Inside diameter measuring tool

a measuring tool and inside diameter technology, applied in the direction of mechanical diameter measurement, measurement devices, instruments, etc., can solve the problems of reducing measurement accuracy, deteriorating operability and operation efficiency, and deteriorating the durability of contact pieces and conical parts, so as to reduce frictional force, enhance durability, and work efficiency and operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0019]An exemplary embodiment of the invention will be described below with reference to the attached drawings.

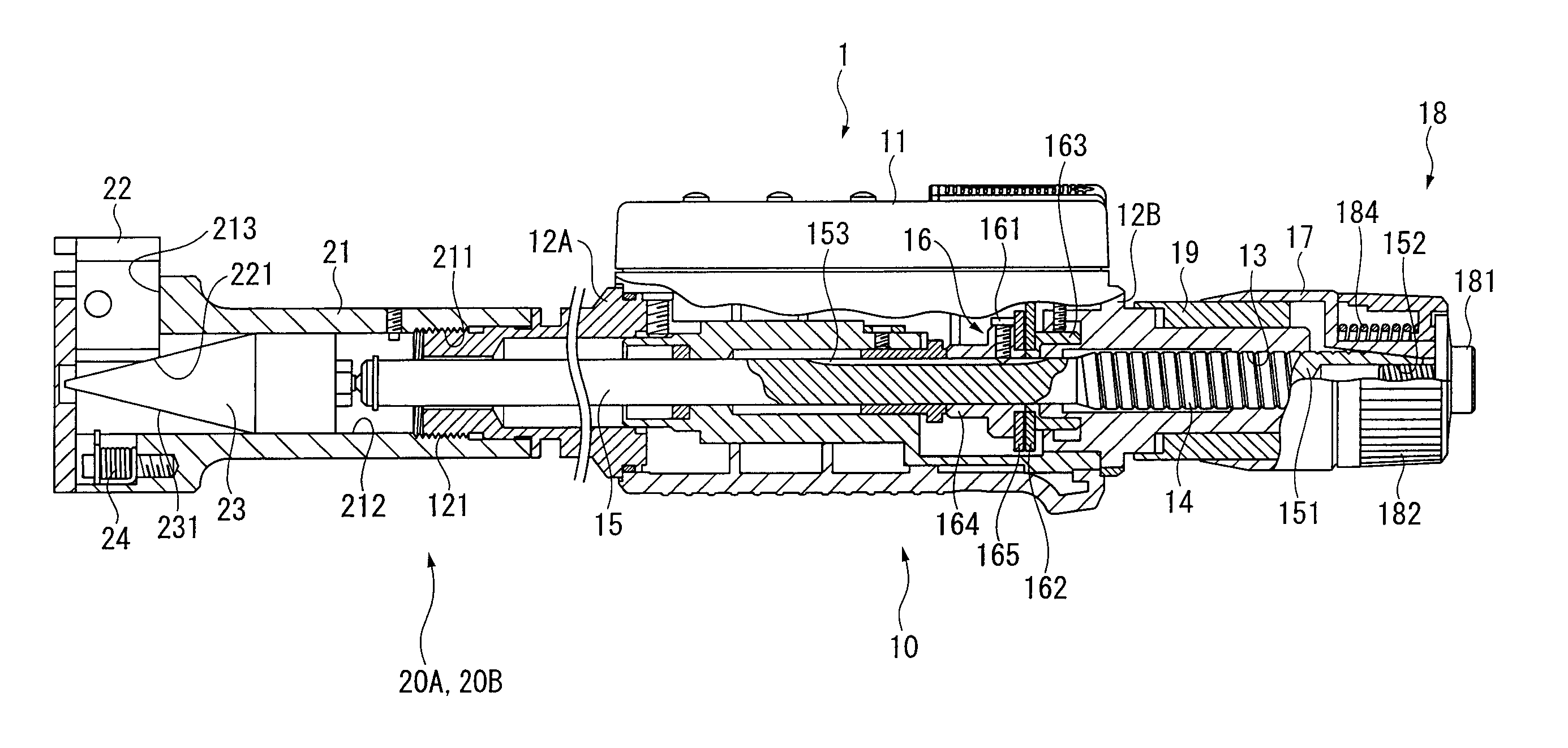

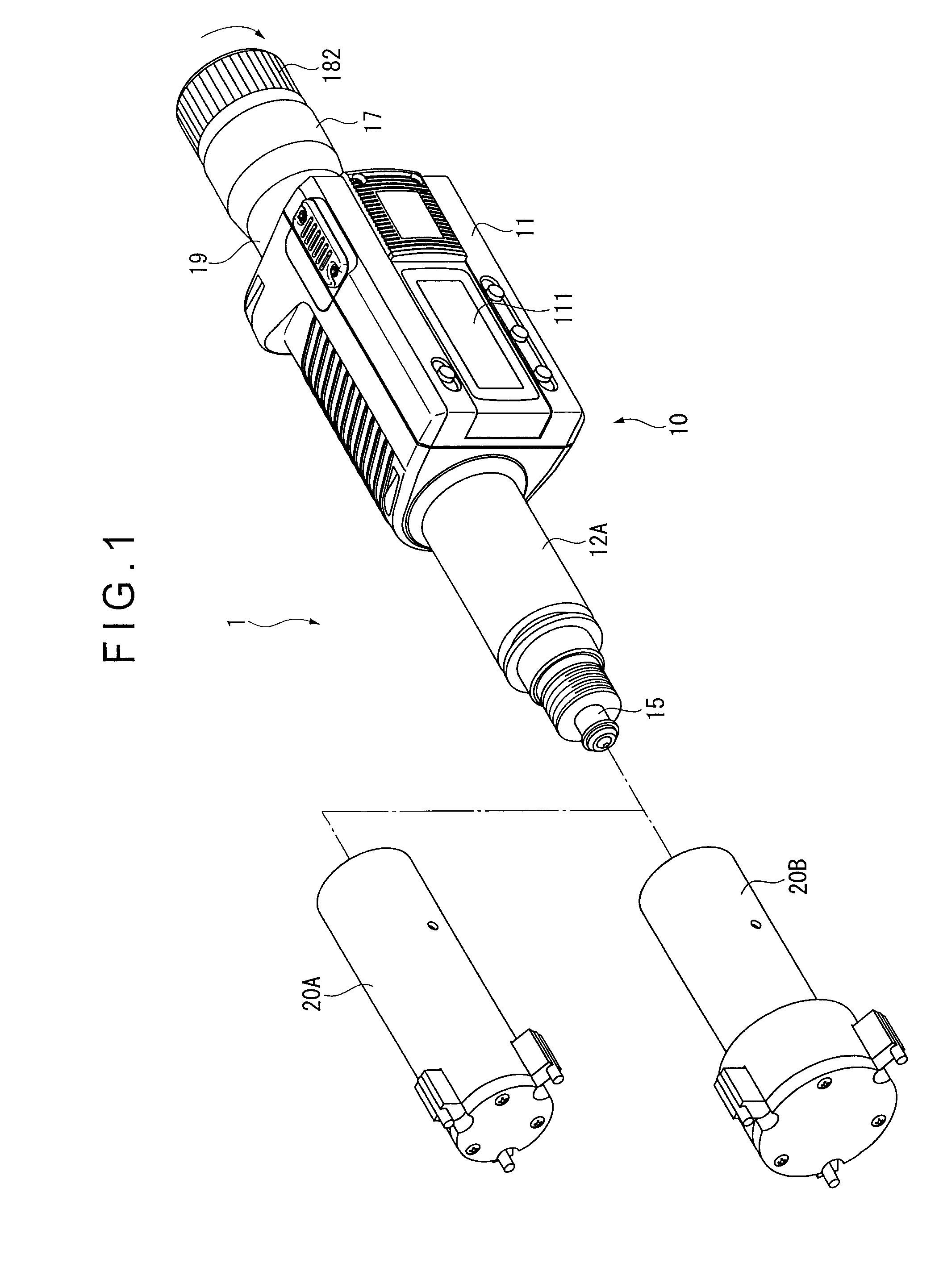

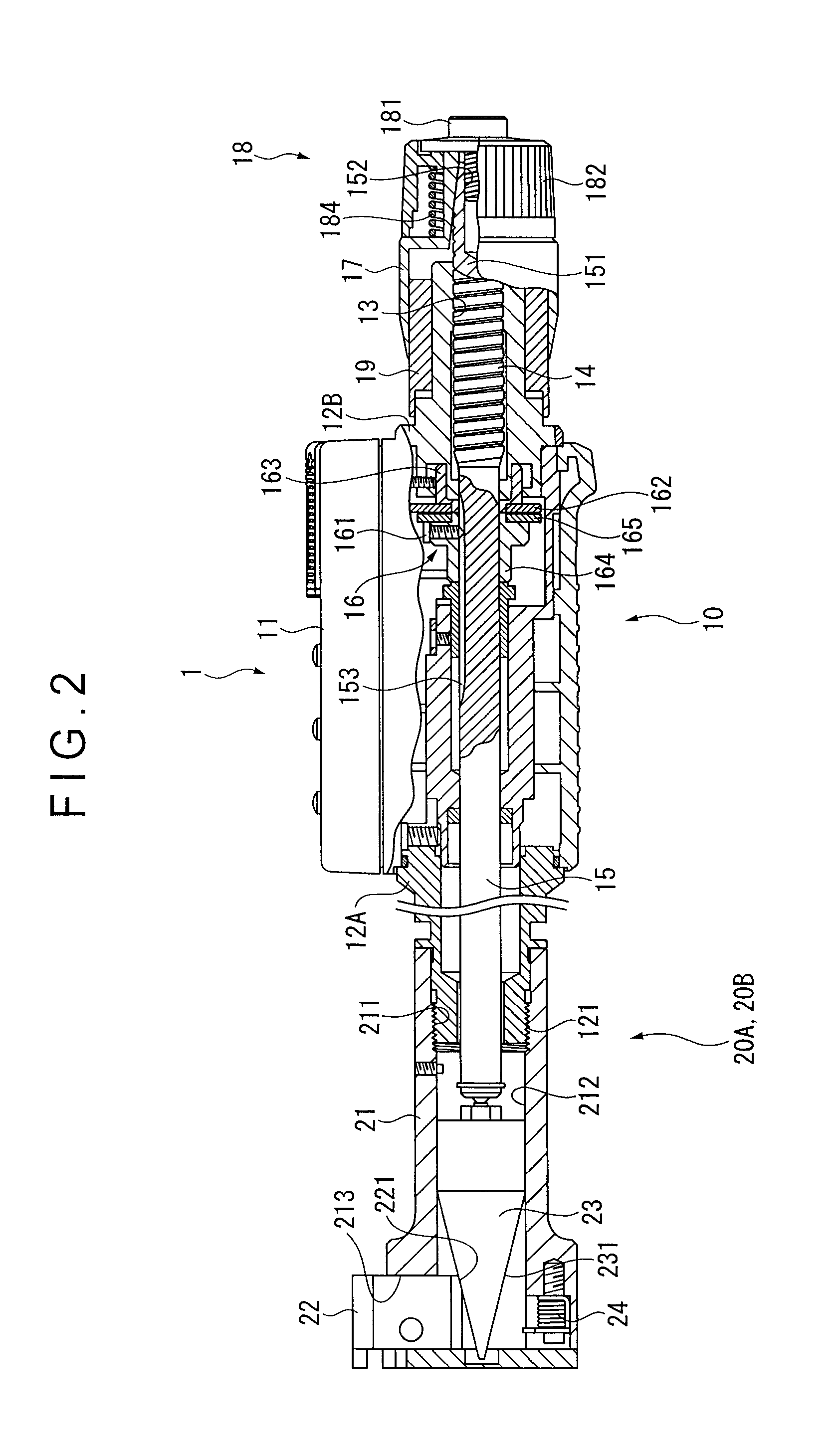

[0020]FIG. 1 is an exploded perspective view of a Holtest 1 (inside diameter measurement tool) according to this exemplary embodiment. FIG. 2 is a cross section of the Holtest 1.

[0021]As shown in FIG. 1, the Holtest 1 includes a main body 10 and a plurality of measuring heads 20A and 20B. The measuring heads 20A and 20B are exchangably used in accordance with an inner diameter of an object to be measured.

Arrangement of Main Body 10

[0022]The main body 10 includes: a rectangular case 11; a substantially cylindrical sleeves 12A, 12B coaxially attached on both sides of the case 11; a spindle 15 screwed with an inner circumference of the sleeve 12B, the spindle 15 advancing and retracting in an axial direction thereof; a detector 16 for detecting the axial displacement of the spindle 15; a thimble 17 for advancing and retracting the spindle 15; and a constant pressure mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com