Air extrusion type interlayer beer fresh-keeping barrel

A technology for beer preservation and beer barrels, applied in liquid distribution, special distribution devices, packaging, etc., to achieve the effect of solving hidden safety hazards, high compatibility, and maintaining the original taste of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

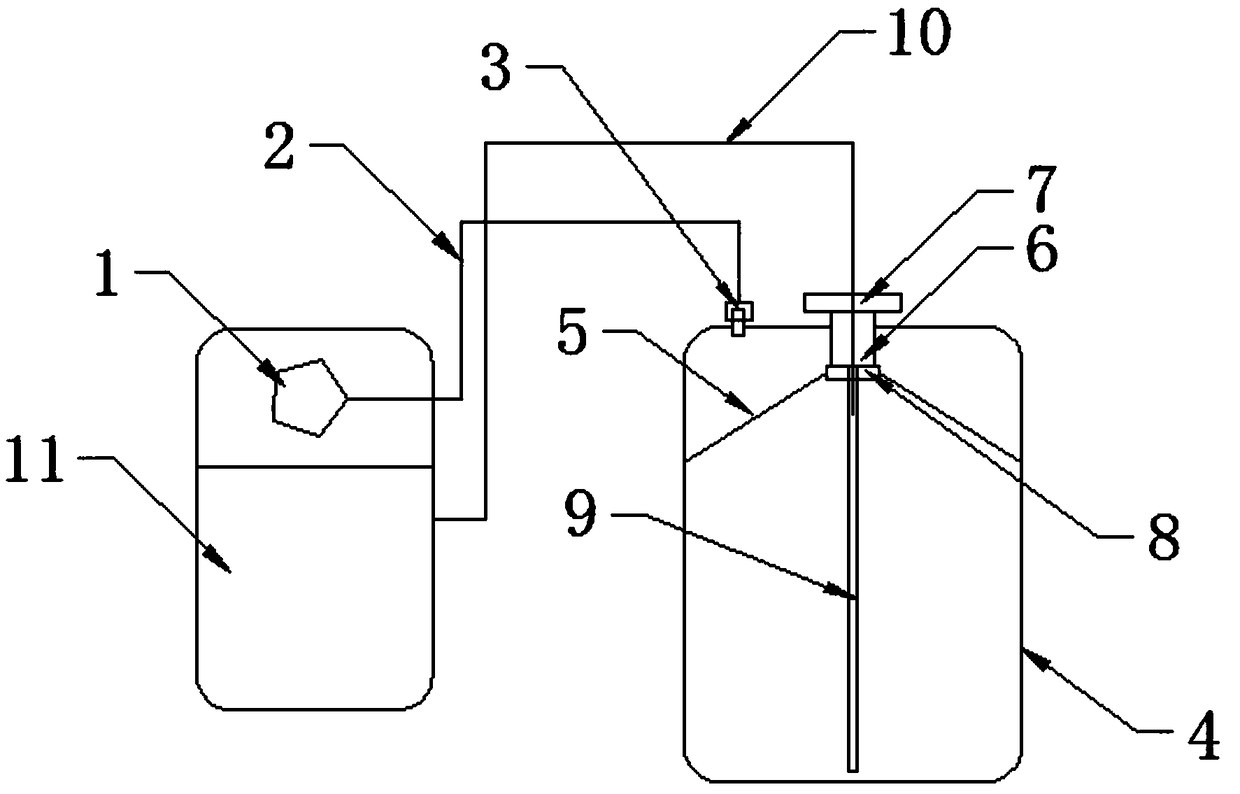

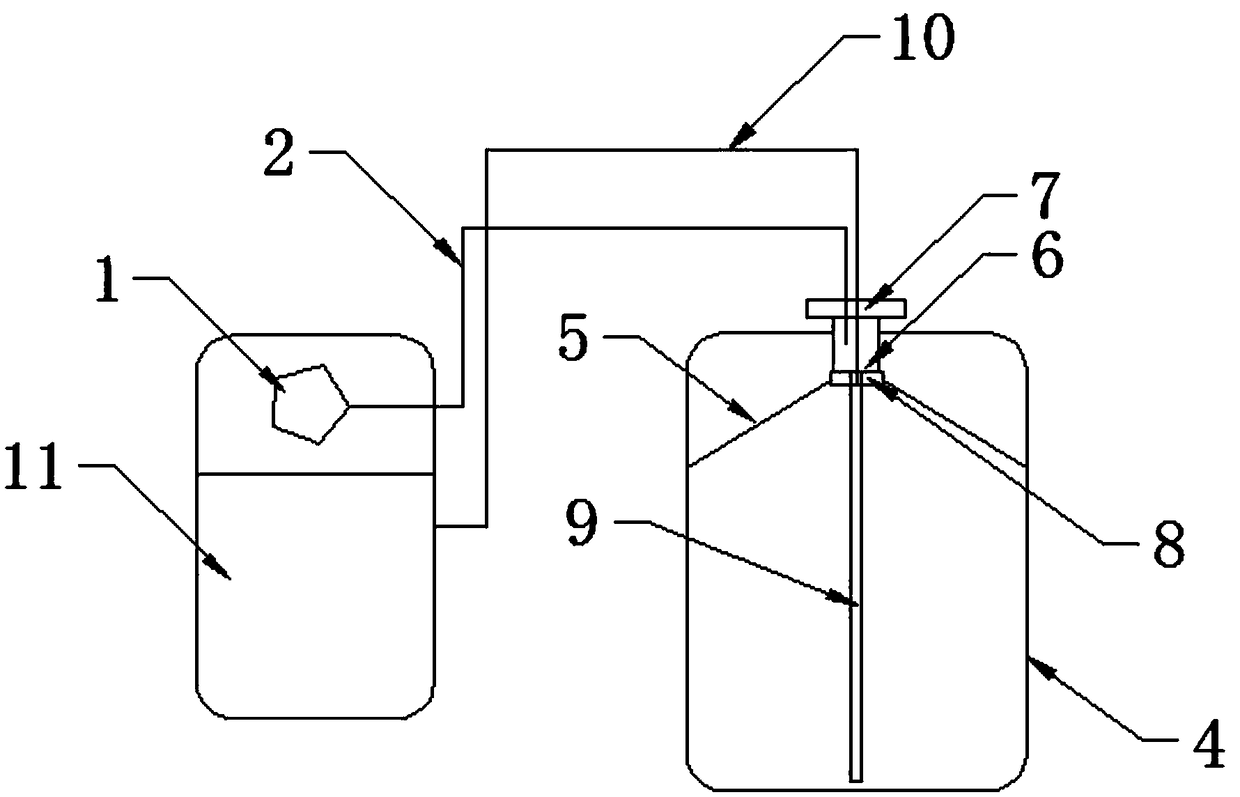

[0029] Embodiment 1: as Figure 1-2 As shown, the beer fresh-keeping barrel is a wine gas separation type; wherein the air pump hose 2 is connected to the beer barrel shell 4 through the air intake valve 3, and the air intake valve 3 is fixed on the beer barrel shell 4; firstly, the beer barrel flexible liner 5, the beer barrel The wine pipes 9 of the wine 6 are respectively assembled and connected by the inner tank connecting parts 8, thereby forming a closed container, the inside is filled with beer and the contact between the beer and the outside air is cut off.

[0030] The air pump 1 pressurizes and adjusts the air between 0.2-0.3Mpa. First, the air is pressurized by the air pump 1. The pressurized range can be adjusted between 0.2-0.3Mpa according to the usage conditions, and then through the air pump hose 2 Send the compressed air to the intake valve 3, and press it between the beer keg shell 4 and the beer keg flexible inner tank 5, squeeze the beer keg flexible inner ...

Embodiment 2

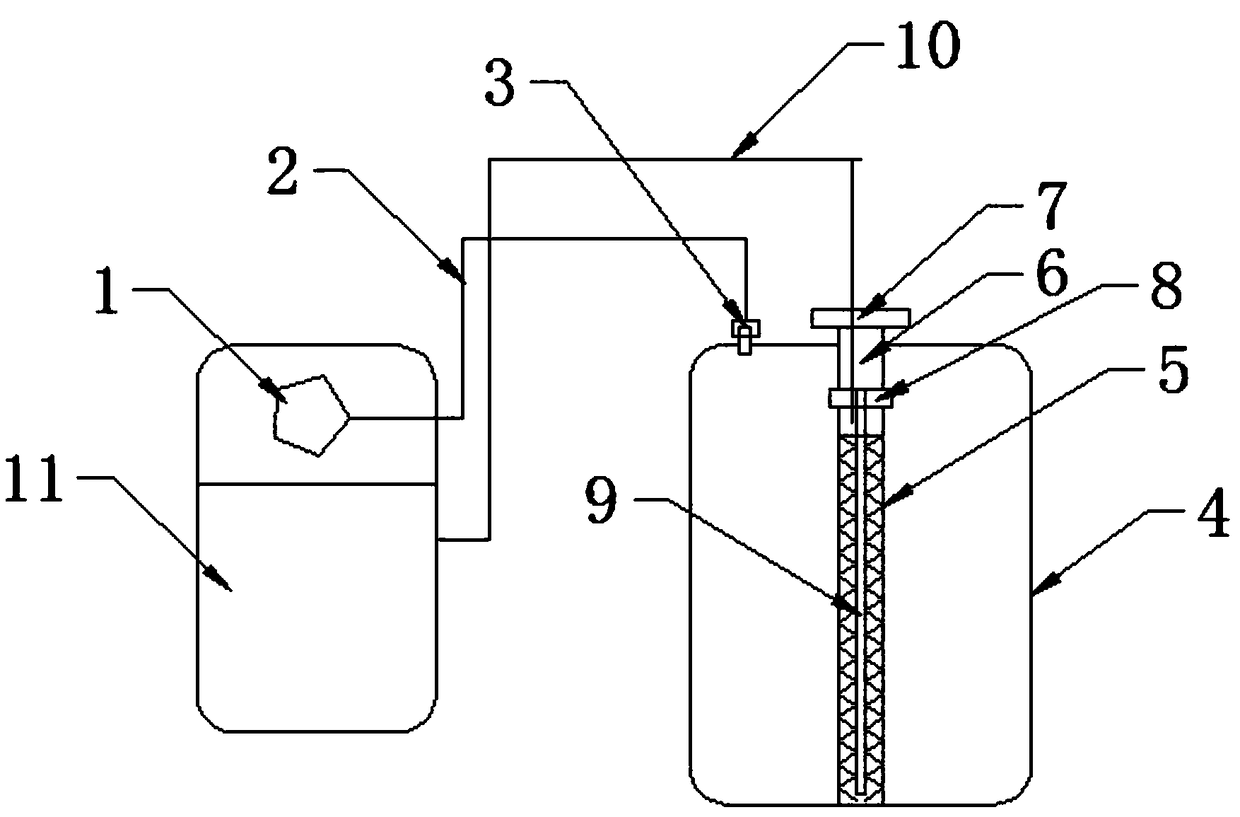

[0032] Embodiment 2: as Figure 3-4 As shown, the beer fresh-keeping bucket is an integrated type of wine gas;

[0033] First, the flexible liner 5 of the beer keg and the liquor introduction pipe 9 of the winegrass 6 are assembled and connected through the inner vessel connecting parts 8 respectively, thereby forming a closed container, filling the inside with beer and isolating the contact between the beer and the outside air; The air is pressurized, and the pressurized range can be adjusted between 0.2-0.3Mpa according to the use conditions. The compressed air is sent to the air pipe interface on the distributor 7 through the air pump hose 2 (the existing market standard product can be used), and the compressed air is compressed. Insert between the beer keg shell 4 and the beer keg flexible liner 5, squeeze the beer keg flexible liner 5, squeeze the beer out of the beer keg through the keg leading tube 9, and squeeze the beer through the keg 6 And the wine pipe interface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com