Polycrystalline silicon semi-melting ingot casting method

A polysilicon ingot furnace and polysilicon technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of unguaranteed quality of ingot finished products, poor impurity removal effect, etc., and achieve preheating and melting process Easy to master, convenient to realize, and simple processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

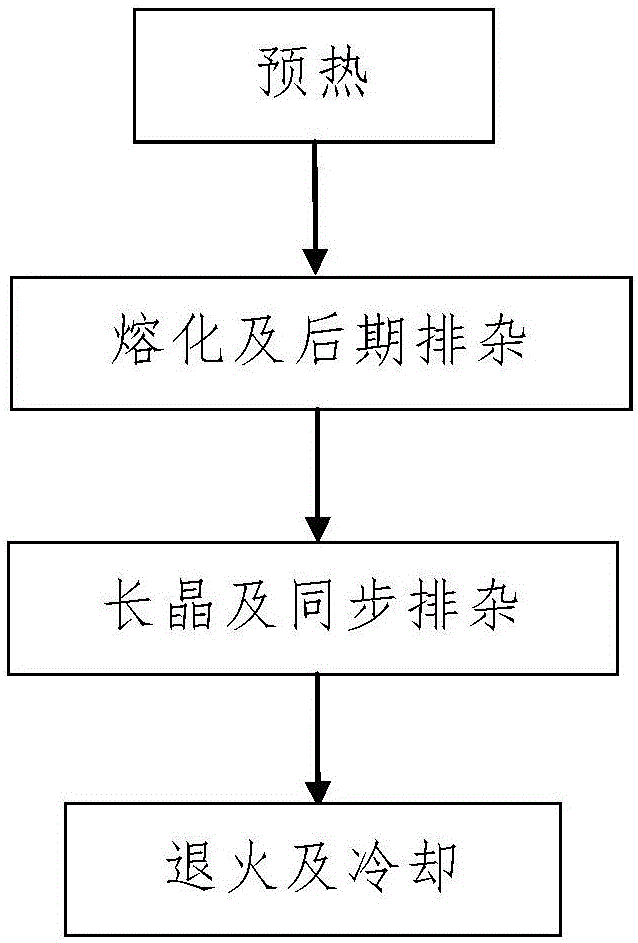

[0055] Such as figure 1 A kind of polysilicon semi-melting ingot casting method shown, comprises the following steps:

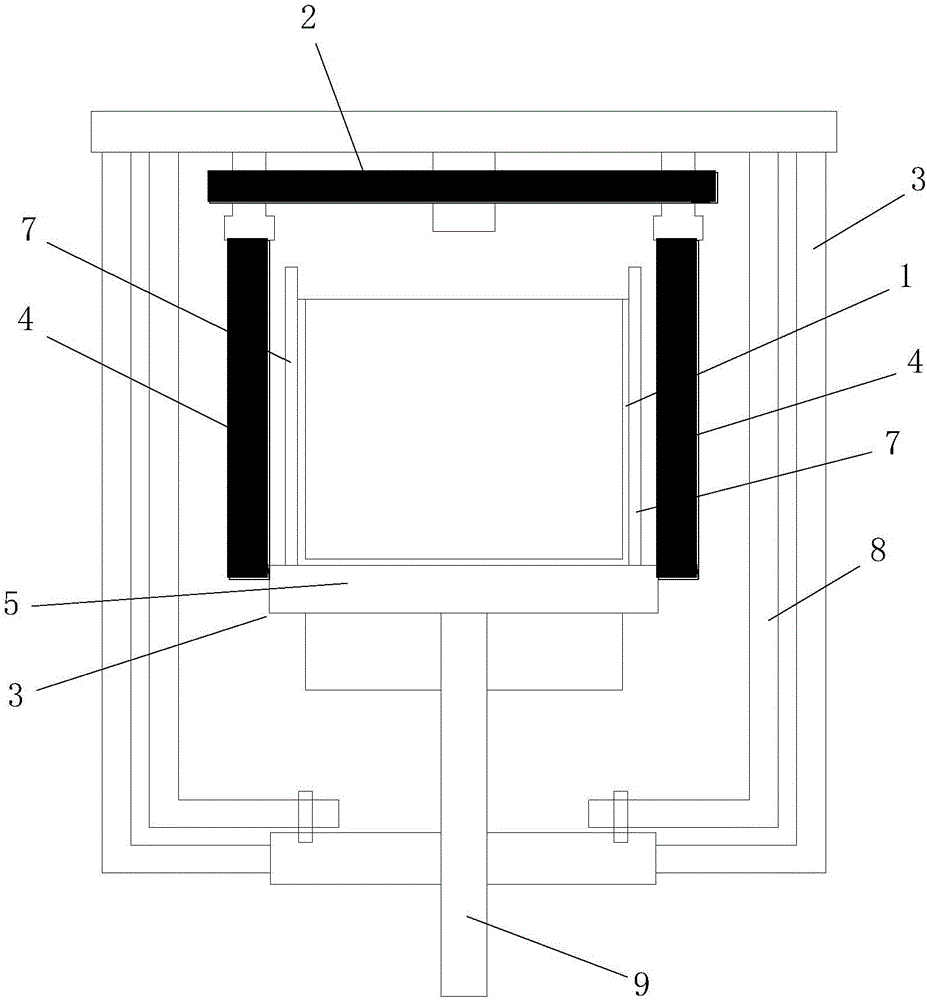

[0056] Step 1. Preheating: Turn on the top heater 2 located above the crucible 1 in the polysilicon ingot furnace 3 and the four side heaters 4 respectively arranged outside the four side walls of the crucible 1, and use polysilicon ingots Furnace 3 preheats the silicon material loaded in crucible 1, and gradually raises the heating temperature of polysilicon ingot casting furnace 3 to T1; the preheating time is 5 hours, where T1=1200°C;

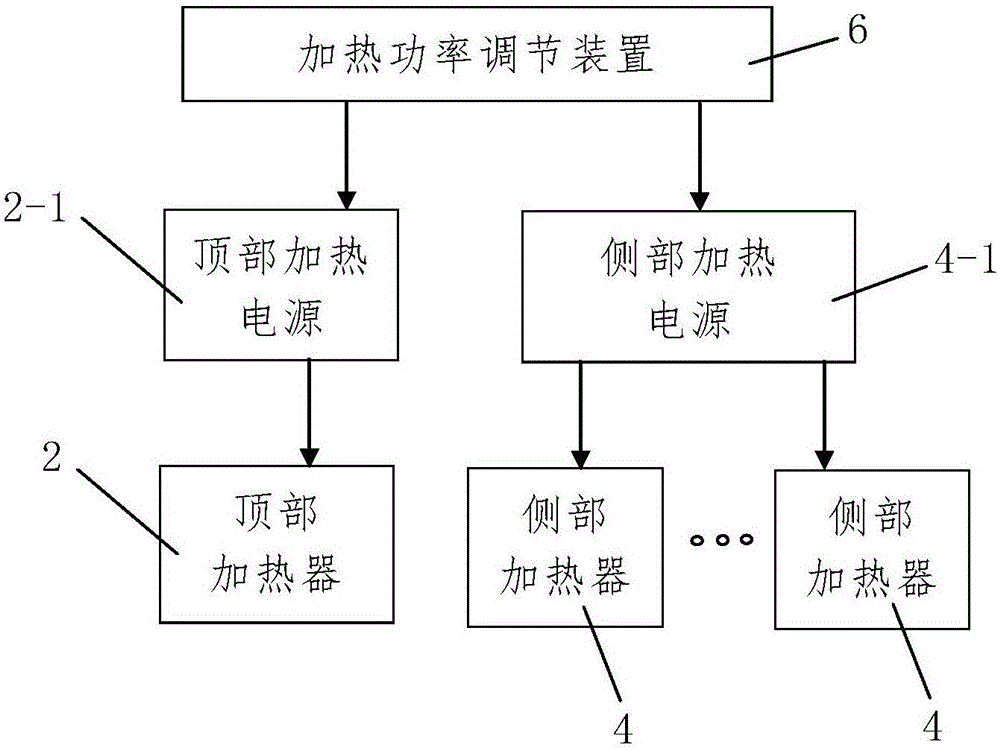

[0057] In this step, the top-side ratio coefficient c=1 of the polysilicon ingot furnace 3;

[0058] Among them, the top-side ratio coefficient c ding is the power ratio coefficient of top heater 2 and P d is the actual heating power of top heater 2, P d max is the maximum heating power of the top heater 2; P c is the actual heating power of the side heater 4, P c max is the maximum heating power of the side hea...

Embodiment 2

[0109] In this example, the difference from Example 1 is: T1=1125°C in step 1, the preheating time is 6h, and P d max 150kW, P c max =220kW; T2=1530 DEG C in the step 201, heat preservation 8h when carrying out the first time heat preservation in the step 2012, heat preservation 14h when carrying out the second heat preservation in the step 2013; Continue melting time in the step 202 is 40min, T3=1420 DEG C; step T4=1410°C in the third step, c in step 301 1 =0.9, c 0 =0.6, the crystal growth time in the early stage is 15h; in step 302, T5=1405°C, and the crystal growth time in the later stage is 35h; the crystal growth rate in step 3 is controlled at 10mm / h; the Q1 described in step 1, step 2 and step 3 = 550 mbar.

[0110] In this embodiment, the remaining method steps and process parameters are the same as those in Embodiment 1.

[0111] In this embodiment, the surface of the processed polysilicon ingot has no impurities, no sticky pot phenomenon, the oxygen content at t...

Embodiment 3

[0113] In this example, the difference from Example 1 is: in step 1, T1=1285°C, the preheating time is 4h, and the P d max 180kW, P c max =260kW; T2=1550 DEG C in the step 201, insulate 4h when carrying out the first time insulation in the step 2012, insulate 10h when carrying out the second insulation in the step 2013; Continue melting time in the step 202 is 15min, T3=1440 DEG C; step T4=1430°C in the third step, c in step 301 1 =0.8,c 0 =0.3, the crystal growth time in the early stage is 10h; in step 302, T5=1425°C, and the crystal growth time in the later stage is 28h; the crystal growth rate in step 3 is controlled at 13mm / h; the Q1 described in step 1, step 2 and step 3 = 650 mbar.

[0114] In this embodiment, the remaining method steps and process parameters are the same as those in Embodiment 1.

[0115] In this embodiment, the surface of the processed polysilicon ingot has no impurities, no sticky pot phenomenon, the oxygen content at the bottom of the ingot is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com