Patents

Literature

60results about How to "Eliminate quality problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

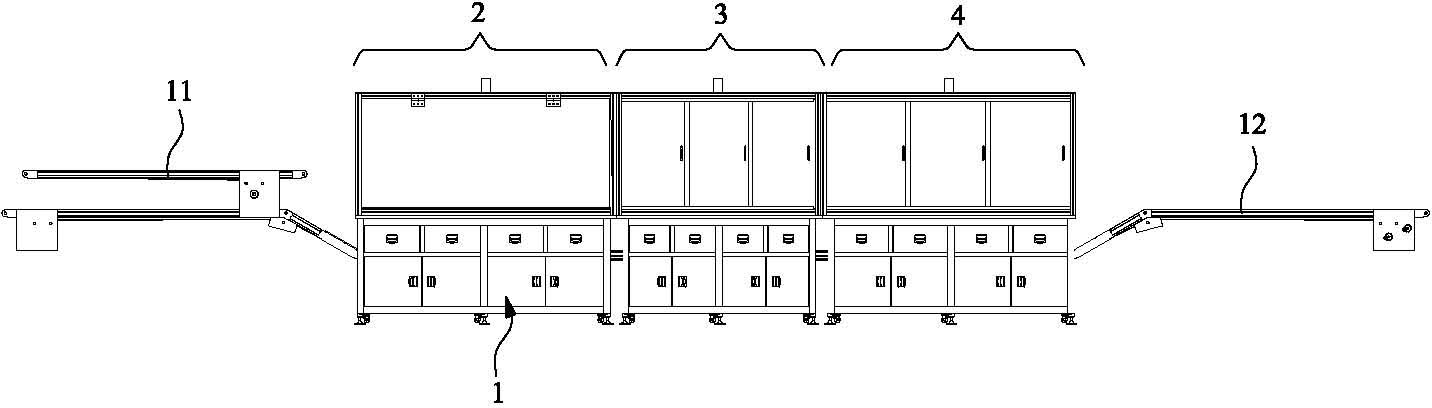

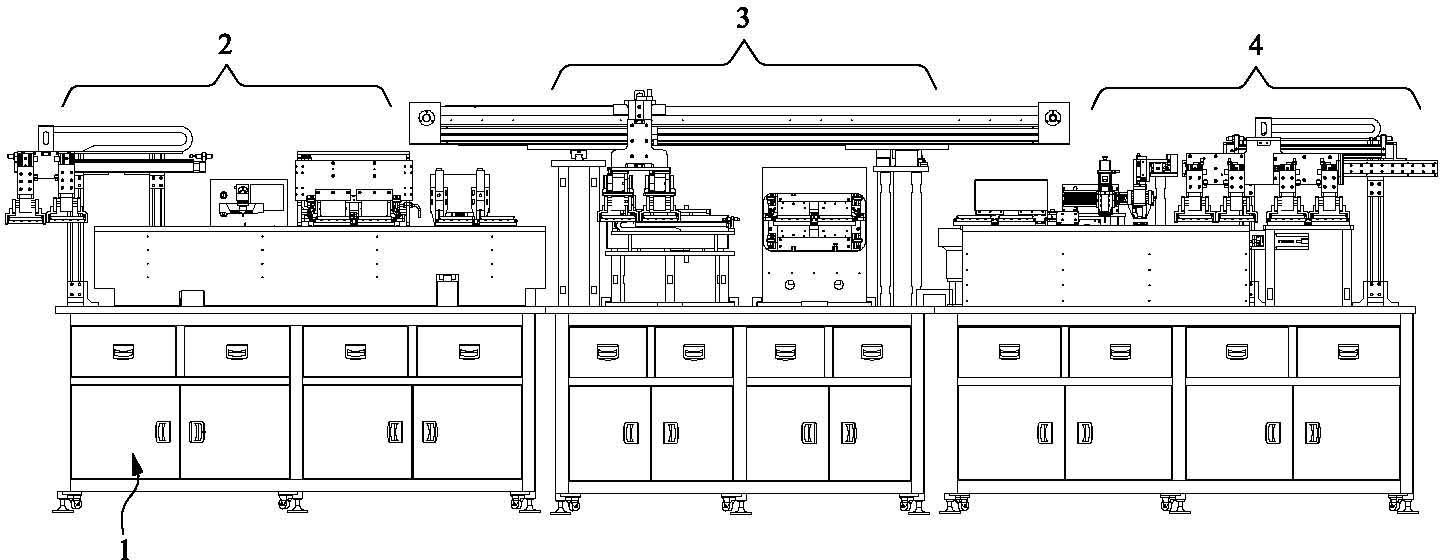

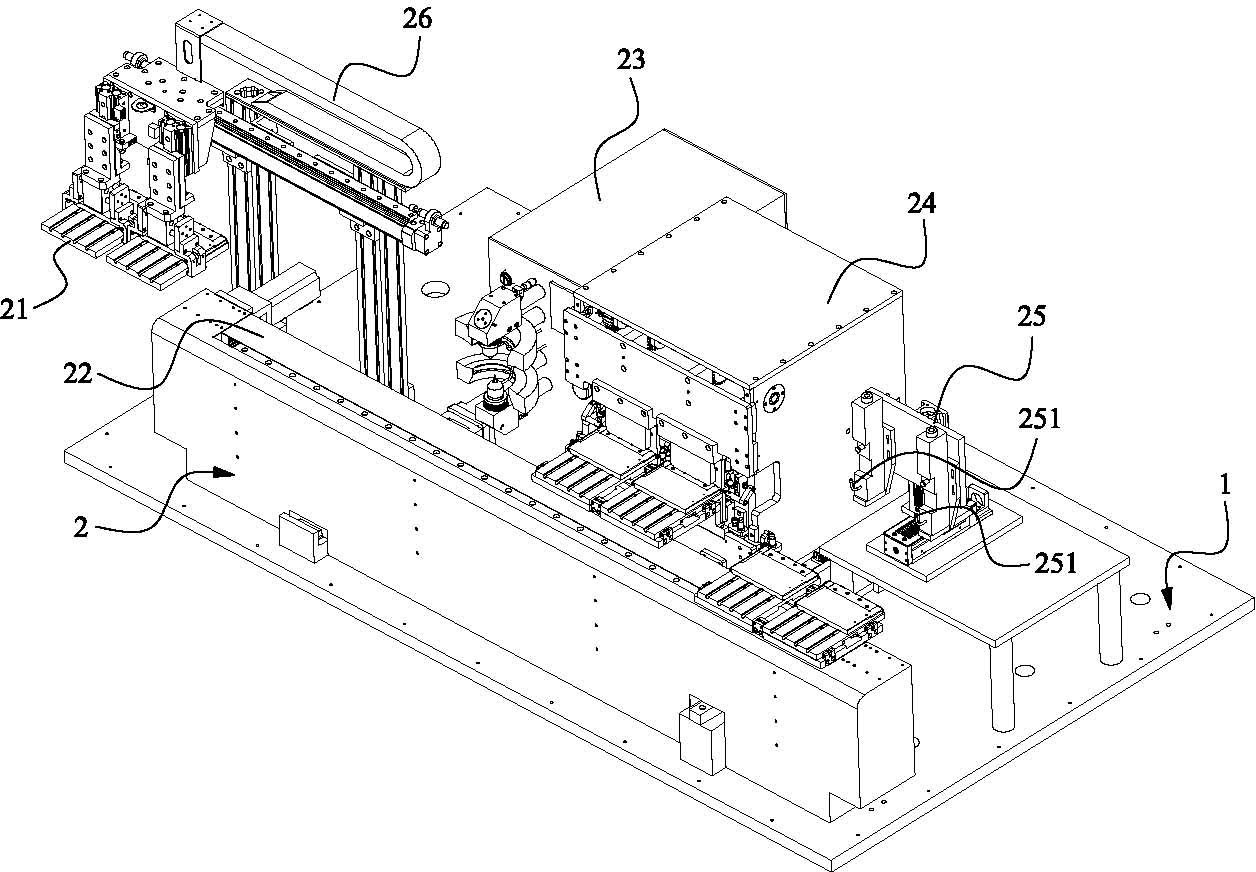

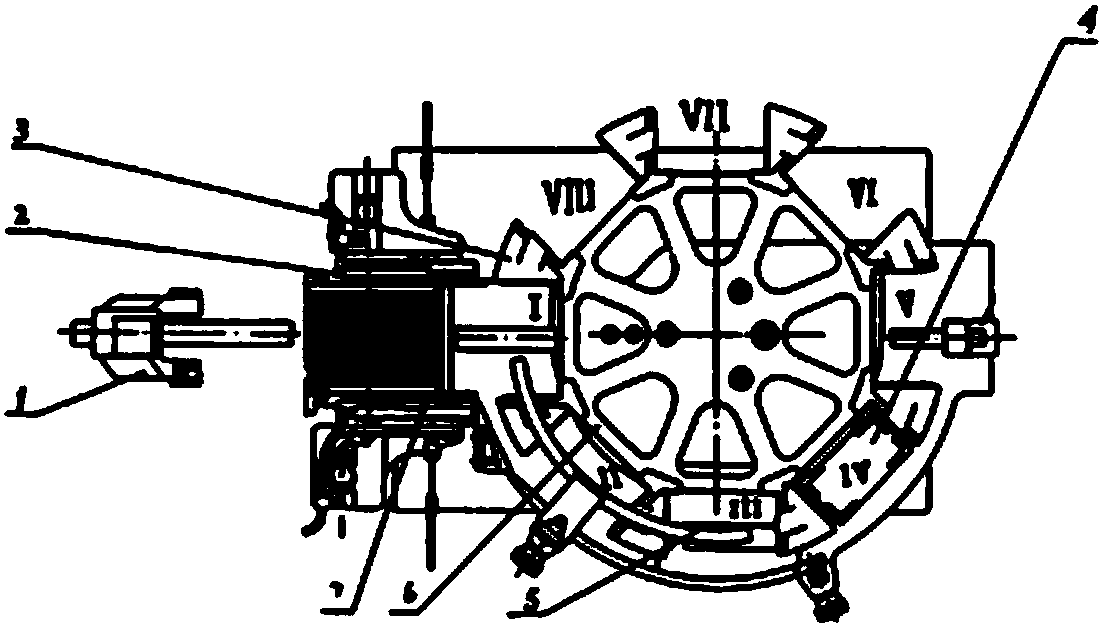

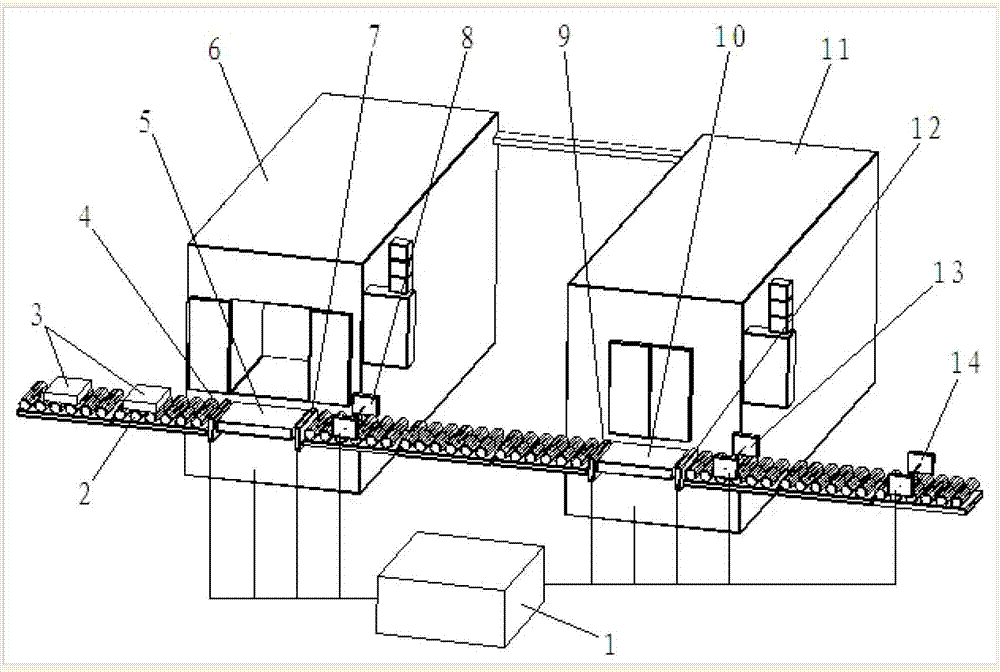

Automatic cable and connector processing, welding and assembling machine

InactiveCN102637988AEliminate weldsEliminate quality problemsLine/current collector detailsEconomic benefitsEngineering

The invention discloses an automatic cable and connector processing, welding and assembling machine, comprising a rack as well as a laser peeling module, an adhered tin trimming module and a plug welding module sequentially arranged on the rack, wherein the laser peeling module comprises a jig, a first transmission device, a laser device, a peeling device and a flux spraying device; the adhered tin trimming module comprises a clamping-jaw feeding device, a tin pot and a trimming device; and the plug welding module comprises a soldering device, a plugging device, a welding device and a clamping-jaw laying-off device. Therefore, the automatic machining on a cable is finished by virtue of the laser peeling module and the adhered tin trimming module, the laser peeling module, the adhered tin trimming module and the plug welding module are matched to weld and connect a connector and the cable together, and a core wire of the cable is kept to be straight in processes of processing and welding the core wire, so that the quality problems of insufficient soldering, leaving out of welding, short circuit and the like during the connection between the cable and the connector are eliminated, and the unmanned automatic processing, welding and assembling procedures are realized to effectively improve the production efficiency of products and to bring more economic benefits to enterprises.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

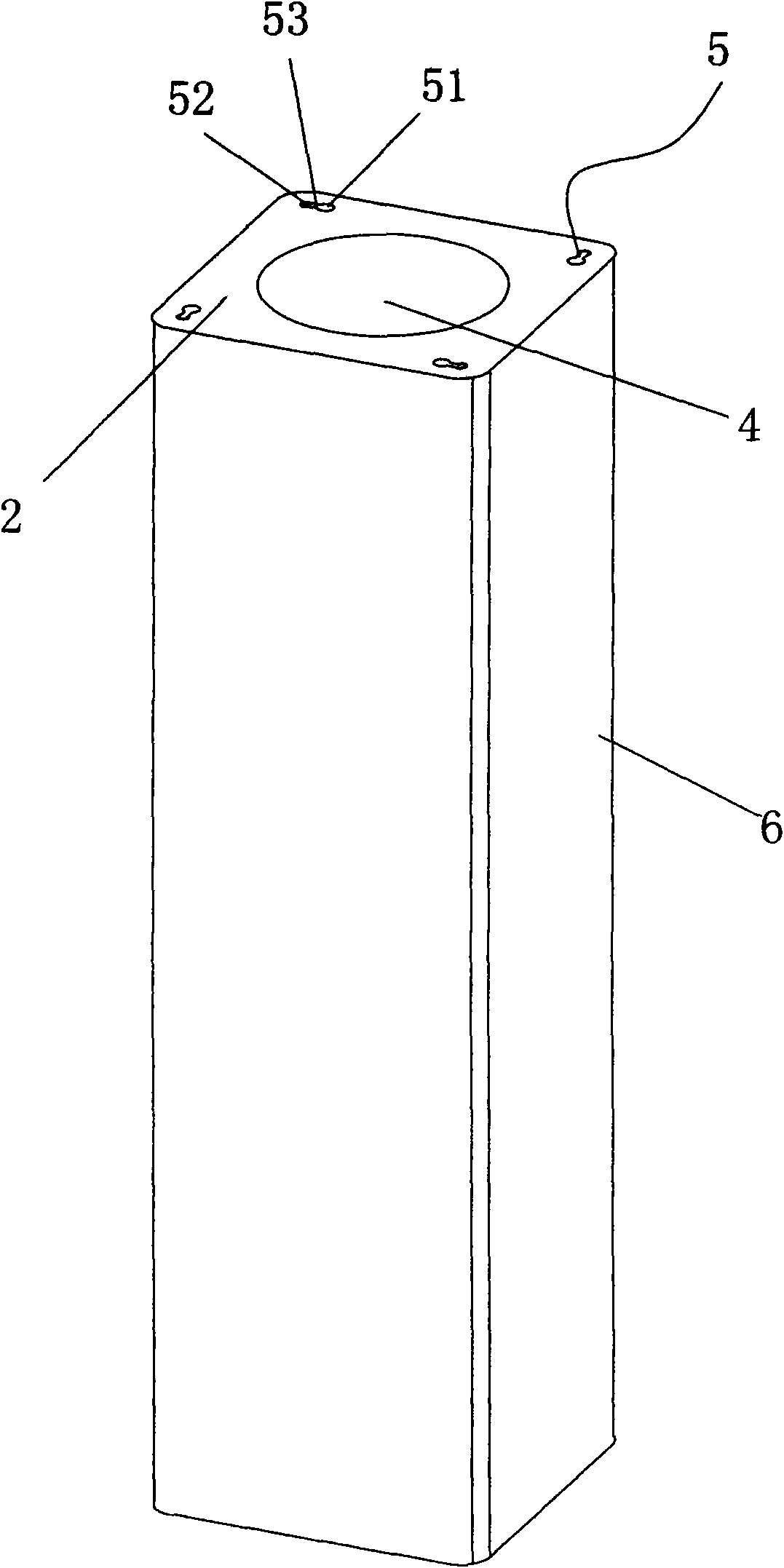

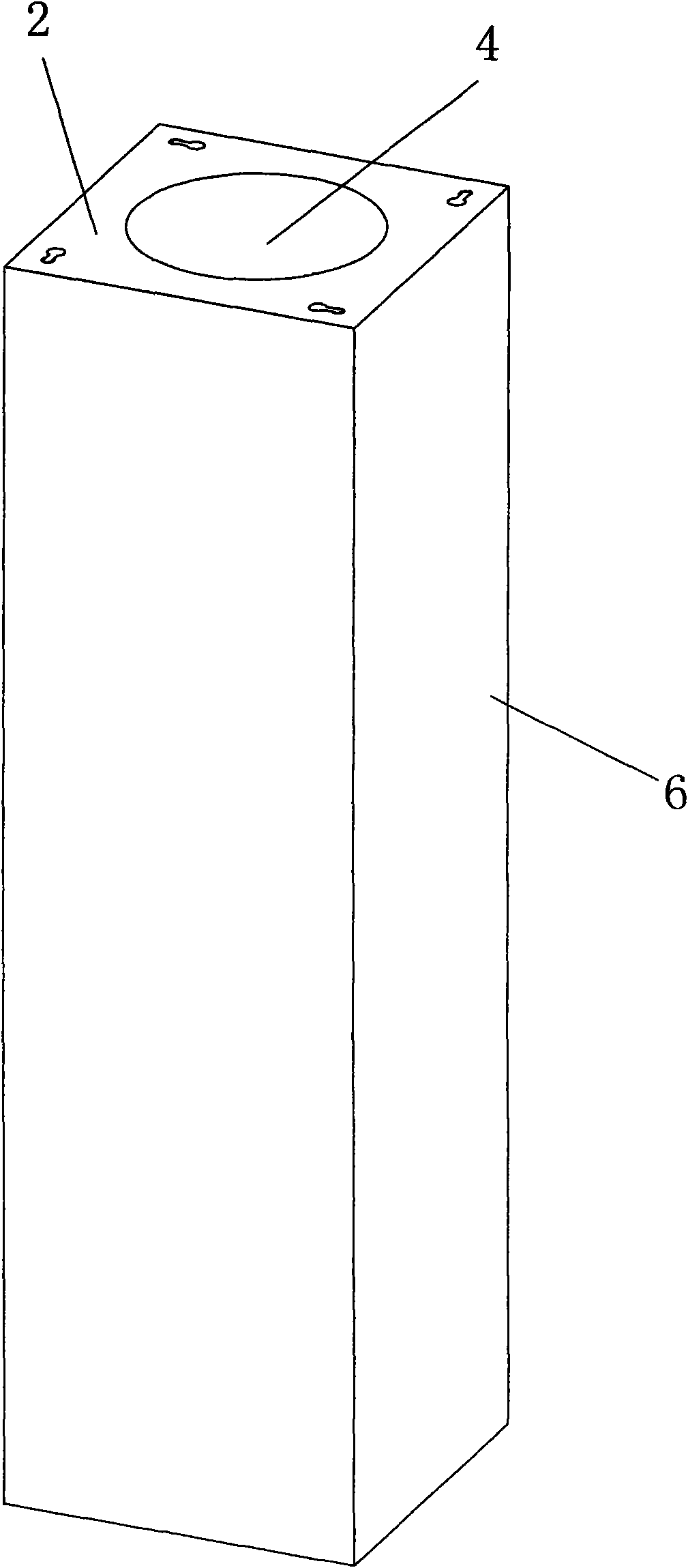

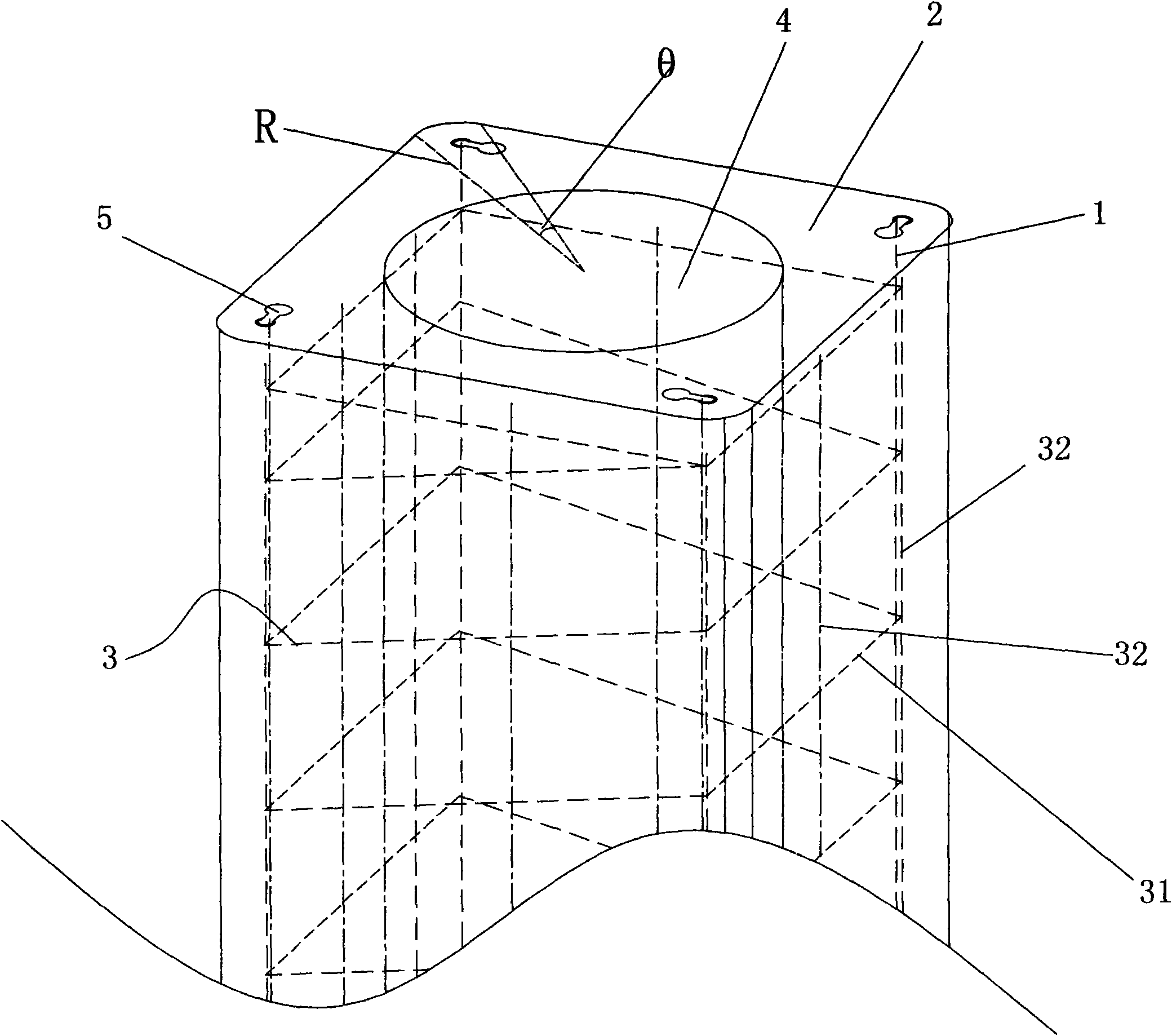

Prestressed concrete hollow square pile and production method thereof

The invention discloses a prestressed concrete hollow square pile comprising a plurality of independent main steel reinforcements. Both ends of each main steel reinforcement are respectively fixedly connected with square end plates; the main steel reinforcements are externally sleeved with steel reinforcement cage racks; each steel reinforcement cage rack comprises a spiral steel reinforcement, and the spiral steel reinforcement is welded with a plurality of auxiliary steel reinforcements; concrete is poured outside the main steel reinforcements and the steel reinforcement cage racks and is combined with the main steel reinforcements and the steel reinforcement cage racks into an integral square pile; and the center of the integral square pile is provided with a central circular hole penetrating through an integral square pile body. The invention aims at providing the prestressed concrete hollow square pile which has the advantages of good molding quality, high single-pile bearing capacity, undamaged steel reinforcement framework before the steel reinforcement framework is used, convenient production, good horizontal anti-bending bearing capacity, high shearing resistant property, convenient stacking and difficult knock damage during pile hoisting, transportation and transferring. The invention also aims at providing a production method of the prestressed concrete hollow square pile.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Method for creating cultivated silkworm chromatic cocoon by using pigment protein

InactiveCN101255423ASolve technical bottlenecksAchieve diversificationMicroinjection basedVector-based foreign material introductionInstabilityHuman health

A colorful silkworm cocoon creation method by pigment protein is disclosed. A pigment protein determining color of coral reed and related marine creature is fusion expressed in bombyx mori silk fibroin by genetic modification of silkworm and especially genetic modification for diapause varieties, so that novel colored silkworm cocoon is created. Exogenous pigment protein is fusion expressed in silk fibroin, and exists stably and uniformly in silk fibroin molecular, so pigment protein will not be lost in silk reeling procedure, and color variety of pigment protein is abundant. The method used by the invention solves two problems of little variety in color of silkworm cocoon and instability in pigment binding, simplifies spinning process of silk fabrics, eliminates harm of dyeing process to silk fiber quality and human health.

Owner:重庆拓桑生物科技有限公司

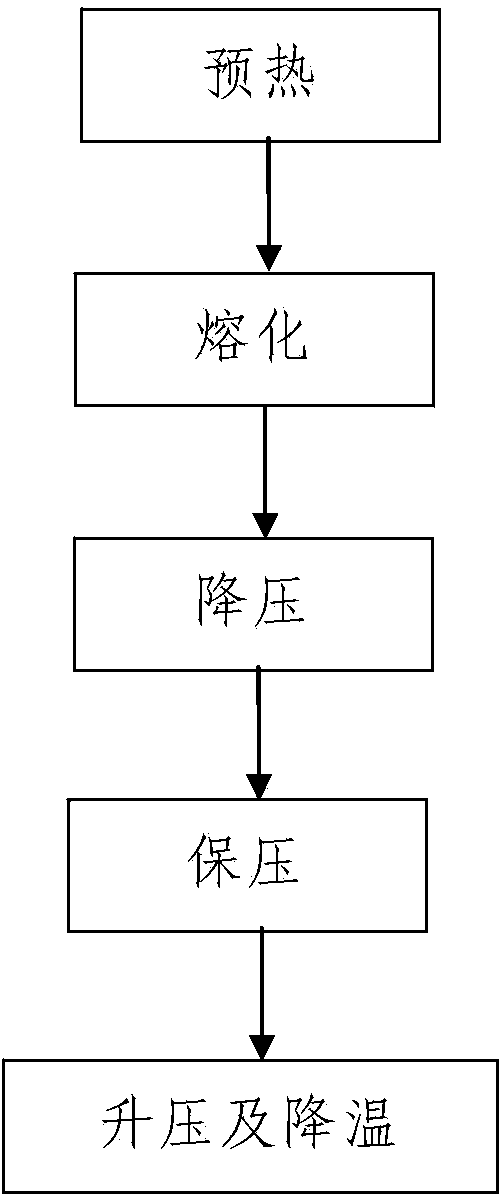

Polycrystalline silicon ingot casting molten material and impurity removing process

InactiveCN103741206AReasonable designThe process steps are simplePolycrystalline material growthFrom frozen solutionsCrucibleIngot casting

The invention discloses a polycrystalline silicon ingot casting molten material and an impurity removing process. The process comprises the following steps: 1, preheating: adopting an ingot furnace to preheat a silicon material filled in a crucible, and gradually raising the heating temperature of the ingot furnace to T1; the preheating time is 6-10h, and T1=1165-1185 DEG C; 2, melting: the melting temperature is T1-T5; T5=1540-1560 DEG C; in the melting process, filling insert gases into the ingot furnace, and keeping air pressure in the furnace in Q1, and Q1=550-650mbar; 3, removing impurities: the process is as follows: the 11th step, reducing pressure: the air pressure of the ingot furnace is reduced from Q1 to Q2, and the pressure reducing time is 8-12min, and Q2=350-450mbar; the 12th step, maintaining pressure; the 13th step, boosting pressure and lowering temperature. The process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect, can discharge gas containing carbon in the furnace in time, and increases the polycrystalline silicon ingot casting quality.

Owner:XIAN HUAJING ELECTRONICS TECH

Hollow capsule and preparation method thereof

ActiveCN102836142AEliminate quality problemsEliminate security concernsPharmaceutical non-active ingredientsCapsule deliveryAmyrisKappa-Carrageenan

The invention discloses a hollow capsule, which comprises the following components in parts by weight: 10 to 30 parts of kappa-carrageenan, 90 to 180 parts of water-soluble crosslinked starch, and 20 to 40 parts of plasticizer. The invention also discloses a preparation of the hollow capsule, which comprises the following steps of: 1) dissolving gum, wherein carrageenan and water-soluble crosslinked starch are stirred, water at a temperature of between 70 and 90 DEG C is added into the mixture, the plasticizer in the amount of the prescription is added and completely dissolved, and the mixture is stirred uniformly; 2) culturing the gum, wherein the gum liquid obtained in the step 1) is cooled to a temperature of between 40 and 45 DEG C, the gum liquid is insulated and stood for 30 to 60 minutes, and the gum liquid is put into a gum soaking tank; and 3) soaking the gum, wherein when the temperature of the gum liquid in the gum soaking tank is cooled to 35 DEG C, operations of gum soaking, drying, shell pulling out, cutting and buckling are automatically carried out through a capsule template. According to the hollow capsule disclosed by the invention, the transparency and toughness are remarkably improved, the friability is remarkably reduced, and the product yield is greatly increased.

Owner:青岛晓丛生物科技有限公司

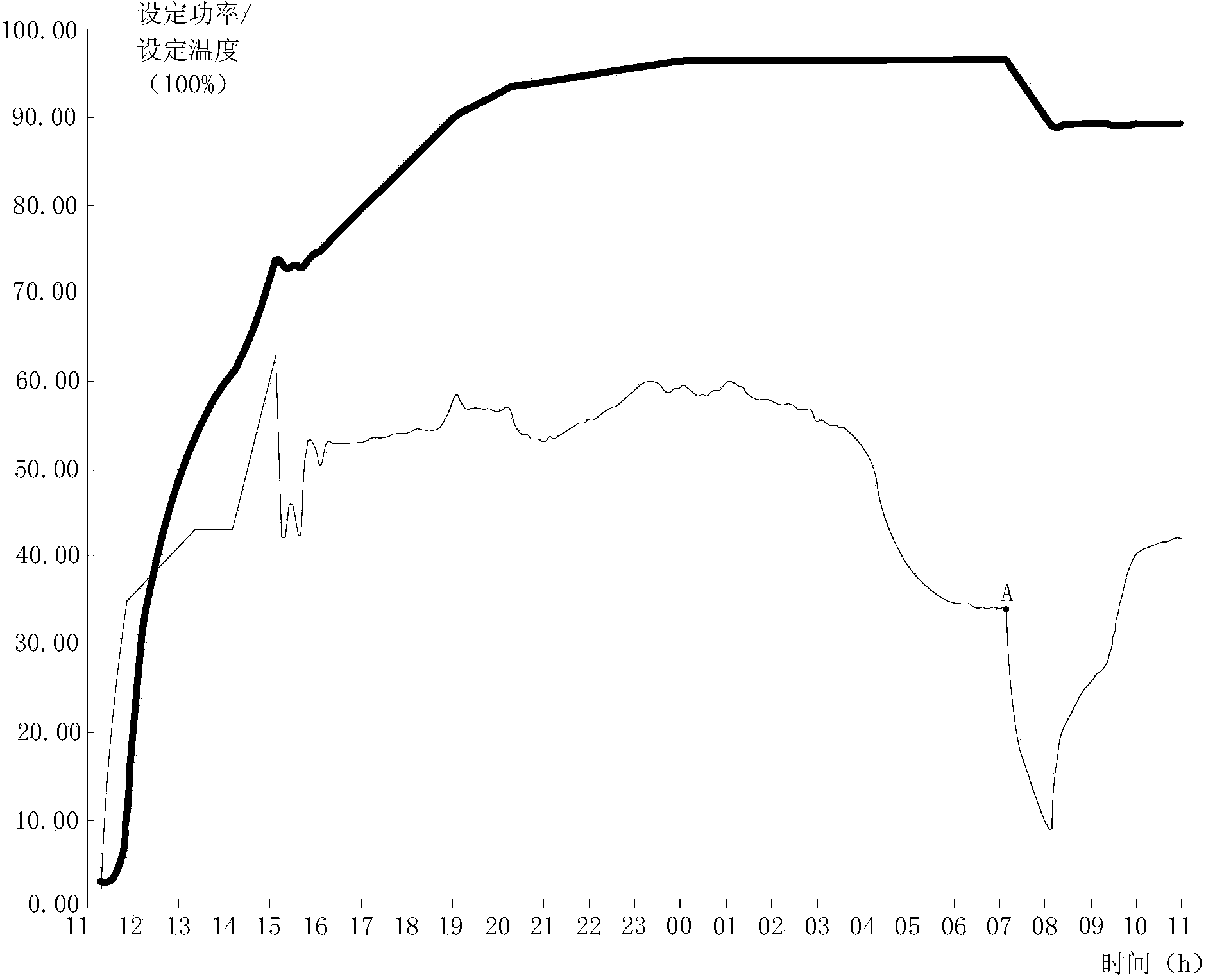

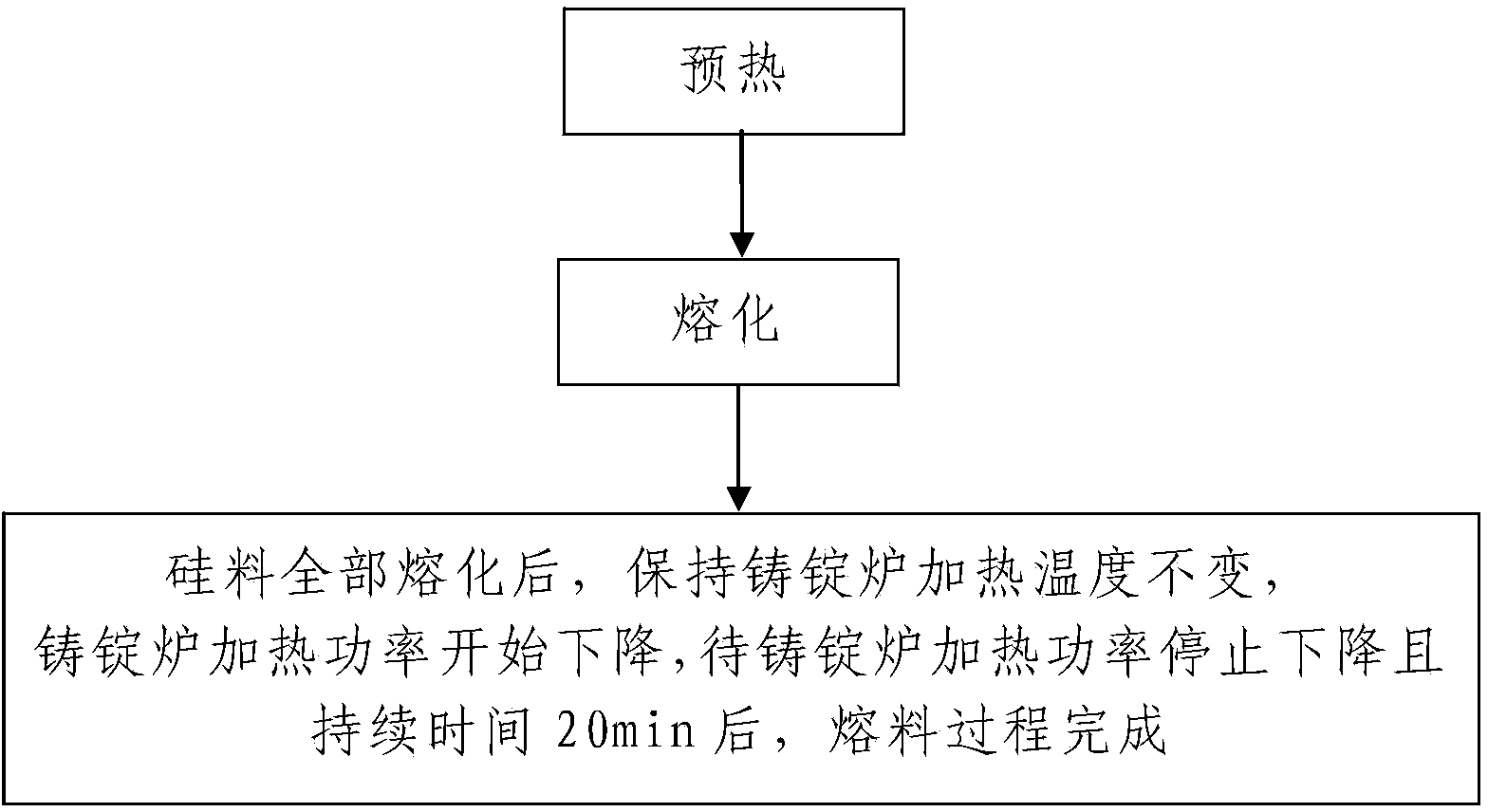

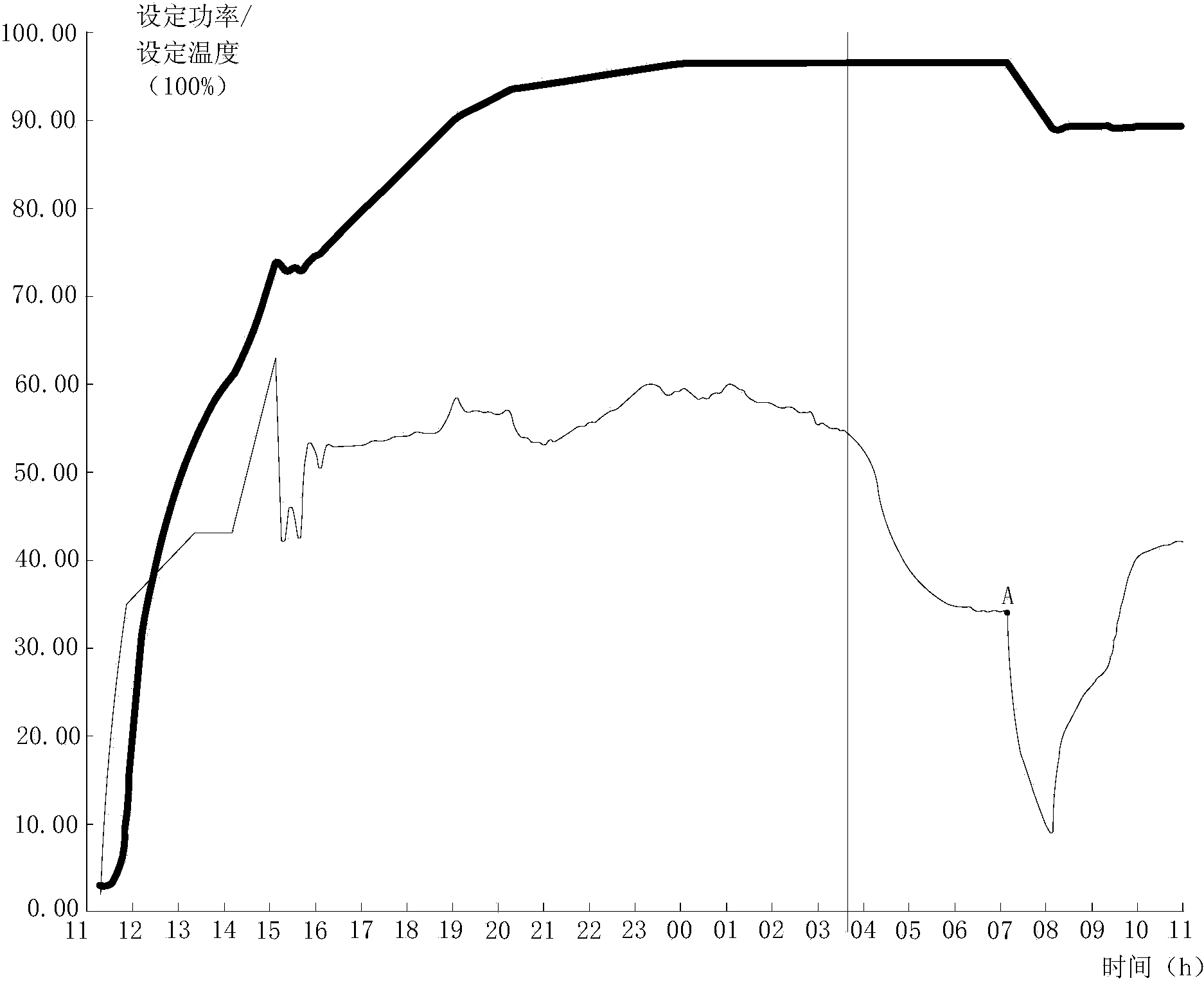

Melting process for polycrystalline silicon cast ingots

InactiveCN103741213AReasonable designThe process steps are simplePolycrystalline material growthSingle crystal growth detailsCrucibleIngot

The invention discloses a melting process for polycrystalline silicon cast ingots. The process comprises the following steps: 1, preheating: an ingot furnace is adopted to preheat a silicon material filled in a crucible, and the heating temperature of the ingot furnace is gradually increased to T1; the preheating time is 6-10h, and T1=1165-1185 DEG C; 2 melting: the silicon material filled in the crucible is melted, the melting temperature is T1-T5, and T5=1540-1560 DEG C; after the silicon material in the crucible is completely melted, the heating temperature of the ingot furnace is controlled to T5, and then the heating power of the ingot furnace begins to decline; after the heating power of the ingot furnace stops declining and lasts for the time t, the melting process is complete; t=18-22min. The process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect and can effectively solve the problem that the quality of the produced polycrystalline silicon cast ingots is reduced as the melting time is deficient or too long.

Owner:XIAN HUAJING ELECTRONICS TECH

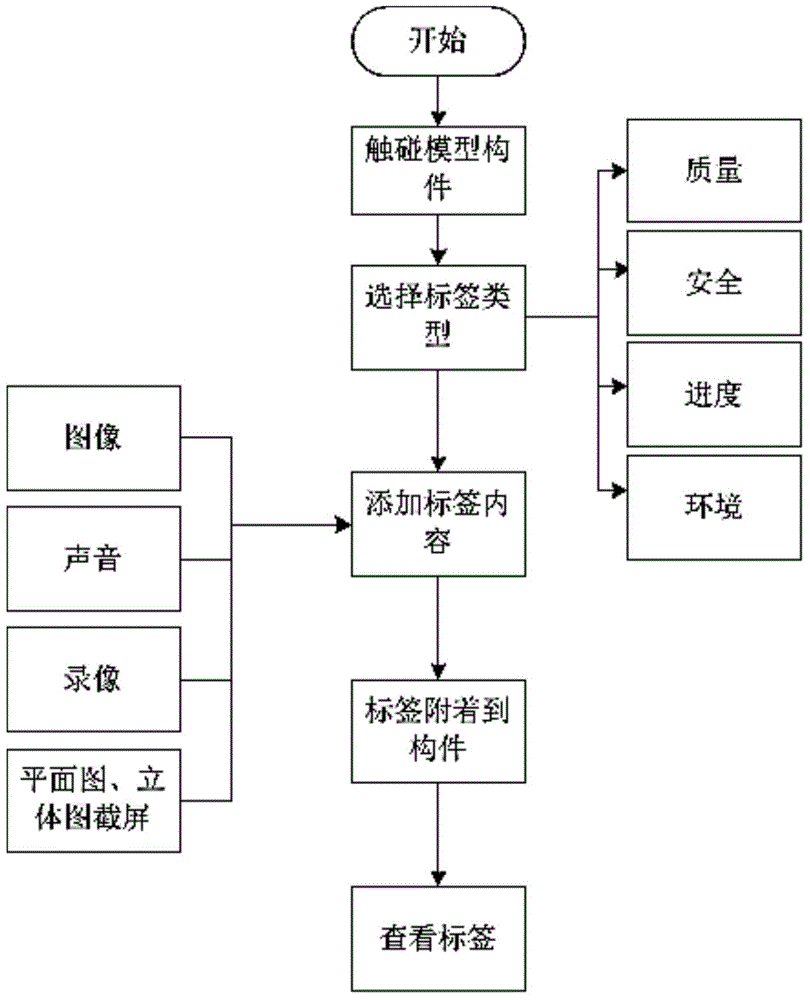

BIM-based event marking method and system

The invention provides a BIM (Building Information Modeling)-based event marking method and system. The BIM-based event marking method comprises the following steps: a label generation step: for BIM, clicking a member in need of adding the label through first-person perspective, creating the label, and creating an event content in the label; a label attachment step: attaching the generated label to the member; a label association step: associating a planar graph with the label in a first-person perspective graph, wherein the planar graph is a 3D model acquired by a first scene camera arranged at the top of the BIM; a label showing step: displaying the event content by the label after receiving a viewing command of a user. The invention is convenient for external staff to record and submit the engineering event on site in time and can effectively monitor a hidden stage of construction; the engineers, general contractors, owners and the like can view the label through a mobile client; a collaborative way is provided.

Owner:SHANGHAI TONGZHU INFORMATION TECH

Welding process of plug-in unit of PCB (Printed Circuit Board)

InactiveCN102950349AImprove protectionImprove securitySoldering auxillary devicesVisual inspectionEngineering

The invention relates to the technical field of welding of a PCB (Printed Circuit Board), and provides a welding process of a plug-in unit of the PCB, which can effectively improve the production efficiency, improves the production quality, reduces the production loss and cost, and reduces the operation difficulty and human errors. The process comprises the following steps of: (1) trimming supporting legs of components: trimming the supporting legs of the components into union and formal specification; (2) inserting the components: respectively the components processed in step (1) into corresponding welding pads of the PCB on a tray of a wave soldering machine; (3) viewing and pressing the components: performing visual inspection to confirm that the components are correctly inserted, and then pressing the components on the PCB; (4) performing wave soldering welding: performing welding operation on the PCB by the wave soldering machine; (5) taking out the PCB: taking out the PCB from the tray of the wave soldering machine; (6) detection: detecting the welding quality of the PCB, if the welding quality is qualified, obtaining the finished product, and if the welding quality is disqualified, performing the next step on the disqualified product; and (7) repairing welding: performing manual repairing welding operation on detected poor welding points of the PCB, and obtaining the finished product.

Owner:QIXIANG ELECTRON SCI & TECH

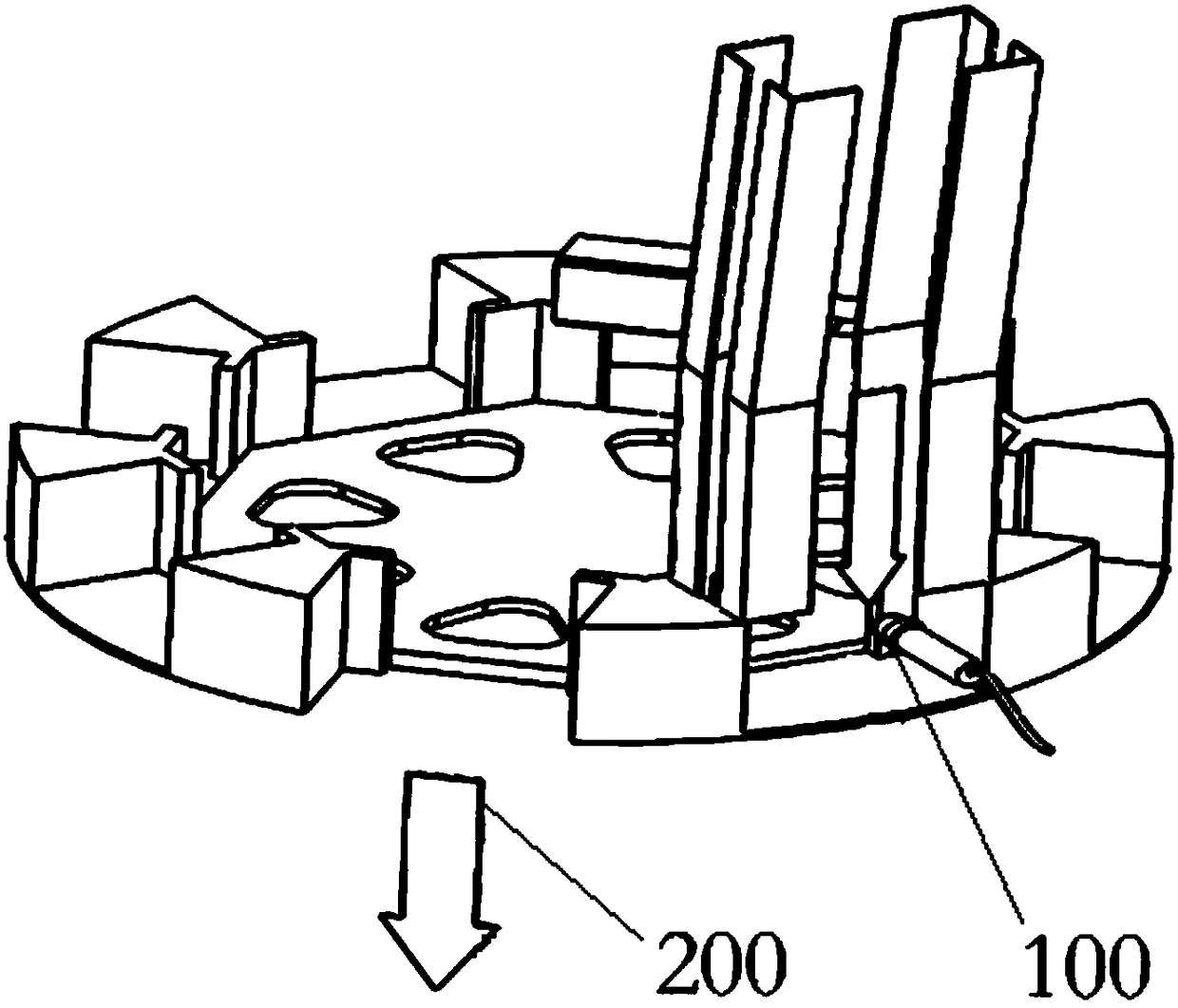

Tobacco bale in-place supplementing alarm device

PendingCN108423224AImprove securityImprove the function of the original machinePackaging cigarettePackaging cigarsFiber optic sensorSafety coefficient

The invention provides a tobacco bale in-place supplementing alarm device. On the next station, that is a tobacco bale supplementing device, of a removing device, an optical fiber sensor is arranged on the outer wall of a rotating tower in a trepanning manner, a sensor mounting support is arranged beside a push rod station, that is, the station where a push rod pushes tobacco bales to a tobacco bale channel from the rotating tower, a rotating tower pulse detection sensor is arranged on the sensor mounting support, and detects the motion of the push rod, the rotating tower pulse detection sensor is connected with a PLC, when an approach switch is arranged beside the tobacco bale supplementing channel, the position of the tobacco bale supplementing device is recognized, the approach switch is connected with a PLC, when the tobacco bale supplementing device carries out supplementing on the tobacco bales in the rotating tower, the rotating tower is positioned through the sensors, the optical fiber sensor carries out recognizing on filling of the tobacco bales in the rotating tower, through treatment of the PLC, shutdown signals and alarm signals are output, the tobacco bales with defective quality are prevented from flowing in the next procedure, and a rotating tower mold box or the push rod is prevented from being damaged due to no-in-time shutdown; equipment running safety coefficients are improved.

Owner:HONGTA TOBACCO GRP

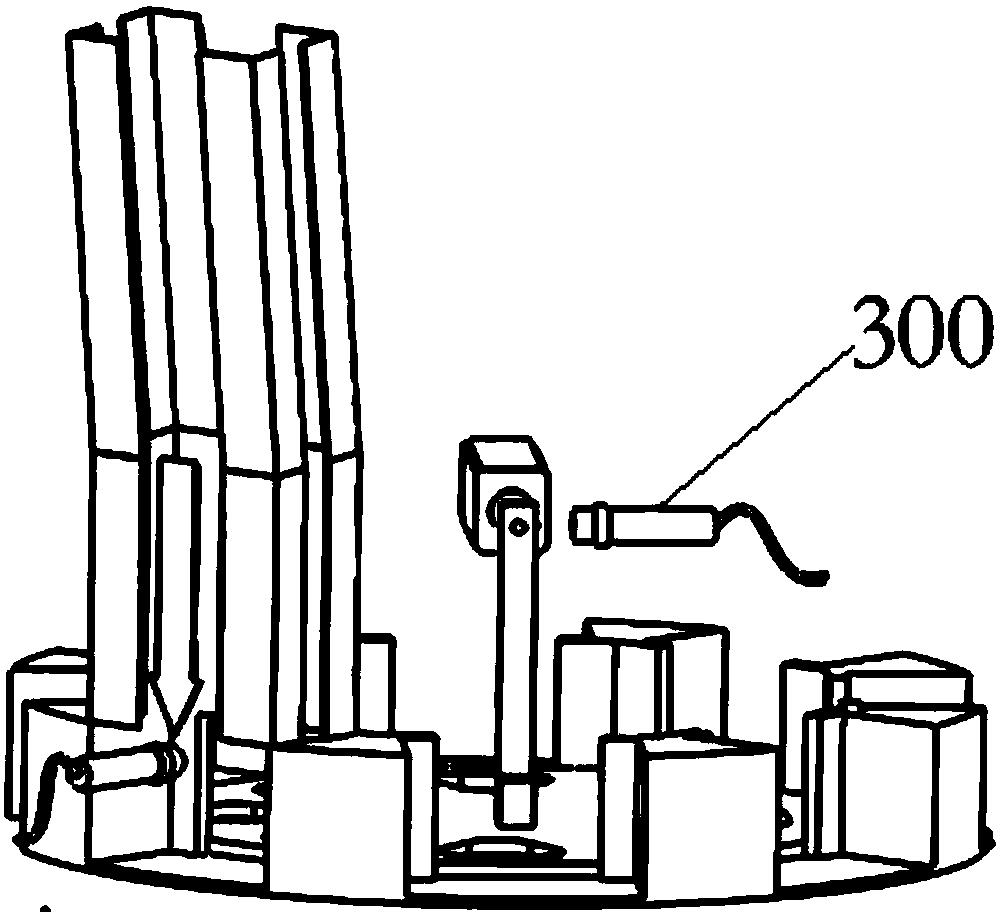

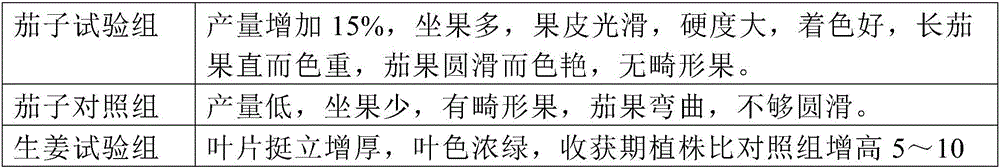

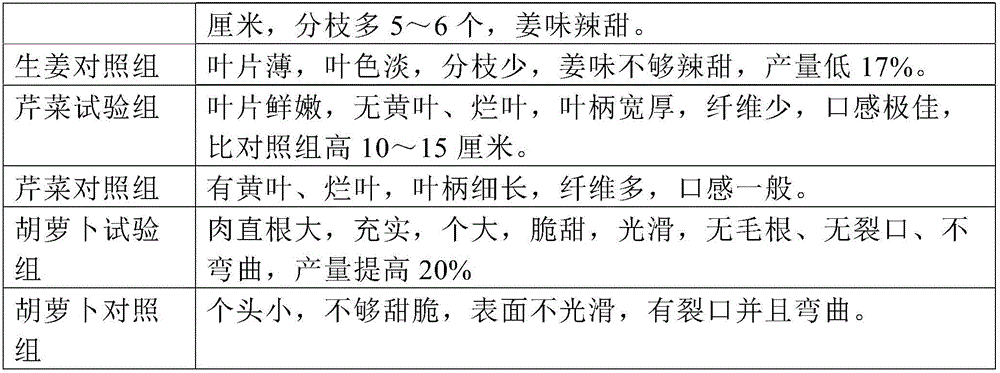

Amino acid fertilizer and preparation method and application thereof

InactiveCN105948972ARich in nutrientsImprove qualityBio-organic fraction processingAnimal corpse fertilisersBiotechnologyPotassium

The invention discloses an amino acid fertilizer including the components in parts by mass: 1-2 parts of enzyme bacteria, 5-10 parts of pineapple pomace, 10-20 parts of oyster shells, 30-40 parts of waste molasses, 5-10 parts of a shrimp head paste, and 10-20 parts of soy bean residues. The invention also provides a preparation method and application of the amino acid fertilizer. The amino acid fertilizer is prepared from the enzyme bacteria and a plurality of wastes, is rich in nutrients and rich in organic matters, organic nitrogen, phosphorus and potassium, humic acid and amino acid, can increase the crop yield after application, improves the crop quality, and also can improve soil effects.

Owner:韩德辉

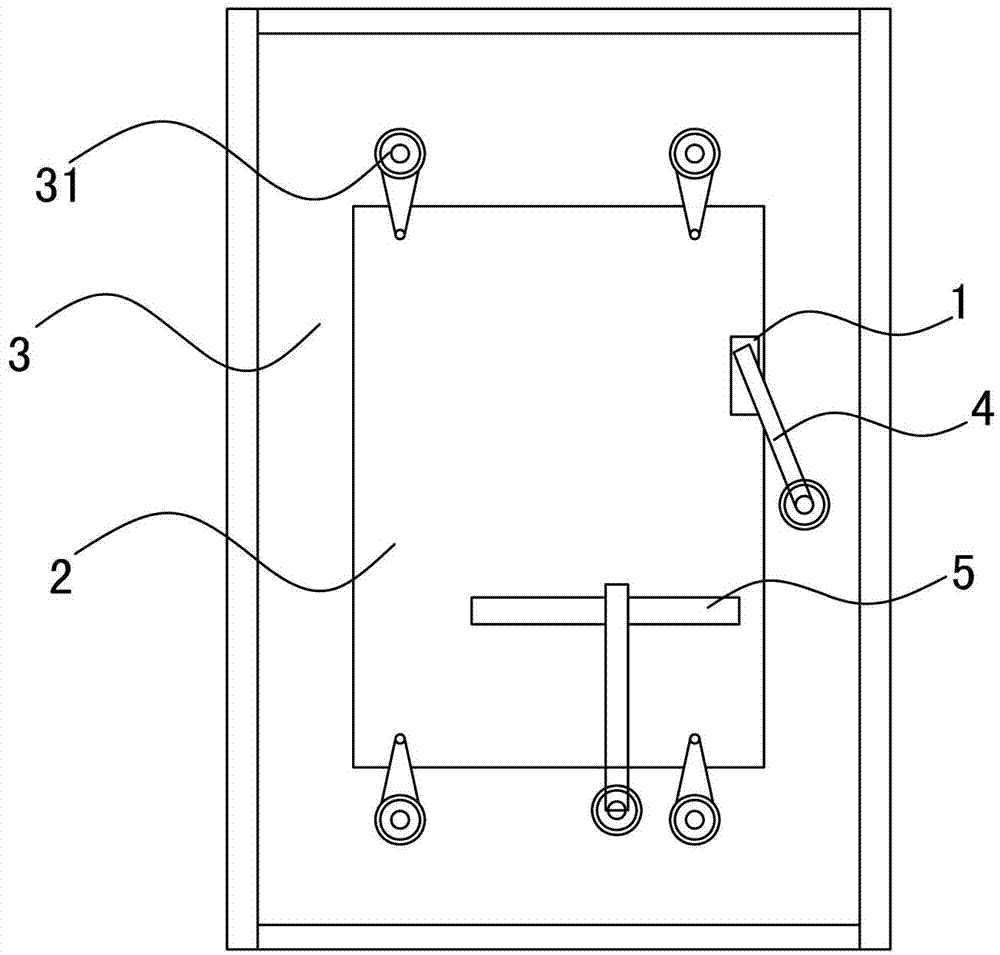

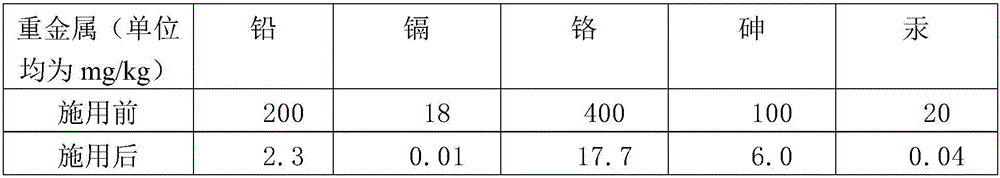

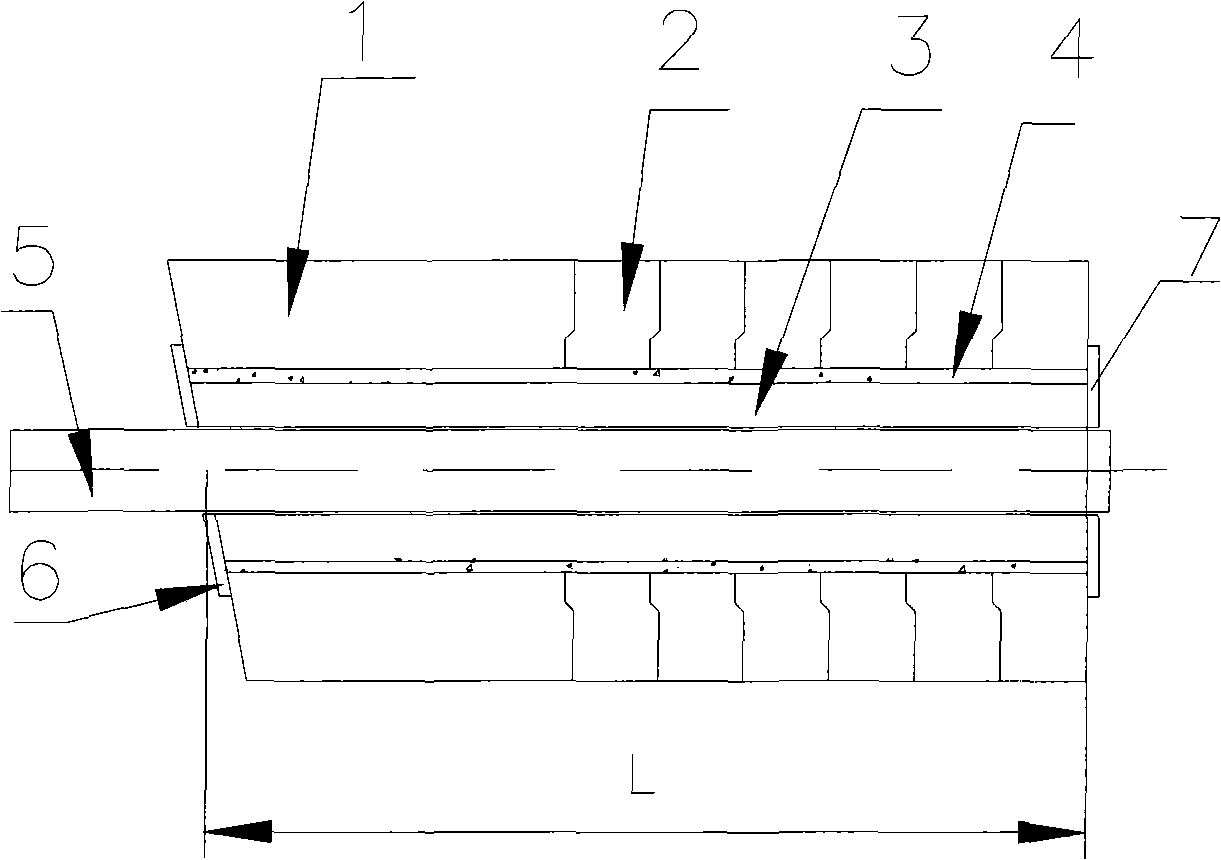

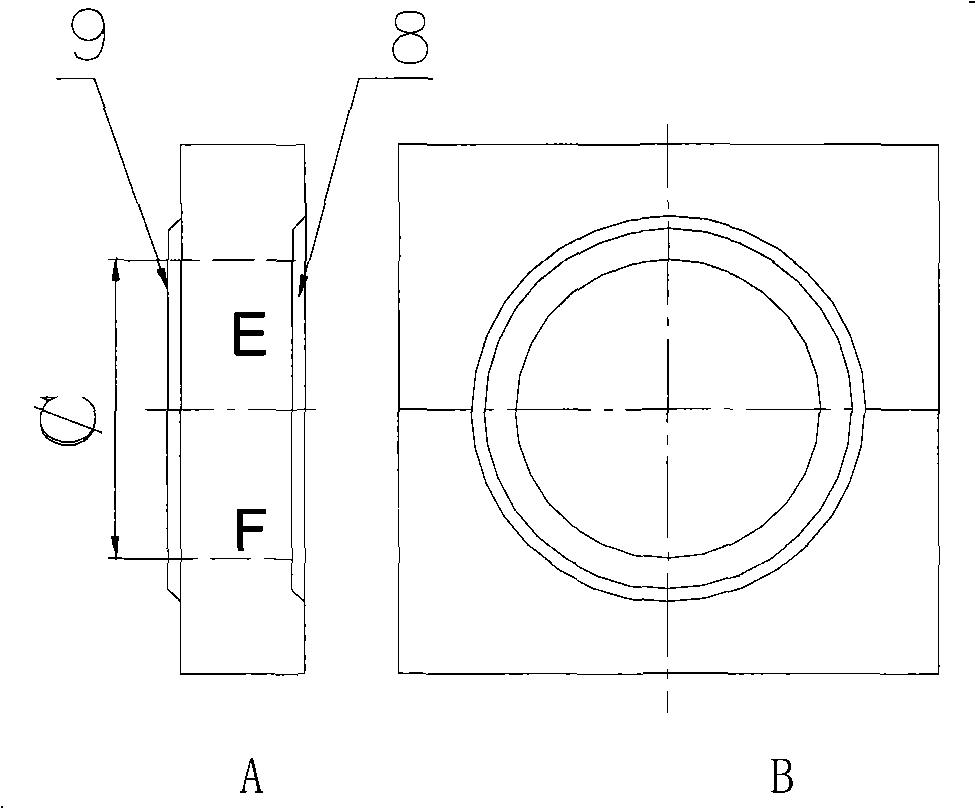

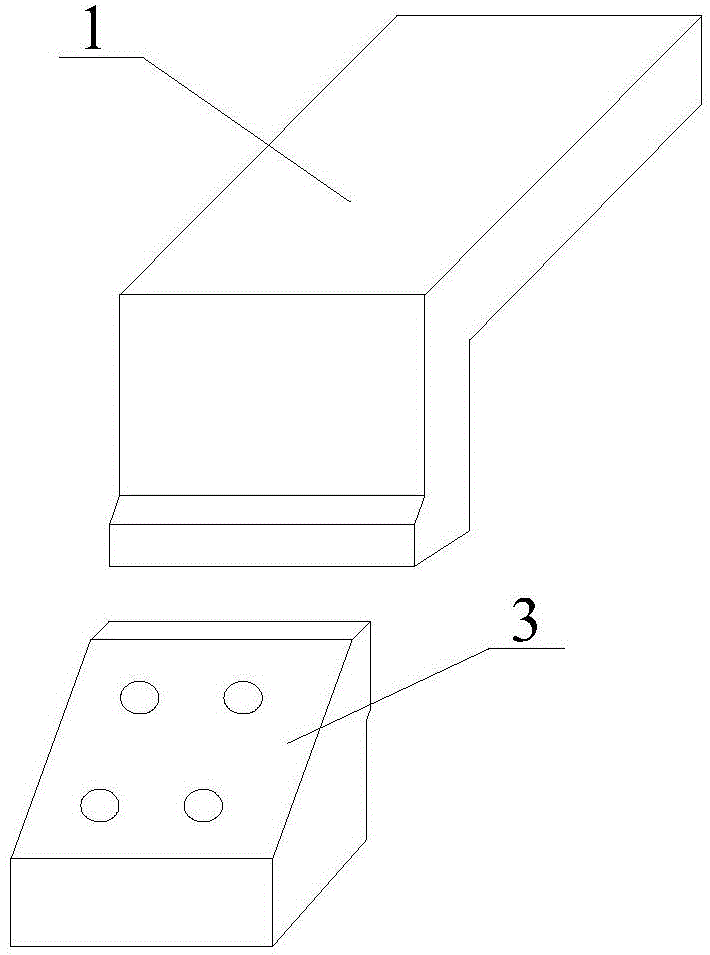

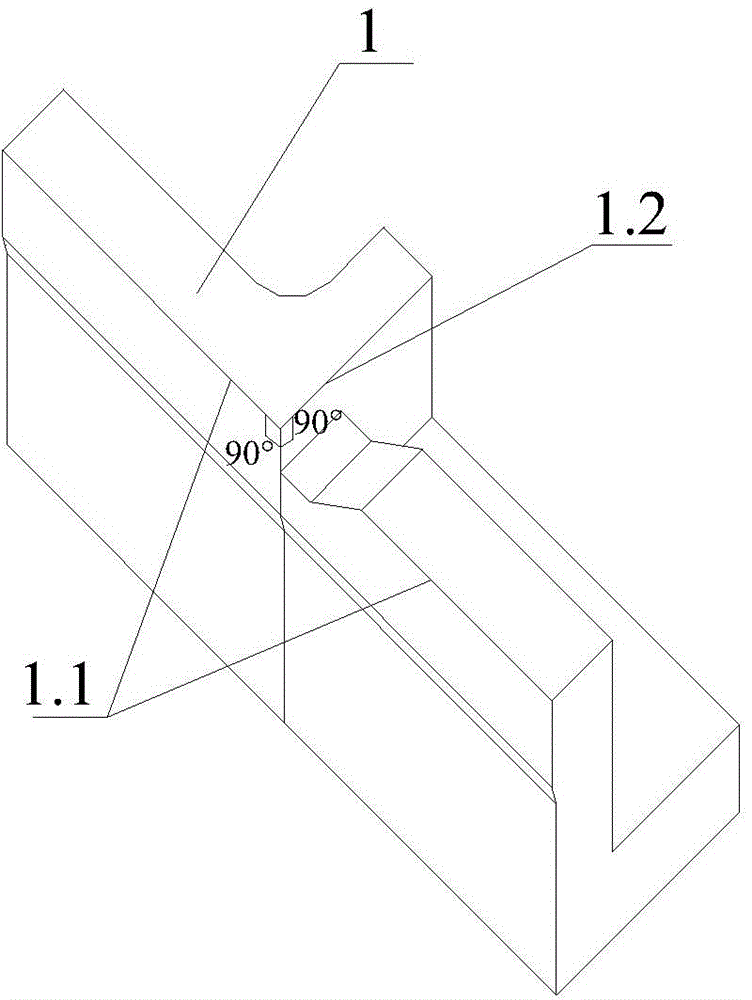

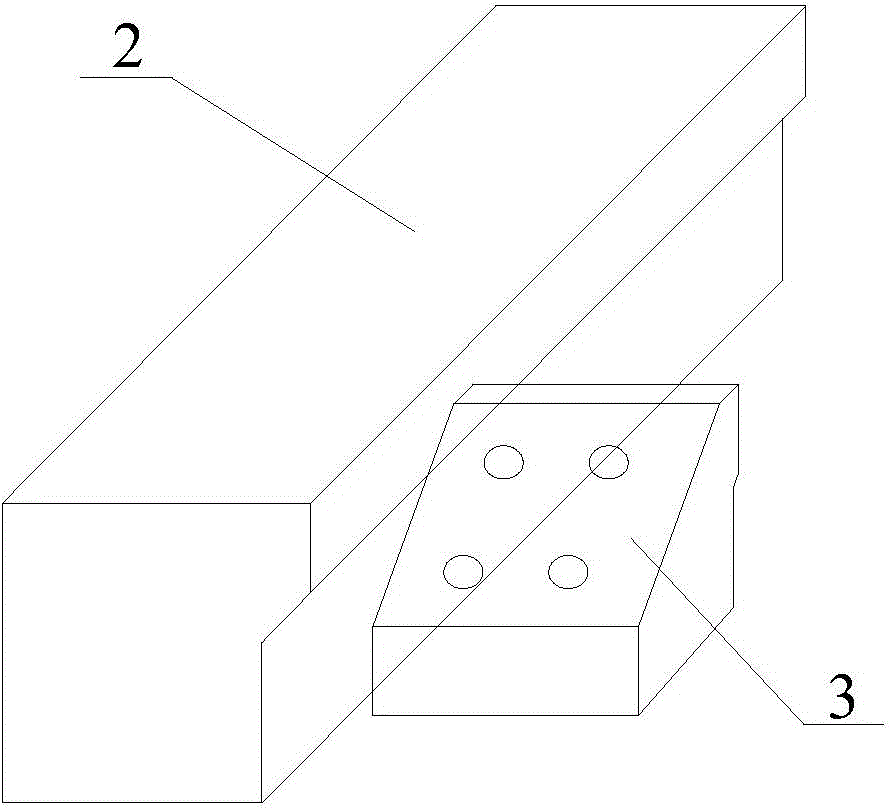

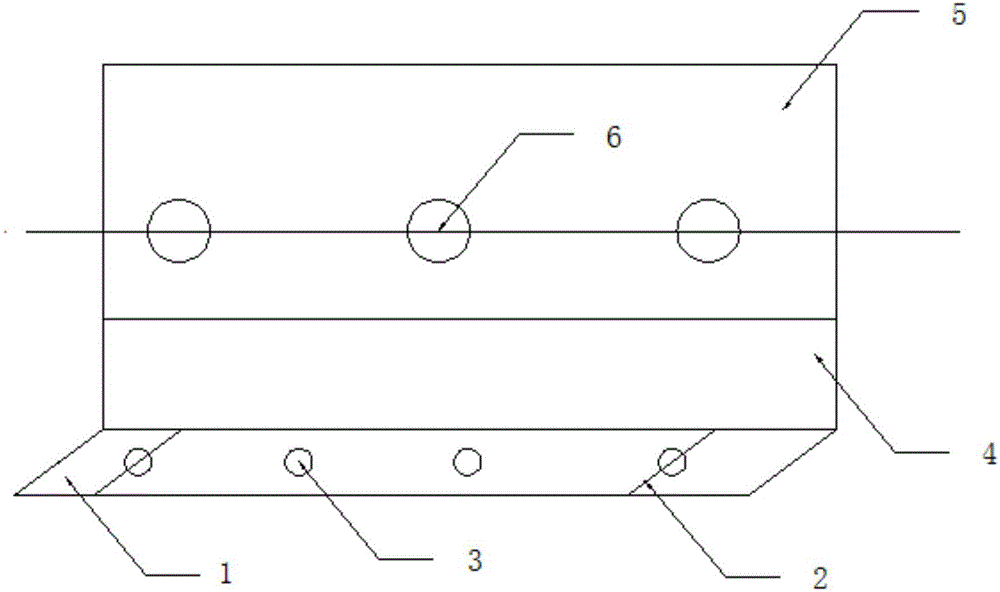

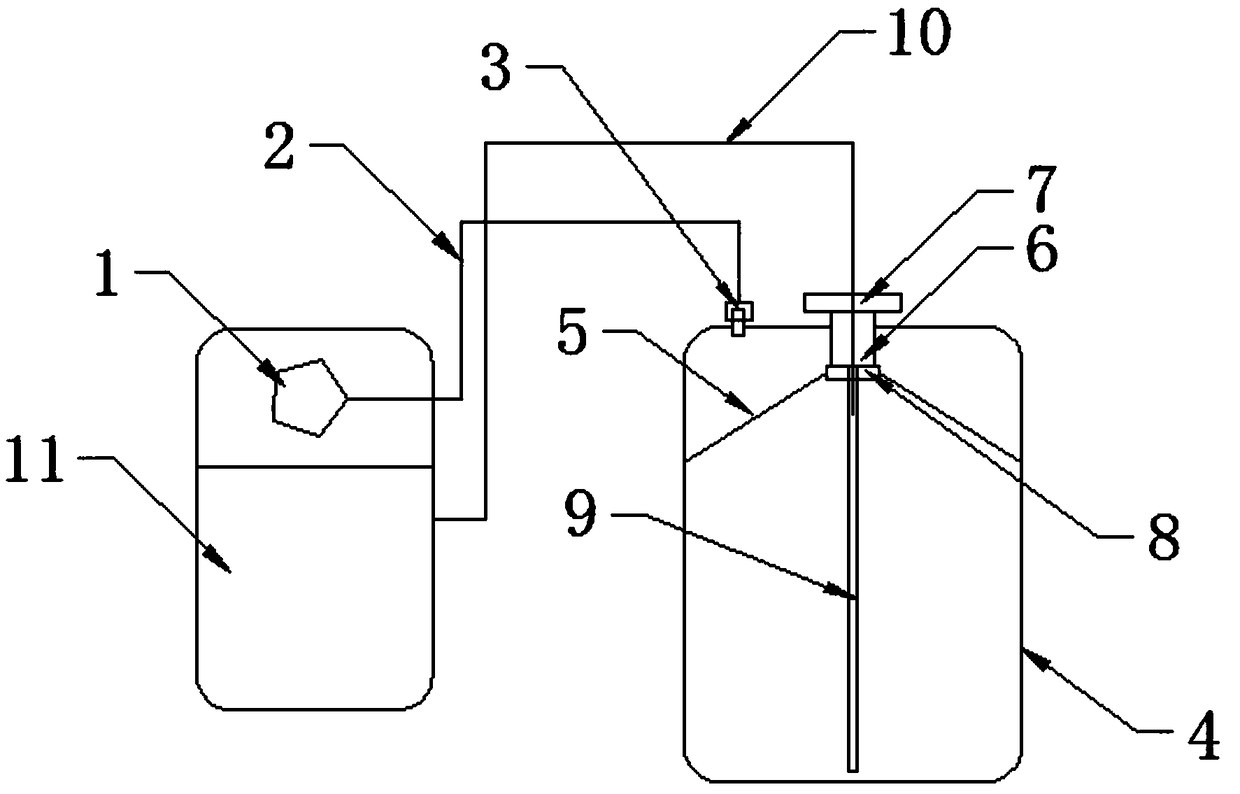

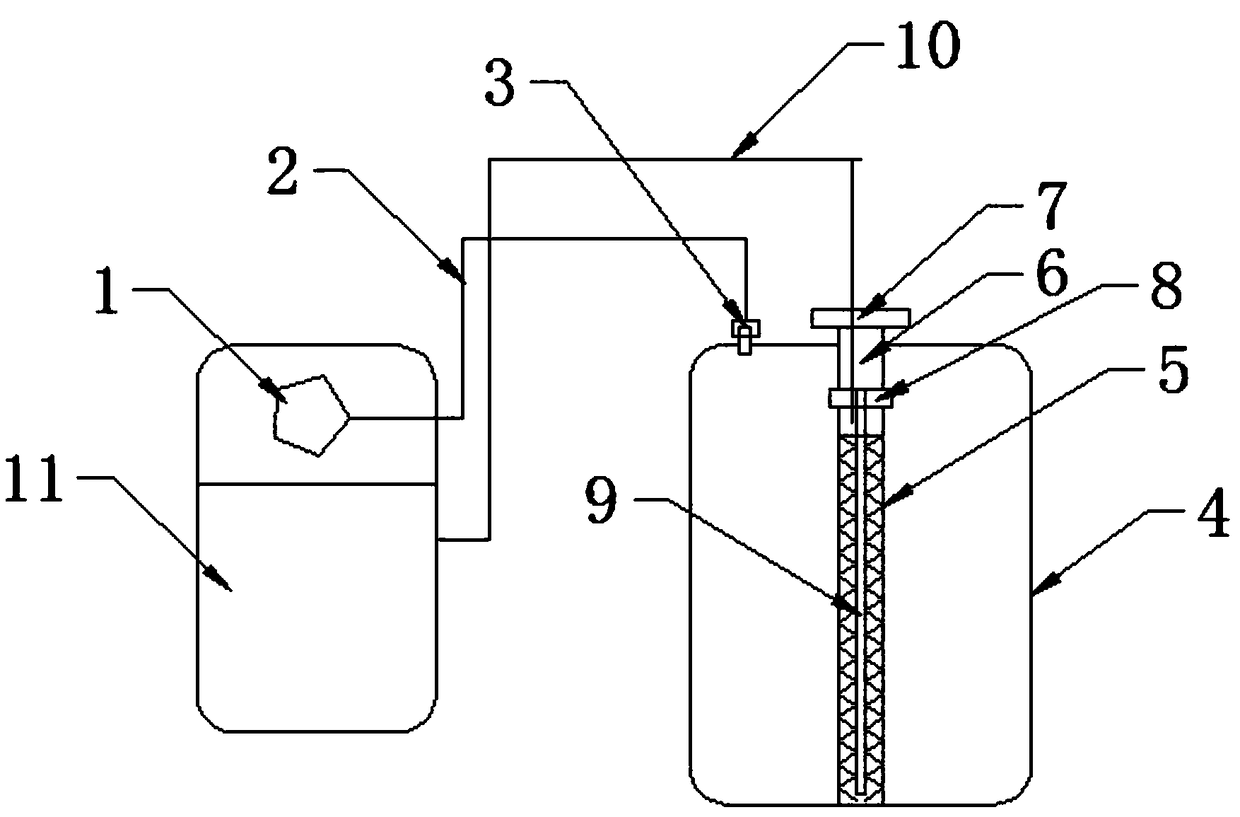

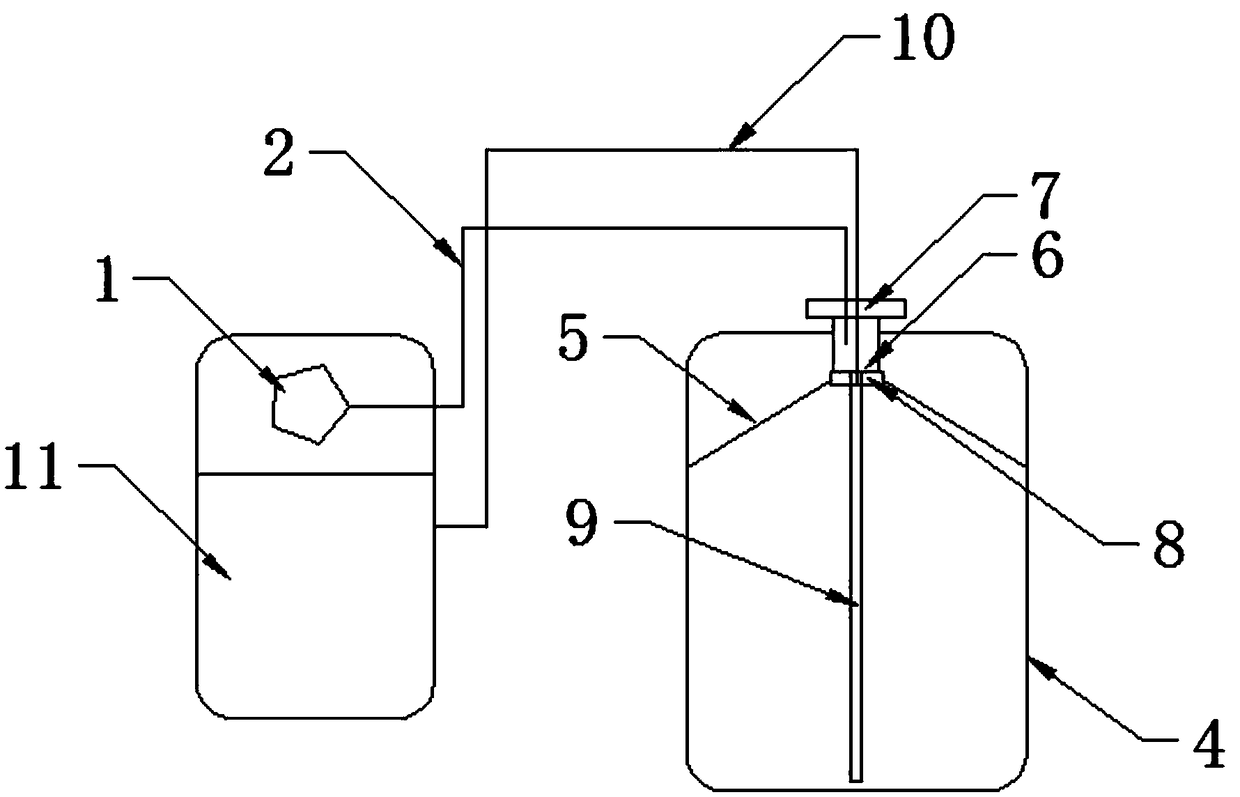

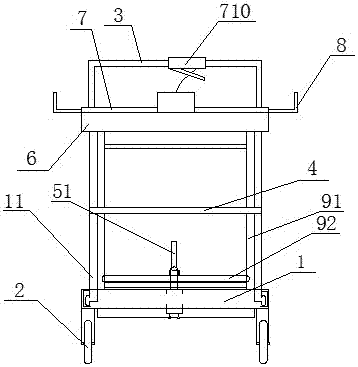

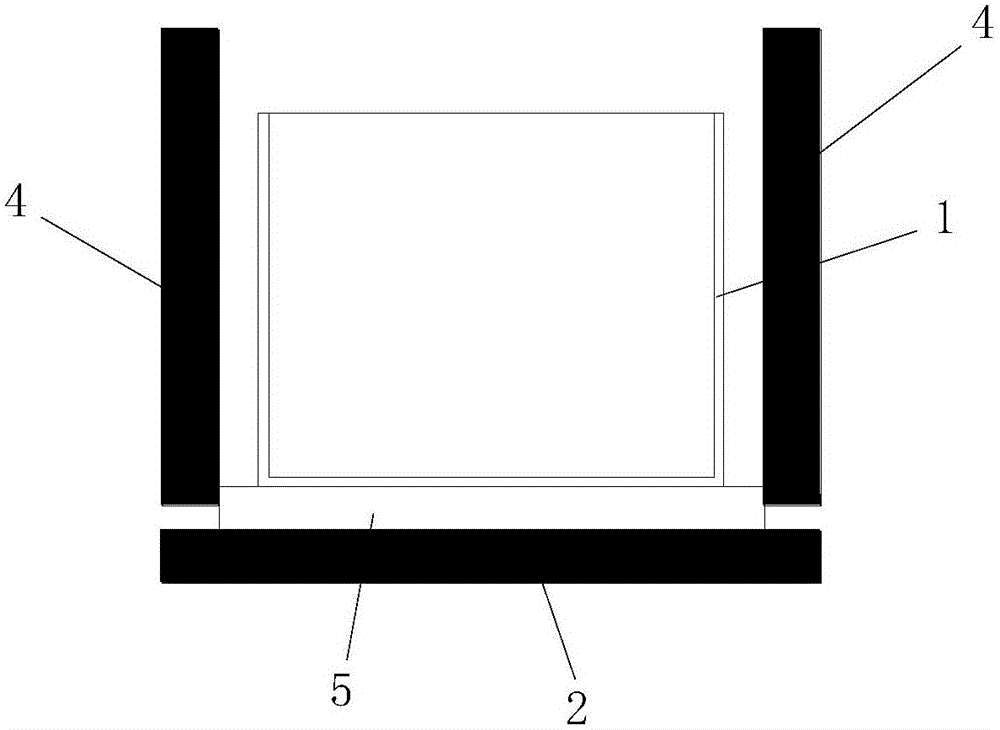

Steel tapping hole assembled outside converter and masonry method thereof

InactiveCN101665853AGuaranteed installation concentricitySave installation timeManufacturing convertersBrickMetallurgy

The invention relates to a steel tapping hole assembled outside a converter and a masonry method thereof. The steel tapping hole comprises a steel tapping hole inner large brick (1), a steel tapping hole outer large brick (2), a steel tapping hole sleeve brick (3), stuffing (4), a steel pipe (5), an inner fixing plate (6) and an outer mounting plate (7) and is characterized in that the steel tapping hole inner large brick (1) and the steel tapping hole outer large brick (2) are sleeved on the steel tapping hole sleeve brick (3); and after the steel tapping hole is integrally assembled and roasted outside the converter, the internal assemblying is carried out when the converter body of the converter is masoned to the position of the steel tapping hole. The invention enhances the masonry quality of the converter steel tapping hole, solves the problem of quality defects and potential safety hazards in the prior steel tapping hole masonry technique and can shorten the installation time ofthe steel tapping hole inside the converter by more than 3 hours under an equal masonry technology condition.

Owner:SHANDONG IRON & STEEL CO LTD

Cold stamping trimming die

The invention relates to a cold stamping trimming die, and belongs to the technical field of cold stamping machining of dies in the automobile industry. The cold stamping trimming die comprises an upper die cutter block, a male die cutter block and a lower die waste cutter block, wherein the lower die waste cutter block is arranged on the part, lower than the male die cutter block, of the side edge of the male die cutter block; the upper die cutter block is arranged above the lower die waste cutter block; an upper die trimming cutting edge and an upper die waste cutting edge are arranged on the upper die cutter block, and are not positioned on the same straight line; the upper die trimming cutting edge and the upper die waste cutting edge are provided with an inclined trimming blade raised from the upper die trimming cutting edge and an inclined waste blade raised from the upper die waste cutting edge at a joint respectively; the inclined trimming blade and the inclined waste blade form a tapered point raised from the upper die trimming cutting edge and the upper die waste cutting edge. According to the cold stamping trimming die, the problem of cutting powder produced by secondary shearing in the prior art is solved, part surface quality problems caused by the cutting powder are solved, and the production efficiency of an automatic line is further improved.

Owner:DONGFENG HONDA AUTOMOBILE CO LTD

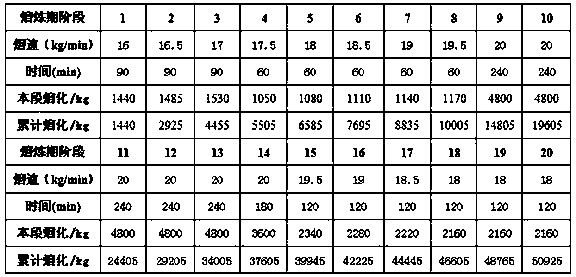

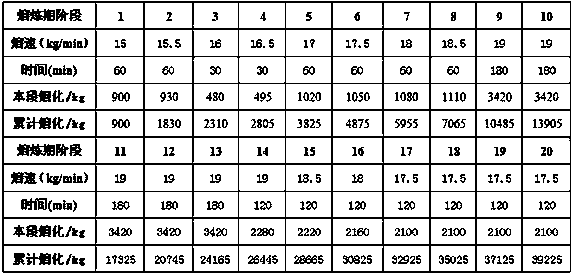

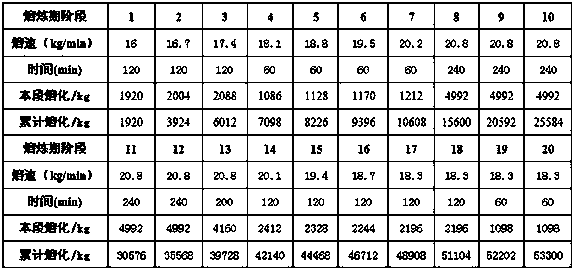

Process for controlling melting speed of large slab electric slag furnace

The invention discloses a process for controlling the melting speed of a large slab electric slag furnace. The process includes the steps of melting speed process design, offline stimulation computation, and procedure intervention and regulation. Procedure intervention and regulation is realized through voltage and current regulation. The three stages of the starting melting speed, the keeping melting speed and the feeding melting speed are adopted for melting speed process design, and the starting melting speed is 14-16 kg / min. According to the process, process design of the melting speed iscarried out, and the three stages of the starting melting speed, the keeping melting speed and the feeding melting speed are adopted; an Excel table tool is used for carrying out offline simulation onthe designed melting speeds; and in the production procedure, voltage and current can be manually regulated according to the conditions of the practical melting speed, so that the effect that the deviation of the practical melting speed and the set melting speed is within the range of + / -1 kg / min is guaranteed, and process execution precision is greatly improved. Production and quality accidentscaused by unreasonable melting speeds are completely eradicated, loss is reduced, production cost is lowered, and benefits are remarkable.

Owner:WUYANG IRON & STEEL

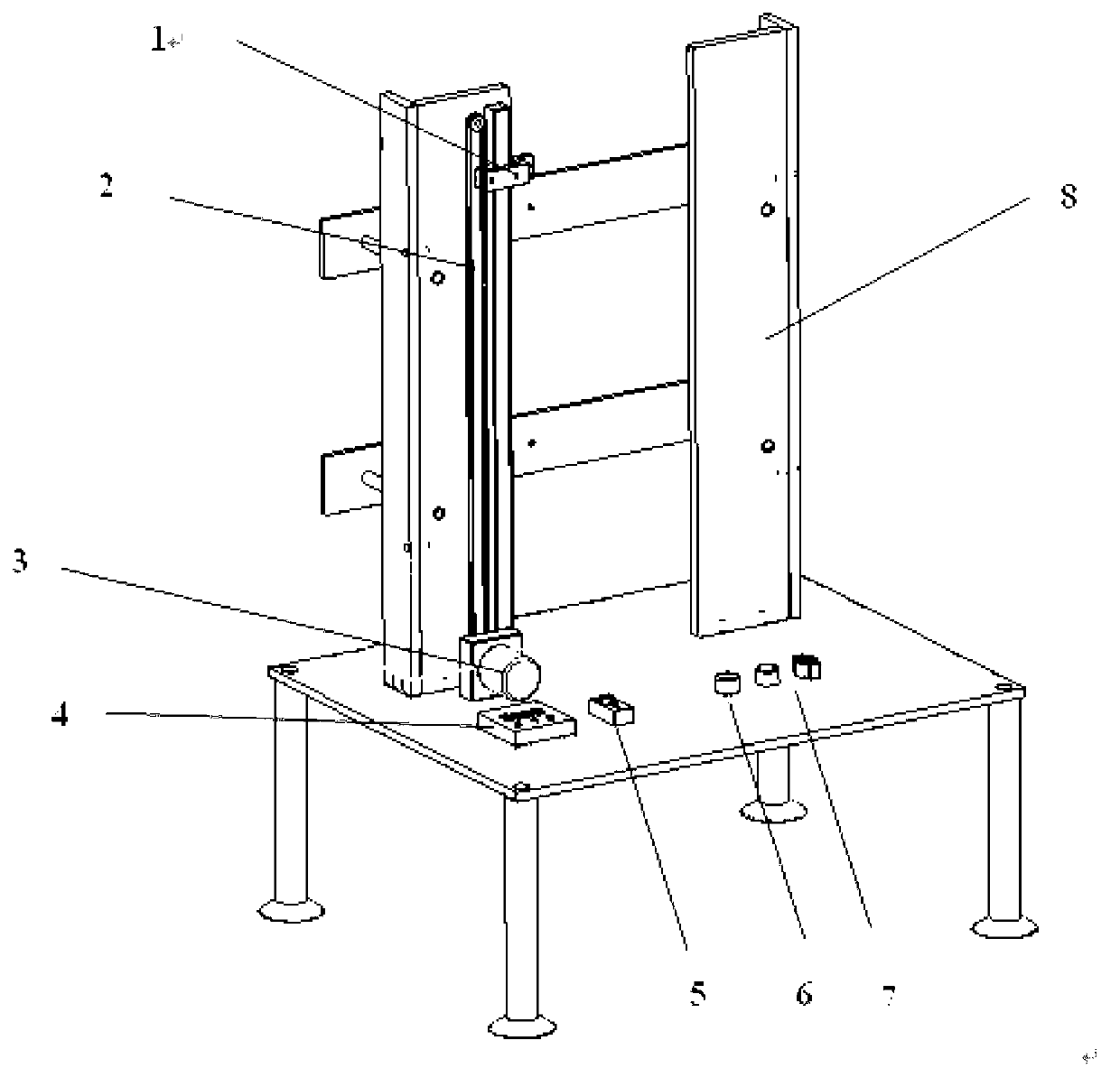

Method for preventing repeated machining and leaked machining of workpieces

ActiveCN103878642ALow costSimple processing methodMeasurement/indication equipmentsMetal working apparatusMulti machineEngineering

The invention belongs to the technical field of machining and particularly relates to a method for preventing repeated machining and leaked machining of workpieces. The controlling process of the method is that the feeding position of a device is provided with baffles and a sensor, the flowing directions and the remaining positions of the workpieces of all states are controlled by controlling the baffles at different positions to ascend and descend, and therefore it is ensured that the workpieces in various states flow to the correct positions. The method for preventing the repeated machining and leaked machining of the workpieces is simple, low in cost and capable of effectively solving the problems of leaked machining and repeated machining of the workpieces in one process and multiple machines, ensuring the machining quality of the workpieces and completely solving the sequential problems of device cutter hitting, cracking up of a machine tool, quality accidents of a complete machine and the like.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

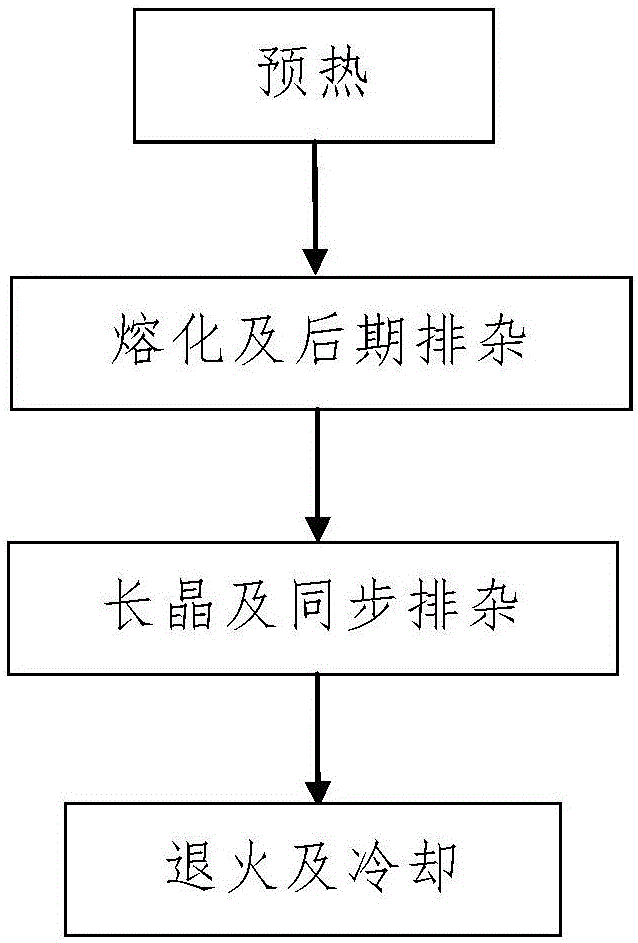

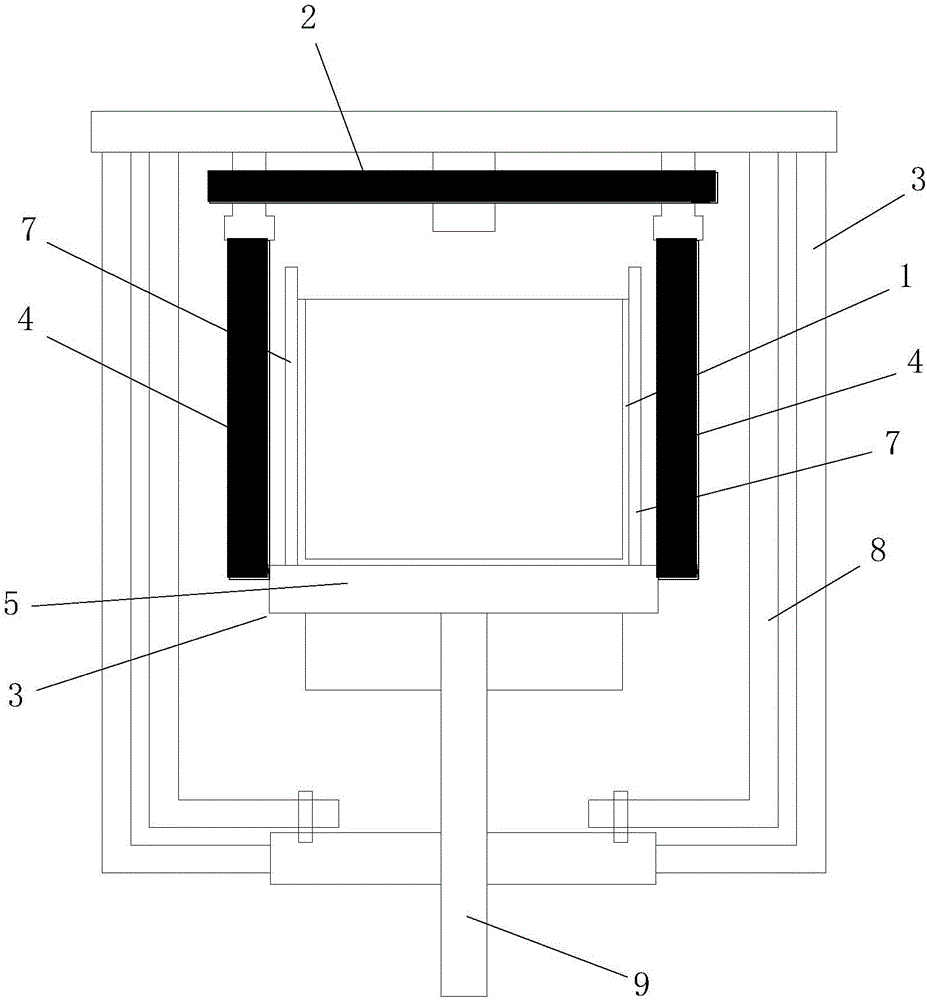

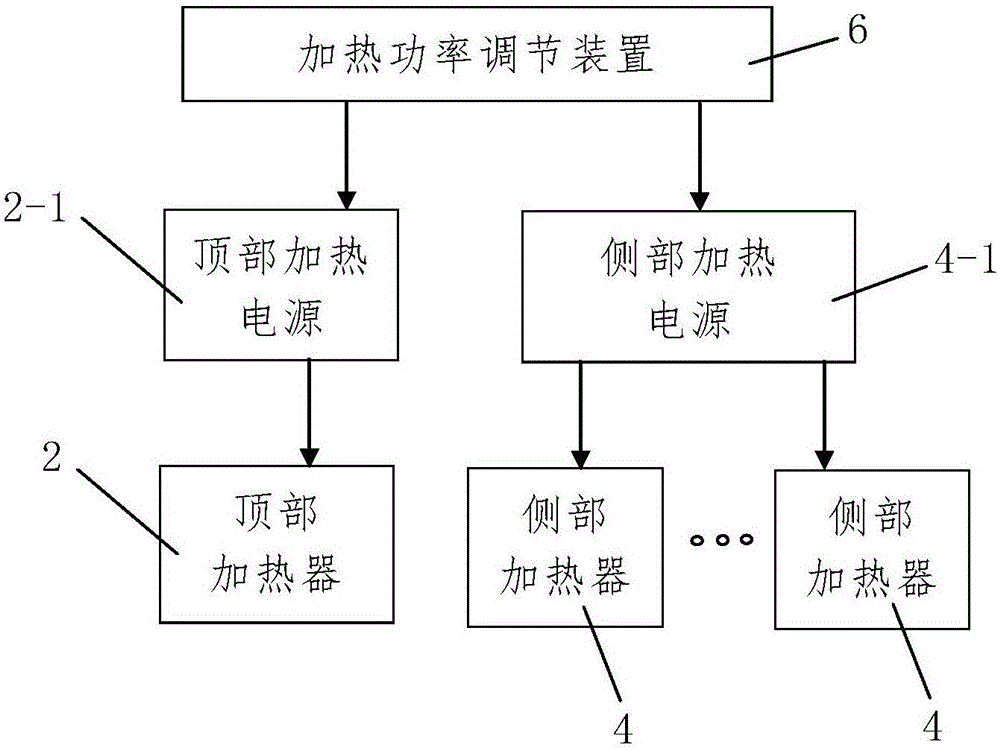

Polycrystalline silicon semi-melting ingot casting method

InactiveCN106119956AReasonable designThe process steps are simplePolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The present invention discloses a polycrystalline silicon semi-melting ingot casting method, comprising the steps of first, preheating: using a polycrystalline silicon ingot furnace to preheat silicon material charged in a crucible, with a top-side ratio coefficient c of the polycrystalline silicon ingot furnace being 1; second, melting and discharging impurities later: 201, melting; 202, discharging impurities in later stage of melting; using the polycrystalline silicon ingot furnace to continuously melt the silicon material for 15-40 min; during melting, adjusting heating power of a top heater and / or four side heaters so as to obtain 0.8> / =c<1; third, growing crystal and discharging impurities at the same time; during crystal growth, adjusting the heating power of the top heater and / or four side heaters so as to obtain 0.3< / =c<0.9; fourth, annealing and cooling. The method of the invention has simple steps and reasonable design, is convenient to implement and effective to use, and may provide a solution to the problems that existing polycrystalline silicon semi-melting ingot casting process has poor impurity-discharging effect and inability to ensure quality of finished ingots.

Owner:XIAN HUAJING ELECTRONICS TECH

Shear wall formwork installation foot angle iron device

InactiveCN106284979AAvoid slurry leakagePut an end to rotten rootsForms/shuttering/falseworksControl linePlastic film

The invention discloses a shear wall formwork installation foot angle iron device, which comprises a base plane and an angle iron unit perpendicularly fixed on the base plane, a plurality of steel nails are arranged on the base plane, the steel nails close to the side edges of the base plane are arranged on control lines, both the steel nails and the angle iron unit are fixed on a rubber-plastic sheet foot, the rubber-plastic sheet foot is fixed at the foot of a shear wall, the angle iron unit is provided with screw holes, the control lines are arranged at the positions 200mm away from both sides of the base plane, the spacing between each two steel nails is equal to or less than 250mm, and the number of the steel nails is not less than 3. The invention relates to shear wall formwork installation construction in formwork construction, and in particular to the angle iron device which is 50 multiplied by 50 multiplied by 3mm, and when in use, the angle iron device can effectively prevent the common quality problems of shear walls, such as foot grout leakage, foot rotting and deformation and displacement phenomenon, improve the appearance of shaped concrete and reduce secondary repair.

Owner:CHINA MCC17 GRP

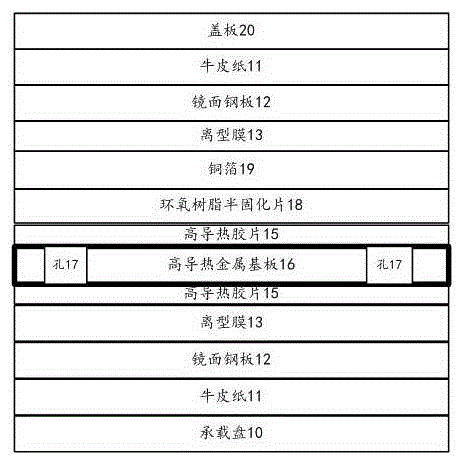

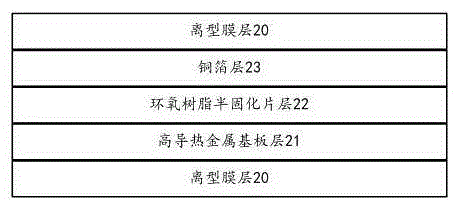

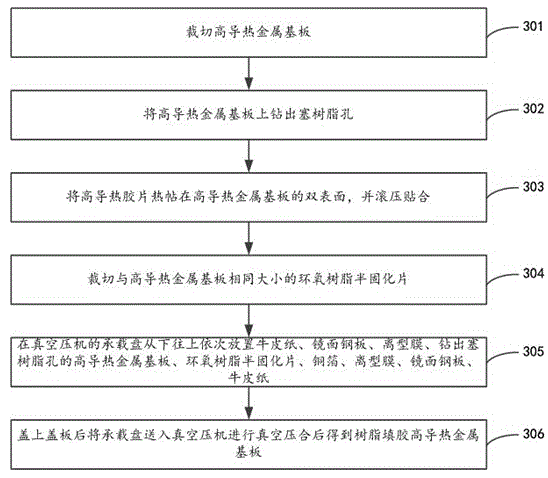

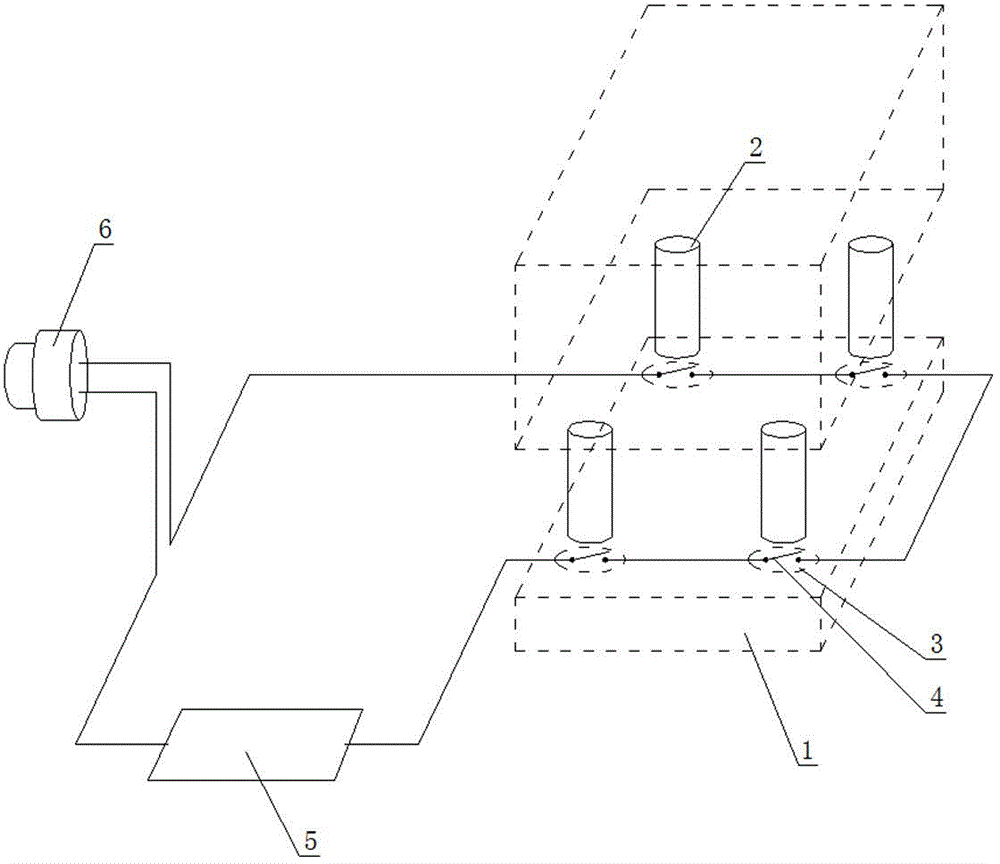

High-heat-conduction metal substrate resin glue filling method, vacuum press fit structure and metal substrate

InactiveCN105216400AEasy to separateAvoid complaintsElectrical equipmentCircuit susbtrate materialsEpoxyCopper foil

The invention discloses a high-heat-conduction metal substrate resin glue filing method, a vacuum press fit structure and a metal substrate, used for improving the production quality of a high-heat-conduction metal substrate. The method comprises the steps of cutting the high-heat-conduction metal substrate; drilling plugging resin holes in the high-heat-conduction metal substrate, hotly attaching high-heat-conduction films to the double surfaces of the high-heat-conduction metal substrate, and carrying out rolling attaching; cutting epoxy resin prepreg with the size same as that of the high-heat-conduction metal substrate; sequentially arranging kraft paper, a mirror surface steel plate, a release film, the high-heat-conduction metal substrate drilled with the plugging resin holes, the epoxy resin prepreg, a copper foil, a release film, a mirror surface steel plate and kraft paper on a bearing disc of a vacuum press from bottom to top in sequence; and after being covered by a cover plate, feeding the bearing disc to the vacuum press to be subjected to vacuum press fit, thus obtaining the high-heat-conduction metal substrate filled with resin.

Owner:HUIZHOU YUXINDA TECH CO LTD

Design method and apparatus for ensuring proper installation of CPU heat sink

ActiveCN104898800AEliminate quality problemsPlay a protective effectDigital processing power distributionDesign methodsMotherboard

The present invention, belonging to the technical field of computers, provides a design method and apparatus for ensuring proper installation of a CUP heat sink. With respect to the structure, the apparatus comprises a main board power supply circuit and a CPU heat sink. A pressure on-off circuit is disposed at the position of the securing screws at each of the four side corners on the base of the CPU heat sink. The four pressure on-off circuits are sequentially connected in series. The main board power supply circuit is connected in series to the power supply switch of a main board jumper. The power supply switch of the main board jumper is sequentially connected in series to the four pressure on-off circuits. The four pressure on-off circuits are connected in series to the main board power supply circuit. According to the present invention, if the screws for the heat sink are not installed or are not properly installed, foolproof design when power is applied fails to be achieved, a protection effect may be exerted on the important components such as the CPU, main board and the like, and the quality problem caused by a failure to install the screws on the heat sink or improper installation of the screws on the heat sink is prevented.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

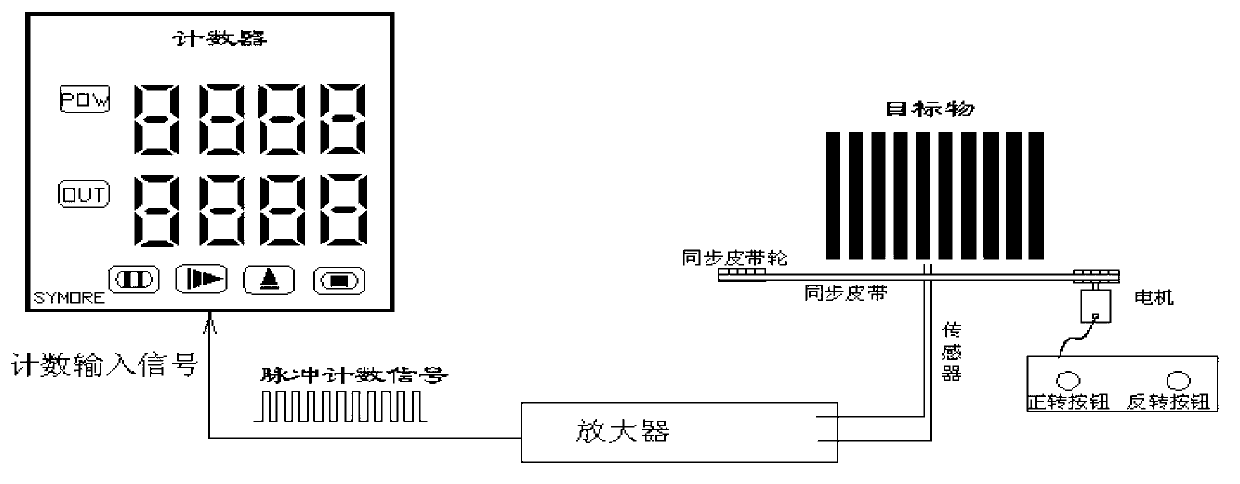

Counting device for circuit board

InactiveCN103020705ALow efficiencyImprove stabilityCounting mechanisms/objectsElectric machineryEngineering

The invention discloses a counting device for a circuit board. The counting device comprises a sensor fixed on a slide rail driven by a motor. The slide rail drives the sensor to reciprocate between two ends of a to-be-counted object. The sensor detects presence of the object during motion and outputs corresponding optical signals into an amplifier. The amplifier performs presence judgment to the object through a preset threshold and converts input optical signals into pulse signals. A counter counts the pulse signals transmitted by the amplifier accumulatively, and displays the counting result. The problem that manual counting is low in efficiency and poor in accuracy is solved, and highly accurate and efficient counting is achieved.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

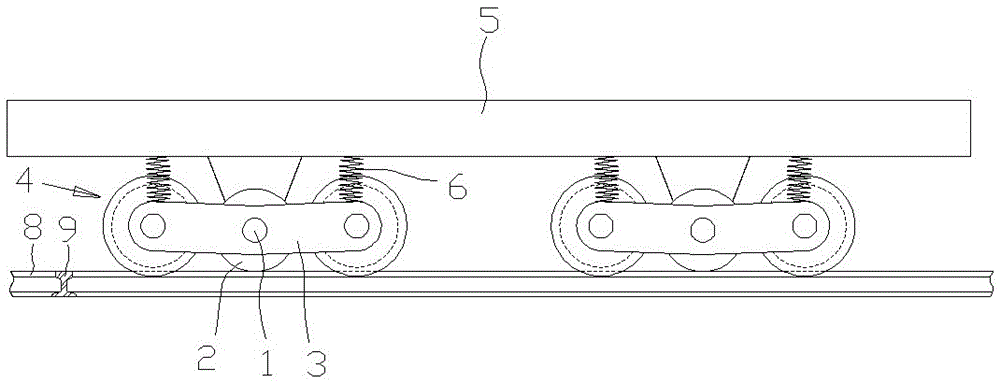

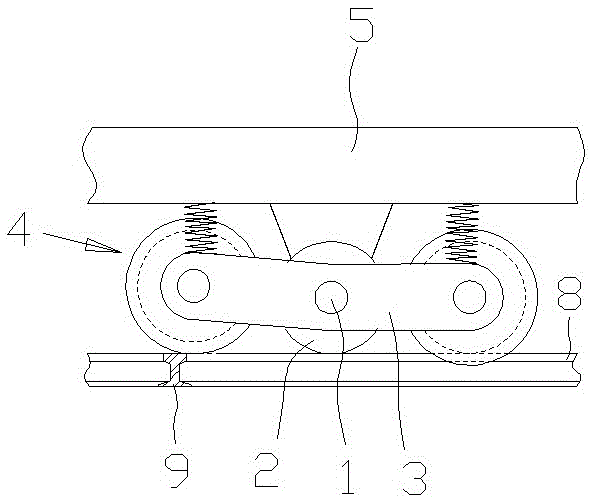

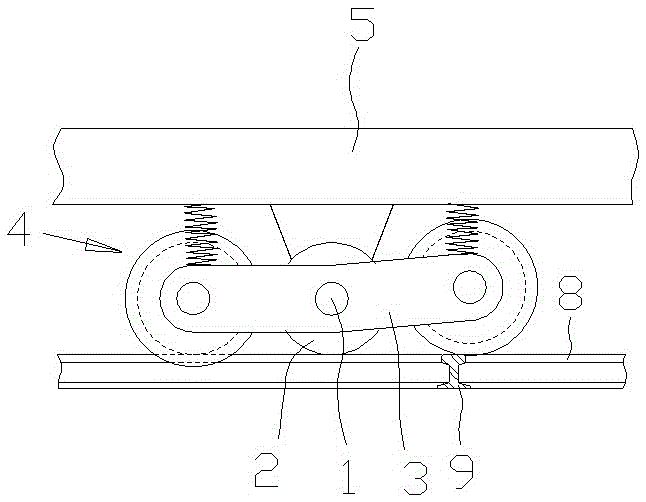

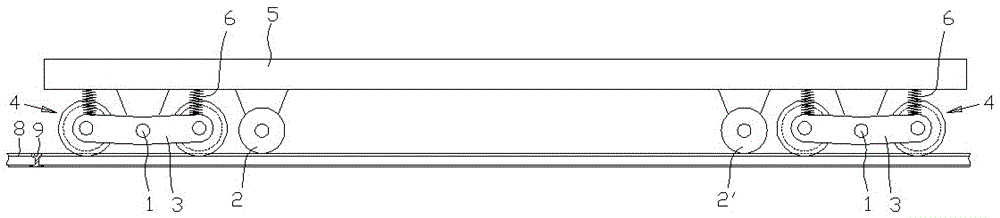

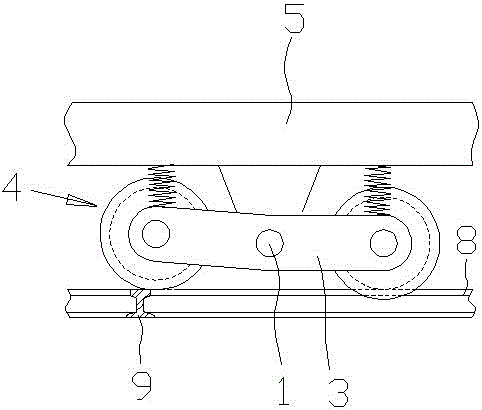

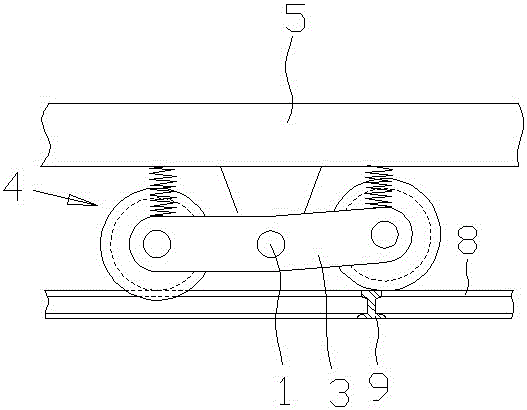

Rail rolling wheel device and seamlessly crossed steel rail matched with same for use

ActiveCN105600324AProtection from derailmentNo derailment guaranteeRunwaysMechanical conveyorsEngineeringFlange

The invention discloses a rail rolling wheel device and a seamlessly crossed steel rail matched with the same for use. The rail rolling wheel device comprises a rolling wheel, a connecting plate, a front guide wheel and a rear guide wheel, wherein the periphery of the rolling wheel is a cylindrical surface; the inner sides and the outer sides of the front guide wheel and the rear guide wheel are each provided with a wheel flange, and springs are arranged between the top of the front end of the connecting plate and a vehicle body and between the top of the rear end of the connecting plate and the vehicle body respectively. The seamlessly crossed steel rail matched with the rail rolling wheel device for use comprises two parallel first steel rail bodies and two parallel second steel rail bodies crossed with the first steel rail bodies, at the cross positions, the left ends of the second steel rail bodies are welded to the left sides of the first steel rail bodies respectively, and the right ends of the second steel rail bodies are welded to the right sides of the first steel rail bodies respectively. By means of the rail rolling wheel device and the seamlessly crossed steel rail matched with the same for use, seamless connection of crossed rails can be achieved, jolts are thoroughly avoided when rolling wheels pass through the rail crossed positions, the potential quality and safety hazards brought to carried precision objects are eradicated, and the service life of the rail is prolonged.

Owner:CHINA UNITED ENG

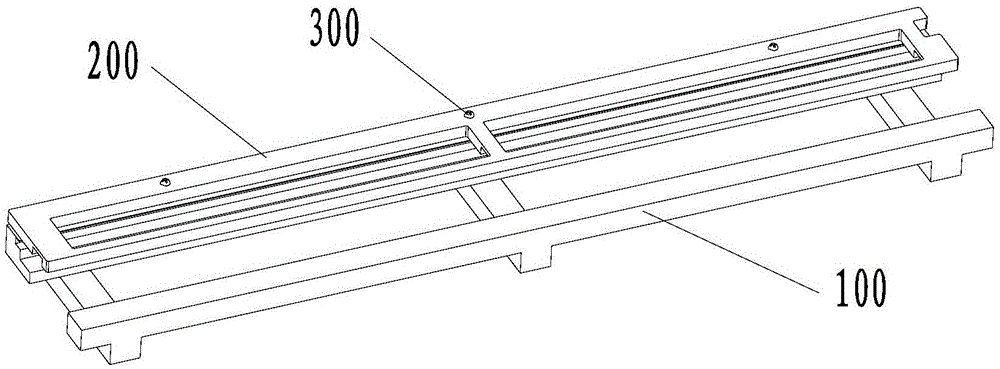

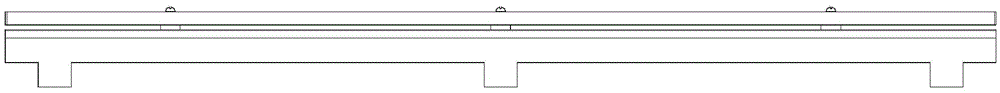

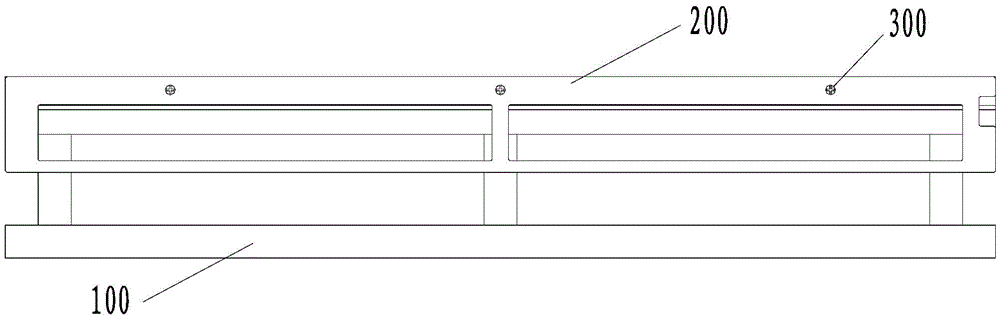

Tool for assembling display assembly

ActiveCN105458983AImplement fixed functionReduce labor intensityWork holdersMetal-working hand toolsDisplay deviceEngineering

The invention provides a tool for assembling a display assembly. The tool comprises a slide rail and a pressure plate, wherein a step is arranged on the slide rail; the step is configured to support the display assembly; the display assembly can slide on the step in a length direction of the step; one end of the pressure plate is arranged on the slide rail; the other end of the pressure plate is suspended; and the pressure plate is configured to limit the display assembly in an up-down direction. According to the tool for assembling the display assembly, the pressure plate is fitted with the slide rail, so that the fixing and sliding functions of the display assembly are realized; and the tool is simple in structure, is convenient and reliable to operate, improves the production efficiency, reduces labor intensity of staff, and avoids and quality and safety hidden danger, so that the purposes of downsizing staffs and improving efficiency are achieved.

Owner:GREE ELECTRIC APPLIANCES CHONGQING +1

Air extrusion type interlayer beer fresh-keeping barrel

PendingCN108313966AAvoid safety hazardsThe amount of compressed gas is not largeLiquid flow controllersLiquid dispensingAir pumpInlet valve

The invention discloses an air extrusion type interlayer beer fresh-keeping barrel. The air extrusion type interlayer beer fresh-keeping barrel comprises a beer barrel shell and a beer barrel flexibleinner container arranged inside the beer barrel shell. The beer barrel flexible inner container is connected with a matched beer straw through an inner container connecting part. The beer straw penetrates the beer barrel shell. A distributor is arranged outside the beer barrel shell. The distributor is fixedly arranged on the top of the beer straw. The distributor is connected with a draft beer machine through a beer hose. An air pump is connected to the draft beer machine. The air pump is connected with an air inlet valve through an air pump hose. The air inlet valve is fixed on the beer barrel shell. According to the air extrusion type interlayer beer fresh-keeping barrel, air is injected into the low-pressure air pump, the pressure of the injected air does not exceed 0.4 MPa, and the use pressure of a stainless steel shell or a plastic resin shell circulating in the market is all within 1 MPa, so that the potential safety hazards of a high-pressure air container and a pipeline aresolved effectively; and in addition, the beer does not come into contact with any foreign gas during the whole process, so that the deterioration of the taste and quality caused by oxidation or impurities caused by foreign gas is eliminated thoroughly, and meanwhile the preservation period is prolonged.

Owner:陆立新 +1

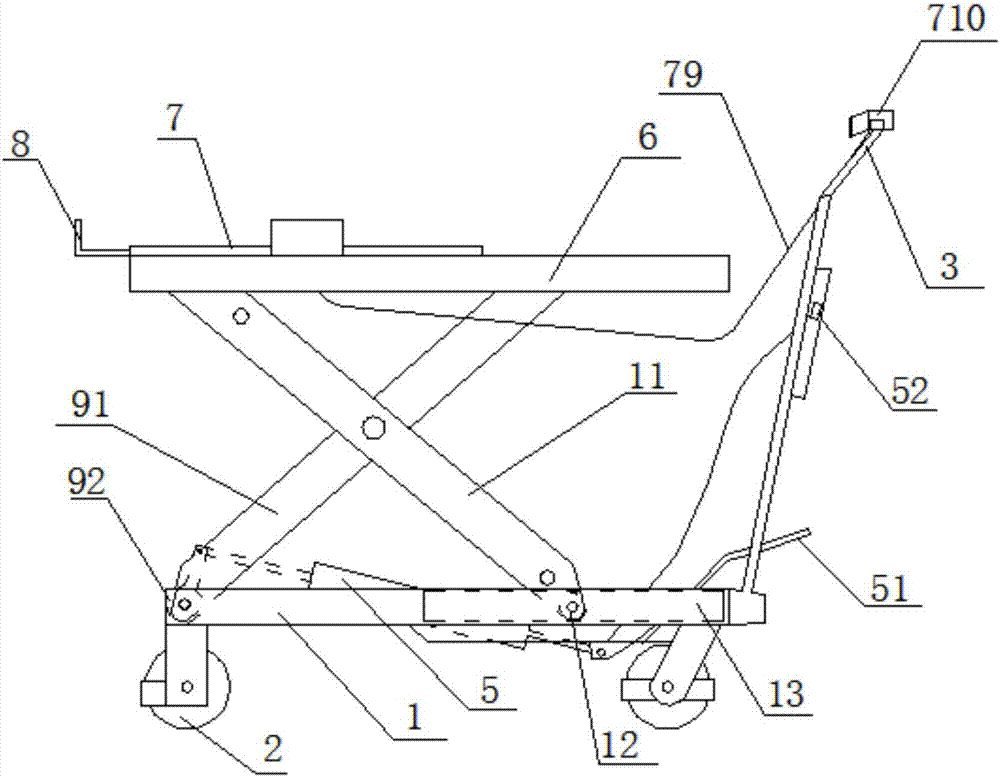

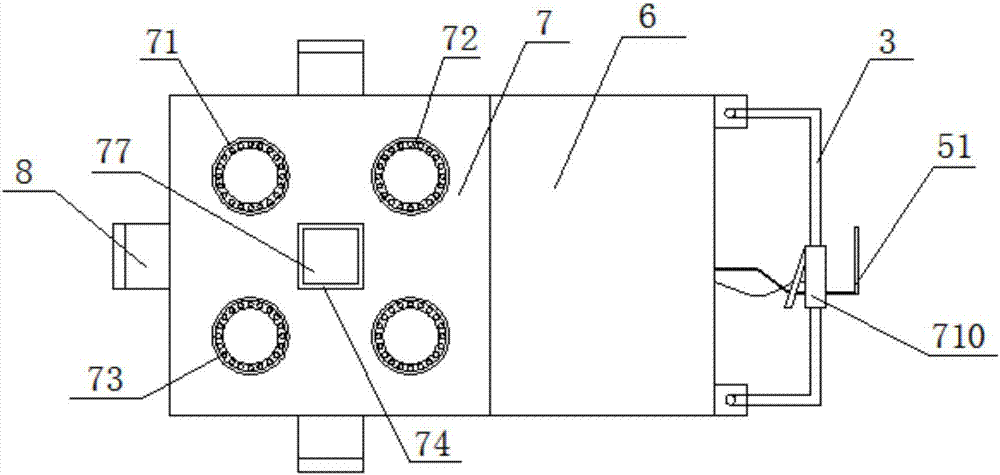

Box girder support mounting trolley

PendingCN107217600AReduce usageImprove ergonomicsBridge structural detailsBridge erection/assemblyControl engineeringControl theory

The invention discloses a box girder support mounting trolley which comprises a chassis, universal walking wheels, a driving lifting frame, a driven lifting frame, a driving cylinder, a tray, a fine adjustment device and an antiskid device. The universal walking wheels are connected on the lower end surface of the chassis, the bottom end of the driving lifting frame is hinged onto the chassis, the driven lifting frame is connected with the driving lifting frame in an intersected manner, the driving cylinder is fixed on the chassis, the tray is connected at the top end of the driving lifting frame and the driven lifting frame, and the fine adjustment device and the antiskid device are arranged in the tray. According to the trolley, the tray is lifted through the lifting frames, a box girder support is supported by the tray, alignment of the box girder support is adjusted through the fine adjustment device, and the box girder support is firmed through the antiskid device. By the aid of the box girder support mounting trolley, operating efficiency is improved, equipment investment is decreased, safety and quality accidents caused by improper operation are eliminated, and finished products and semi-finished products are effectively protected.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Rail flat car and seamless intersection steel rails used in fit with same

ActiveCN105774826AProtection from derailmentNo derailment guaranteeRail switchesMovable tracksEngineeringSpring steel

Owner:CHINA UNITED ENG

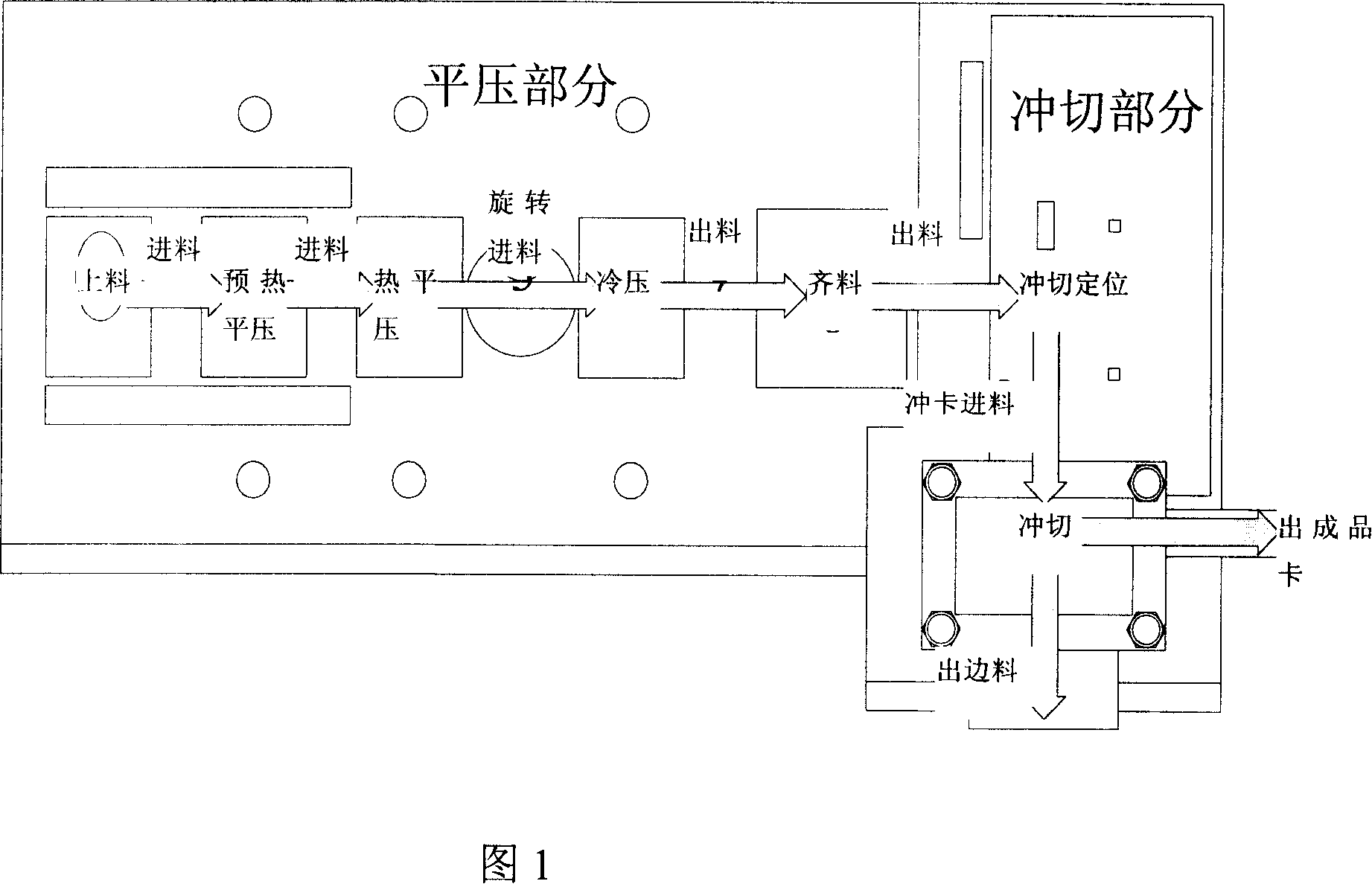

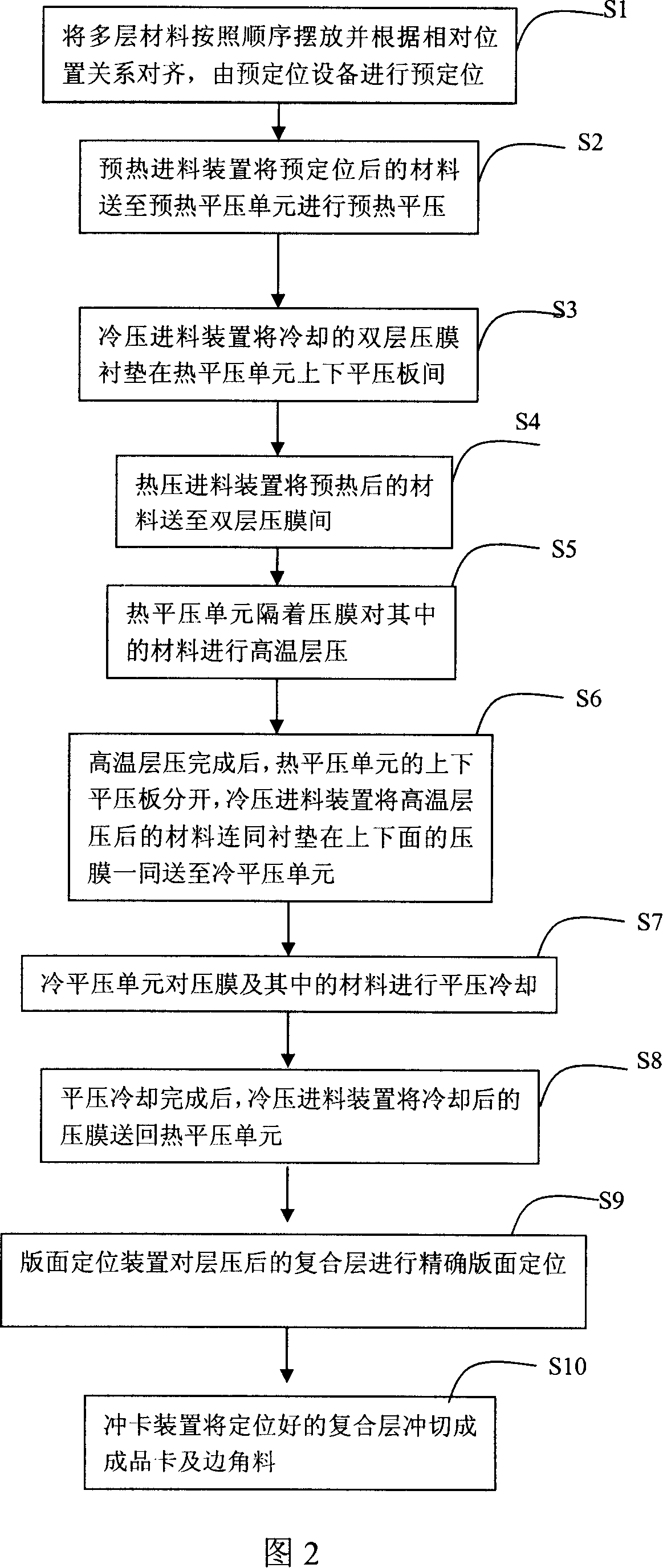

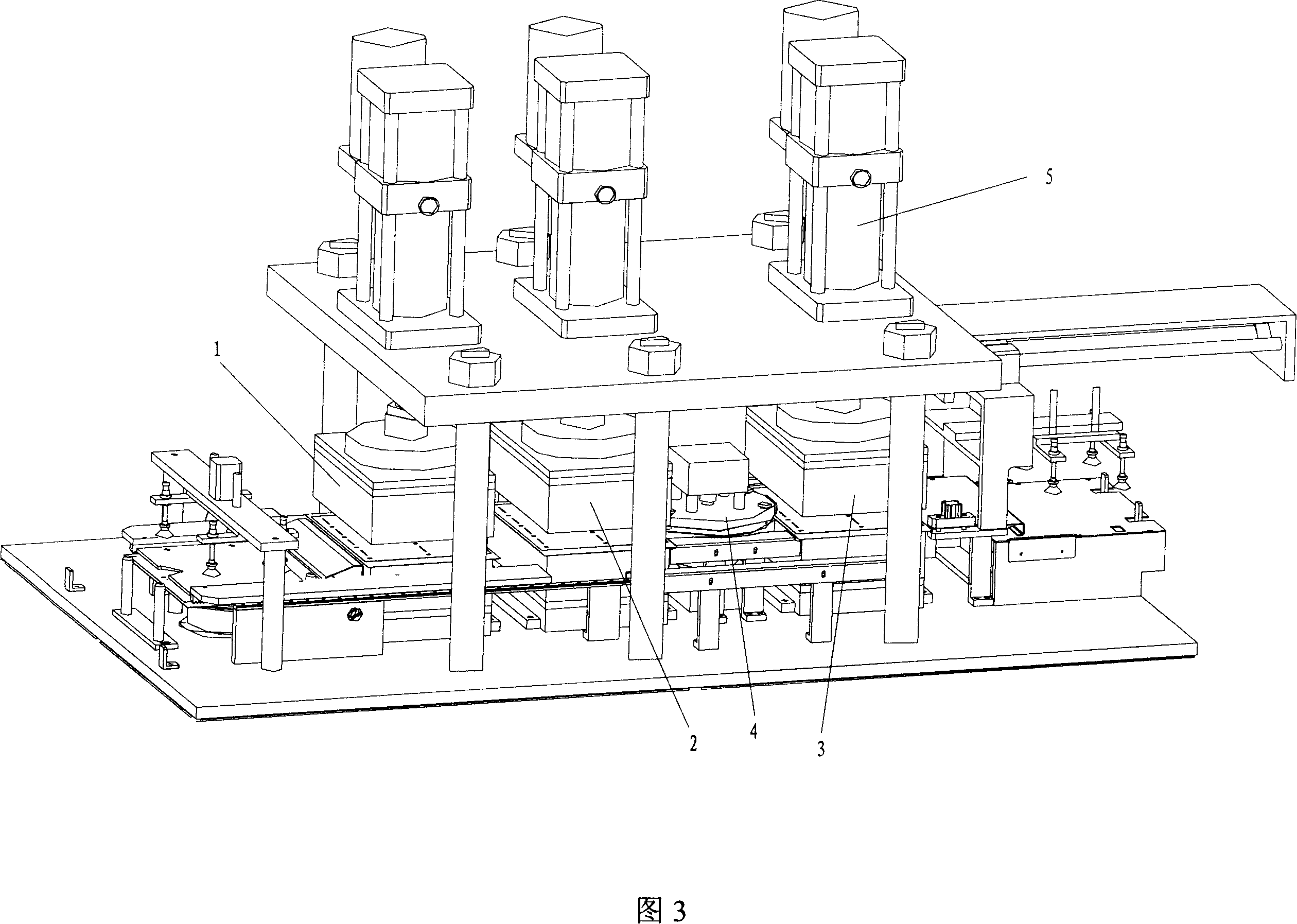

Certificate and card manufacturing method and system

ActiveCN101148098AReduce energy consumptionEliminate quality problemsPaper/cardboard articlesEngineeringPower consumption

The present invention relates to certificate card making process and system. The certificate card making process includes the following steps: 1. pressing several layers of material in certain order into one composite layer; and 2. cutting the composite layer into card products. The certificate card making system includes one pre-locator to locate the layers, one flat press to form the composite layer, and one die cutter to cut the composite layer into card products. The present invention has simplified laminating process, low power consumption, high production efficiency and high product quality.

Owner:INT SECURITY TECH SHENZHEN +3

Simple detecting method for auxiliaries in cleaning room

InactiveCN102914541AEliminate productivityEliminate quality problemsOptically investigating flaws/contaminationAlcoholEngineering

The invention provides a simple detecting method for auxiliaries in a cleaning room. The simple detecting method includes the following steps of firstly, selecting clean pollution-free glass, dripping 1-2ml of newly-distilled analytically pure alcohol on the glass, taking pictures by an optical microscope after the alcohol is volatilized and building a file; dripping 1-2ml of newly-distilled analytically pure alcohol at the edge of a detected material on the glass, impregnating the detected material on the glass and taking off the detected material; and respectively observing quantity of non-volatilized residues through the optical microscope after the alcohol is volatilized; and secondly, comparing non-volatilized residues of the detected material observed by the optical microscope with non-volatilized residues of a qualified material on the same condition, and judging the detected material to be qualified if the residues of the detected material is fewer than or equal to the residues of the qualified material. Accordingly, auxiliaries used on site are guaranteed to be qualified, possible harmful affection on production and product due to quality auxiliary quality fluctuation can be eliminated.

Owner:IRICO FOSHAN FLAT PANEL DISPLAY

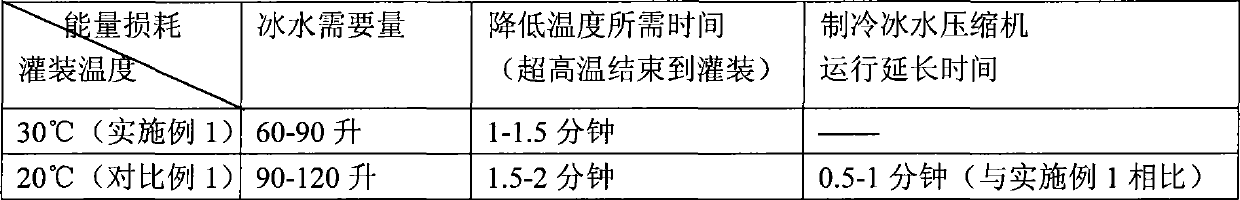

Stabilizer composition and application thereof and liquid milk product comprising same

The invention provides a stabilizer composition and application thereof and a liquid milk product comprising the same. The stabilizer composition comprises type k carrageenan, and also comprises at least one of sodium alginate, gellan gum, microcrystalline cellulose, guar gum and xanthan gum. The stabilizer composition of the invention can be added to the liquid milk product in such a manner thatthe amount of the type k carrageenan is 0.1 to 0.15 per millage of the total weight of the liquid milk product. The composition of the invention is applied to the liquid milk product as the stabilizer, which can change filling requirement, lower production cost and improve the stability of the liquid milk product.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Spraying method for improving quality of primer of anti-corrosion coating of blade profile

PendingCN113770003AImprove primer qualityAvoid foamingPretreated surfacesSpecial surfacesCoated surfaceSand blasting

The invention discloses a spraying method for improving the quality of a primer of an anti-corrosion coating of a blade profile. The spraying method for improving the quality of the primer of the anti-corrosion coating of the blade profile comprises the following steps of (1) controlling a spraying environment, and ensuring temperature, humidity and cleanliness; (2) pre-treating the blade, cleaning the surface of a substrate, and removing pollutants; (3) conducting sand blasting on the substrate, conducting full-coverage sand blasting on an area to be sprayed, and enabling the surface roughness of the substrate to be 4 to 10 microns; (4) conducting primer spraying, spraying a blade body, an air inlet and outlet edge, a blade top and a blade root adapter face step by step, and enabling the coating thickness to be uniform and consistent; and (5) conducting primer surface drying, controlling the surface drying environment and the surface drying time, and after the surface of the coating is completely whitened, conducting curing in a furnace. According to the spraying method, the spraying environment, the substrate surface cleanliness, the substrate sand blasting quality, the spraying technique and the coating surface drying process are controlled, so that the to-be-sprayed process is stable, clean and orderly, the process is prevented from being out of control, the quality problems of blistering, cracking, salient points and the like of the primer are completely eradicated, and then the quality of the primer of the anti-corrosion coating of the blade profile is effectively improved.

Owner:WUXI TURBINE BLADE

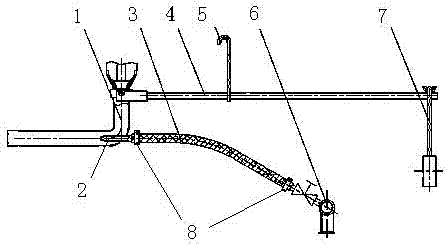

Continuous casting tundish water port online baking bottom exhaust device and method

InactiveCN106862548ARaise the preheat temperatureReduce media costsMelt-holding vesselsCooking & bakingProduct gas

The invention discloses a continuous casting tundish water port online baking bottom exhaust device and a method, belongs to the technical field of continuous casting tundish water port baking equipment and methods, and is used for online baking continuous casting tundish water ports. The device is characterized in that the upper end of a water port bottom exhaust pipe is connected with a water port lower port; the front end of a gas spraying pipe is fixedly connected to an L-shaped bending place of the water port bottom exhaust pipe; a nozzle direction of the gas spraying pipe is in an outlet direction of the water port bottom exhaust pipe; the back end of the gas spraying pipe is connected with the front end of a wind pressure hose; the back end of the wind pressure hose is connected with a compressed air distributor; and the compressed air distributor is connected with a compressed air pipe. The device adopts a gas spraying drainage technology to perform the water port bottom exhaust drainage by using compressed air, combines the water port bottom exhaust pipe with the gas spraying pipe to replace a high-power exhaust fan and an exhaust pipe, achieves the purposes of improving the bottom exhaust heat utilization efficiency and increasing the water port preheating temperature, and largely reduces the equipment investment and the energy medium cost.

Owner:SHIJIAZHUANG IRON & STEEL

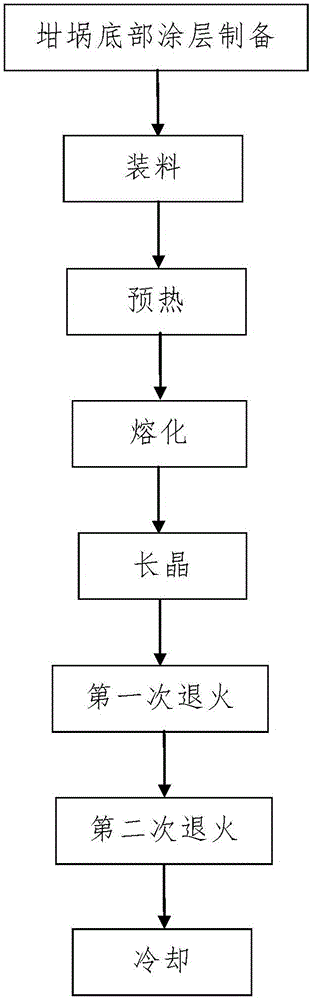

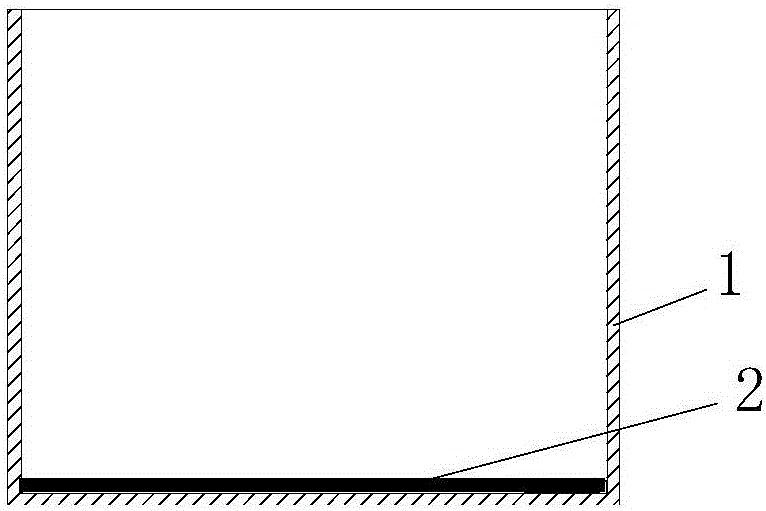

Polycrystalline silicon ingot casting process based on boron nitride coating

InactiveCN106283183AThe process steps are simpleReasonable designPolycrystalline material growthAfter-treatment detailsCrucibleIngot casting

The invention discloses a polycrystalline silicon ingot casting process based on a boron nitride coating. The process includes the first step of preparing a coating at the bottom of a crucible and the second step of conducting polycrystalline silicon ingot casting, wherein filling, preheating, melting, nucleating, and annealing and cooling are conducted in sequence, and the annealing and cooling step includes the substeps of primary annealing, wherein the heating temperature of a polycrystalline silicon ingot casting furnace is lowered to T4 and the temperature is kept for 2-3 h, and T4 is 1250-1280 DEG C; secondary annealing, wherein the heating temperature of the polycrystalline silicon ingot casting furnace is lowered to T5 from T4 and the temperature is kept for 2-3 h, and T5 is 900-950 DEG C; cooling. The process is simple in step, reasonable in design, easy and convenient to implement and good in use effect; by coating the bottom of the crucible with a layer of bottom coating with boron nitride as the main raw material, the oxygen content of the bottom of the crucible can be effectively reduced, the hard point of a finished ingot casting product can be effectively reduced, the annealing process is adjusted, and the quality of the finished ingot casting product can be improved.

Owner:XIAN HUAJING ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com