Patents

Literature

257results about How to "Increase the amount of feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

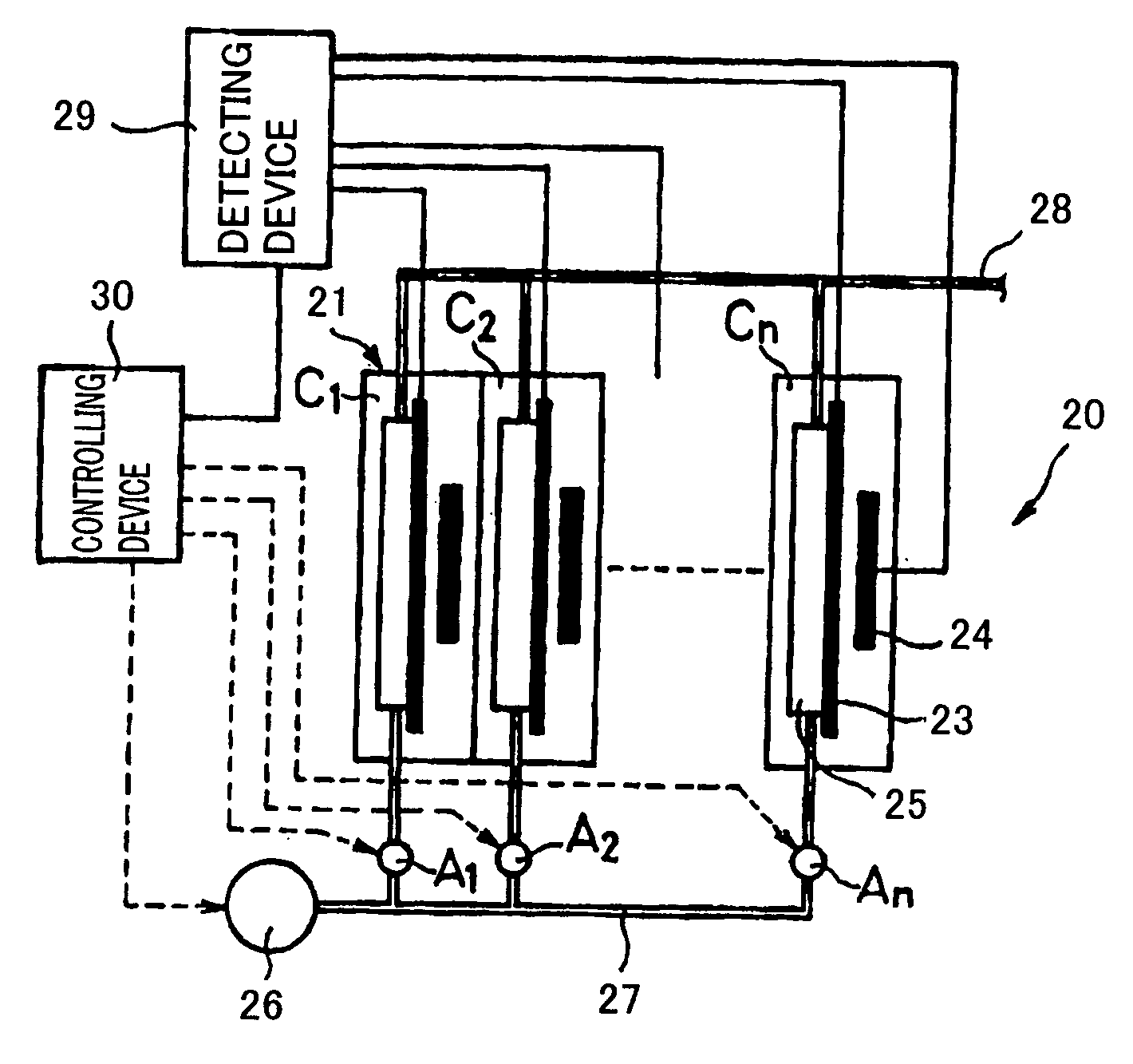

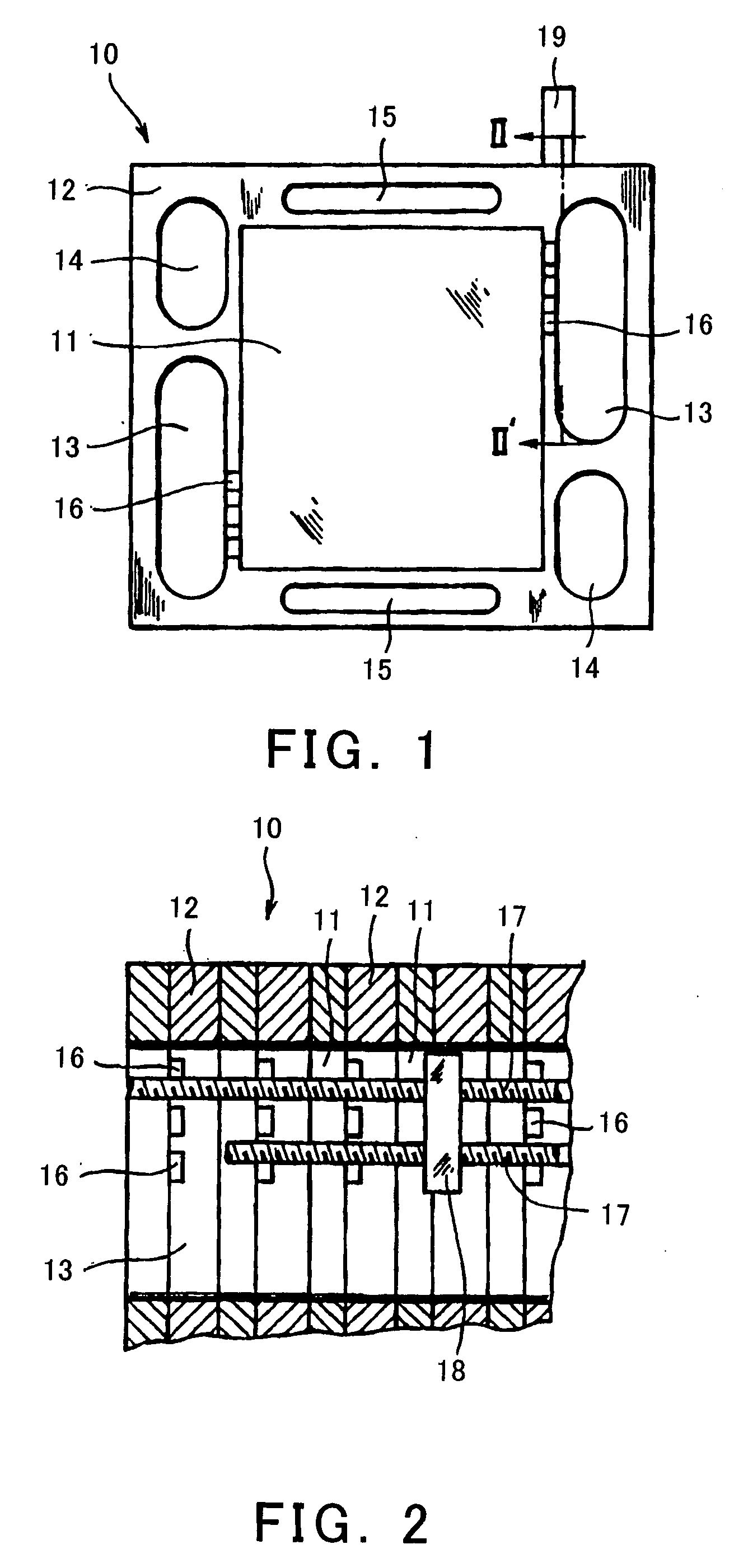

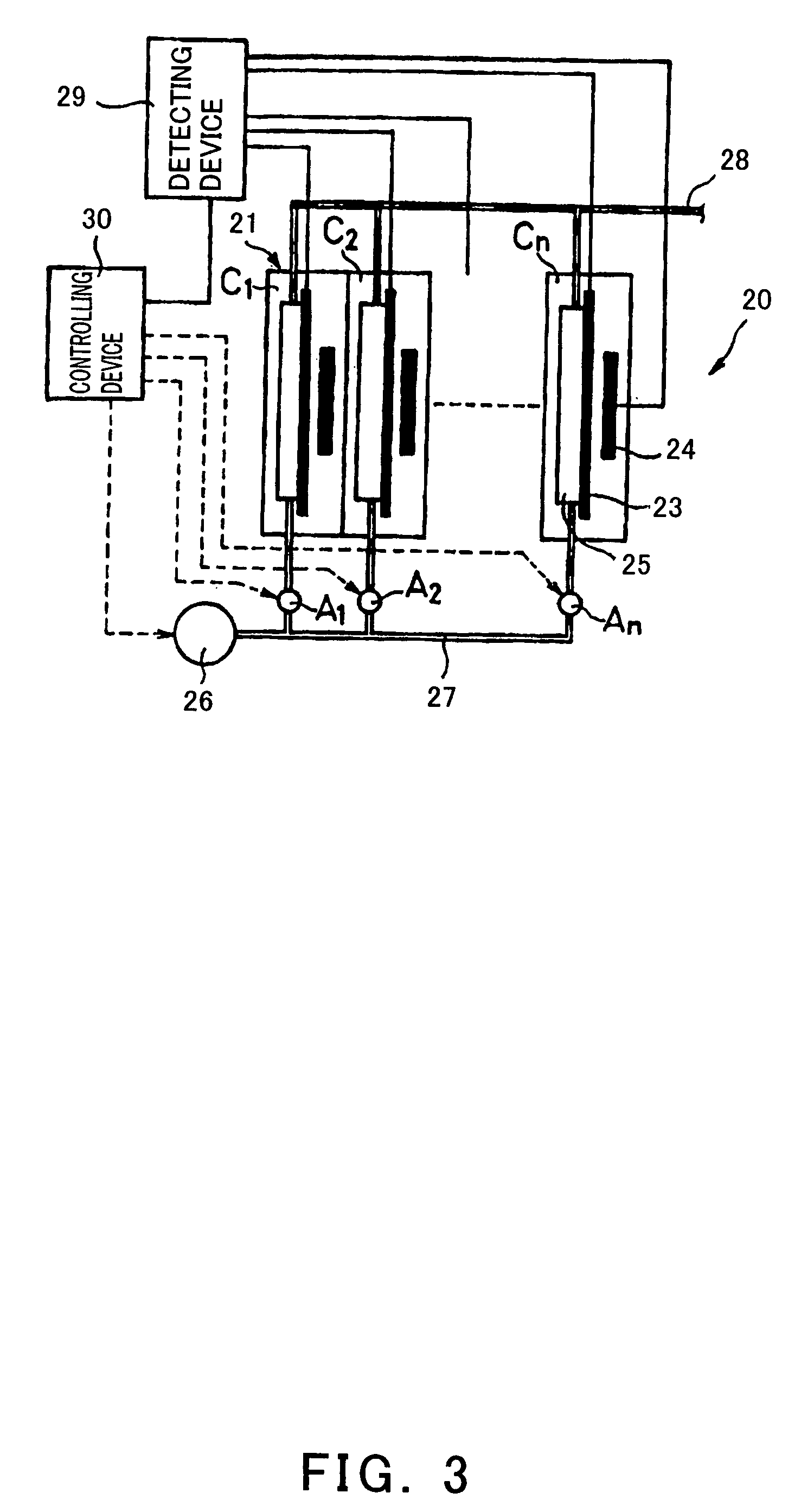

Method of operation fuel cell system and fuel cell system

InactiveUS20040137292A1Feeding amount of the oxygen-containing gas on the oxygen electrode isIncrease the amount of feedFuel cells groupingFuel cell auxillariesFuel cellsAutomotive engineering

Owner:PANASONIC CORP

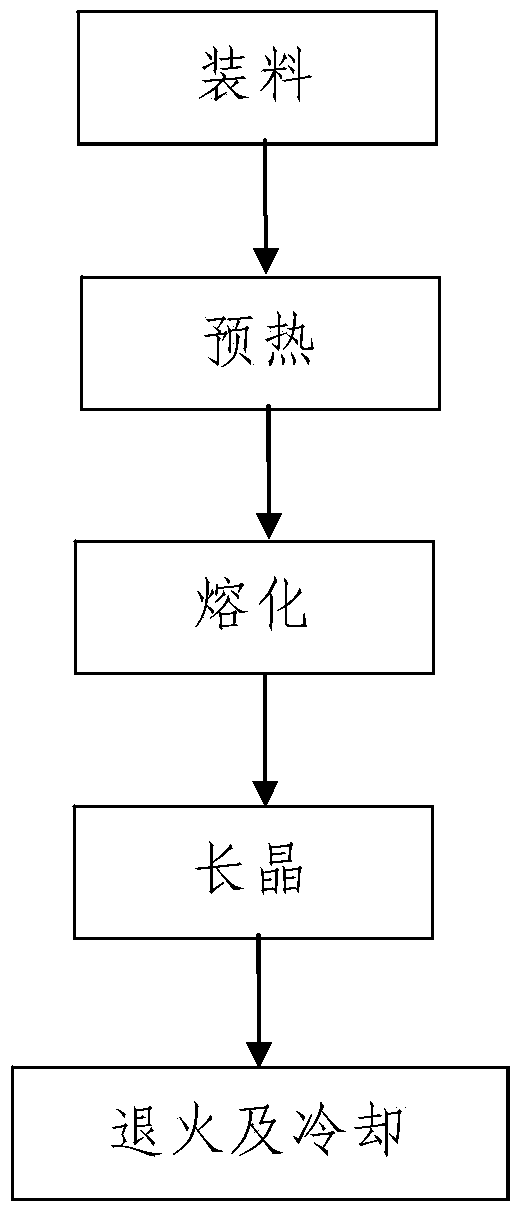

Ingot casting method of granular polysilicon

InactiveCN103741215AReasonable designThe process steps are simplePolycrystalline material growthSingle crystal growth detailsPolycrystalline siliconRise time

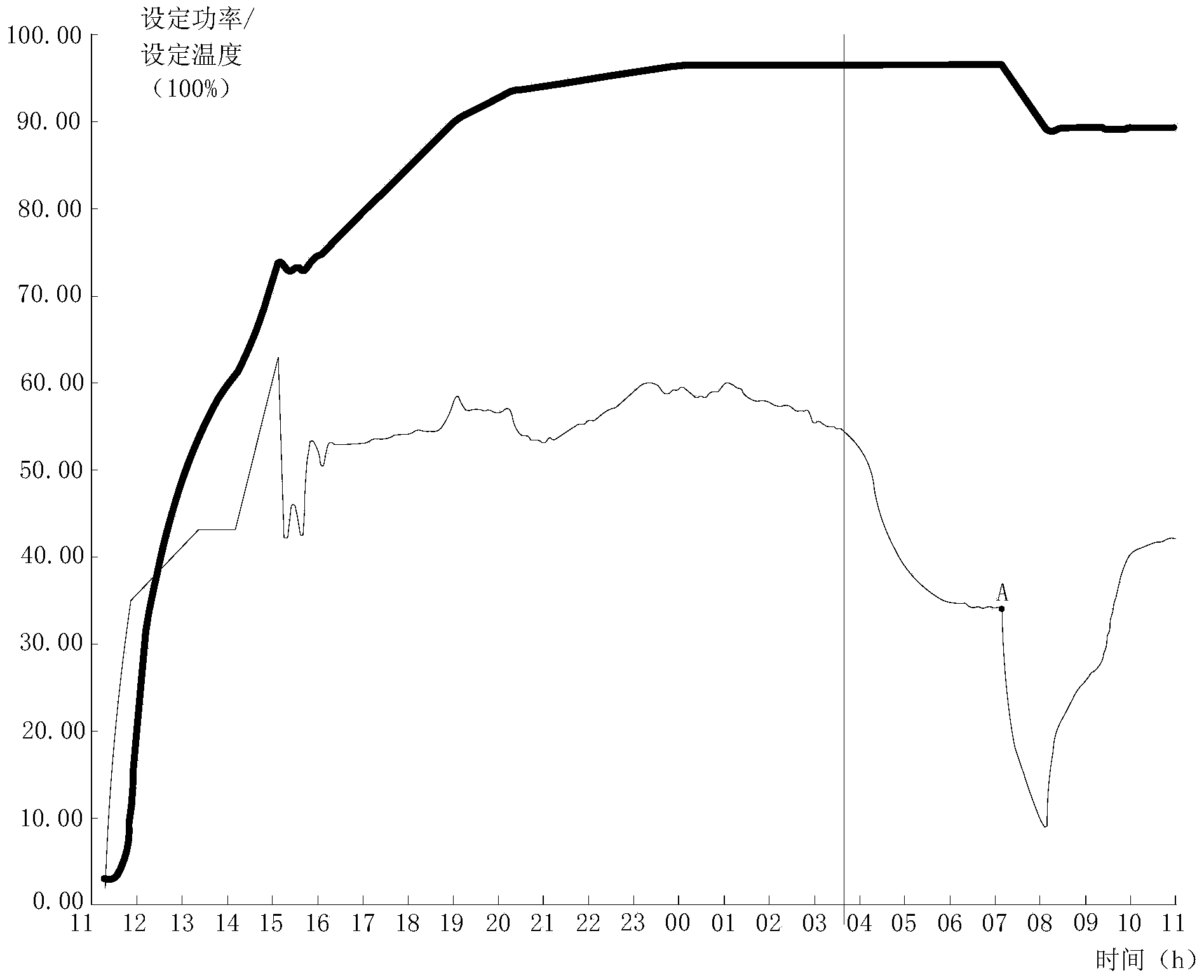

The invention discloses an ingot casting method of granular polysilicon. The method comprises the following steps: firstly, charging: putting the granular polysilicon into a crucible as silicon ingot casting materials; secondly, preheating; thirdly, melting, wherein the melting process comprises the following steps: step 1, carrying out heat preservation; steps 2 to 5, heating and implementing pressurization; step 6, raising temperature for the first time and keeping pressure, namely raising the temperature to T3 which is equal to 1450 DEG C; step 7, raising the temperature for the second time and keeping the pressure, namely raising the temperature to T4 which is equal to 1500 DEG C; step 8, raising the temperature for the third time and keeping the pressure, namely raising the temperature to T5 which is equal to 1550 DEG C, wherein temperature rise times from the step 6 to step 8 are all 260 to 300 minutes; step 9, carrying out heat preservation; step 10, continuously carrying out the heat preservation; fourthly, growing crystals; fifthly, annealing and cooling. The method disclosed by the invention is simple in steps, reasonable in design, convenient in realization, easily mastered, and good in use effect. Furthermore, ingot casting products with high conversion efficiency can be manufactured by using the low- cost granular polysilicon, thereby achieving the purposes of reducing wastes and lowering cost.

Owner:XIAN HUAJING ELECTRONICS TECH

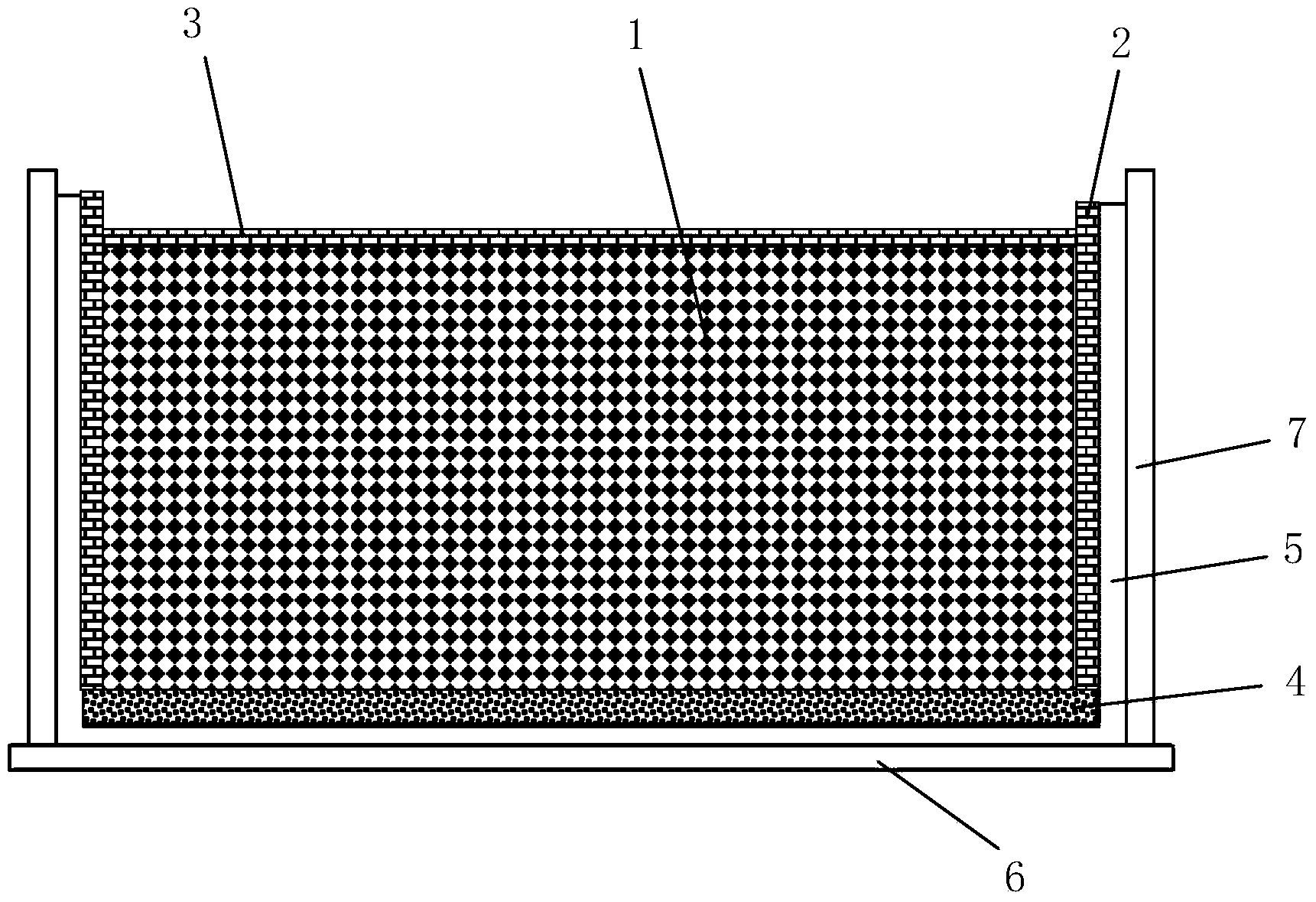

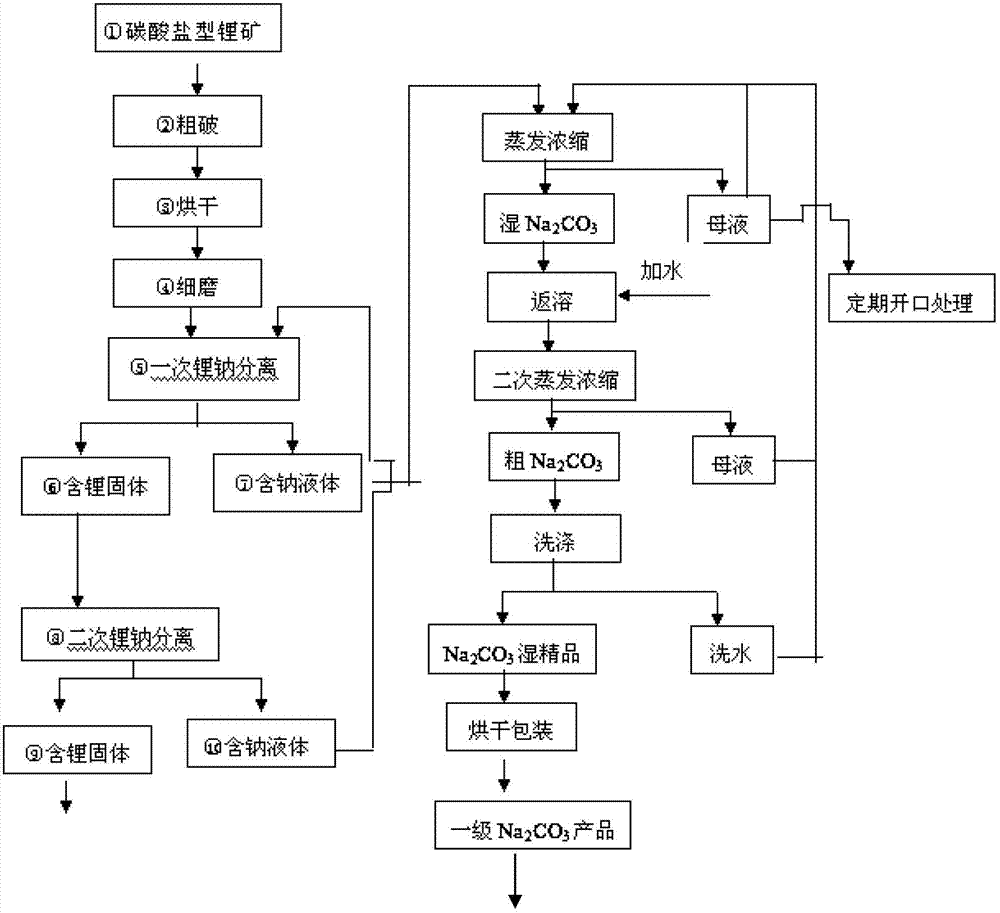

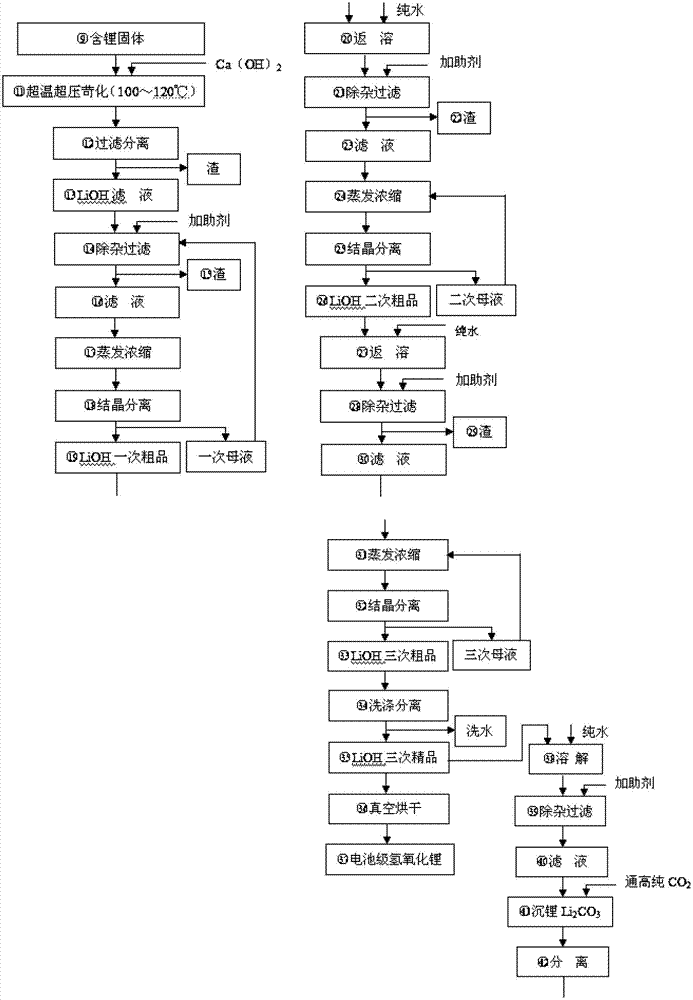

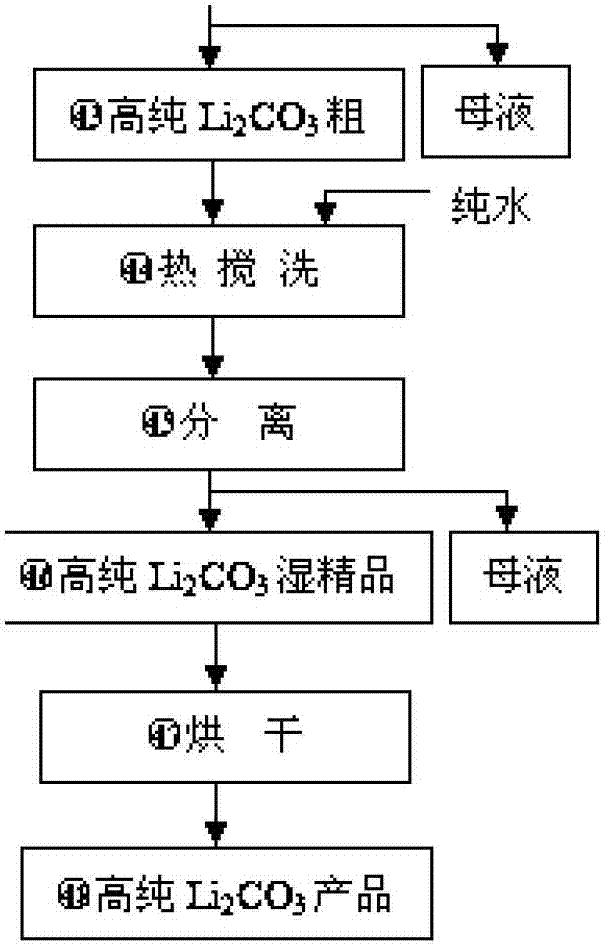

Method for industrially producing industrial, cell-grade or high-purity lithium hydroxide monohydrate

InactiveCN102826576AReduce consumptionReduce pollutionLithium oxides/hydroxidesLithium carbonateWater resources

The invention provides a method for industrially producing an industrial, cell-grade or high-purity lithium hydroxide monohydrate, which comprises the following steps of: (1) grinding; (2) removing impurities by a thermal precipitation method; (3) causticizing; and (4) removing impurities, crystallizing, washing, separating and drying. The invention also provides a method for preparing high-purity lithium carbonate. After causticizing reaction equipment and a reaction method which are provided by the invention are utilized, the feeding amount of the single causticizing production can be greatly improved and the large-scale industrial continuous production of the industrial and cell-grade lithium hydroxide monohydrate and the high-purity lithium carbonate is implemented; the consumption of water resources and energy can be effectively reduced and in the reaction, only a cheap precipitating agent or a cheap complexing agent needs to be used, so that the production cost is reduced; and the reaction is simple and convenient to operate and, the environment pollution is small, the obtained product has high quality and yield, the quality of the obtained product is stable and the product has wide industrial application prospect.

Owner:四川长和华锂科技有限公司

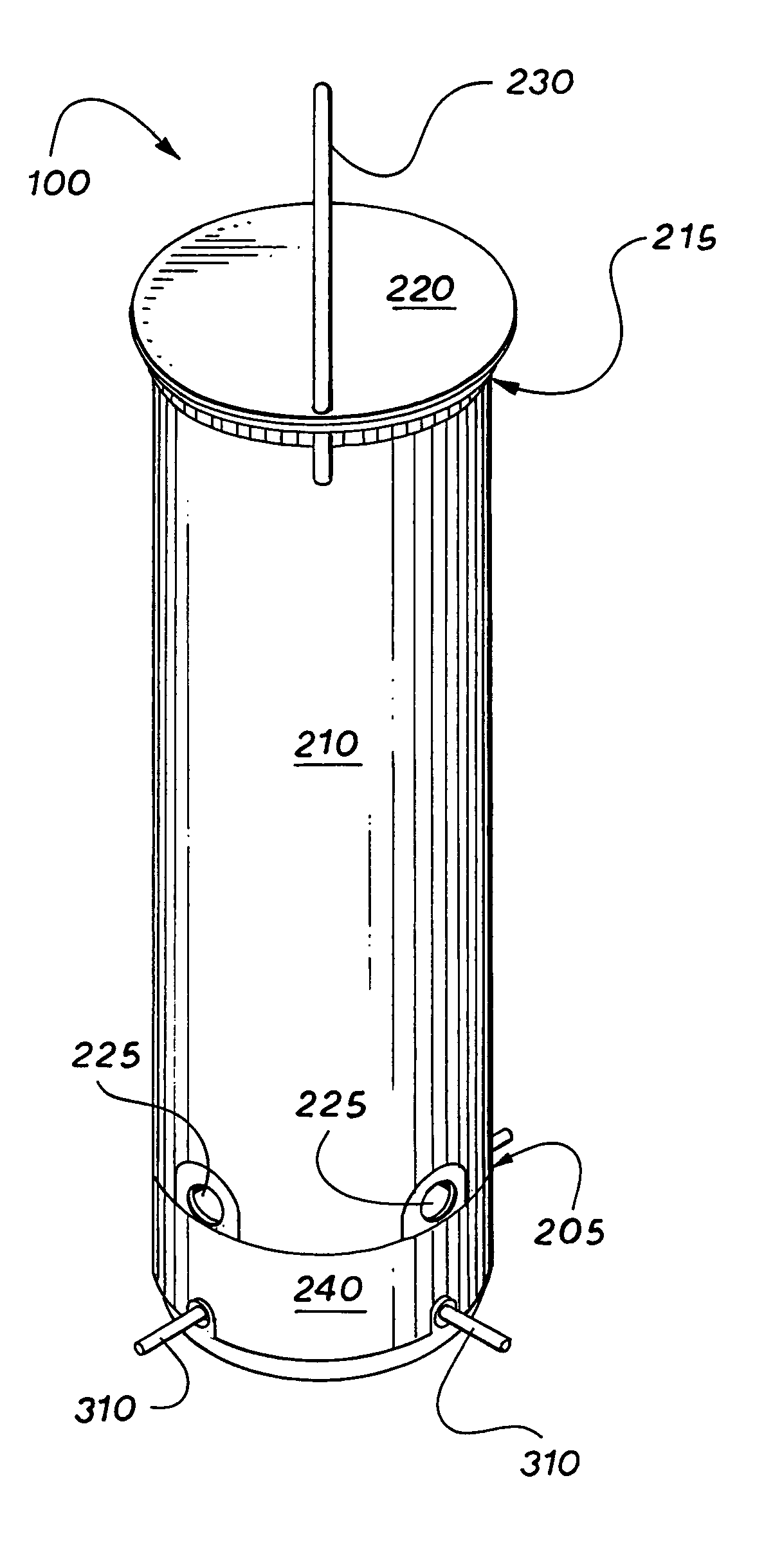

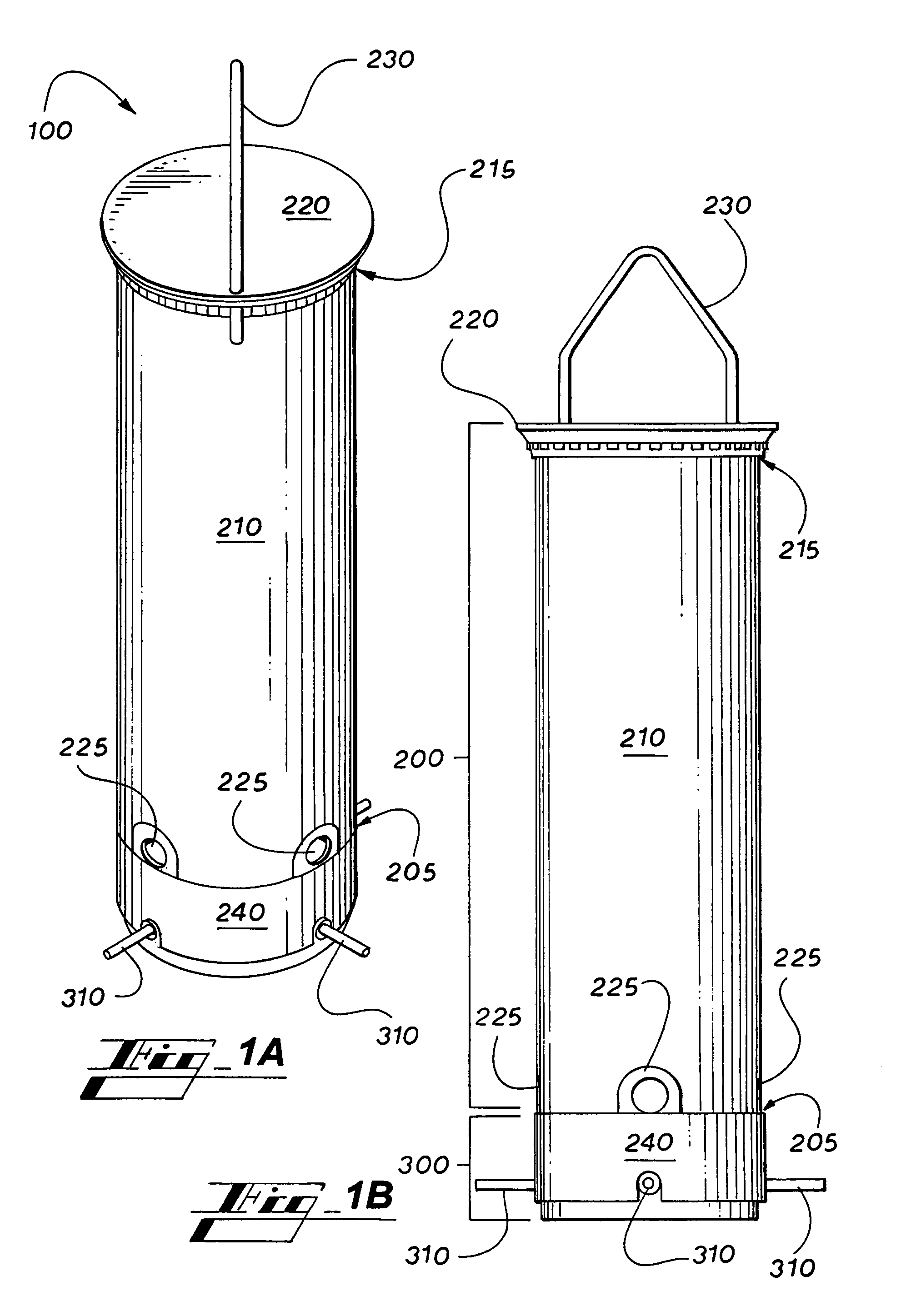

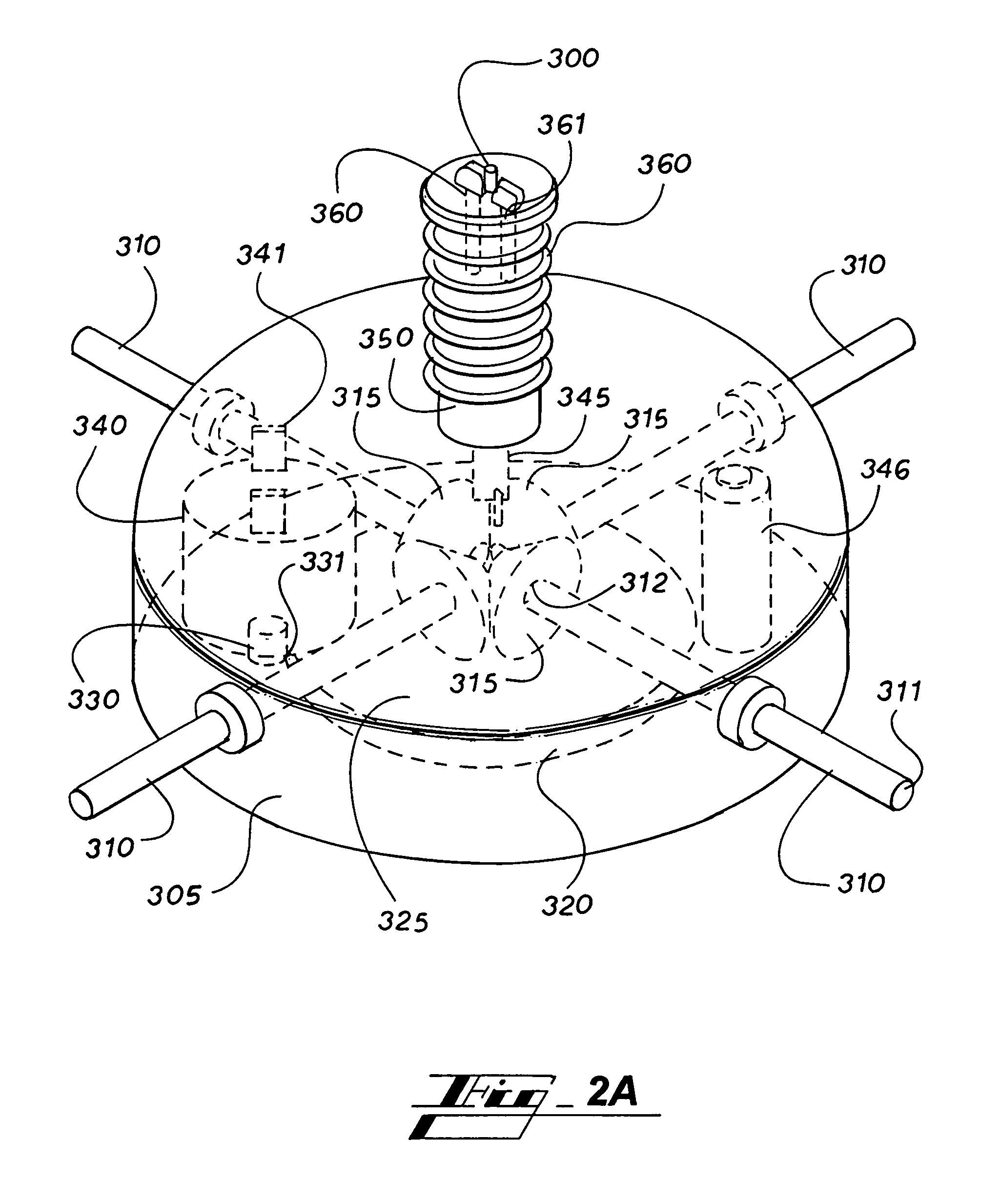

Multiple perch squirrel proof bird feeder

InactiveUS7418923B1Increase amount of feedIncrease in amountPisciculture and aquariaBird housingsBird feederEngineering

A weight sensitive squirrel proof bird feeder with multiple perch rods. In general, a feed reservoir includes perch rods positioned generally perpendicular to an outer surface of the feed reservoir. When a predetermined weight is placed upon the perches, the perches rotate about their longitudinal axis by a motor thereby expelling the source of the weight, typically squirrels or other undesirable animals from the perches.

Owner:LG ELECTRONICS INC

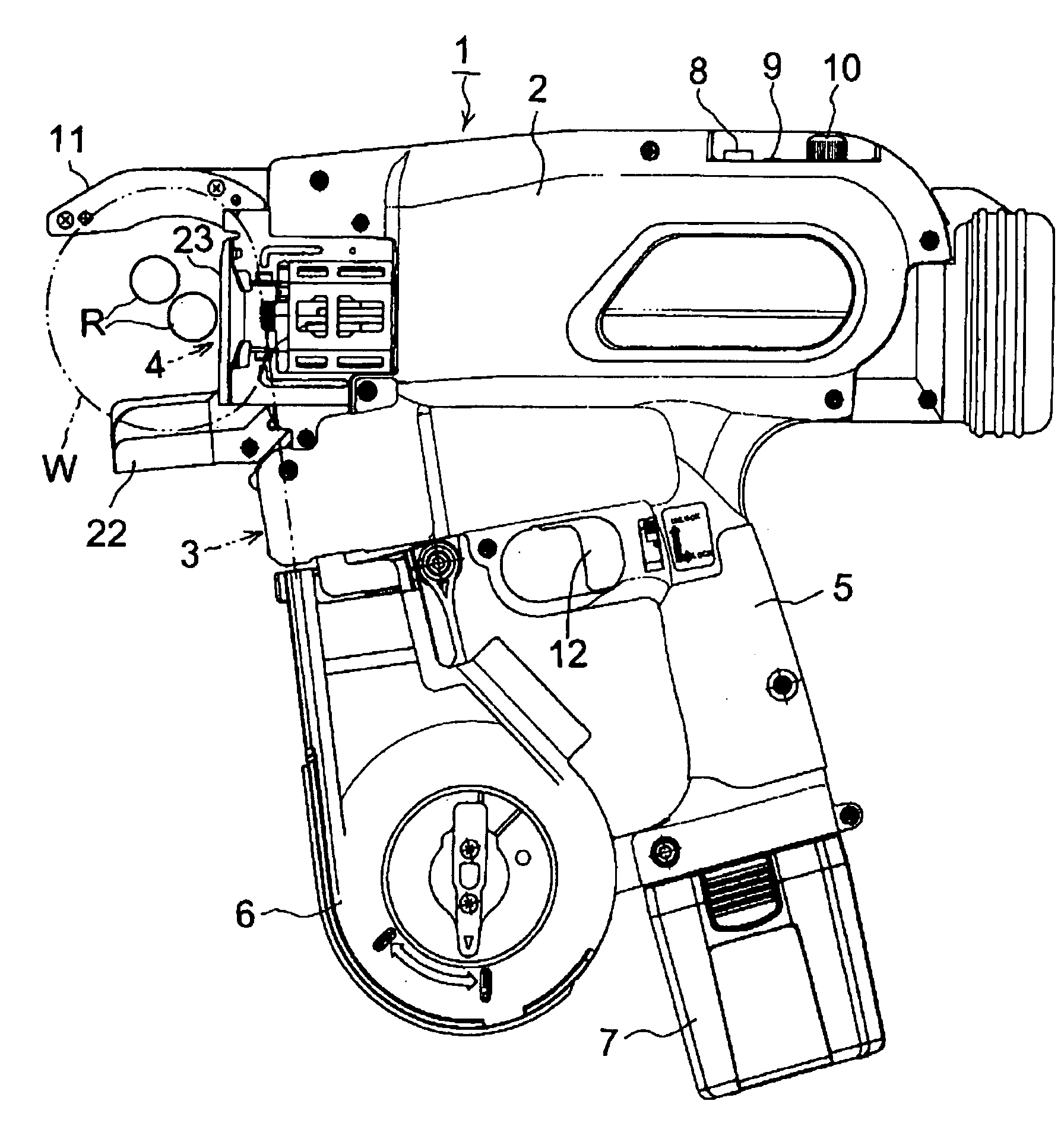

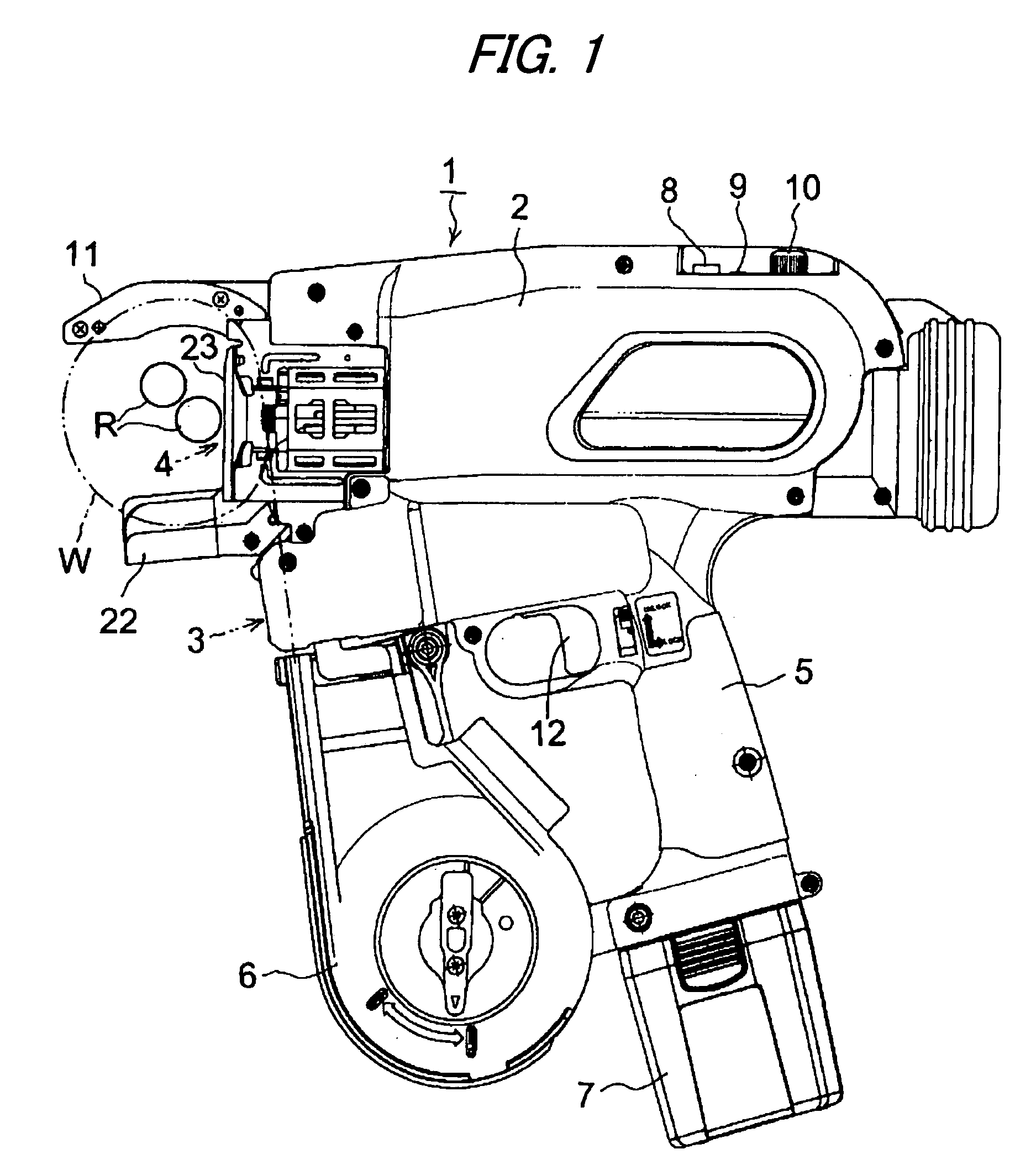

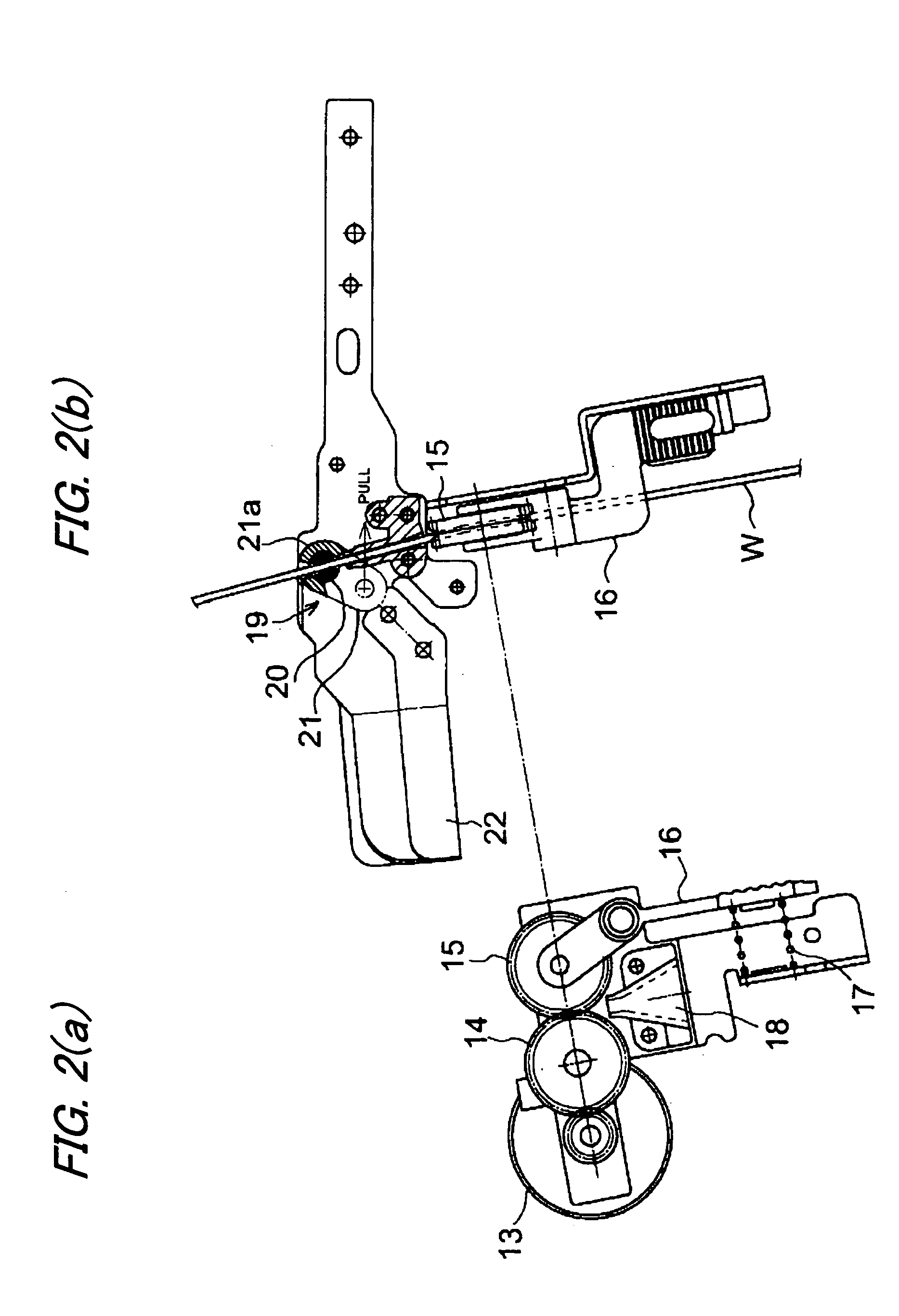

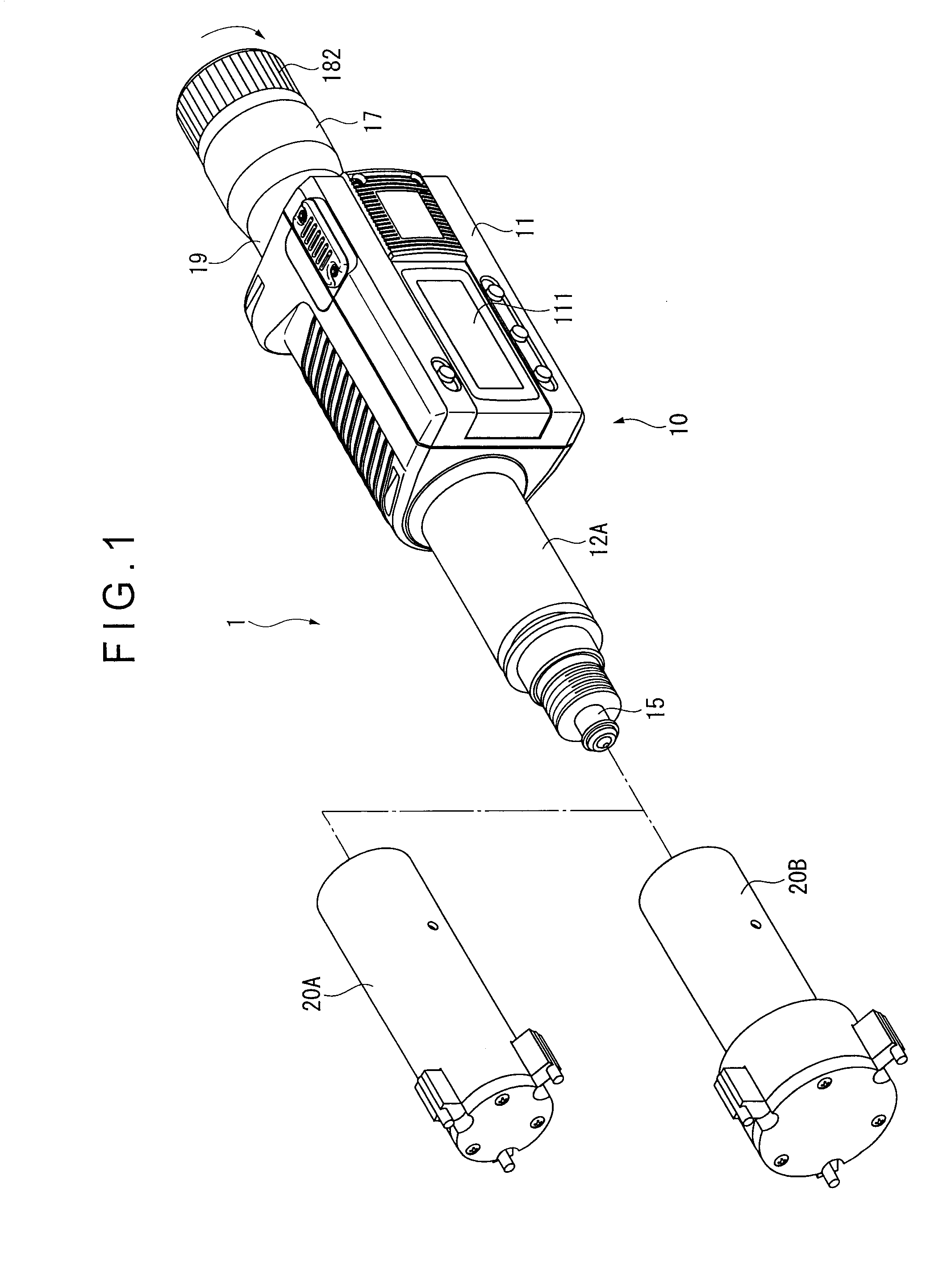

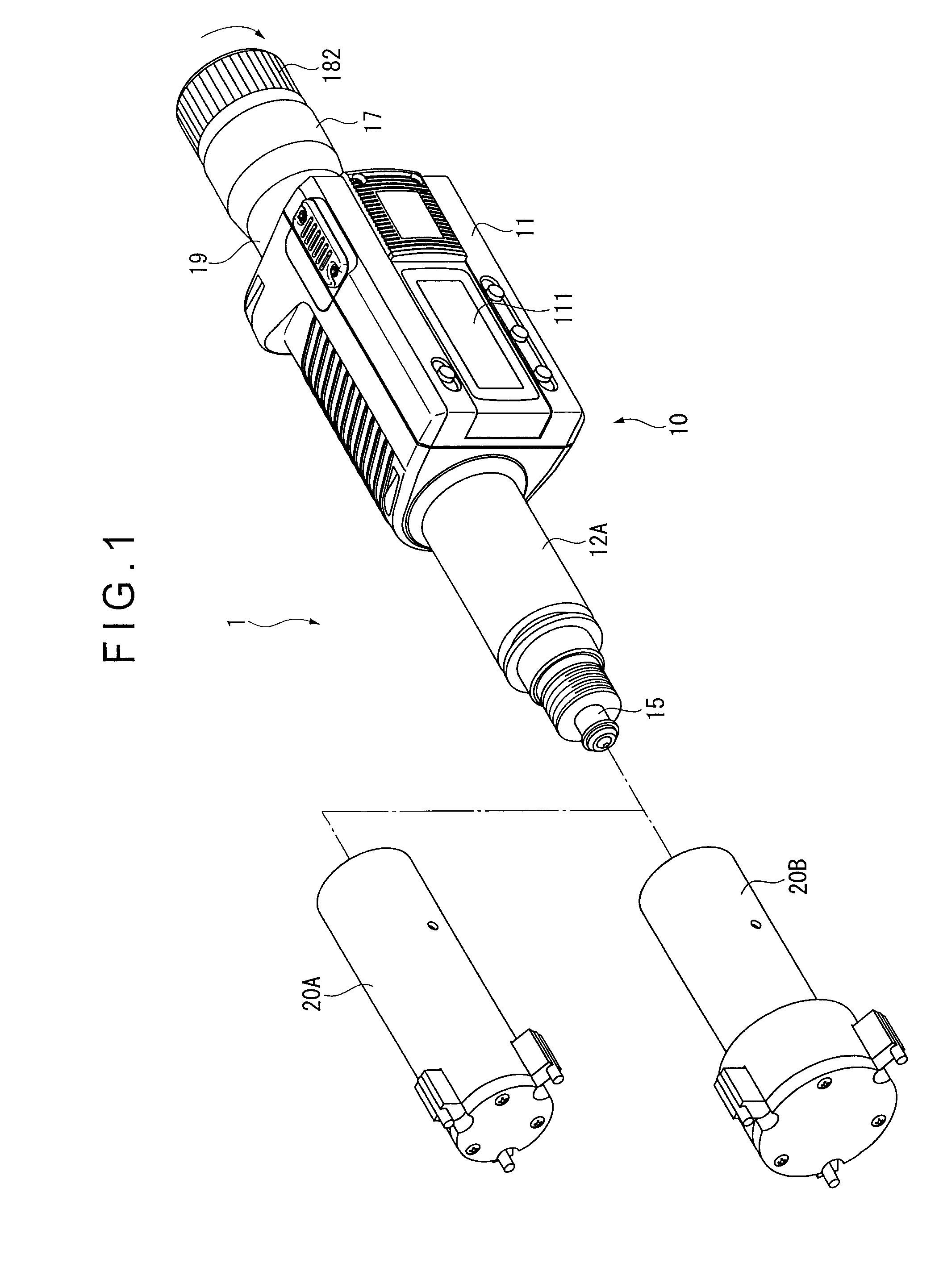

Reinforcing Bar Tying Tool

InactiveUS20080110354A1Increase the amount of feedGuaranteed uptimeBuilding material handlingBundling machine detailsWire cuttingEngineering

It includes a driving load detecting device which detects a driving load amount of a tie wire cutting mechanism, and a tie wire feeding amount control device which controls a feeding amount of the tie wire in a subsequent tying operation in accordance with the detected driving load amount. If the driving load amount when cutting the tie wire is equal to or less than a cutting determination reference value, the tie wire is fed by a normal feeding amount with a predetermined amount being added thereto in the subsequent tying operation to compensate the tie wire feeding amount, whereby a tip end of the tie wire is fed to a position which is same as the position in the normal state. The subsequent tying cycle is executed normally even if the tip end of the biding wire is failed to be clamped due to the failure of the feeding operation of the tie wire and the tie wire is pulled excessively.

Owner:MAX CO LTD

Crystallization refining method of Meropenem

ActiveCN101921276AIncrease the amount of feedIncrease production capacityOrganic chemistryOrganic solventAlcohol

The invention relates to a crystallization refining method of Meropenem, which has low impurity content. The crystallization refining method of Meropenem comprises the following steps: a) dissolving Meropenem crude into methyl alcohol; b) decoloring, decarbonizing, degerming and filtering; c) adding the mixture of water and precipitator into filtrate, and precipitating, wherein the precipitator is the one or the mixture of two-four types of C2-C6 alcohol, C3-C8 ketone, C2-C8 ether or tetrahydrofuran at any ratio, and the volume ratio of water to precipitator is 1:3-1:5; d) filtering to obtain crystallization; e) washing the crystallization by mixed solvent of water and organic solvent of alcohol and esters; and f) drying to obtain the finished product. The invention utilizes the characteristic that Meropenem is easy to dissolve in methyl alcohol, and a small quantity of methyl alcohol can cause Meropenem to dissolve at normal temperature; same equipment can increase inventory for multiple times if being compared with the prior art, and production capability is obviously improved. Because a small quantity of methyl alcohol is used, a great quantity of crystallization solvent can be added, crystallization is complete, yield is high, and impurities can be thoroughly removed.

Owner:JIANGSU DESANO PHARMA

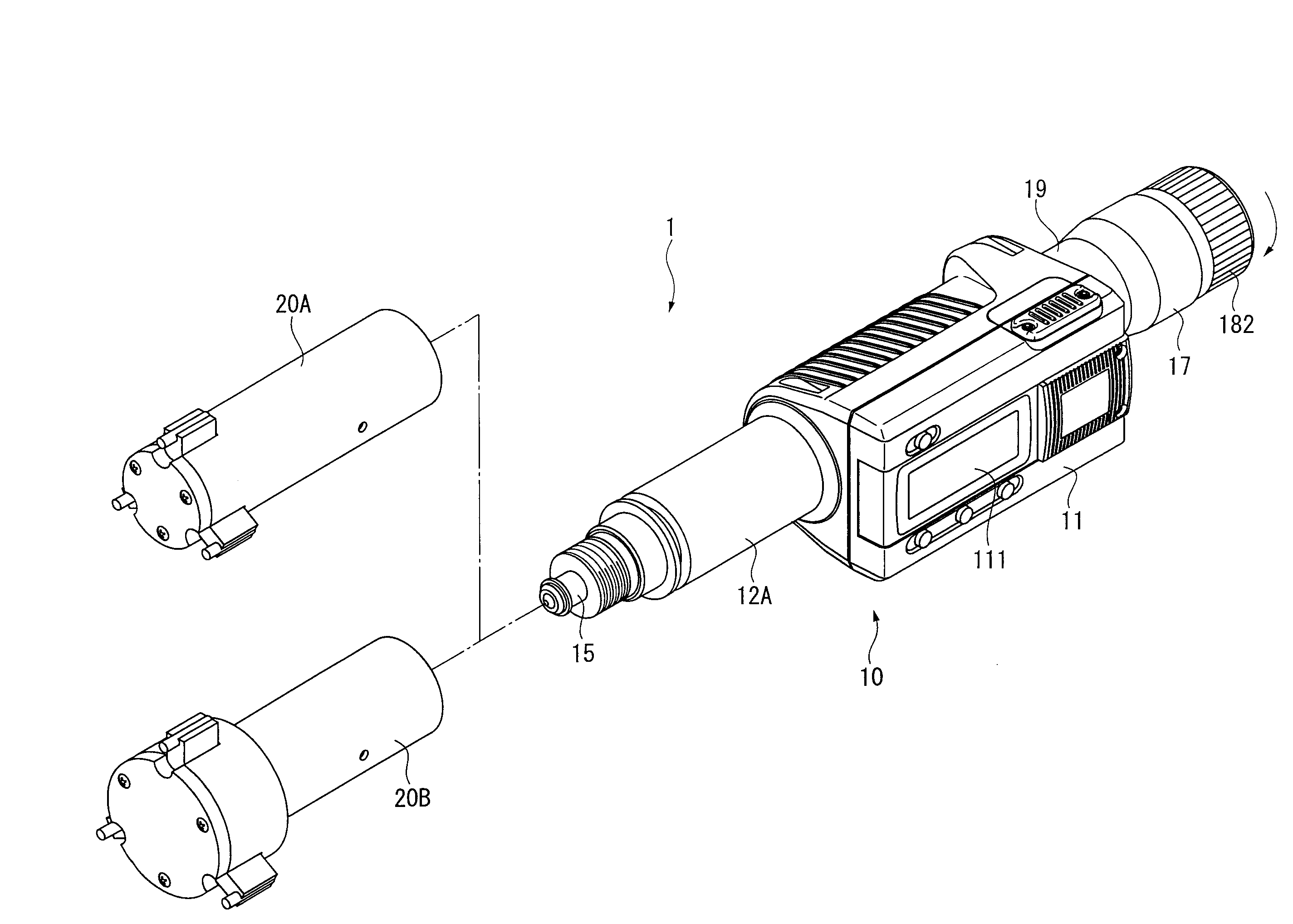

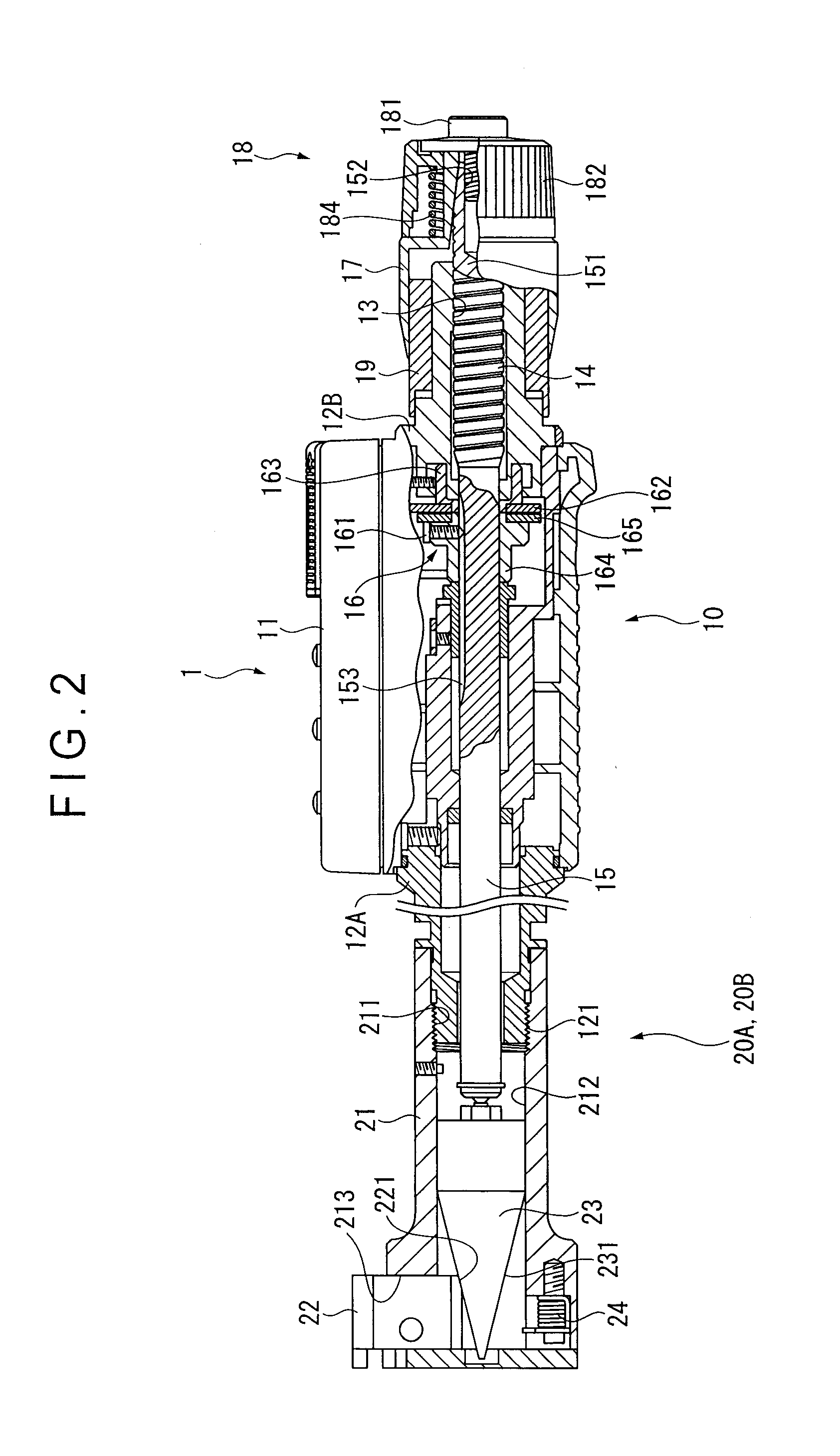

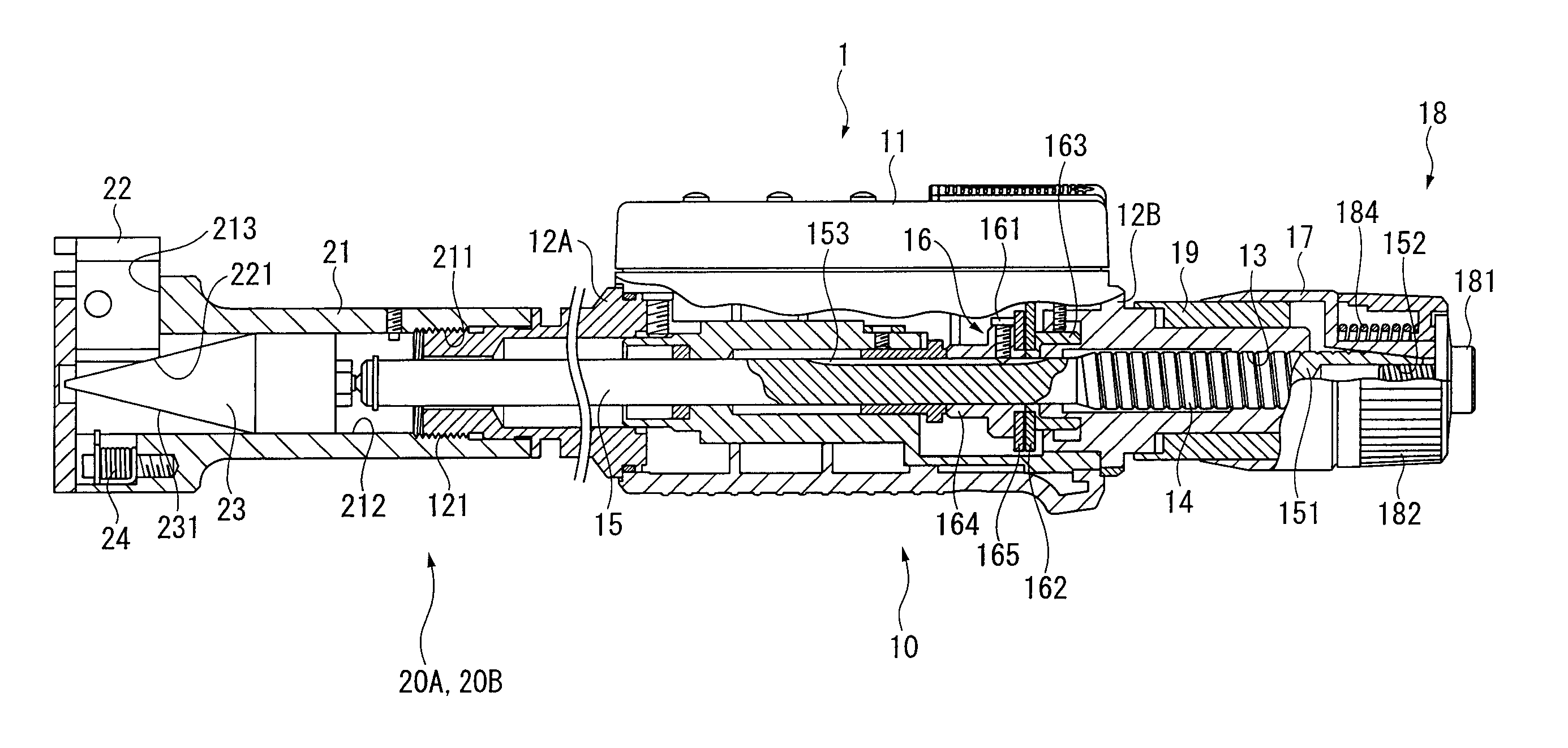

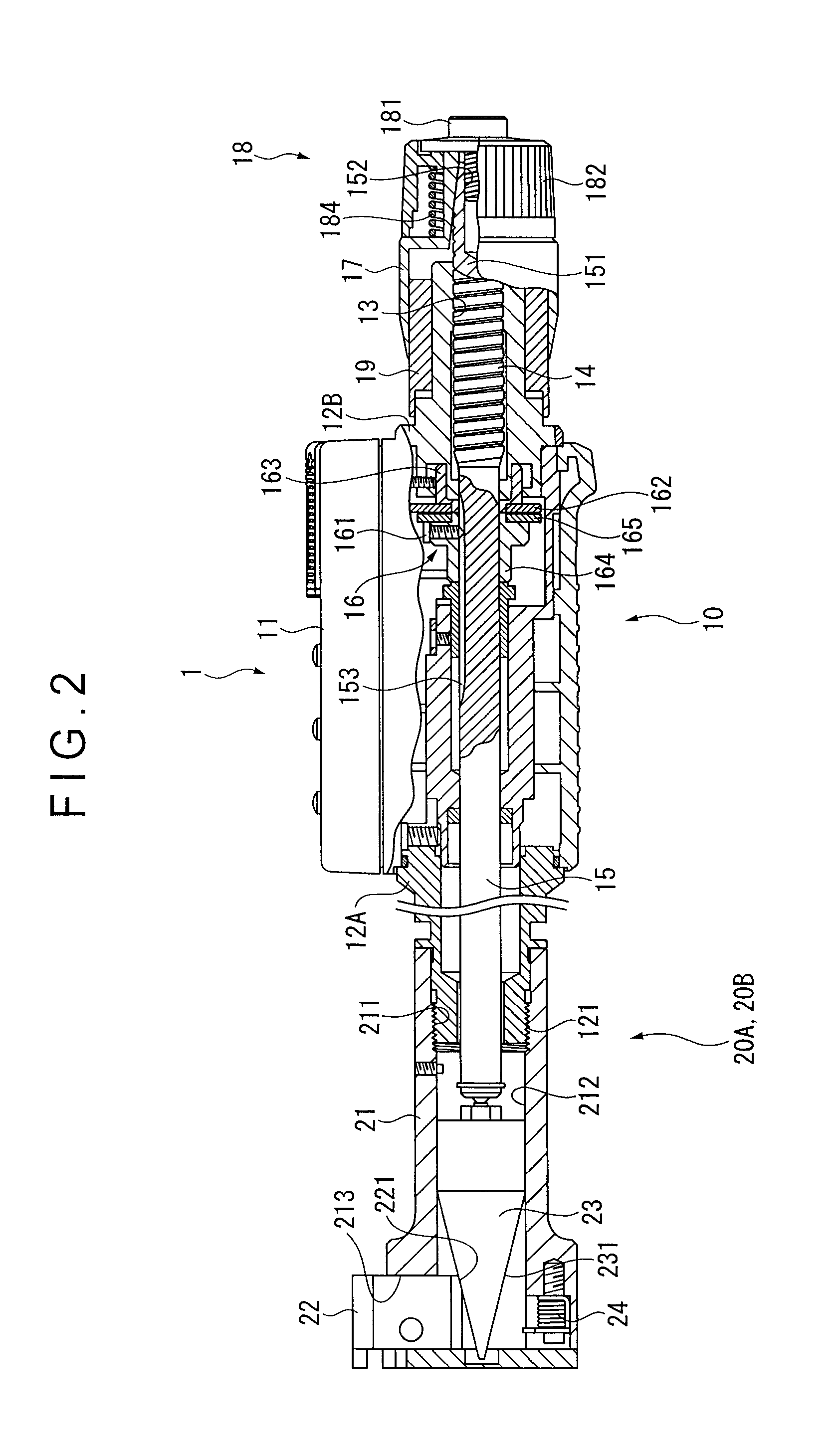

Inside diameter measuring tool

ActiveUS20100005676A1Increased durabilityEasy to operateMicrometersMechanical diameter measurementsScrew threadEngineering

An inside diameter measuring tool includes: a main body; an axially moving spindle having a male screw to be screwed to the main body; a plurality of contact pieces provided on the main body, the measuring pieces moving in a direction substantially orthogonal to the axial direction of the spindle; and a conical member interposed between the contact pieces and the spindle, the conical member advancing and retracting the contact pieces in the direction substantially orthogonal to the axial direction of the spindle. The lead of the male screw of the spindle is 1.0 mm or more and the cone angle of the conical member is less than 53 degrees. Preferably, the lead of the male screw is 2.0 mm and the cone angle of the conical member is approximately 28 degrees.

Owner:MITUTOYO CORP

Method for preparing alpha-acetyl-gamma-butyrolactone

ActiveCN101768141AReduce pollutionQuick responseOrganic chemistryAlpha-acetyl-gamma-butyrolactoneEthyl fumarate

The invention provides a method for preparing alpha-acetyl-gamma-butyrolactone. In the method, gamma-butyrolactone and an acetylating agent (ethyl acetate and methyl acetate or a mixture of ethyl acetate and methyl acetate) are used as starting materials, metal sodium is used as a catalyst, and the product is obtained by acylation, neutralization and distillation. The method has the advantages that: the raw materials are used as the solvent at an initial stage of the reaction, so that the environmental pollution brought by the solvent is lowered, the material feeding amount is increased, the production efficiency is improved, and the production cost is lowered; the metal sodium is added into the reaction system continuously or for several times, so that potential safety risks such as outshoot and combustion caused by difficult control of the reaction speed can be effectively avoided when the sodium metal is reacted at a melting temperature; and by adopting the pressure-regulating distillation method, the byproducts are effectively recovered, the environmental pollution is lowered, and the comprehensive economic benefits are improved.

Owner:鞠彩霞

Method for increasing yield of agaricus bisporus

ActiveCN104920070AIncrease productionReduce pollutionCultivating equipmentsMushroom cultivationAgaricusFermentation

The invention discloses a method for increasing the yield of agaricus bisporus. The method includes the following steps of raw material preparation, primary fermentation, after fermentation, sowing, earthing management, fruiting management and falling rock discharge, and harvesting. According to the method, an M-shaped bed surface is arranged to increase the batch charging quantity, the heat radiating area and the unit fruiting quantity, explosive fruiting is achieved at the early stage, and finally the purpose of increasing the yield of agaricus bisporus and the purpose of increasing benefits are achieved. By the adoption of the method, resources such as agricultural production waste corncobs and farm animal excrement are fully utilized, environmental pollution is greatly lowered, and the production cost is saved.

Owner:SUQIAN AGRI SCI RES INST JIANGSU ACAD OF AGRI SCI

Method for preparing straw-fermented health care feed for sows

InactiveCN102178117AReduce inputReduce the cost of farmingAnimal feeding stuffAccessory food factorsImmunocompetenceDrug additive

The invention relates to a method for preparing a straw-fermented health care feed for sows, which comprises the following steps: (1) crushing straws into 60-80-mesh straw powder, and uniformly blending with fine maize flour, wheat bran, bean pulp powder or bean cake powder; (2) taking pure well water, then adding fermented beneficial bacterium liquid, brown sugar and edible salt into the pure well water, and uniformly stirring to form concentrated straw powder; (3) mixing the fermented beneficial bacterium liquid with the pure well water to form mixed water, and spraying the mixed water ontothe concentrated straw powder to form fermented straw powder; and (4) putting the fermented straw powder into a fermentation pool to obtain the straw-fermented health care feed for sows. Through the health care function of the fermented feed, more than 80% of drug additives required by the daily feeding of sows are reduced, and the application amount of the feed for increasing the disease-resistant immunocompetence of sows by using drug ingredients is reduced, thereby truly accomplishing the pollution-free breeding of sows.

Owner:TIANJIN YUANYUAN LIVE PIG BREEDING SPECIALIZED COOP

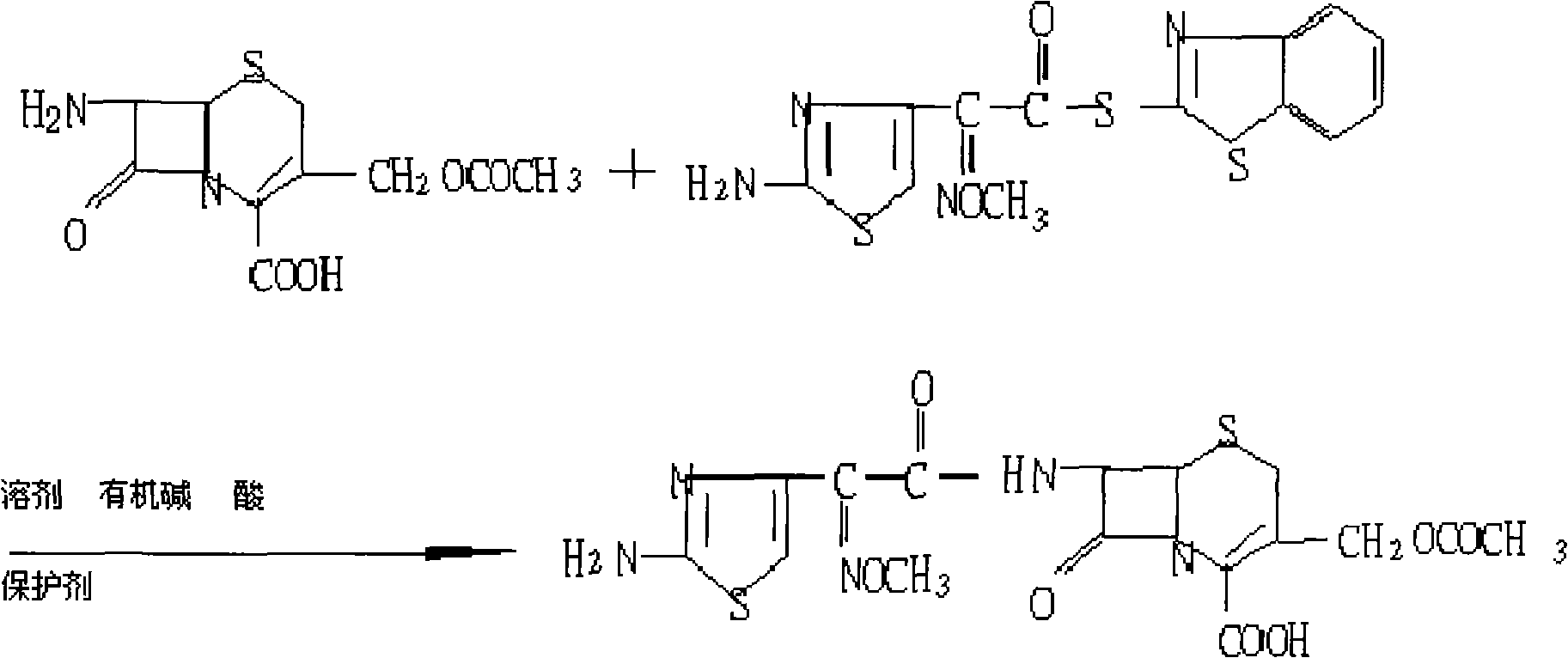

Preparation technology of cefotaxime

The invention relates to a preparation technology of cefotaxime, belonging to the preparation technology of medical compounds. The technology comprises the following steps: adding 7-ACA and AE-active resin reagents in solvent, and then adding an organic base and an alcohol catalyst to carry out a synthesis reaction. The preparation technology is characterized in that an acidifier is directly added for acidification after the reaction is finished so as to devitrified. The invention has simple and convenient operation, short production period, high product yield and low solvent consumption and can obtain products with uniform crystallized grains, good colors, high purity, low cost and stable quality.

Owner:REYOUNG PHARMA

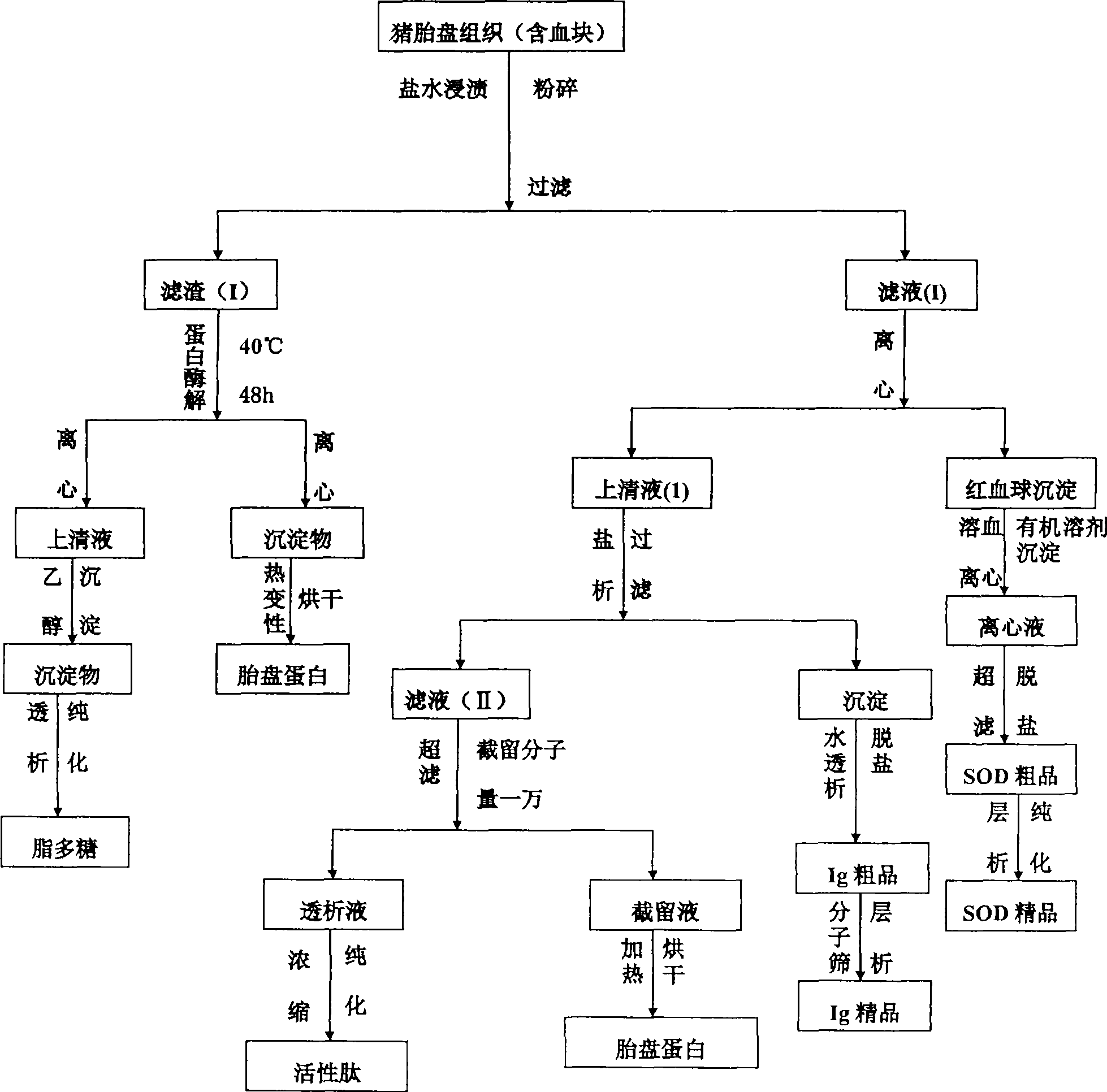

Coproduction process for extracting various bioactivators from pig placenta

ActiveCN101544965ATake advantage ofReduce manufacturing costImmunoglobulins against animals/humansPeptide preparation methodsBiotechnologyBiological integration

The invention provides a coproduction process for extracting various bioactivators from pig placenta, which comprises the following steps: taking the pig placenta (containing farrowing blood) as a raw material, utilizing components rich in the raw material such as immune globulin (Ig), immunocompetent peptide, superoxide dismutase (SOD), lipopolysaccharide, placental protein and the like, and applying modern biochemistry technology and biological integration technology such as salting in, salting out, chromatography, ultra-filtration and the like according to different structures, molecular weights, isoelectric points, physical and chemical properties, biological activities of the components to make the coproduction process suitable for industrial production. Therefore, in the same flow of the production process, the effective components in the pig placenta with market development value can be produced, namely five products of the immune globulin, the immunocompetent peptide, the superoxide dismutase, the lipopolysaccharide and the placental protein. The process combines the conventional and modern processes, produces various products through coproduction, and not only makes full use of placenta resources to change the waste into the treasure, does not discharge waste liquid and prevents the environment, but also can greatly reduce the production cost and improve the economic benefit.

Owner:ZHENGZHOU NUBLION BIOTECH

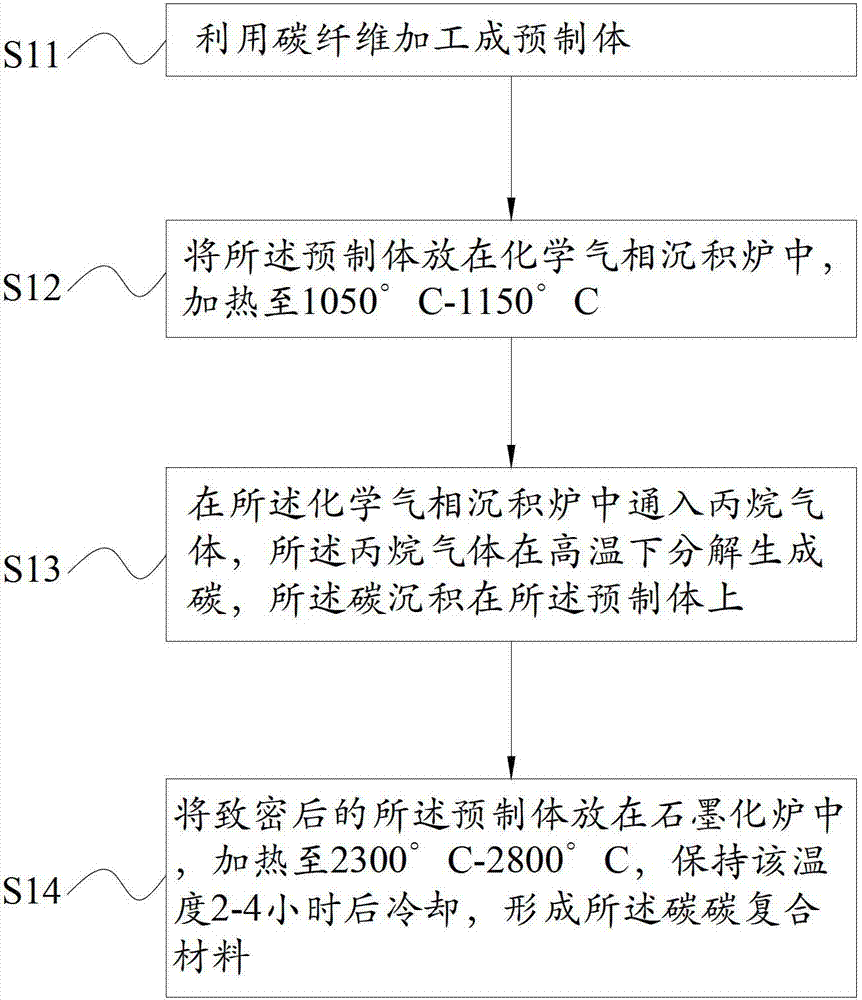

Straight pulling single crystal furnace and processing method of carbon-carbon composite material for straight pulling single crystal furnace

InactiveCN102731134ASimple processing methodContains less impuritiesBy pulling from meltFiberCarbon composites

The invention discloses a processing method of carbon-carbon composite material for a straight pulling single crystal furnace. The method comprises the steps of processing carbon fiber into a prefabricated body, then heating the prefabricated body in a chemical deposition furnace to 1050-1150 DEG C, and introducing propane gas, wherein the propane gas is decomposed at high temperature to generate carbon and the carbon is deposited in the prefabricated body; placing the compacted prefabricated body in a graphitization furnace; heating to 2300-2800 DEG C, and maintaining the temperature for 2-4 hours and cooling to form the carbon-carbon composite material. The invention further discloses the straight pulling single crystal furnace which comprises a heater processed by the carbon-carbon composite material. Density of the heater is greater than or equal to 1.8g / cm<3>. The processing method of the carbon-carbon composite material provided by the invention replaces a method of repeated impregnation by carrying out compacting treatment to the prefabricated body by using the chemical vapor deposition furnace, so that not only is the process simple, but also more impurities do not be doped in the compacting treatment process, and high temperature purification is not needed, thereby greatly simplifying the processing method.

Owner:BEIJING JINGYI CENTURY ELECTRONICS

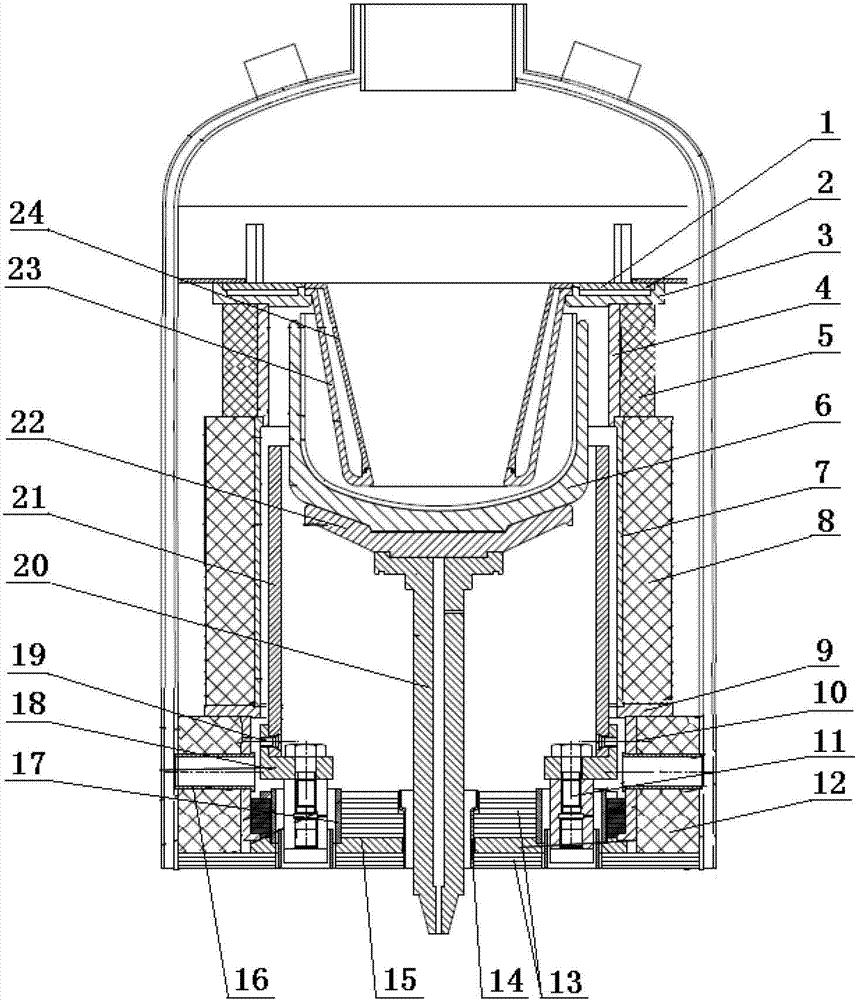

Method for preparing nano molybdenum disulfide with fullerene structure

The invention discloses a method for preparing nano molybdenum disulphide with a fullerene structure. The method comprises the following steps sequentially: by using industrial molybdenum trioxide as raw material, argon as carrier gas and hydrogen as reducing agent, molybdenum dioxide nano particle is generated by gas-phase reaction; the nano molybdenum disulphide and elemental sulfur are reacted under the condition of high temperature self-pressurization to produce powder material of the nano molybdenum disulphide with the fullerene structure; the molybdenum dioxide is nano particle generated directly by the reaction of the molybdenum trioxide after gasification under 700 to 1,000 DEG C with the hydrogen under 400 to 950 DEG C; the molybdenum disulphide with the fullerene structure is compound molybdenum disulphide by the self-pressurization reaction of the nano molybdenum dioxide and elemental sulfur in a vessel under 500 to 950 DEG C. The method for preparing the nano molybdenum disulphide with the fullerene structure has the advantages of simple process, high production efficiency, low cost of the raw material and product and short reaction time and the method can easily control the size of the molybdenum dioxide nano particle.

Owner:CHANGAN UNIV

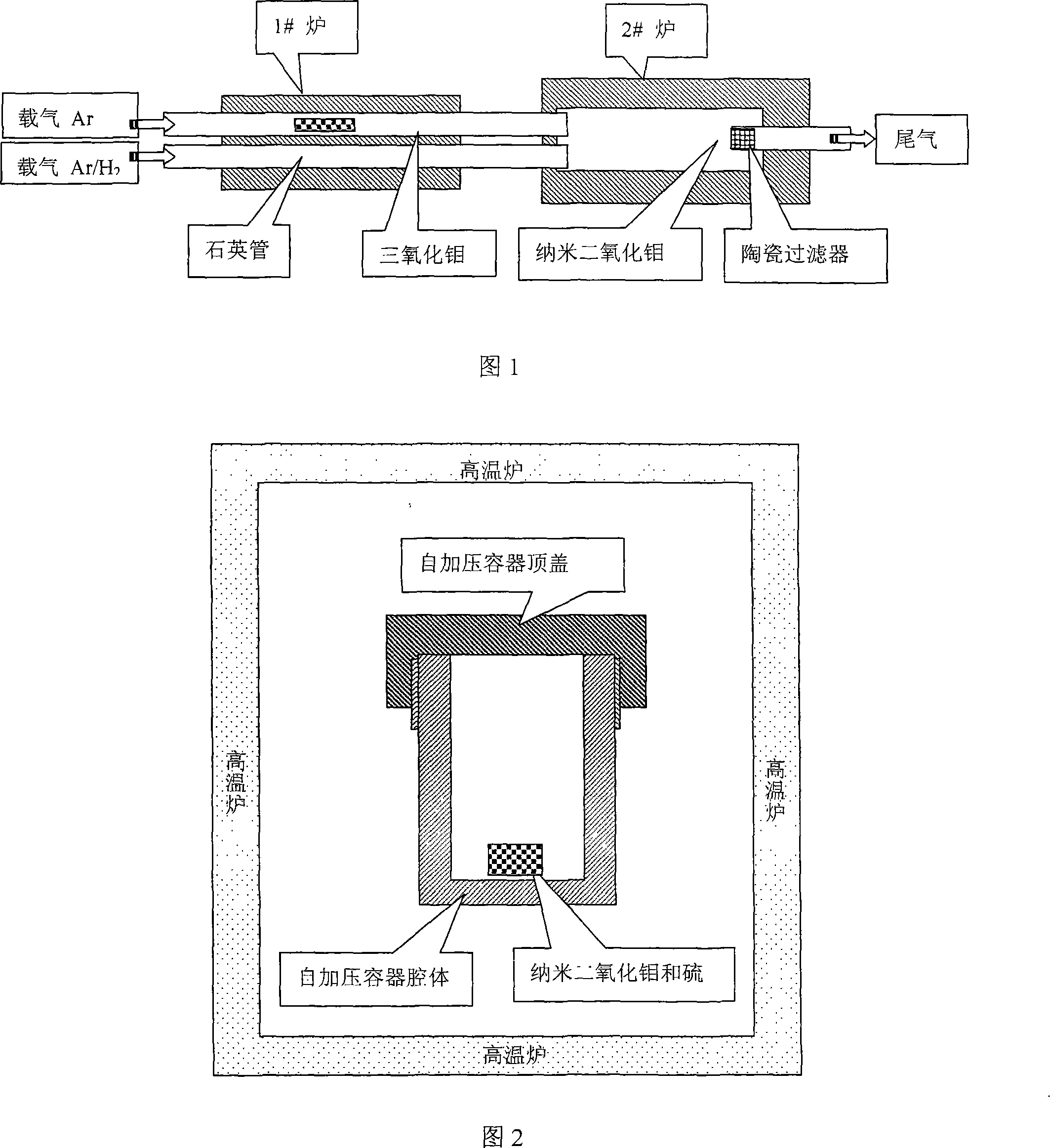

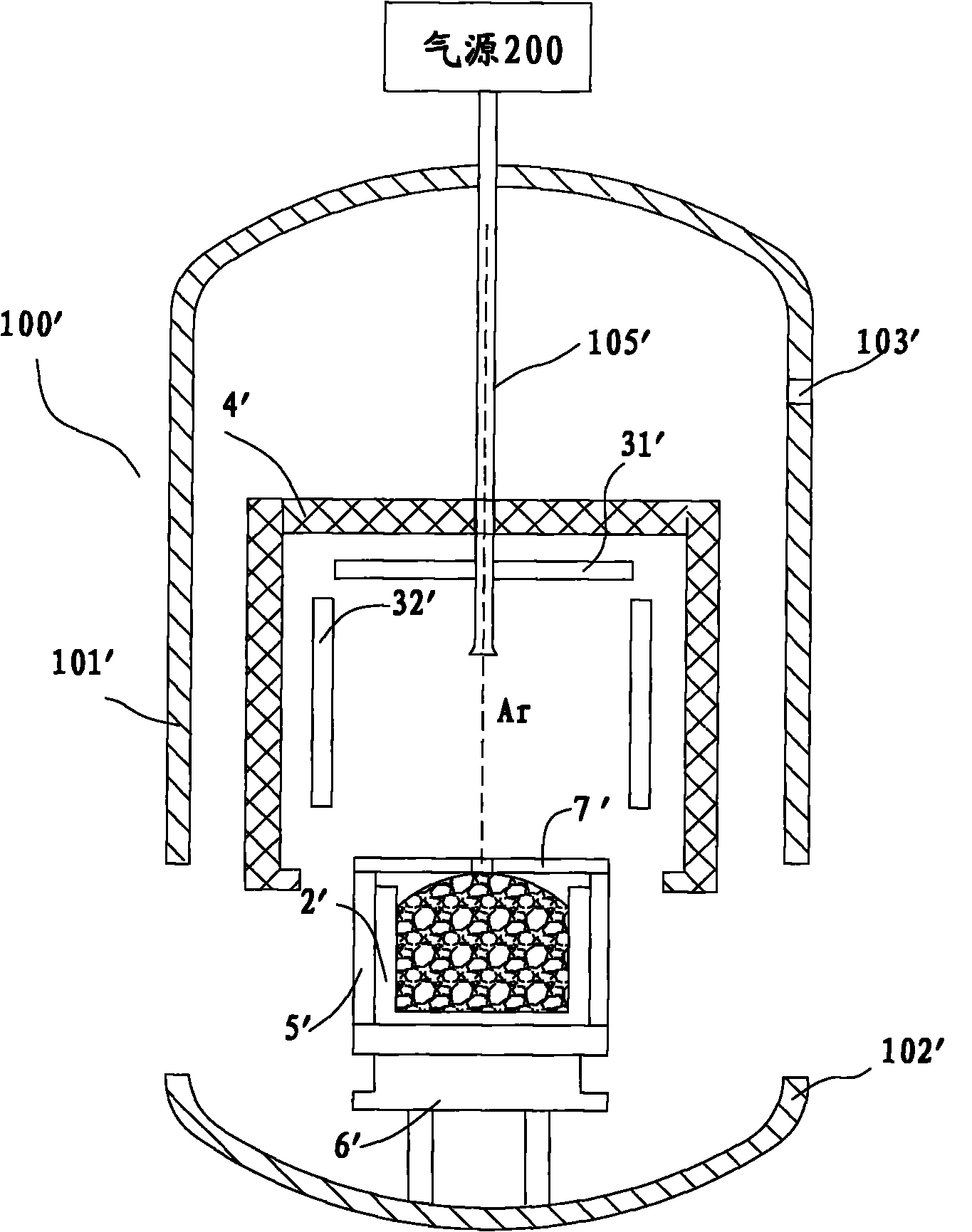

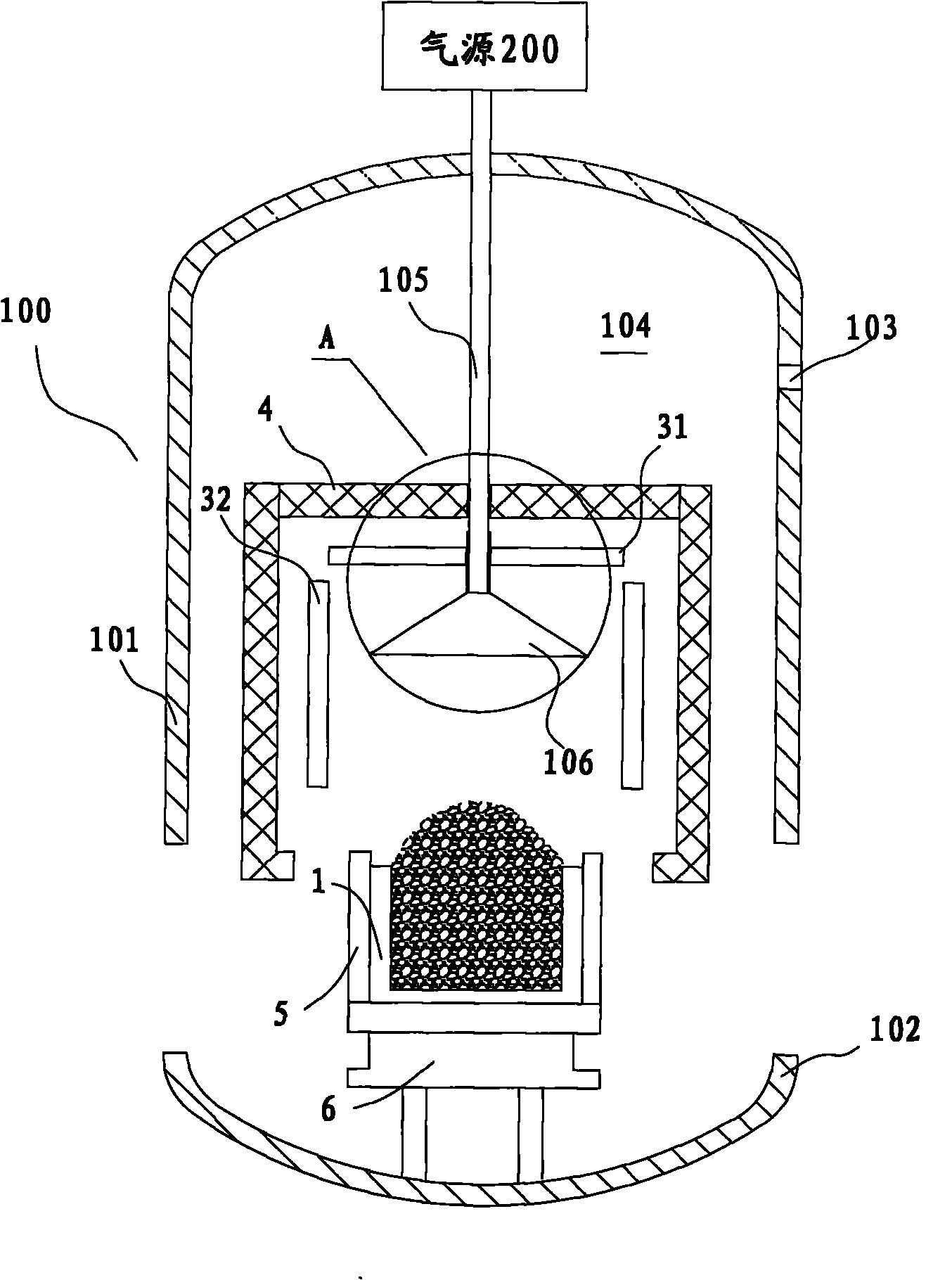

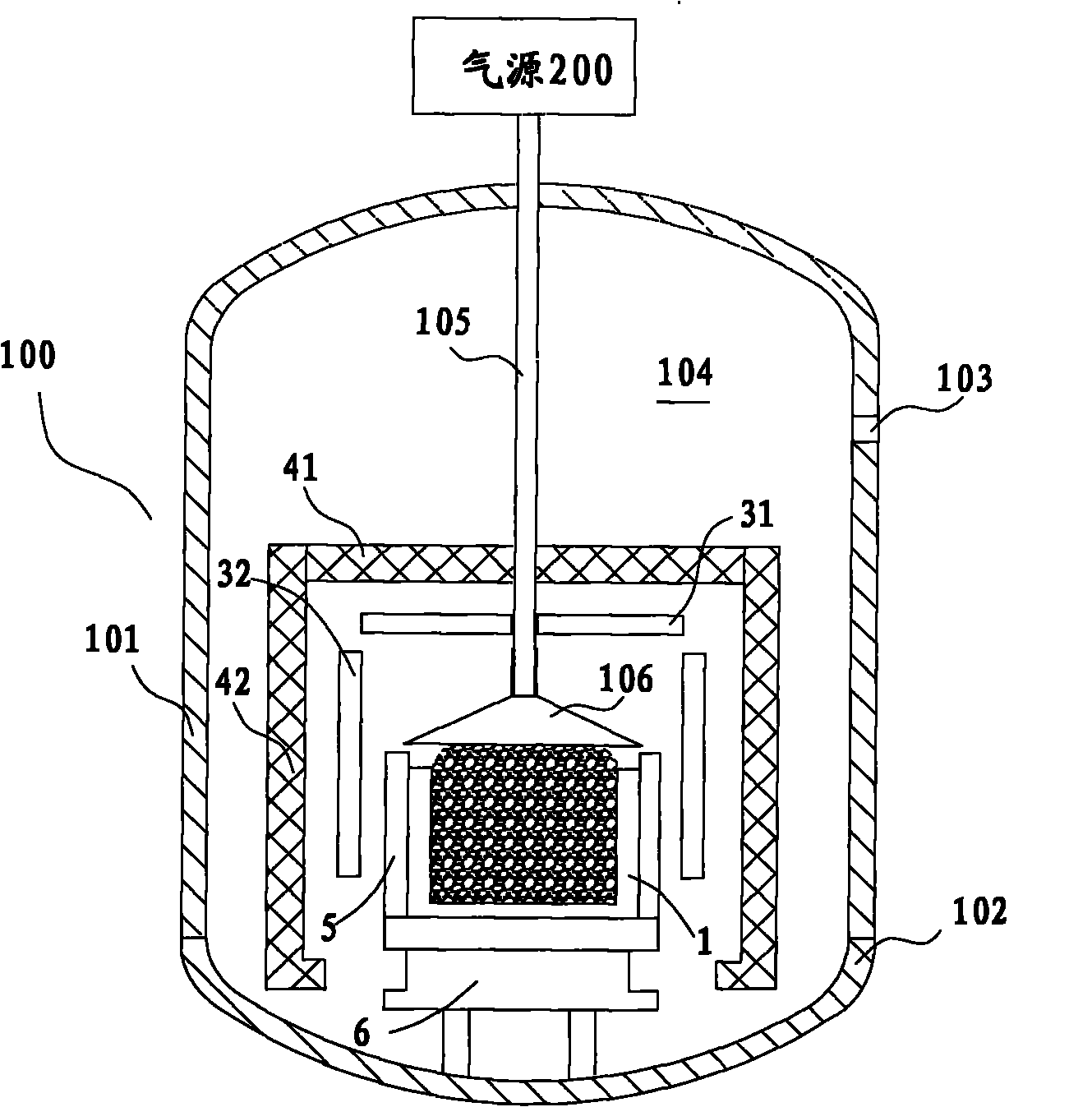

Directional solidification furnace with improved crucible cover part

InactiveCN101914805ANot cause pollutionCreate pollutionPolycrystalline material growthFrom frozen solutionsBreatherCrucible

The invention discloses a directional solidification furnace, which comprises an upper furnace body, a lower furnace body, a crucible, at least one heater, a crucible holder, a heat insulation component, a breather pipe and a crucible cover part, wherein the lower furnace body is matched with the upper furnace body to form a furnace body space; the crucible is arranged in the furnace body space and constructed to accommodate a feedstock; the at least one heater is used for heating the crucible and melting the feedstock accommodated in the crucible; the crucible holder is used for holding the crucible; the heat insulation component is constructed to longitudinally move relative to the crucible so as to control directional solidification of the feedstock in the crucible; the breather pipe is connected with an external gas source and vertically passes through the heat insulation component; and the crucible cover part is detachably arranged at the bottom of the breather pipe, and the sizeof the crucible cover part is adapted to the size of the top of the crucible so as to cover above the crucible. The directional solidification furnace can ensure that the furnace cavity is not polluted at the same time of realizing increment of the feedstock so as to improve the production efficiency and reduce the cost at the same time of ensuring the quality of a produced billet.

Owner:王楚雯

Prepn process of malonic ester

InactiveCN101066921AReduce usageReduce dosageOrganic compound preparationCarboxylic acid esters preparationAcetic acidChloroacetic acids

The present invention provides preparation process of malonic ester. Malonic ester is prepared with chloroacetic acid as material and through a neutralization reaction, a cyanidation, an acidification, a dewatering step, a hydrolysis and twice esterification. The preparation process with twice esterification has total malonic ester yield as high as 90 %, obviously reduced consumption of extractant toluene, high apparatus utilizing rate and lowered production cost.

Owner:CHONGQING UNISPLENDOUR CHEM

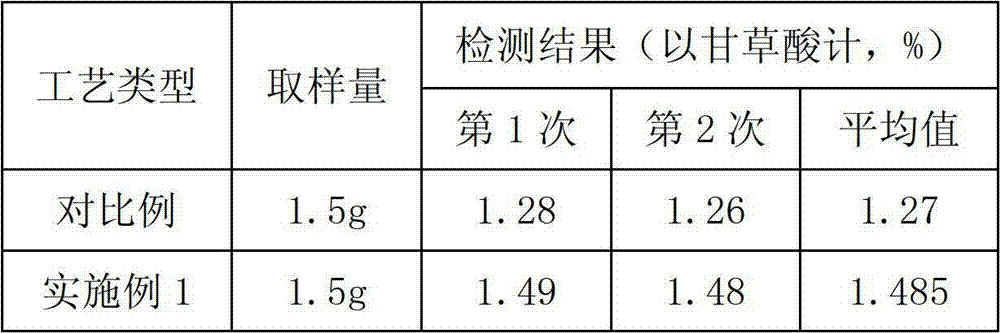

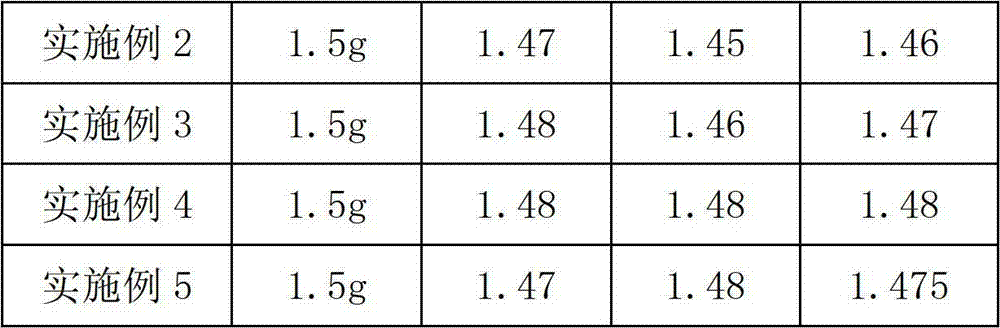

Preparation method of licorice particles for livestock and poultry

ActiveCN102727569AChanging the high temperature decoction processPromote leachingAntibacterial agentsDigestive systemCyclodextrinSolvent

The invention discloses a preparation method of licorice particles for livestock and poultry, comprising the following steps of: firstly taking licorice, placing it into an extraction pot to form a medicinal material layer, adding water and immersing, adjusting the operating temperature of the extraction pot to 60-80 DEG C for extraction, leading out parts of an extract from the bottom of the extraction pot during the extraction process and carrying out vacuum concentration while the concentration temperature is 50-70 DEG C, condensing steam generated by the concentration, returning the stream used as a new solvent into the extraction pot for permeating extraction of the medicinal material layer, continuously repeating for 2-3 hours, condensing to finally obtain a fluid extract, adding anhydrous glucose and maltodextrin or cyclodextrin and the fluid extract into a spray drying granulator, and carrying out granulation so as to obtain the licorice particles for livestock and poultry. According to the preparation method of the licorice particles for livestock and poultry, the two processes of licorice extraction and condensation are synchronously carried out so as to change a high-temperature decocting technology of a traditional extraction pot under pressure and at normal pressure. Therefore, energy can be saved by 0.3-0.5 time; the amount of a hydrosolvent is minimized by 0.5-1 time; the feeding amount is increased by 30-60%; extract yielding rate is raised by more than 10%; the storage process is minimized; and electric power energy is saved by more than 30%.

Owner:ZHENGZHOU BARY ANIMAL PHARMA

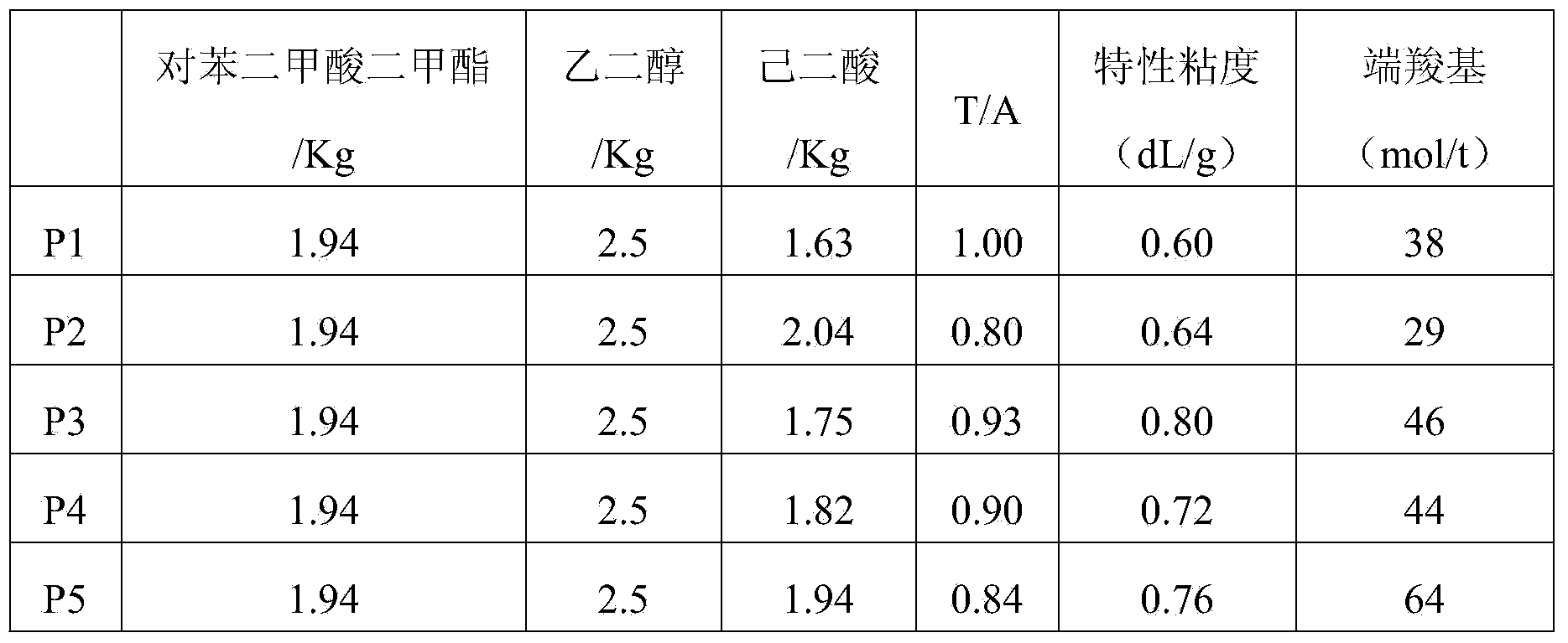

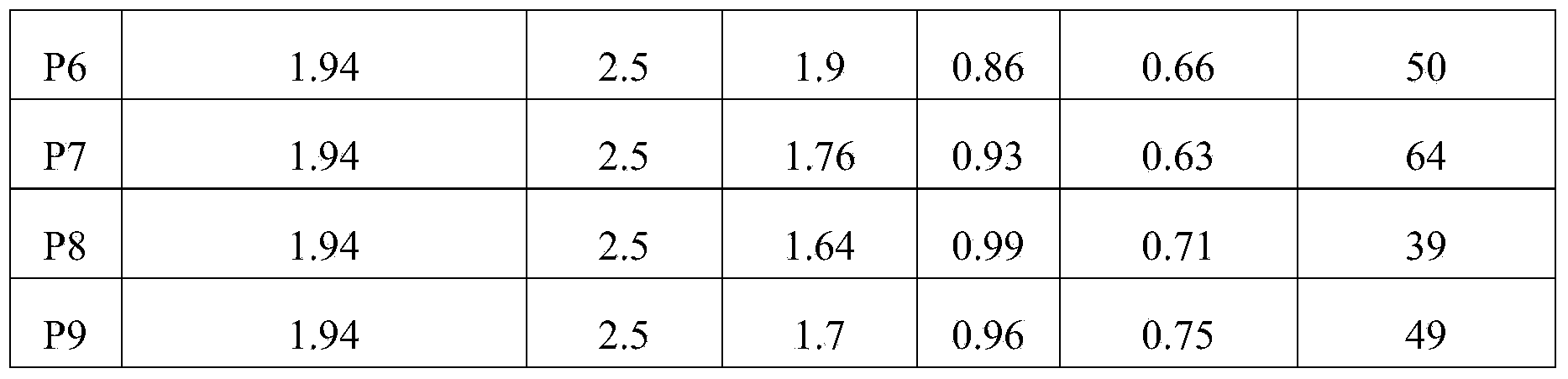

Modified PET copolyester and preparation method and application thereof

The invention belongs to the technical field of polyester preparation, and discloses a modified PET copolyester with high viscosity and a low terminal carboxyl group and a preparation method and application thereof. The copolyester contains the following ingredients in parts by weight: 100 parts of low-viscosity PET copolyester, 0.8-2.0 parts of oxazoline compound and 0.6-2.0 parts of a hydroxyl chain extender. The method prepares the high-viscosity modified PET copolyester by adding the oxazoline compound and the hydroxyl chain extender. The oxazoline compound is added to react with the terminal carboxyl group in resin, the terminal carboxyl group content of resin is reduced, therefore, the hot water resisting performance of resin is increased. The hydroxyl chain extender is added, the molecular weight of resin is increased, and the balance between a physical performance and a processing performance is achieved. The viscosity and the melt strength of the modified PET copolyester are increased, the content of terminal carboxyl group is reduced, and the hot water resisting performance is greatly increased. Moreover, the production method shortens the polycondensation time and the production cycle, effectively reduces the thermal degradation reaction, and also increases the output of equipment.

Owner:KINGFA SCI & TECH CO LTD

Inside diameter measuring tool

InactiveUS8033032B2Friction minimizationImprove accuracyMicrometersMechanical diameter measurementsEngineeringElectrical and Electronics engineering

An inside diameter measuring tool includes: a main body; an axially moving spindle having a male screw to be screwed to the main body; a plurality of contact pieces provided on the main body, the measuring pieces moving in a direction substantially orthogonal to the axial direction of the spindle; and a conical member interposed between the contact pieces and the spindle, the conical member advancing and retracting the contact pieces in the direction substantially orthogonal to the axial direction of the spindle. The lead of the male screw of the spindle is 1.0 mm or more and the cone angle of the conical member is less than 53 degrees. Preferably, the lead of the male screw is 2.0 mm and the cone angle of the conical member is approximately 28 degrees.

Owner:MITUTOYO CORP

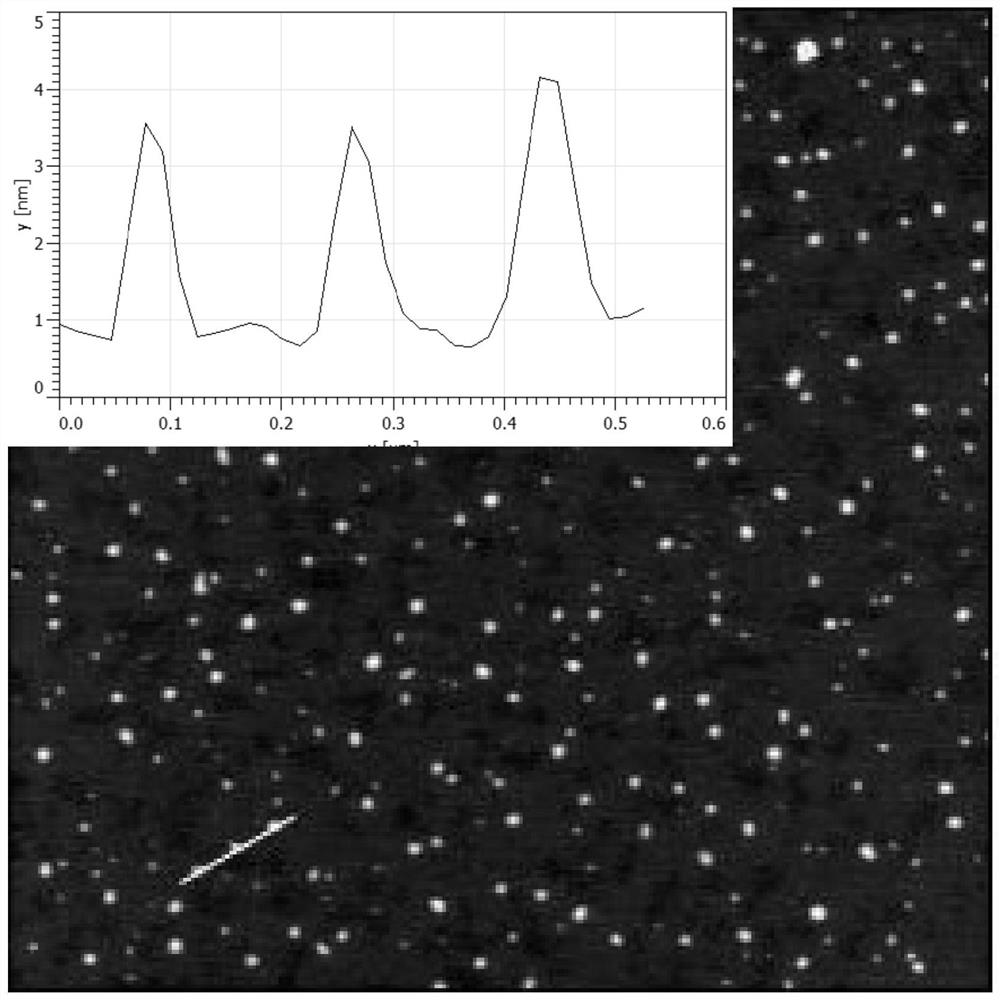

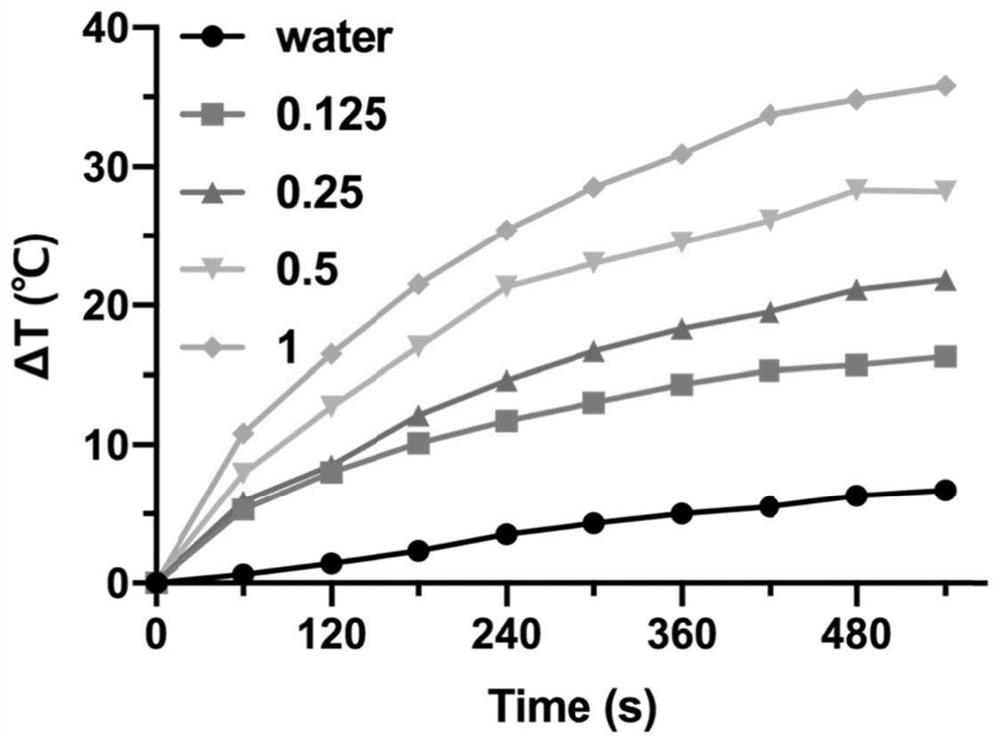

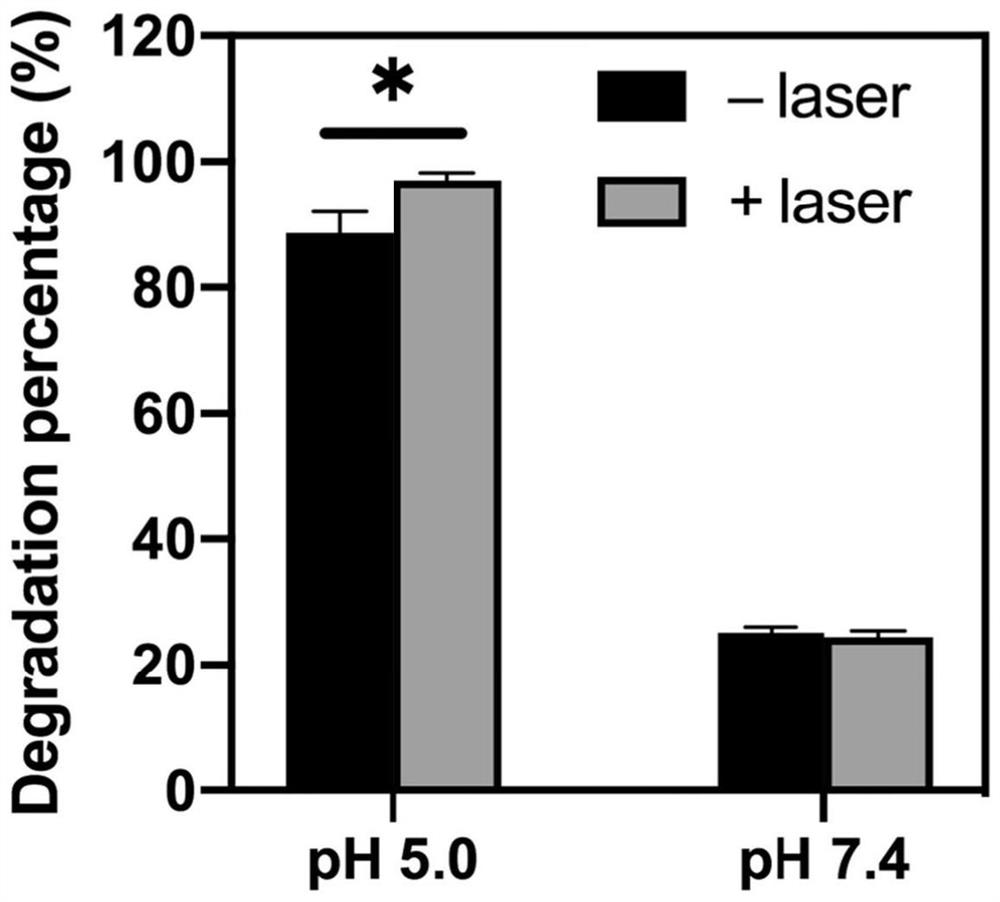

Nano-drug for tumor photo-thermal and iron agent combined treatment and preparation method of thereof

ActiveCN112791185AGood killing effectImprove stabilityMaterial nanotechnologyEnergy modified materialsPharmaceutical medicineIron agent

Owner:GUANGZHOU MEDICAL UNIV

Method for preparing graphene porous membrane

InactiveCN106395802AUniform sizeGood for research and understanding storageGrapheneOrganic solventMicrosphere

The invention provides a method for preparing a graphene porous membrane. The method includes the steps that oxidized graphite is added into water, oxidized graphite dispersion liquid is obtained and subjected to ultrasonic dispersion, and an oxidized graphene solution is obtained; a pore forming agent is added into the oxidized graphene solution and evenly dispersed into oxidized graphene, the mixture is subjected to suction filtration and / or dried, and a composite membrane of the oxidized graphene and the pore forming agent is obtained; the composite membrane of the oxidized graphene and the pore forming agent is reduced and washed, and a composite membrane of graphene and the pore forming agent is obtained; the pore forming agent is removed with an organic solvent, and under the moist condition, the product is further treated with the critical point drying method, and the graphene porous membrane is obtained; the pore forming agent is one or more of homopolymer microspheres and copolymer microspheres. The size of pores inside the graphene porous membrane prepared with the method ranges from 100 nm to 1,000 nm, the porosity can be regulated and controlled by regulating the concentration or the size of the pore forming agent, the yield of the graphene porous membrane is high, and an operating device is simple.

Owner:SHANDONG UNIV OF TECH

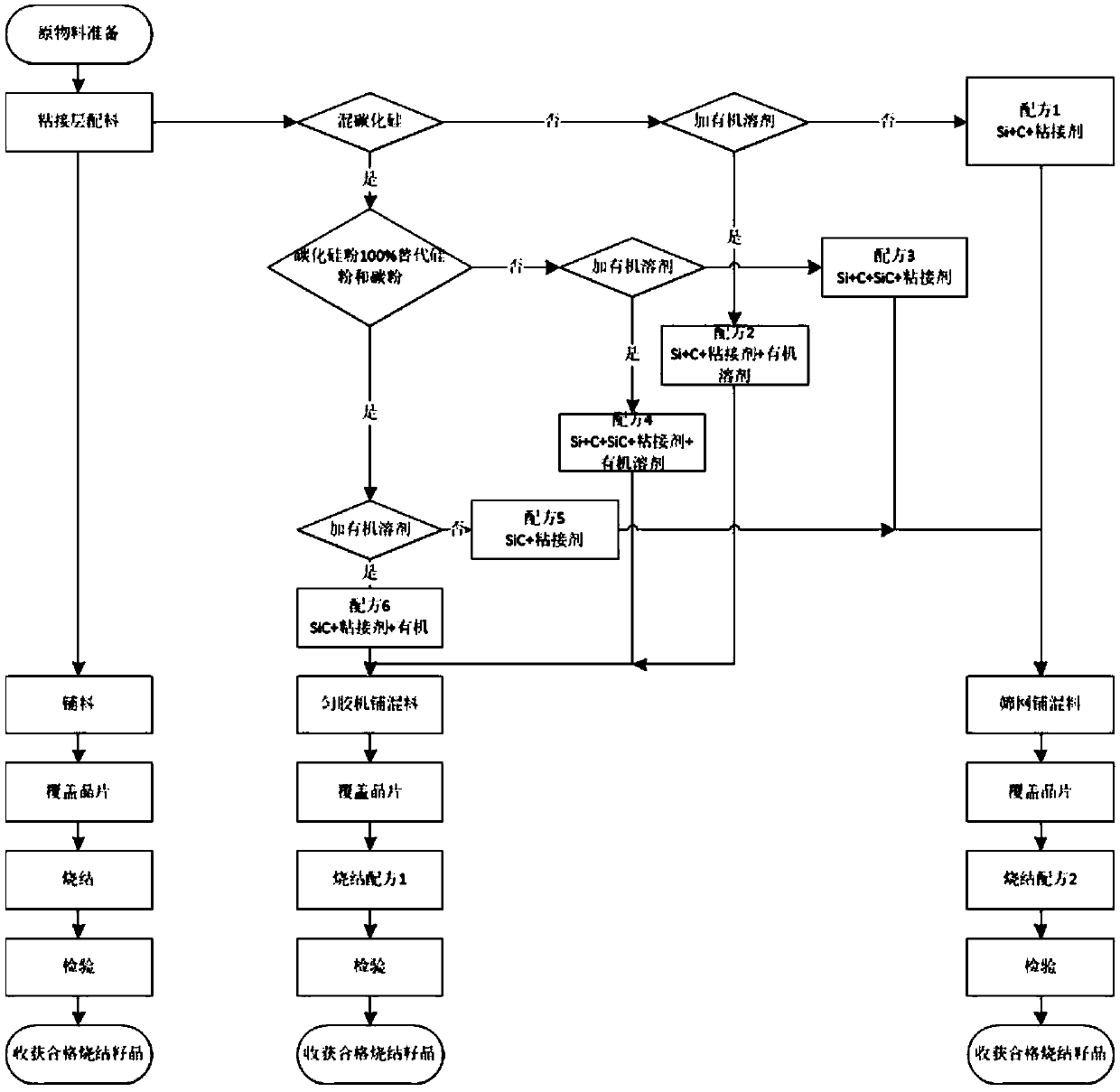

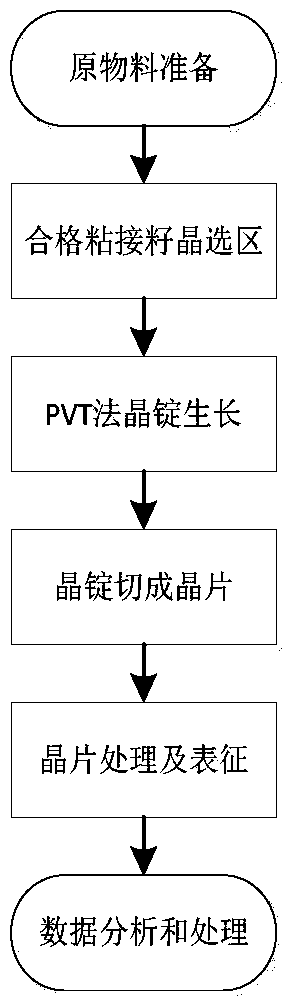

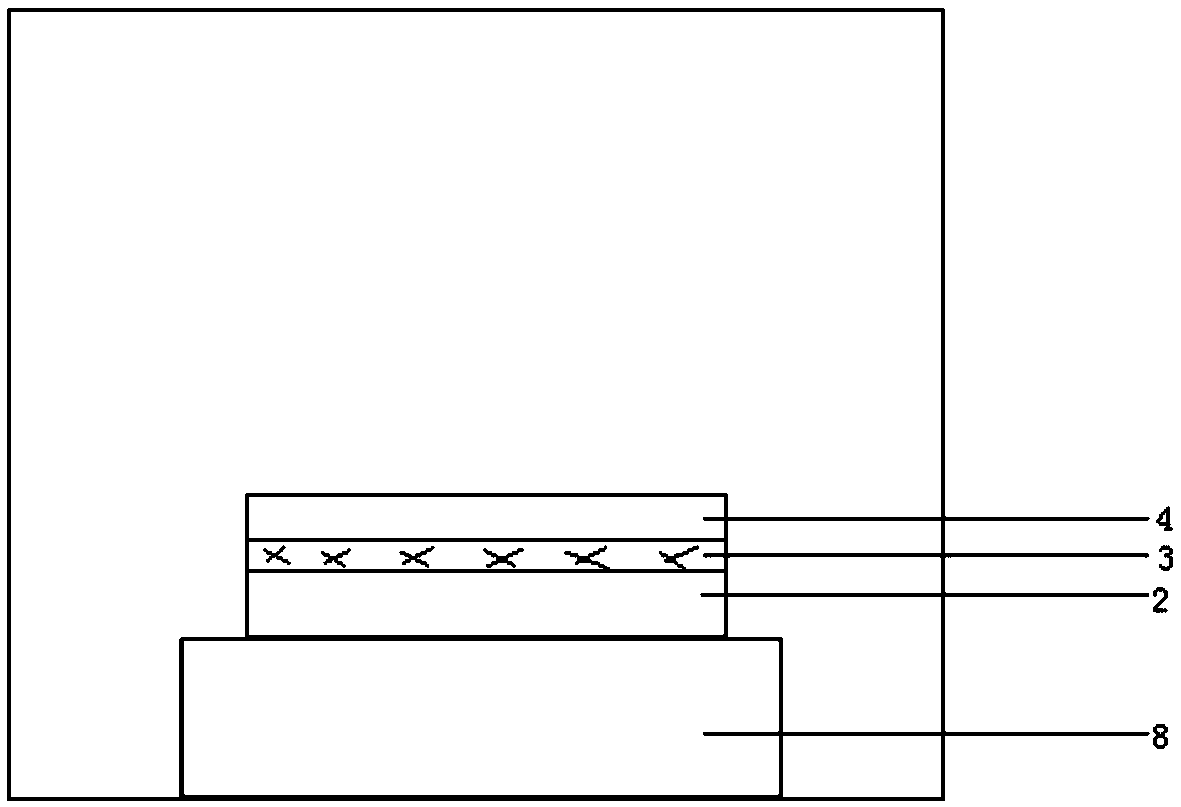

Bonding method of silicon carbide seed crystals and preparation method of silicon carbide single-crystal ingot

InactiveCN109554759AImprove heat transfer performanceFast and efficient heat transferPolycrystalline material growthFrom condensed vaporsIngotCrystal growth

The invention discloses a bonding method of silicon carbide seed crystals and a preparation method of silicon carbide single-crystal ingot. The bonding method of the silicon carbide seed crystal comprises the following steps: mixing silicon carbide powder, carbon powder and silicon powder, adding a binder, uniformly carrying out mixing to obtain mixed powder, coating a silicon carbide wafer with the mixed powder, placing the silicon carbide seed crystals on the mixed powder, and enabling the seed crystals to be tightly bonded with the silicon carbide wafer under an inert atmosphere at a temperature of 1500-2000 DEG C to obtain the silicon carbide bonded seed crystals, wherein no impurities are introduced. When the silicon carbide bonded seed crystals obtained through the method is used ingrowing the silicon carbide single-crystal ingot through a physical vapor transport (PVT) method in a silicon carbide crystal growth furnace, heat conduction is rapid, heat transfer is uniform, and the high-quality silicon carbide single-crystal ingot can be obtained. According to the method, the feeding space and the feeding amount of the raw materials are increased, so that the size of a singlecrystal ingot is increased, the wafer output of a single crystal ingot is increased, and operation cost of the silicon carbide crystal growth furnace is reduced.

Owner:安徽长飞先进半导体有限公司

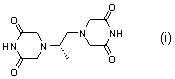

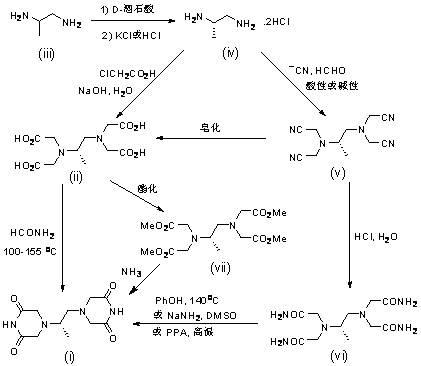

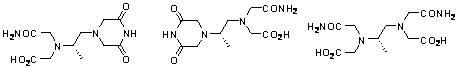

Preparation method of high-purity dexrazoxane

ActiveCN102675227AIncrease the degree of steamingGood dispersionOrganic chemistryPressure reductionSodium salt

The invention relates to a preparation method of high-purity dexrazoxane, which comprises the following steps of: (1) cyclization reaction: carrying out cyclization reaction between (S)-1, 2-propane diamine-N, N, N', N'-tetracetic acid or disodium salt of (S)-1, 2-propane diamine-N, N, N', N'-tetracetic acid and formamide, wherein a high boiling point solvent is used; (2) preparation of salt-containing crude product: evaporating the mixture, which is obtained after reaction, for removing the formamide by pressure reduction and concentration, adding organic solvent into the mixture, and filtering to obtain solid; (3) preparation of crude product: adding dioxane into the salt-containing crude product, heating for backflow, filtering, concentrating the filtrate, adding organic solvent into the filtrate to obtain the crude product of dexrazoxane; and (4) refining: adding the crude product of dexrazoxane into N, N'-dimethyl formamide, heating for dissolving, dropwise adding the solvent, carrying out crystallization, filtering to obtain solid, washing the obtained solid with the solvent, drying to finally obtain the high-purity dexrazoxane. The method for synthesizing dexrazoxane is stable in yield and easy in condition control; the product purity is higher than 99.5% and residual organic solvent is little, and the synthesis cost can be reduced.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Oral freeze dried formulation of specific yelk immunoglobulin and its preparation method and usage

InactiveCN1621090AGuaranteed natural activityGuaranteed stabilityAntibacterial agentsPowder deliveryYolkDisease

The peroral freeze dried specific yolk immune globulin preparation includes specific immune globulin, excipient and solute in solvent. The preparation process includes preparing specific pathogen antigen; adding incomplete Folin reagent in the same amount as the antigen for fully emulsification to obtain immunogen; immunizing the layer with the immunogen; extracting specific yolk immune globulin from the egg of the layer; mixing the specific immune globulin, the excipient and the solvent to obtain mixture liquid; freeze drying the mixture liquid to produce the peroral freeze dried specific yolk immune globulin preparation. The preparation has the specific yolk immune globulin with less denaturation and maintained natural activity, and may be used in preparing medicine, food or health article for treating digestive tract disease caused by pathogenic microbe.

Owner:SHENZHEN ANTUOXING BIOTECH DEV

Two-machine two-flow electron beam cold bed smelting furnace

The invention discloses a two-machine two-flow electron beam cold bed smelting furnace. The furnace comprises a double-layer water-cooling structure furnace body, a high-power electronic gun arrangedon a furnace cover, transverse feeding systems connected to the side faces of the furnace body, a smelting crucible connected to the feeding system and arranged in the furnace body, crystallizers connected to a smelting crucible refining area, ingot pulling devices connected to the crystallizer in a matched mode, an observation window used for observing the condition in the furnace and a matched vacuumizing system. The two transverse feeding systems are arranged on the two sides of the furnace body respectively, the two crystallizers and the two ingot pulling devices matched with the crystallizers are arranged, and the smelting crucible refining area is provided with two melt guide openings which are connected with the crystallizers respectively. According to the furnace, the smelting amount each time is increased, two cast ingots can be produced at the same time, and the ingot pulling production efficiency and the product specification diversity are improved.

Owner:YUNNAN HEAVY EQUIP MFG GRP

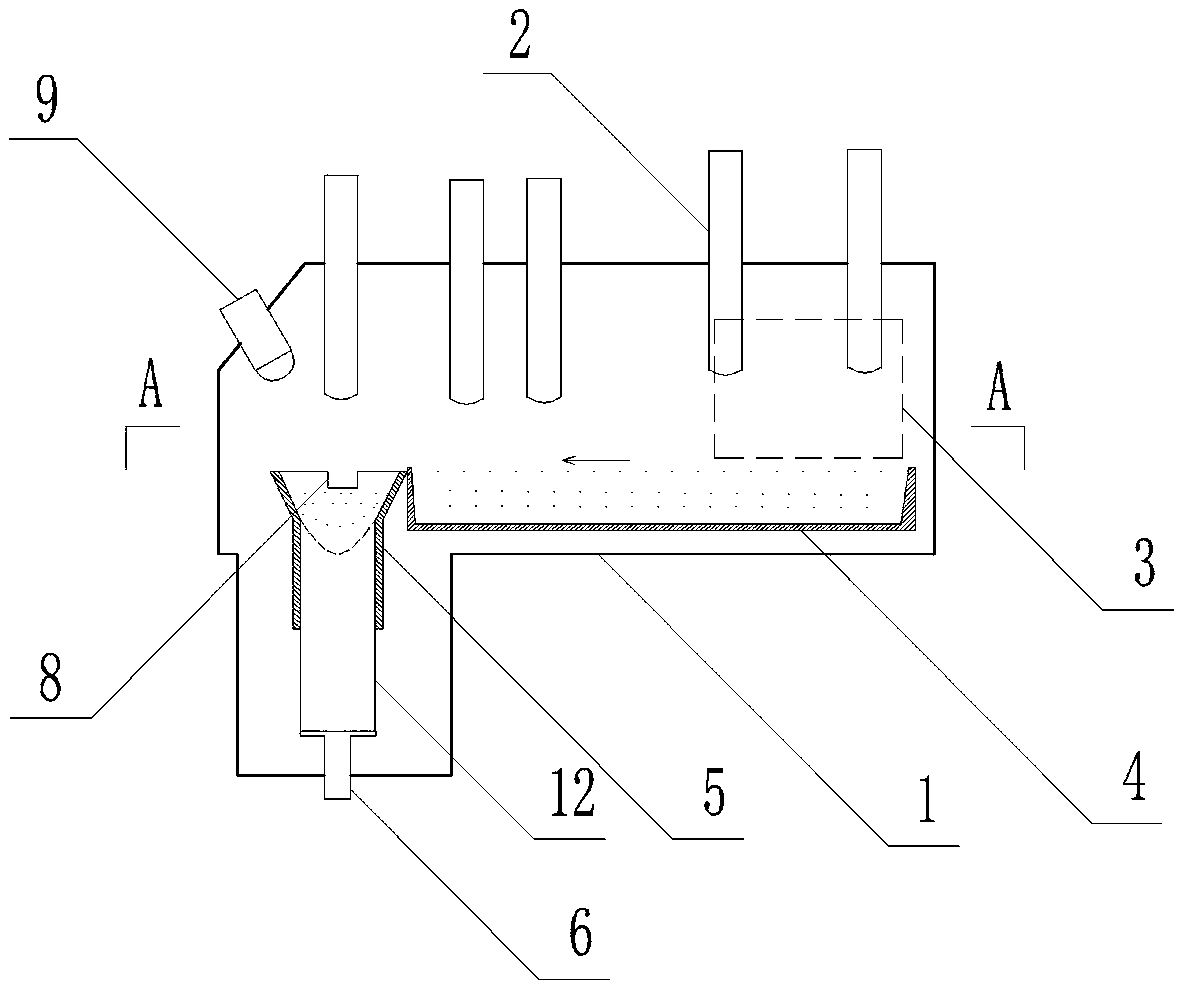

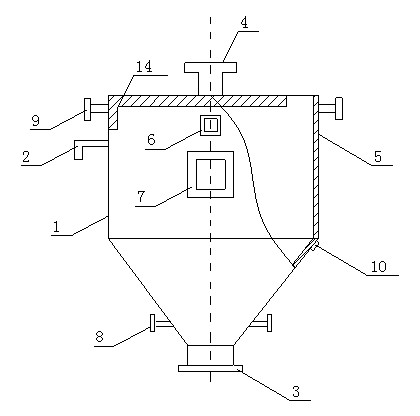

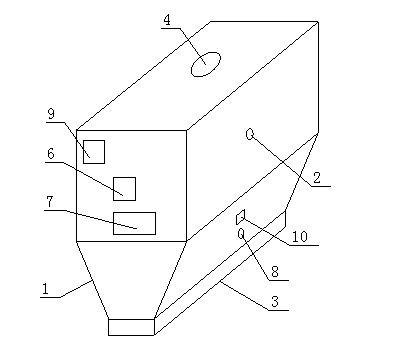

Glass microballoon manufacturing device and preparation method thereof

InactiveCN102417291APrevent molten buildupReduce devitrificationGlass shaping apparatusGlass productionDevitrificationCombustor

The invention discloses a glass microballoon manufacturing device comprising a furnace body (1) and a waste gas treatment device, wherein the furnace body (1) is formed by air-tight connection of an upper part and a lower part, the upper part of the furnace body is of a cubic shape, a waste gas emission port (4) is arranged at the top of the upper part, one or more injection-type burners (2) are horizontally installed on the side of the upper part, a preheating air pipe (14) is arranged in the upper part, the lower part of the furnace body is of a square conical shape, and one or more microballoon collectors (3) are arranged at the bottom of the lower part. According to the glass microballoon manufacturing device and the preparation method thereof provided by the invention, the furnace body which adopts the cubic structure enlarges the cooling space; the horizontally installed injection-type burners and the preheating air pipe arranged in the furnace body can give full play to the heat value of fuel, thus reducing energy source waste, saving energy and reducing emission; TiO2 and Al2O3 with relatively lower costs are adopted, the refractive index of the product is greater than or equal to 1.93; and the glass microballoon manufacturing device and the preparation method thereof have the advantages of reducing devitrification, improving the cooling velocity, having good product quality, improving the utilization ratio of raw material, being capable of large-scale production, and the like.

Owner:SICHUAN ZHONGKE BETTER TECH

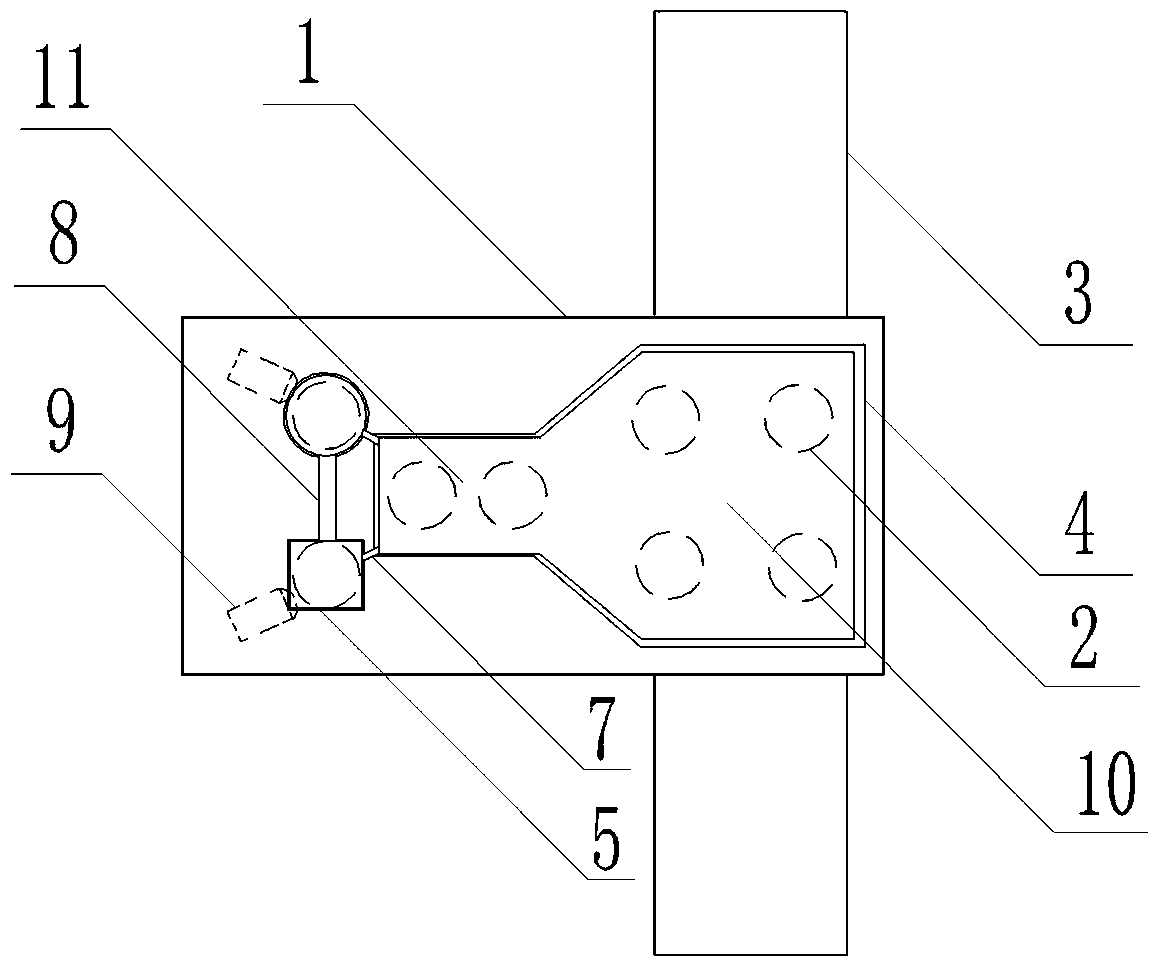

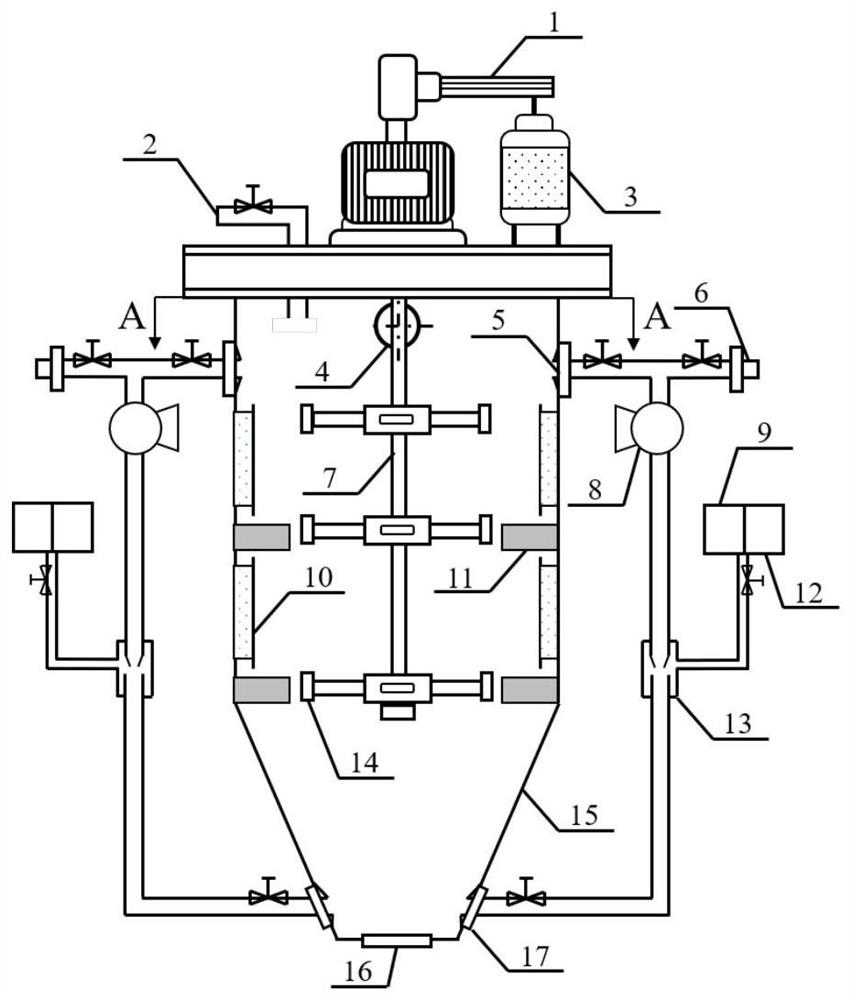

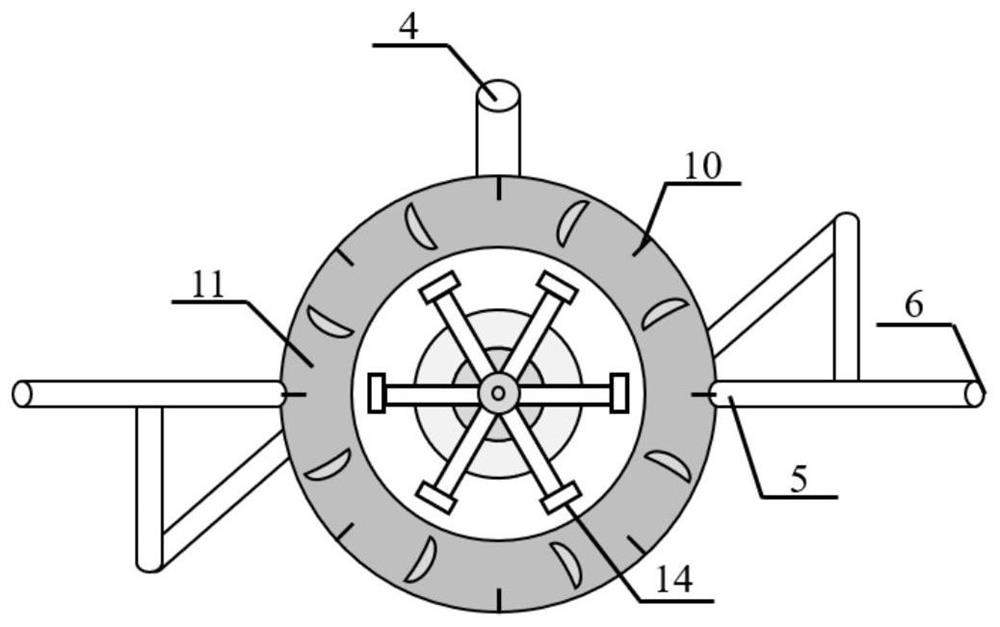

Pre-selection efficient size mixing method suitable for wide-size-fraction flotation

ActiveCN111871620AAssist in shearingIncreased turbulent energy dissipation rateRotary stirring mixersTransportation and packagingFoaming agentPulp and paper industry

The invention discloses a pre-selection efficient size mixing method suitable for wide-size-fraction flotation. The pre-selection efficient size mixing method is suitable for peat check. The method includes following steps: firstly, wide-size-fraction ore pulp is fed through ore pulp feeding ports in the two sides of a pulp mixing barrel to form high-speed jet flow, wherein the high-speed jet flowenters from the inlet end of a dosing pipe of a Venturi tube structure to form negative-pressure area ore pulp, a collecting agent and a foaming agent are self-sucked into the negative-pressure areaore pulp in a Venturi vertical pipe structure to be emulsified, and the cavitation phenomenon occurs in the ore pulp; then, ore pulp jet flow openings in the two sides of the ore pulp inverted halfpace structure are tangentially jetted and fed into the bottom of the pulp mixing barrel to form upward strong rotational flow, and the rotating direction of a rotating impeller on a stirring shaft in the pulp mixing barrel is controlled to be always opposite to the strong rotational flow direction to guarantee ore pulp reverse flow; upward strong rotational flow ore pulp and the rotary impeller formcountercurrent pulp mixing in the forced stirring area, stress distribution is reduced through the annular shearing partition plate and the flow guide plate, equipment stability is improved, meanwhile, the auxiliary shearing effect on the strong rotational flow ore pulp moving upwards is achieved, so that the pulp mixing effect is improved. The method is simple, and the size mixing effect is good.

Owner:CHINA UNIV OF MINING & TECH

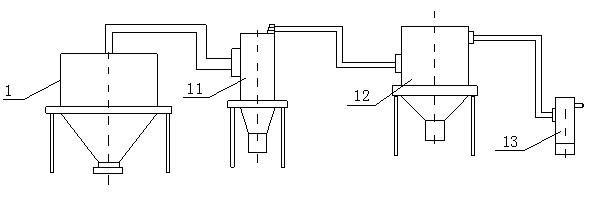

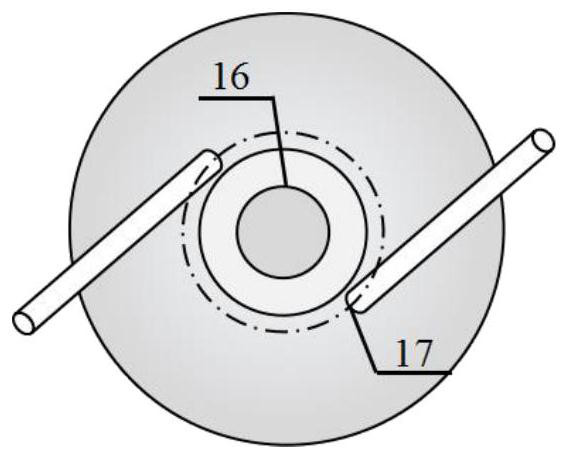

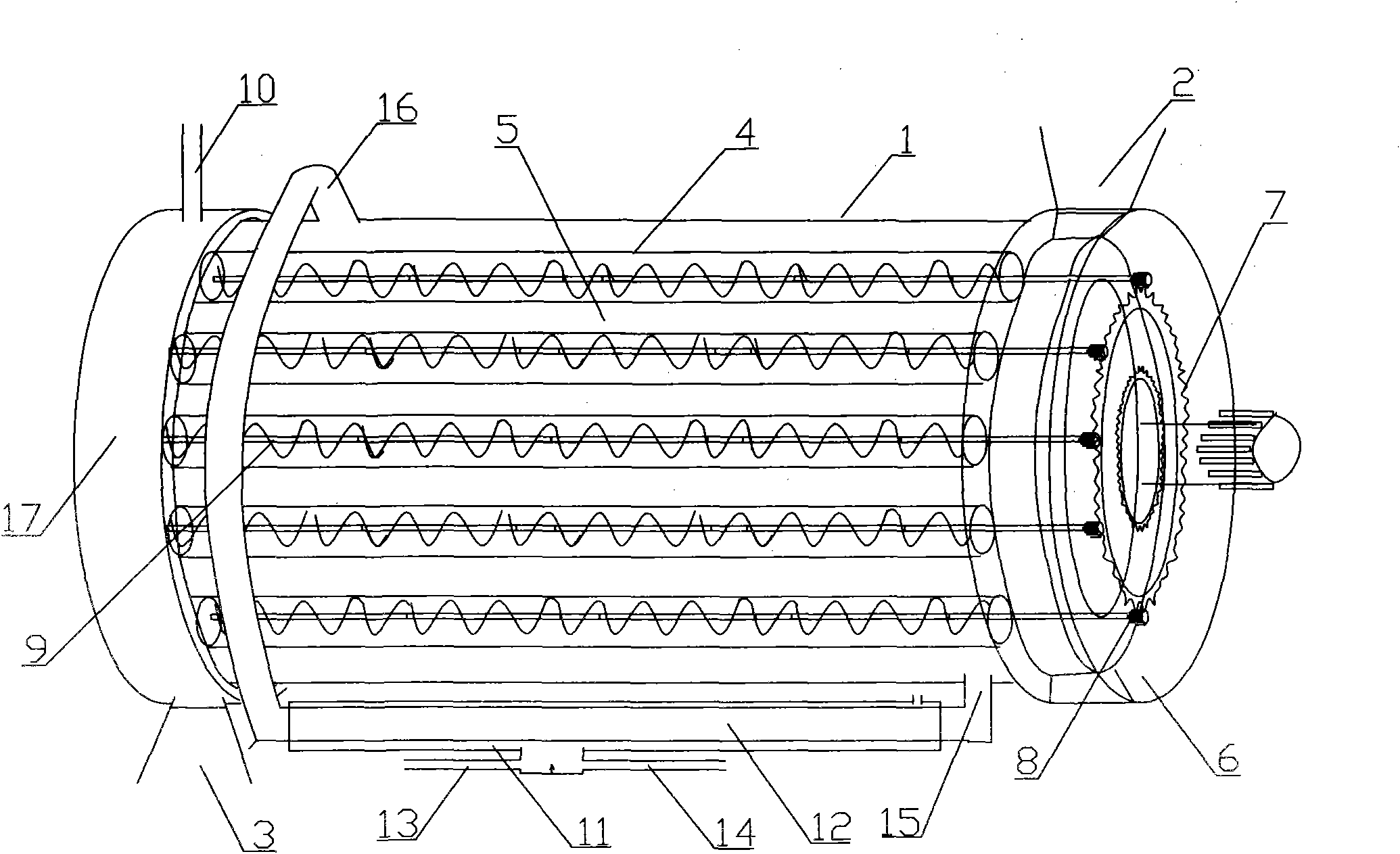

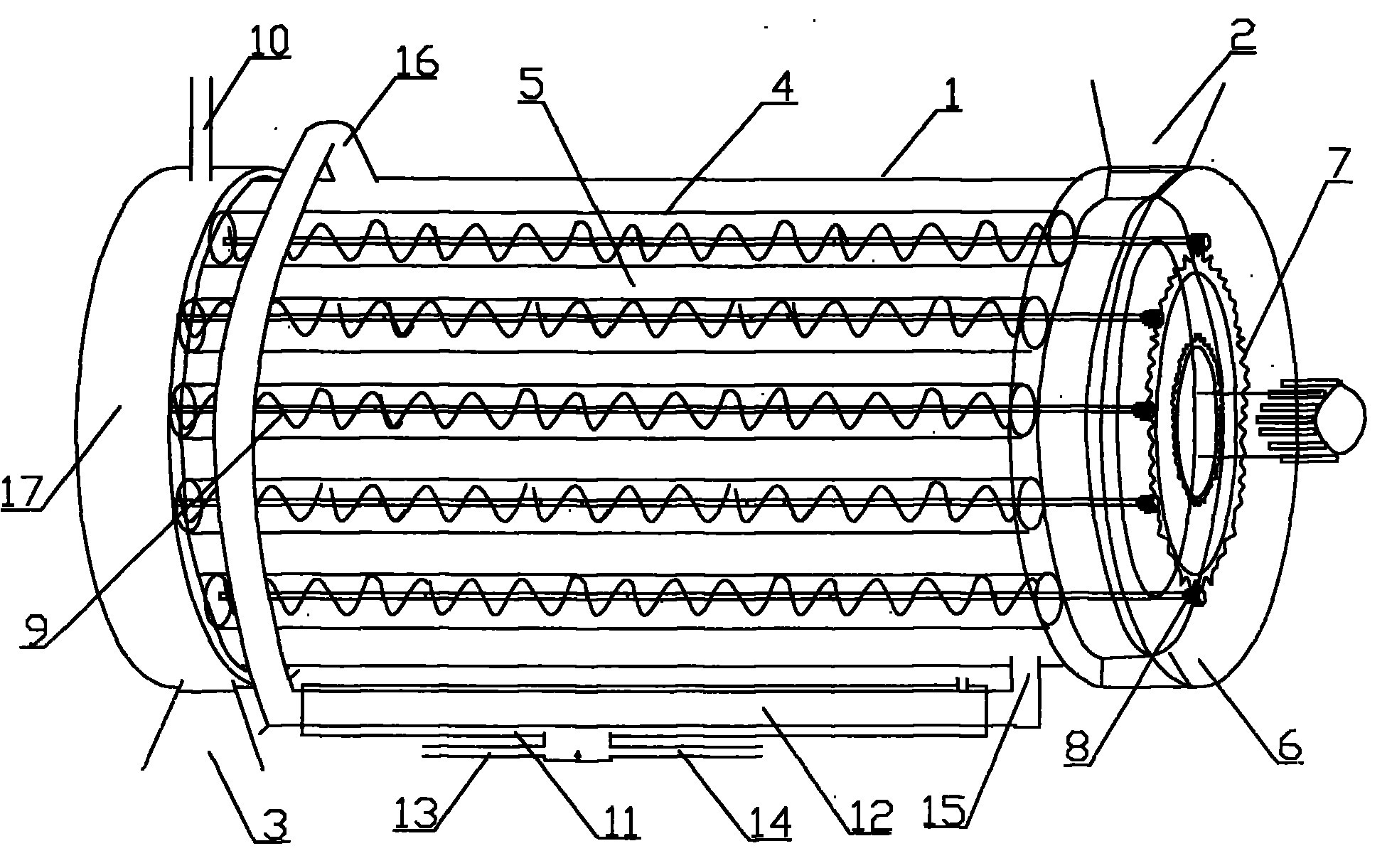

In-tube propelled coal material decomposition device

ActiveCN101984023AFully generate conductionIncrease profitFurnace typesIndirect heating destructive distillationDecompositionTar

The invention discloses an in-tube propelled coal material decomposition device, which includes a sealed kiln, a coal material propelled decomposition tube is installed in the kiln, the coal material propelled decomposition tube is provided with a coal feeding port, a coal discharging port and a decomposition gas collection tube, a heat exchange chamber is formed between the coal material propelled decomposition tube and an inner wall of the kiln and connected with a high-temperature gas heating mechanism via an intake tube, in the invention, the coal material propelled decomposition tube is installed in the kiln, so much hot air in the high-temperature kiln surrounds the coal material propelled decomposition tube, and transmits and radiates to pulverized coal in the coal material propelled decomposition tube, the pulverized coal fully absorbs the heat to be warmed and decomposed, and the pulverized coal is decomposed into a fuel gas, a tar gas and a coal having a higher heat value in the coal material propelled decomposition tube.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

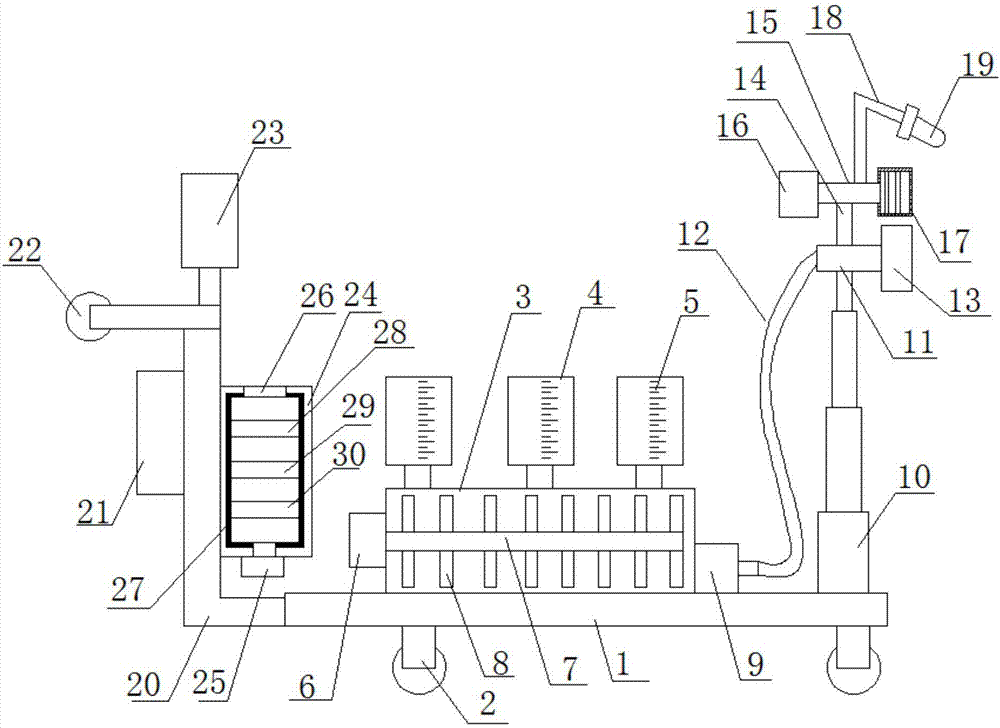

Mural color restoring device with drying function

InactiveCN107282325AReduce labor intensityReduce the chance of being destroyedSpray nozzlesPainting preservationEngineeringUltimate tensile strength

The invention discloses a mural color restoration device with a drying function, which comprises a base, a mixing box is arranged on the upper side of the base, a material spray pump is arranged on the right end of the mixing box, and a multi-stage electric motor is arranged on the upper right end of the base. Telescopic device, the upper end of the multi-stage electric telescopic device is provided with a spray pipe, the left end of the spray pipe is connected with the spray pump through the feed pipe, the right end of the spray pipe is provided with a spray head, and the upper side of the spray pipe The middle part is provided with a pole, the upper end of the pole is provided with an air duct, the left end of the air duct is provided with a first fan, the right end of the air duct is provided with a hot air nozzle, and the upper side of the air duct is provided with a mounting frame, the The installation frame is provided with a high-definition camera, the left end of the base is provided with a support, the upper end of the support is provided with a high-definition display screen, and the right side of the support is provided with a purification box. The invention has the advantages of simple structure, convenient use, reduced labor intensity, improved restoration quality and high use comfort.

Owner:CITY COLLEGE WENZHOU UNIV +4

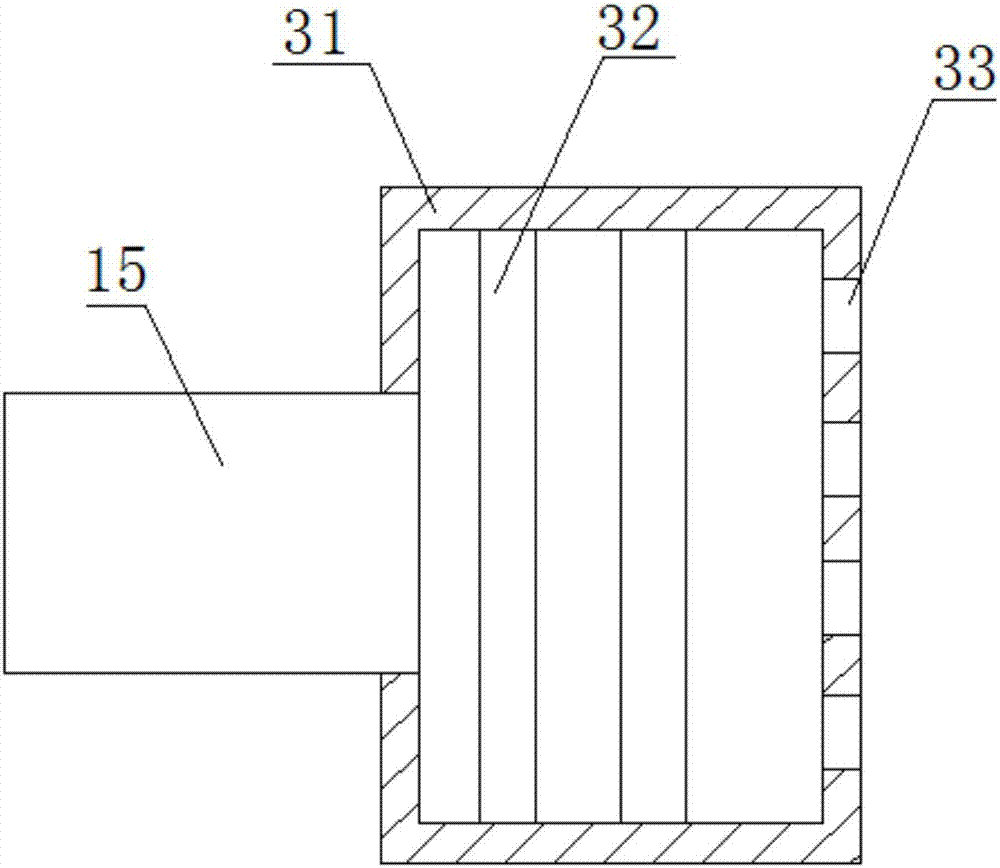

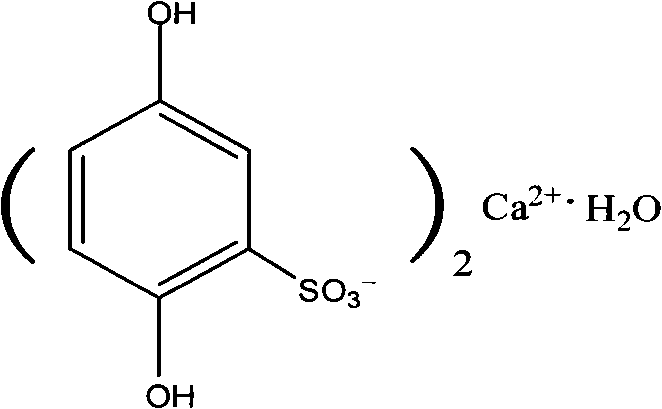

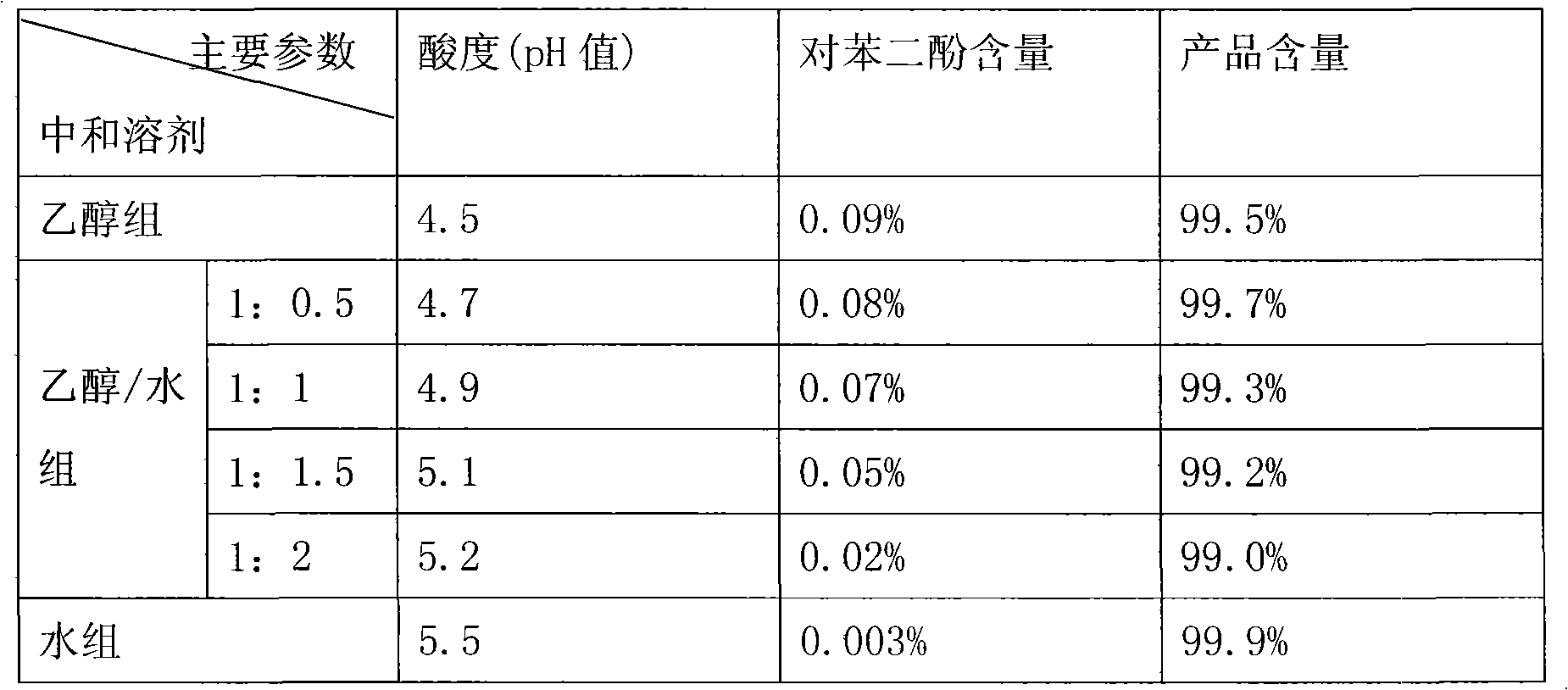

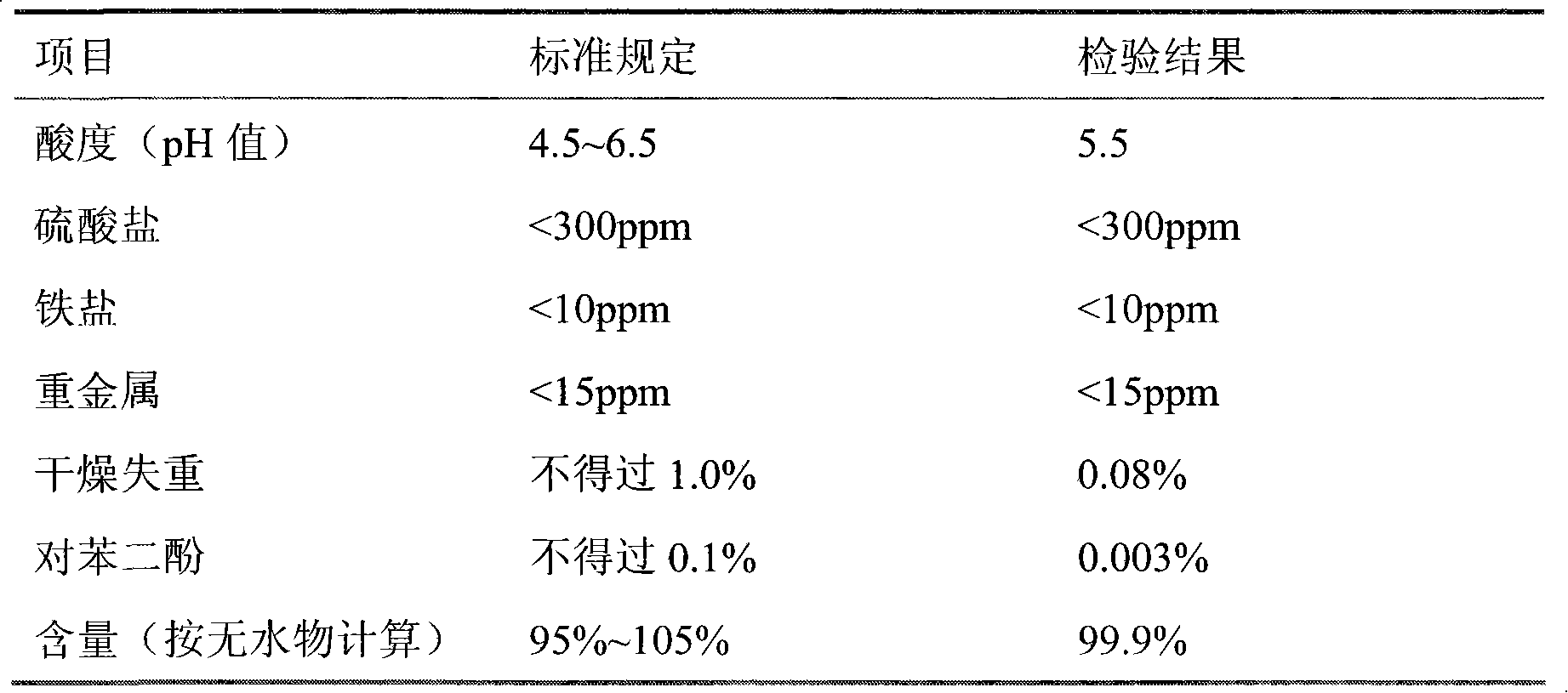

Synthetic reaction of calcium dobesilate hydrate

ActiveCN101880248AStable yieldMild reaction conditionsSulfonic acids salts preparationHydroquinone CompoundCalcium carbonate

The invention relates to a synthesizing process of calcium dobesilate hydrate in pharmaceutical industry. Hydroquinone and concentrated sulfuric acid are directly sulfonated and then the sulfonated product in water solution state and calcium carbonate are neutralized to prepare the calcium dobesilate hydrate. In the synthesizing process, the operation is simplified, the industrialization cost is saved, the reaction conditions are mild, the product purity is high, the reaction end point is controllable, and the process is suitable for industrial mass production.

Owner:KANGYA OF NINGXIA PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com