Amphibole type primary iron ore grading process

A process and original technology, which is applied in the field of separation process of amphibole-type primary iron ore, can solve the problems that cannot be utilized, cannot be effectively recovered, and is difficult to effectively recover, so as to achieve high recovery rate, reduce energy consumption, and avoid The effect of flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

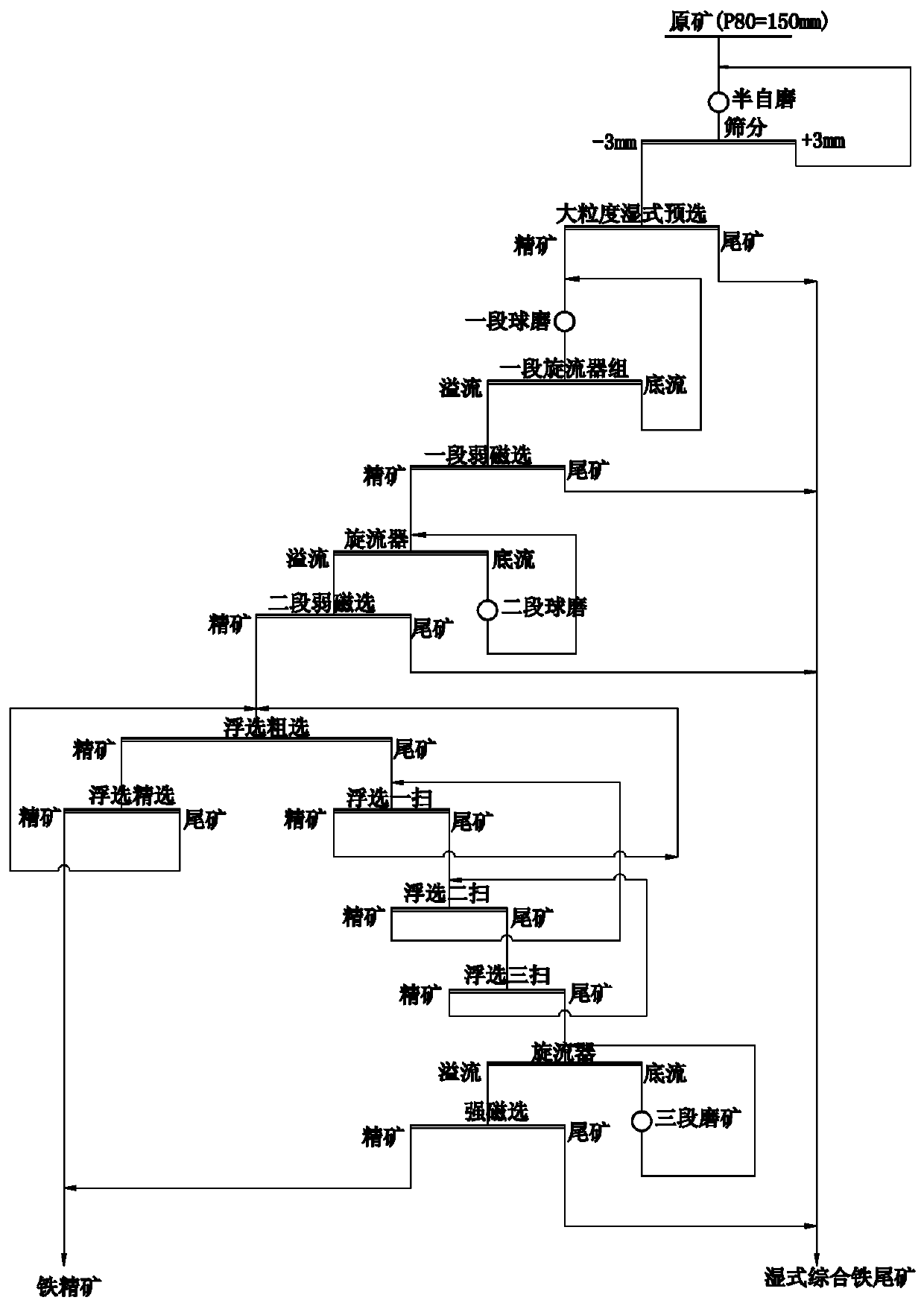

[0027] Such as figure 1 As shown, a kind of amphibole-type primary iron ore sorting process of the present invention comprises that the iron ore embedding particle size is P80=17 microns, and the iron ore of low grade that is difficult to separate undergoes rough crushing and a stage of dry pre-magnetic separation , the obtained grade is 28.62%, the recovery rate is 98.51%, and the one-stage dry pre-magnetic separation concentrate with a particle size of P80=150 mm is used as the raw ore, which is characterized in that: the raw ore is subjected to wet pre-magnetic separation-weak magnetic separation- The reverse flotation-strong magnetic separation process is used for sorting, and the specific steps are as follows:

[0028] 1) Wet pre-magnetic separation:

[0029] The raw ore with a grade of 28.62% is subjected to semi-autogenous grinding-screening closed-circuit grinding, and the 0-3mm product is fed into the second-stage large-grain size wet pre-magnetic separation to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com