Ingot casting method of granular polysilicon

A polysilicon, granular technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., to achieve the effect of easy mastery, good use effect and convenient realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

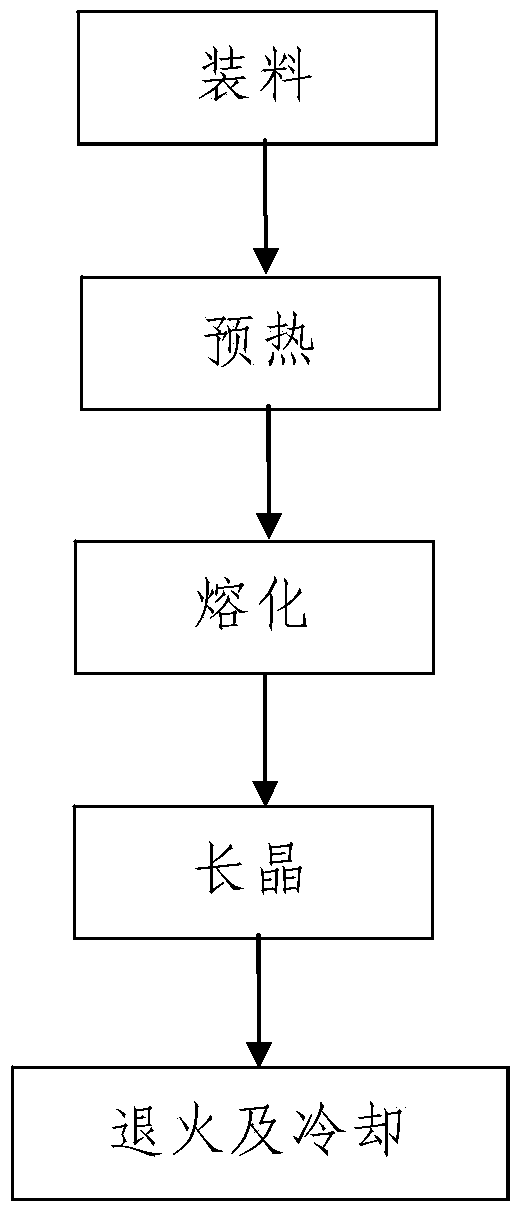

[0058] Such as figure 1 The shown ingot casting method of granular polysilicon includes the following steps:

[0059] Step 1. Loading: The granular polysilicon 1 is charged into the crucible as a silicon material for ingot casting.

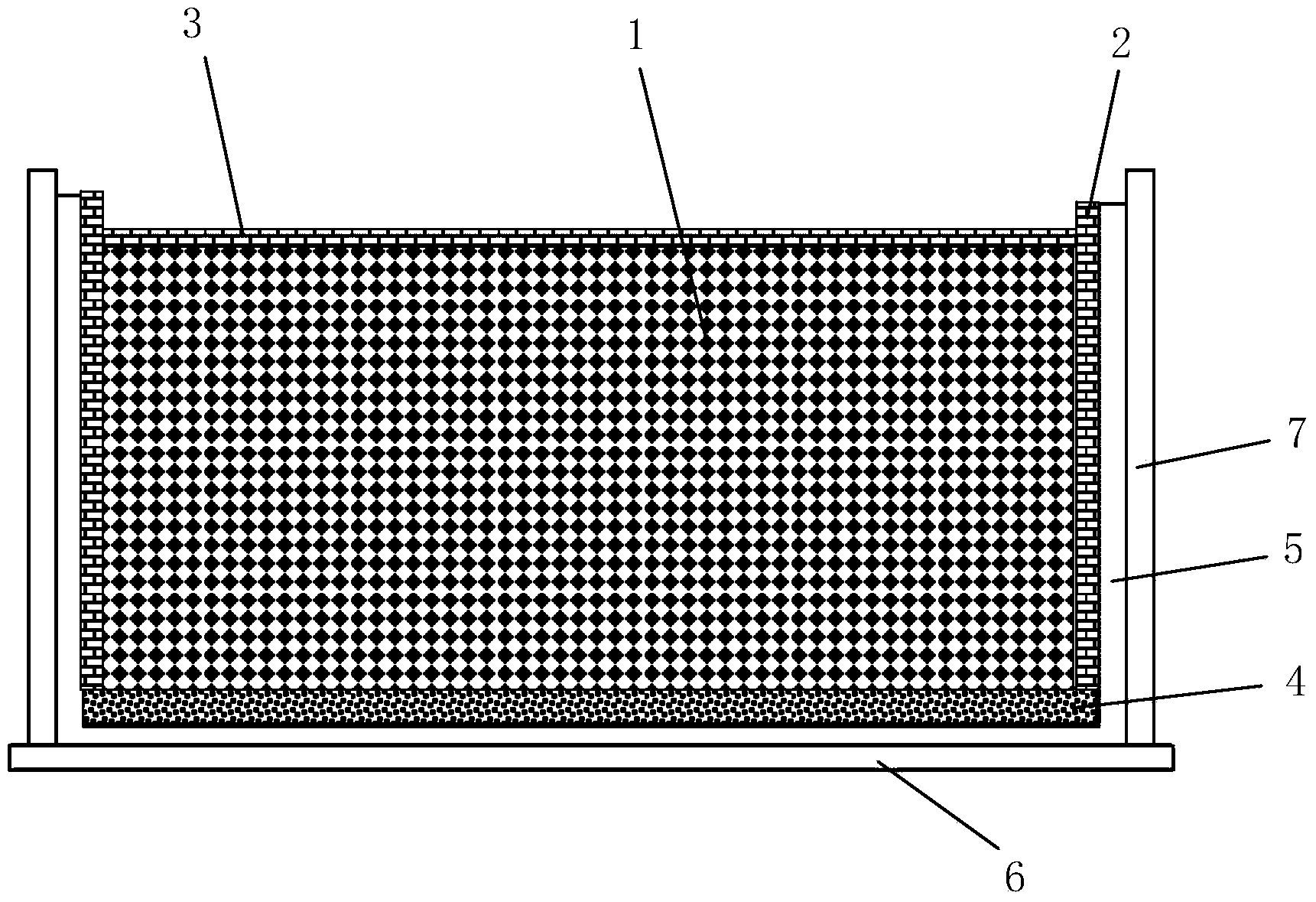

[0060] Such as image 3 As shown, after the charging in step one is completed, the charging structure in the crucible includes granular polysilicon 1 filled in the crucible, and a pad mounted between the inner side wall of the crucible and the granular polysilicon 1. A layer of edge guard 2 formed by assembling block polycrystalline silicon and a layer of cover 3 formed by assembling block polysilicon on the granular polysilicon 1. The cover 3 is located in the edge guard 2; after the filling is completed , The silicon material in the crucible includes granular polysilicon 1, edge guard 2 and cover 3.

[0061] In this embodiment, the crucible is laid flat on a horizontal bottom plate 6, which is provided with an outer guard plate 7 that limits the quar...

Embodiment 2

[0133] In this embodiment, the difference from embodiment 1 is: before charging in step one, a layer of 20mm-thick broken silicon wafers is first laid on the bottom of the crucible to form a broken silicon wafer paving layer 4; In the 10th step, the 5mm-thick broken silicon wafers in the broken silicon paving layer 4 are not melted; the preheating time in the second step is 6h and T1=1185°C, P1=80kW; in the third step T5=1560°C, t=18min, Q1=650mbar; the holding time in the first step is 0.4h; in the second step to the fifth step, T2=1210℃, the heating time is 0.4h; in the sixth step T3=1460℃ and the heating time is 260min ; In the 7th step, T4=1510℃ and the heating time is 260min; in the 8th step T5=1560℃ and the heating time is 260min; the 9th step is 3.5h; the 10th step is 4h.

[0134] In this embodiment, the process of heating and pressurizing in steps 2 to 5 is as follows:

[0135] The second step, the first step is to increase: the heating temperature of the ingot furnace is ...

Embodiment 3

[0145] In this embodiment, the difference from embodiment 1 is: before charging in step 1, a layer of 25mm-thick broken silicon wafers is first laid on the bottom of the crucible, and a broken silicon wafer paving layer 4 is formed; In the 10th step, the 20mm-thick broken silicon wafers in the broken silicon pavement layer 4 are not melted; the preheating time in the second step is 10h and T1=1165°C, P1=70kW; in the third step T5=1540°C, t=22min, Q1=550mbar; the holding time in the first step is 0.6h; in the second step to the fifth step, T2=1190℃, the heating time is 0.6h; in the sixth step T3=1440℃ and the heating time is 280min ; In the 7th step, T4=1490℃ and the heating time is 280min; in the 8th step T5=1540℃ and the heating time is 280min; the 9th step is 4.5h; the 10th step is 8h.

[0146] In this embodiment, the process of heating and pressurizing in steps 2 to 5 is as follows:

[0147] The second step, the first step is to increase: increase the heating temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Life expectancy | aaaaa | aaaaa |

| Life expectancy | aaaaa | aaaaa |

| Life expectancy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com