotating arm and a fixing device arranged on the rotating arm, the fixing device can be fixed to a container door of the container, and the rotating arm is used for driving the fixing device to rotate so as to achieve opening and closing of the container door. By the adoption of the technical scheme, the container boxing device is simple in structure and convenient to operate, automatic opening and closing of the container door can be achieved, the door locking process can be completed without climbing of operators, and therefore the overall efficiency of boxing operation is effectively improved.

Owner:中淮集装箱装备科技(天津)有限公司

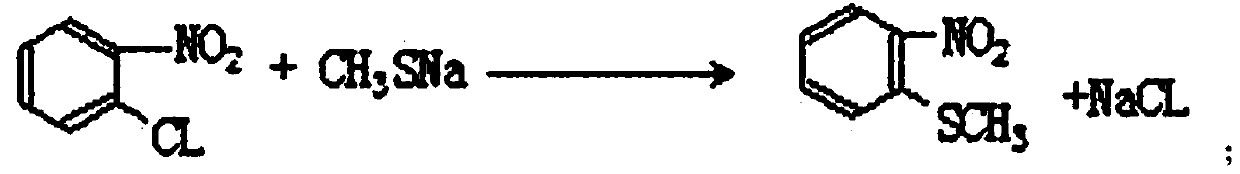

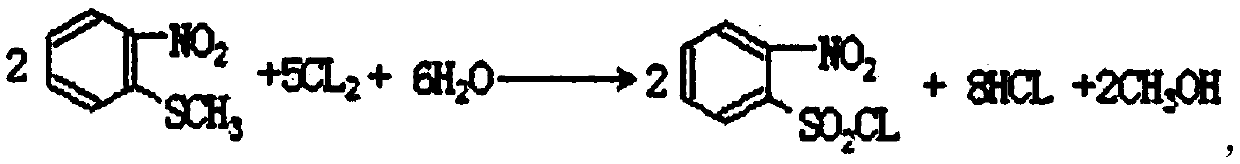

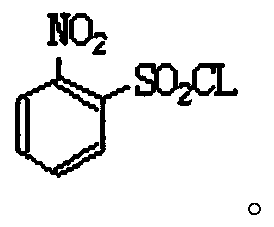

Industrial production method of o-nitrobenzenesulfonyl chloride

InactiveCN110105251ALow toxicityAddressing Purity IssuesOrganic compound preparationSulfonic acid preparationO-nitrochlorobenzeneNitrobenzene

The invention discloses an industrial production method of o-nitrobenzenesulfonyl chloride. The method comprises the following steps that o-nitrochlorobenzene and sodium methyl mercaptide are subjected to an etherification reaction, filtering is conducted, an obtained filter cake is subjected to recrystallization, and through centrifugation separation and drying, a dry product of o-nitrobenzene dimethyl sulfide is obtained; the dry product of o-nitrobenzene dimethyl sulfide is subjected to a chlorination reaction in batches to obtain a wet crude product, an appropriate amount of hydrochloric acid is added in a chlorination reaction system, the chlorination reaction is carried out in a hydrophilic organic acid solvent, and the mole ratio of the o-nitrobenzene dimethyl sulfide to water during the chlorination reaction is 1:(5-15); a finished product of o-nitrobenzenesulfonyl chloride is obtained through refining and drying. Through HPLC detection, the content of the o-nitrobenzenesulfonyl chloride synthesized by means of the method is 98-98.5%; the yield is 0.72-0.75, the acquisition rate is 0.97 or above, the turbidity (ppm) is 1.5-2, and the melting point is 66-67 DEG C. By adopting the hydrophilic organic acid solvent, the problems about large-scale production discharging, yield and quality are solved, and meanwhile the purposes of mixed application and post-treatment separation of large-scale production water-soluble solvents are achieved.

Owner:苏州市泽宸贸易有限公司

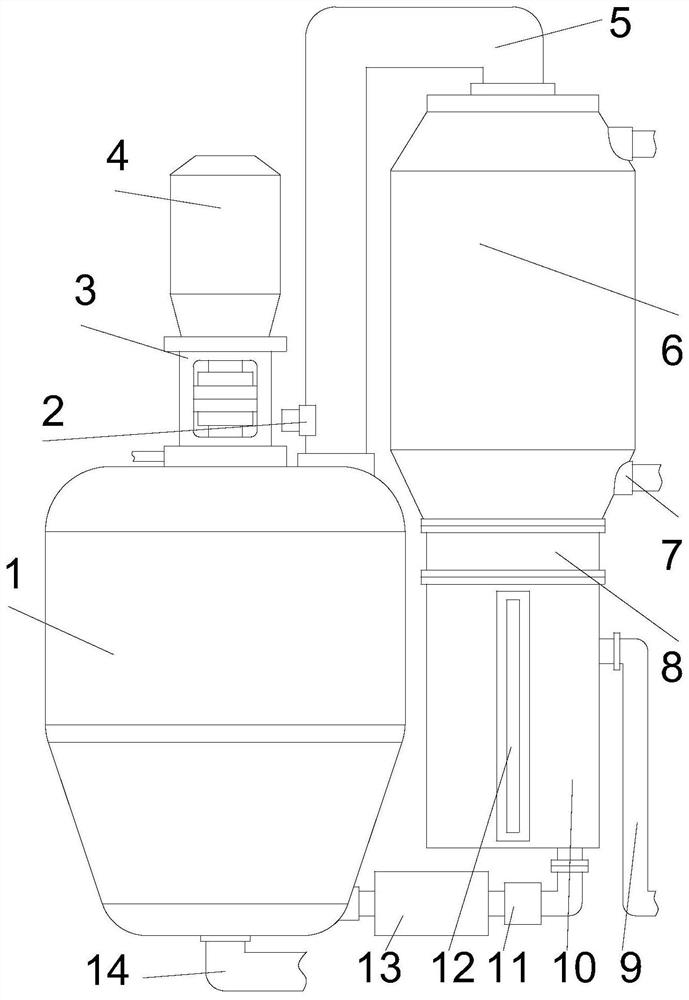

Efficient reaction equipment for rectification

PendingCN112295254AAvoid flushingReasonable designProcess control/regulationProductsElectric machineryStructural engineering

The invention discloses efficient reaction equipment for rectification. The equipment mainly comprises an outer frame, a motor, a steam pipe, a condensation shell, a water passing head, a middle shell, a liquid outlet pipe, a layering shell, a densimeter, an electromagnetic liquid level meter, a metering pump, a middle rod, a pneumatic frame and a condensation pipe,the middle part of the outer frame is fixedly provided with a sealing sleeve, the inner wall of the sealing sleeve is fixedly provided with a wear-resisting sleeve, a middle rod is rotationally installed on the inner side of the wear-resisting sleeve, an air supply cavity is formed in the middle of the middle rod, a speed reducer is fixedly installed in the middle of the top end of the outer frame and fixedly connected with thetop end of the middle rod, and a motor is fixedly installed at the top end of the speed reducer. The equipment is reasonable in structural design, the Luneng efficiency is improved through a built-inefficient Luneng structure, the discharging purity and downstream stability are improved through detachable filtering equipment and an equipartition structure, and material flushing caused by floodingis prevented; and with simple electronic equipment, controllable liquid level control can be achieved, the purity of discharged liquid is guaranteed, and the reaction equipment is provided with a flexibly-changed stirring and scraping structure and is high in practicability.

Owner:苏州市浒墅关化工添加剂有限公司

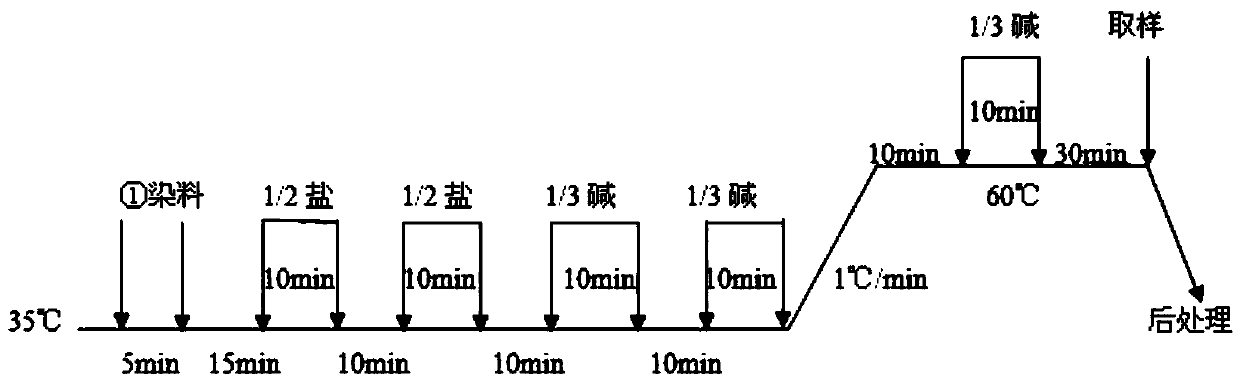

Dyeing and finishing method of full-color modal polyester peach skin yarn-dyed fabric and fabric

ActiveCN110592970AChicken paw prints noChafing problem noShrinkingDry-cleaning apparatus for textilesFiberYarn

The invention provides a dyeing and finishing method of a full-color modal polyester peach skin yarn-dyed fabric and the fabric. The method includes the steps of unwinding, preprocessing, dyeing, postprocessing, rewinding, warping, slashing, weaving and after-finishing; the after-finishing process includes the steps of zero-shrinkage-rate pre-shrinkage, singeing, desizing, water sanding, air washing+enzyme washing, sizing and pre-shrinkage. The method has the advantages that the green cutting problem between modal fiber under the low cohesive force is avoided; treatment is conducted through ascouring agent in the preprocessing step, grease on the modal fiber surface is sufficiently removed, and the dyeing uniformity is improved; dyes excellent in compatibility and high in color light reproducibility are selected in the dyeing step, the dyes, anhydrous sodium sulphate and sodium carbonate are added at a low temperature, and the problem is solved that modal is quite to color and prone to dyeing defects; the shrinkage rate is 0% in the zero-shrinkage-rate pre-shrinkage step, the fabric is ironed, and dead creases are avoided; by means of the fabric sanding process of water sanding and air washing+enzyme washing, the fabric is endowed with the polyester peach skin effect.

Owner:张家港市金陵纺织有限公司

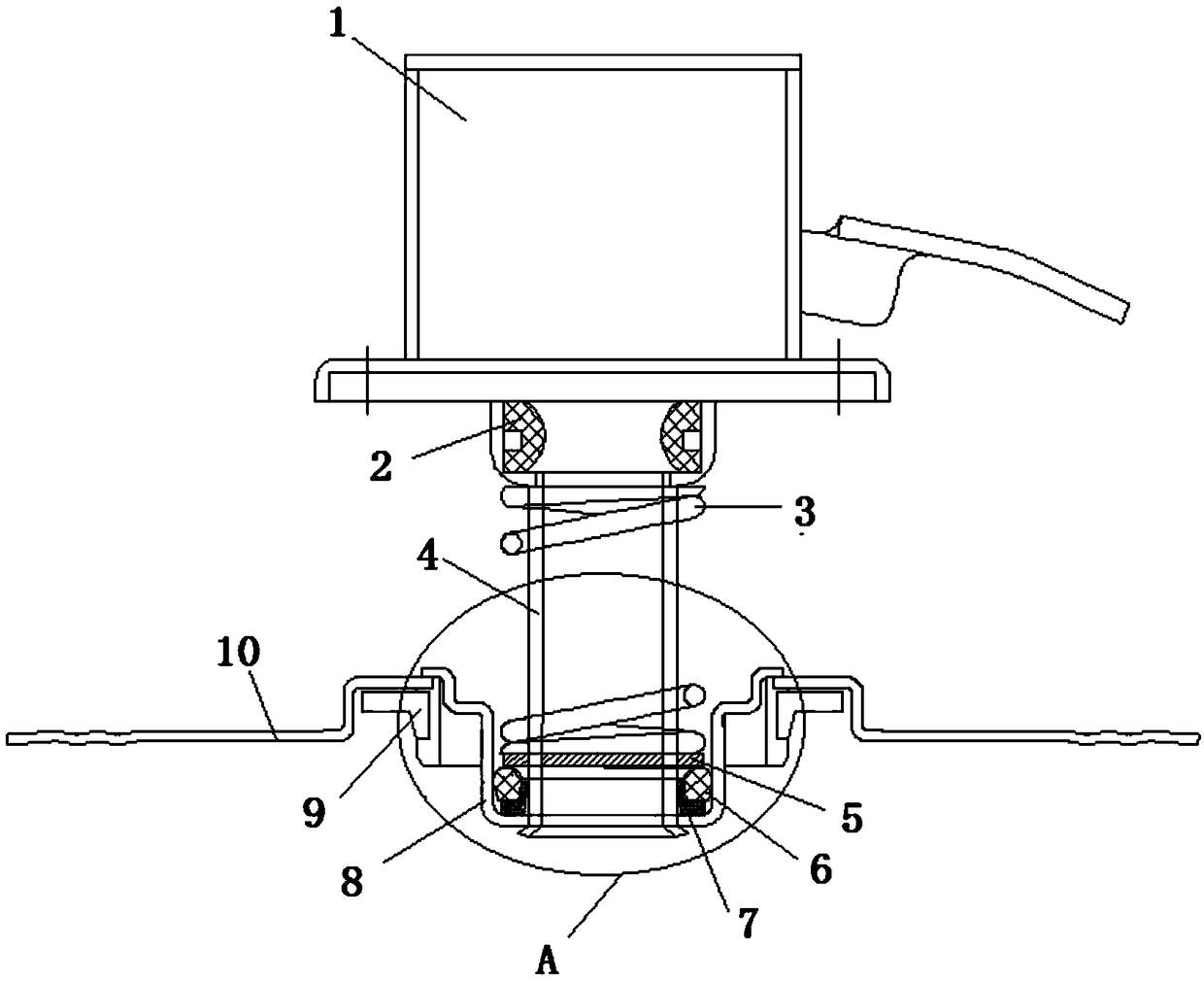

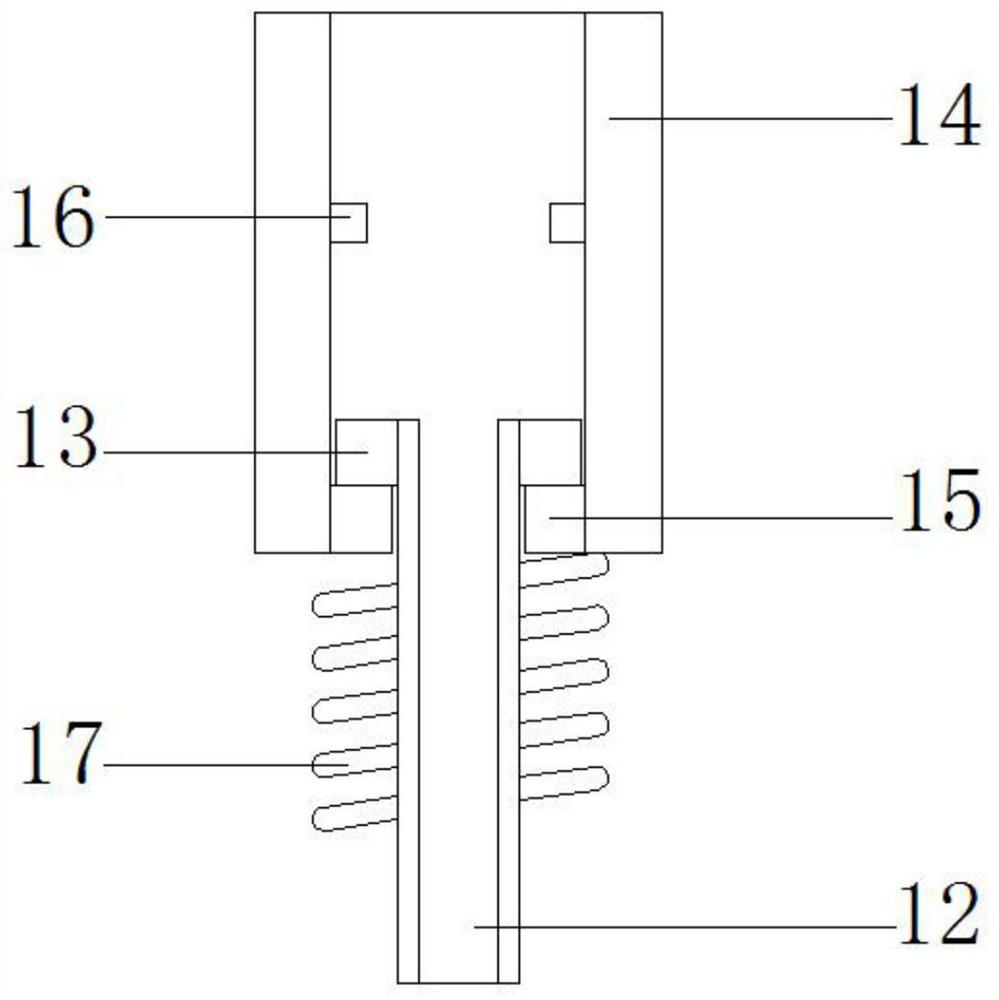

Lock sealing structure for yarn dyeing

The invention discloses a lock sealing structure for yarn dyeing. The structure comprises a locking portion, an intermediate sealing ring is arranged at the lower end of the locking portion, a core tube is arranged at the lower end of the intermediate sealing ring, and a spring is arranged on the outside of the core tube; the lower end of the spring is provided with a gasket; a second annular elastic pad is disposed between the core tube and a sealing seat, and an annular groove is formed in the outer upper portion of the second elastic pad; an annular first elastic pad is arranged in the groove; the bottom of the groove is a plane, the bottom of the first elastic pad is a plane matching the groove, and the bottom of the first elastic pad is embedded in the groove; the natural height of the first elastic pad is higher than the height of the groove; the upper end of the first elastic pad abuts against the lower side surface of the gasket. The structure adds two sealing structures of thefirst elastic pad and the second elastic pad at the bottom of the spring, achieves the effect of completely sealing a lock head, does not cause leakage problem during long-term use, avoids the unevenly dyeing phenomenon of a dyed yarn, and avoids yarn roughing.

Owner:无锡得金印染机械厂

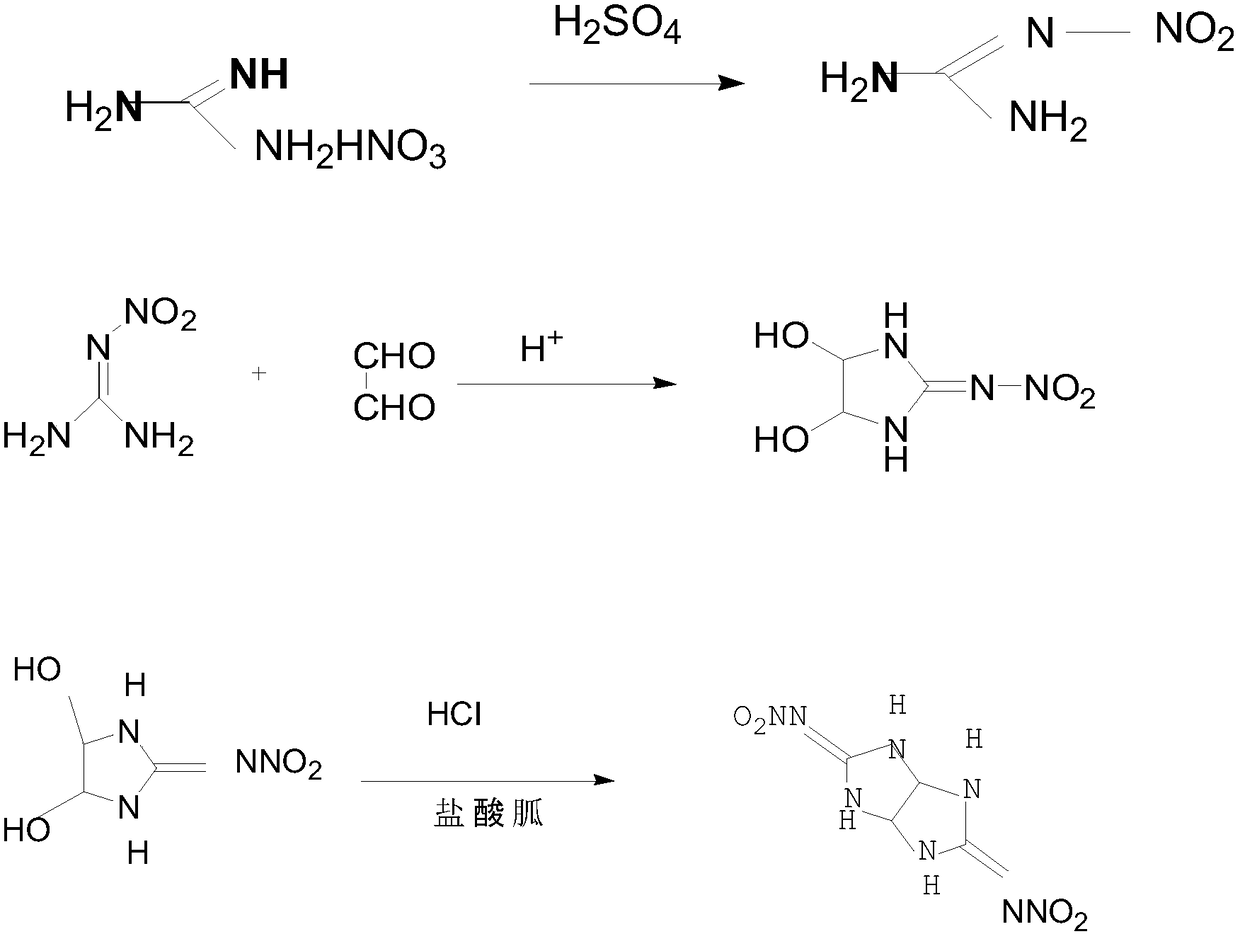

Preparation method of dinitroglycol guanidine

InactiveCN109134473AAvoid decompositionLow impurity contentOrganic chemistryEconomic benefitsGlyoxal

The invention discloses a preparation method of dinitroglycol guanidine. Dinitroglycol guanidine is prepared from guanidine nitrate, concentrated sulfuric acid, glyoxal and hydrochloric acid by an ultrasonic reaction, wherein the reaction comprises the following steps: guanidine nitrate is dehydrated by 98% concentrated sulfuric acid and processed by ice, guanidine nitrate is prepared and subjected to the ultrasonic reaction with glyoxal in presence of hydrochloric acid, dinitroglycol guanidine is generated and subjected to postprocessing of filtering, washing, recrystallization and drying, and solid dinitroglycol guanidine is obtained. Prepared dinitroglycol guanidine is high in purity, low in impurity content and high in molar yield, and has good economic benefit; the preparation methodis safe, environmentally friendly and applicable to industrial production.

Owner:NANTONG TENDENCI CHEM

Cooling and drying integrated machine of riding belt

InactiveCN102901364APrevent leakageSave energyDrying gas arrangementsHandling discharged materialCold airEngineering

The invention provides a cooling and drying integrated machine of a riding belt, and the machine is used for overcoming the defects in the prior art. The cooling and drying integrated machine comprises a cooling chute, a drying chute and a cooling device, wherein the cooling chute is a blanking channel defined by an upper panel, a lower panel, a left panel and a right panel of the cooling chute; the drying chute is a blanking channel defined by an upper panel, a lower panel, a left panel and a right panel of the drying chute; the upper and lower panels of the cooling chute, and the upper and lower panels of the drying chute are provided with non-material-leaking air vents; the feeding end of the cooling chute is located below a kiln head cover of a rotary kiln; the upper panel of the cooling chute is located below the lower panel of the drying chute; and the cooling device is used for supplying cold air to the interior of the cooling chute through the lower panel of the cooling chute. The cooling and drying integrated machine of the riding belt has two functions of cooling and drying, utilizes hot waste gas generated by material cooling treatment to carry out drying treatment on wet materials, and can be used for greatly reducing the consumption of energy sources.

Owner:高玉宗

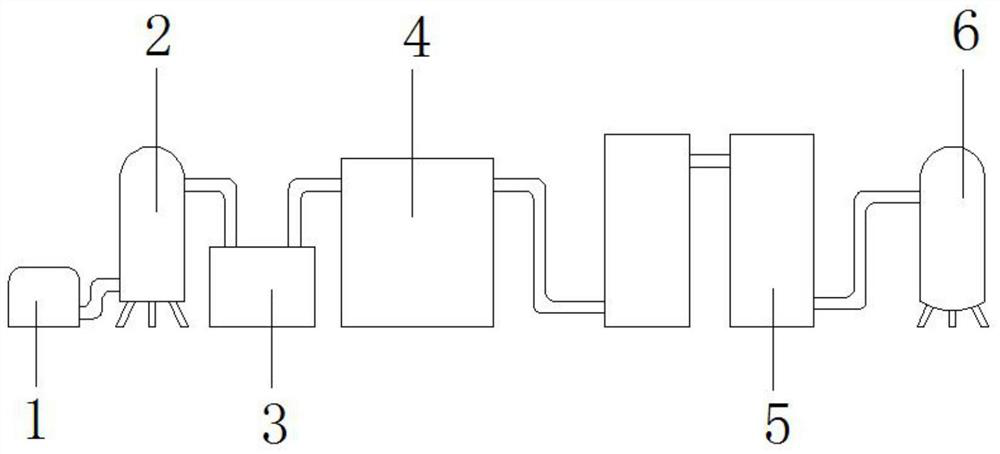

Pressure swing adsorption oxygen production device for producing high-purity oxygen by using two-stage PSA (Pressure Swing Adsorption)

PendingCN114345081APrevent from being washed out or damagedExtended service lifeDispersed particle separationOxygen preparationProcess engineeringStructural engineering

The invention discloses a pressure swing adsorption oxygen production device for producing high-purity oxygen by using two-stage PSA (Pressure Swing Adsorption). Comprising an air compressor, an air buffer tank connected to the air outlet end of the air compressor through a connecting pipe, a freeze dryer communicated with the air buffer tank through a connecting pipe, a filter set connected to the inner wall of one side of the freeze dryer in a sleeving mode, an oxygen generation main machine connected to one end of the filter set in a sleeving mode and an oxygen buffer tank connected to the air outlet end of the oxygen generation main machine in a sleeving mode. Sliding grooves are formed in the inner walls of the two sides of the air buffer tank, sliding blocks are slidably mounted in the sliding grooves, mounting pipes are welded to the outer walls of the opposite sides of the two sliding blocks, the inner walls of the bottom ends of the mounting pipes are sleeved with filter elements, and partition plates are welded to the outer walls of the top ends of the mounting pipes. The spring buffers impact force borne by the filter element, the filter element can be prevented from being burst open or damaged, the service life of the filter element is prolonged, compressed air can smoothly enter the air outlet pipe while buffering is conducted, and the working efficiency is improved.

Owner:苏州希特高纯气体设备有限公司

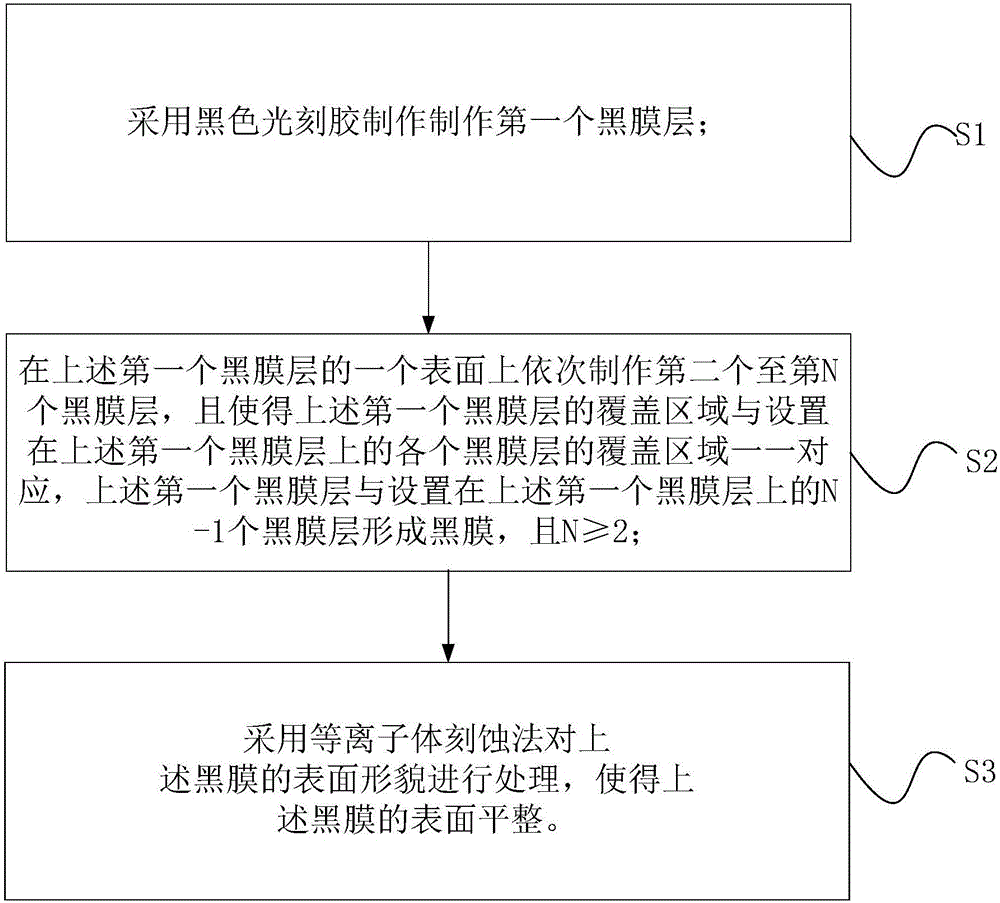

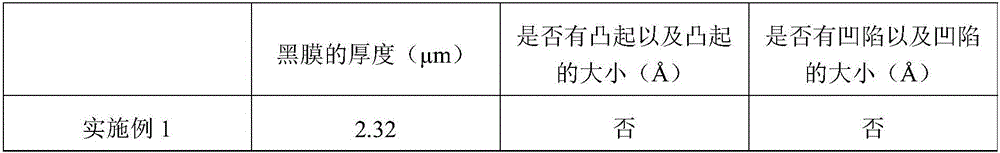

Manufacturing method of black film, black film and light-emitting device

ActiveCN106654060AAvoid flushingFlat surfaceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPhotoresist

The invention provides a manufacturing method of a black film, the black film and a light-emitting device. The manufacturing method comprises the following steps of (S1) manufacturing a first black film layer by using a black photoresist; (S2) sequentially manufacturing a second black film layer to an Nth black film layer on one surface of the first black film layer, making a coverage area of the first black film layer correspond to the coverage areas of various black film layers arranged on the first black film layer one by one and forming a black film by the first black film layer and N-1 black film layers arranged on the first black film layer, wherein N is greater than or equal to 2; and (S3) processing the surface appearance of the black film by adopting a plasma etching method and making the surface of the black film smooth. According to the manufacturing method, the relatively thick black film can be manufactured, and the black film is relatively good in surface appearance and relatively smooth in surface.

Owner:NANJING TECH CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com