Continuous casting tundish water port online baking bottom exhaust device and method

A continuous casting tundish and ventilation device technology, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve the problems of heavy maintenance workload, many pipe bends, thermal shock fractures, etc., and achieve simple equipment, Improve the preheating temperature and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

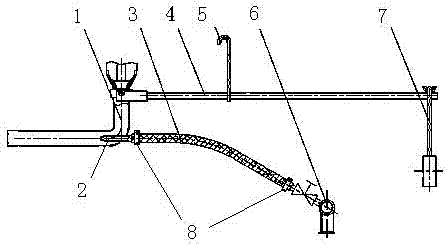

[0020] The continuous casting tundish nozzle online baking bottom exhaust device of the present invention consists of a nozzle bottom exhaust pipe 1, a gas injection pipe 2, a wind pressure rubber hose 3, a bracket 4, a hook 5, a compressed air distributor 6, a balance weight 7, and a rubber hose Clamp hoop 8 forms.

[0021] As shown in the figure, the suction pipe 1 at the bottom of the nozzle is an L-shaped pipe, and the upper end of the suction pipe 1 at the bottom of the nozzle is shaped like a bowl. There is a gasket sealing connection between the inner wall of the bowl mouth of the air duct 1 and the outer wall of the lower mouth of the nozzle.

[0022] As shown in the figure, the front end of the gas injection pipe 2 is fixedly connected to the L-shaped bend of the suction pipe 1 at the bottom of the nozzle, and the nozzle direction of the gas injection pipe 2 is along the outlet direction of the suction pipe 1 at the bottom of the nozzle.

[0023] As shown in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com