Stabilizer composition and application thereof and liquid milk product comprising same

A technology for dairy products and compositions, applied in dairy products, applications, milk preparations, etc., can solve problems such as affecting product quality and stability, product marbling, consuming more power and energy, etc., to achieve formula cost advantages, production Cost advantage, effect of good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

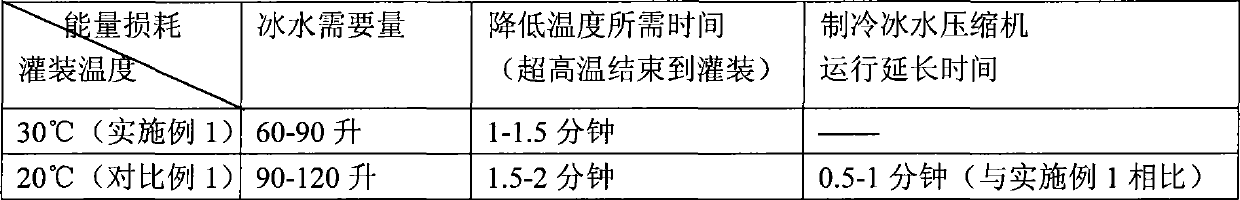

Examples

Embodiment 1

[0048] The liquid milk formula of the present embodiment is:

[0049] 800 servings of fresh milk

[0050] White sugar 50 parts

[0051] 6 parts cocoa powder

[0052] Stabilizer composition (composition of κ-type carrageenan and sodium alginate 1:5) 0.8 parts

[0053] Sodium tripolyphosphate 0.3 parts

[0054] Sodium hexametaphosphate 0.1 parts

[0055] Sodium pyrophosphate 0.1 parts

[0056] Sodium citrate 0.3 parts

[0057] Essence 1 part

[0058] Purified water is added to 1000 parts of the total ingredients.

[0059] The performance indicators of the raw materials used meet the requirements of relevant quality standards.

[0060] The production process used in this embodiment is as follows:

[0061] 1. Raw milk inspection: Raw milk inspection should meet the requirements of fat ≥ 3.3%, protein ≥ 3.00%, dry matter ≥ 11.85%, subject to the test results of 120 whole milk analyzer; and the acidity ≤ 15°, adopt the national standard detection method; alcohol Experiment...

Embodiment 2

[0075] The liquid milk formula of the present embodiment is:

[0076] 800 servings of fresh milk

[0077] White sugar 50 parts

[0078] 6 parts cocoa powder

[0079] Stabilizer composition (κ-type carrageenan, sodium alginate and guar gum at a ratio of 1:3:1) 0.5 parts

[0080] Glyceryl monostearate 1.0 parts

[0081] Sodium stearoyl lactylate 0.3 parts

[0082] Sodium tripolyphosphate 0.3 parts

[0083] Sodium hexametaphosphate 0.1 parts

[0084] Sodium pyrophosphate 0.1 parts

[0085] Sodium citrate 0.3 parts

[0086] Essence 1 part

[0087]Purified water is added to 1000 parts of the total ingredients.

[0088] The performance indicators of the raw materials used meet the requirements of relevant quality standards.

[0089] The preparation method is basically the same as in Example 1. The cocoa milk product of this embodiment has a product viscosity of about 3.97 centipoise and a pH value of about 6.79.

Embodiment 3

[0091] Whole milk 500 parts

[0092] 70 parts white sugar

[0093] 6 parts cocoa powder

[0094] Stabilizer composition (κ-type carrageenan, sodium alginate and microcrystalline cellulose at a ratio of 1:5:8) 1.4 parts

[0095] Sucrose fatty acid ester 0.3 parts

[0096] Sodium stearoyl lactylate 0.2 parts

[0097] Monoglyceride fatty acid ester 0.3 parts

[0098] Sodium tripolyphosphate 0.06 parts

[0099] Sodium hexametaphosphate 0.02 parts

[0100] Sodium pyrophosphate 0.02 parts

[0101] Sodium citrate 0.3 parts

[0102] Essence 0.8 parts

[0103] Purified water is added to 1000 parts of the total ingredients.

[0104] The performance indicators of the raw materials used meet the requirements of relevant quality standards.

[0105] The preparation method is basically the same as in Example 1. The cocoa beverage product of this embodiment has a product viscosity of about 2.95 centipoise and a pH value of about 6.89.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com