Dyeing and finishing method of full-color modal polyester peach skin yarn-dyed fabric and fabric

A processing method and fabric technology, which are applied in the field of textile printing and dyeing, can solve the problems of chicken paw prints, difficult control of shade, and easy generation of color flowers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Fabric specification: 120*90 30 Modal + 40 Modal * 30 Modal + 40 Modal. The fabric has a certain thickness and tightness, which makes it feel like suede. The use of two yarn counts is mainly to improve the three-dimensional effect of the fabric.

[0034] A method for dyeing and finishing full-color modal jeanette yarn-dyed fabric, which is characterized in that the processing steps include: loosening → pre-treatment → dyeing → post-processing → rewinding → warping → sizing → weaving → post-finishing;

[0035] After the tube loosening step, put a sock cover on the tube yarn;

[0036] In the pre-treatment step, use 2g / L scouring agent at 90°C for 30 minutes to fully remove the surface oil and improve the uniformity of yarn dyeing;

[0037] In the dyeing step, the dosage of sodium sulfate is 30-70g / L, and the dosage of soda ash is 5-15g / L. The selected dyes have excellent compatibility, bright and uniform color, and good color reproducibility. For example, RFR yellow, RFB...

Embodiment 2

[0048] Fabric specification: 120*90 30 Modal+40 Modal*30 Modal+40 Modal.

[0049] A method for dyeing and finishing full-color modal jeanette yarn-dyed fabrics, characterized in that the processing steps include: loosening → pre-treatment → dyeing → post-processing → rewinding → warping → sizing → weaving → post-finishing;

[0050] After the tube loosening step, put a sock cover on the tube yarn;

[0051] In the pre-treatment step, use 2g / L scouring agent at 90°C for 30 minutes to fully remove the surface oil and improve the uniformity of yarn dyeing;

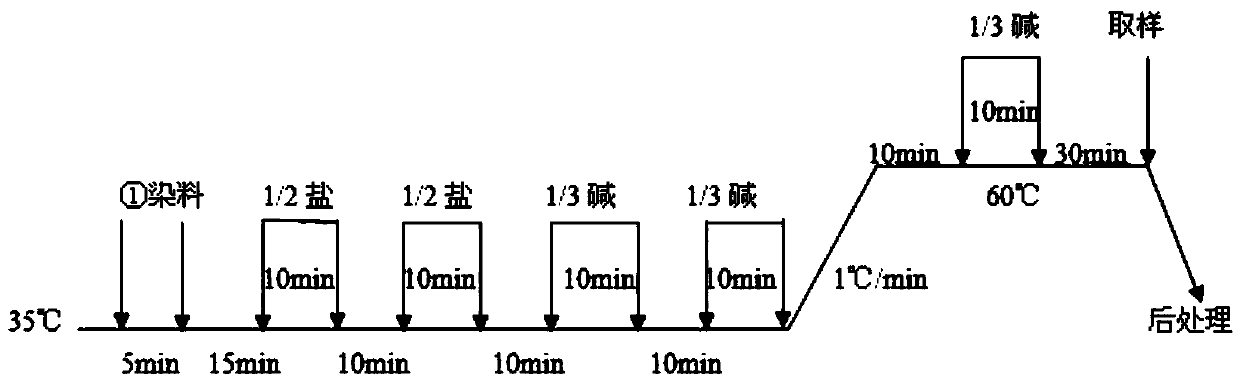

[0052]In the dyeing step, the dosage of sodium sulfate is 30-70g / L, and the dosage of soda ash is 5-15g / L. The selected dyes have excellent compatibility, bright and uniform color, and good color reproducibility. For example, RFR yellow, RFB red, MD blue; the dyeing steps are carried out as follows: Add 1g / L chelating agent at 35°C → pour into the main vat and run for 5 minutes, return to the auxiliary vat to add dye → melt an...

Embodiment 3

[0063] Fabric specification: 120*90 30 Modal+40 Modal*30 Modal+40 Modal.

[0064] A method for dyeing and finishing full-color modal jeanette yarn-dyed fabric, which is characterized in that the processing steps include: loosening → pre-treatment → dyeing → post-processing → rewinding → warping → sizing → weaving → post-finishing;

[0065] After the tube loosening step, put a sock cover on the tube yarn;

[0066] In the pre-treatment step, use 2g / L scouring agent at 90°C for 30 minutes to fully remove the surface oil and improve the uniformity of yarn dyeing;

[0067] In the dyeing step, the dosage of sodium sulfate is 30-70g / L, and the dosage of soda ash is 5-15g / L. The selected dyes have excellent compatibility, bright and uniform color, and good color reproducibility. For example, RFR yellow, RFB red, MD blue; the dyeing steps are carried out as follows: Add 1g / L chelating agent at 35°C → pour into the main vat and run for 5 minutes, return to the auxiliary vat to add dye ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com