Patents

Literature

266results about How to "Guaranteed to be straight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

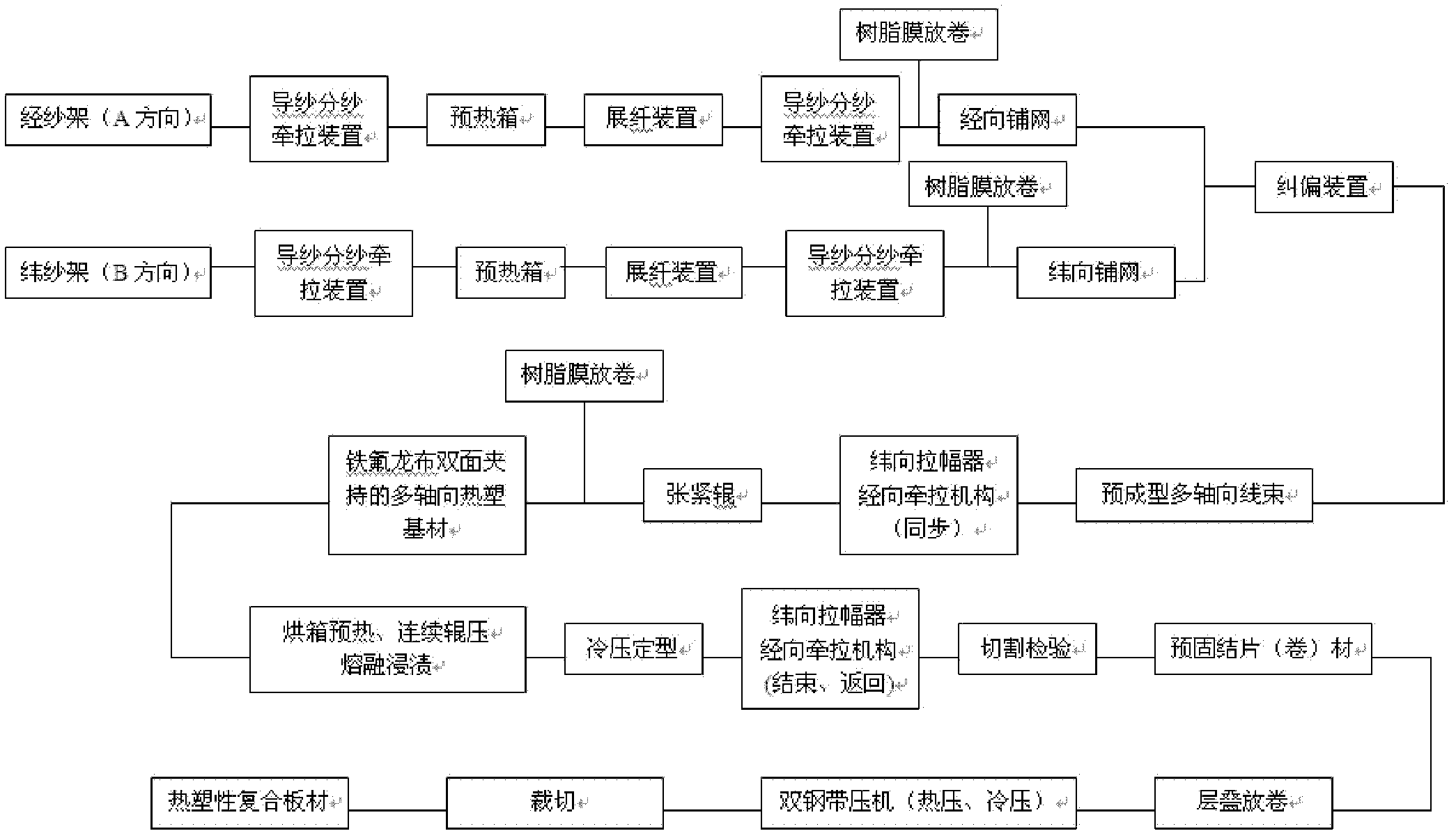

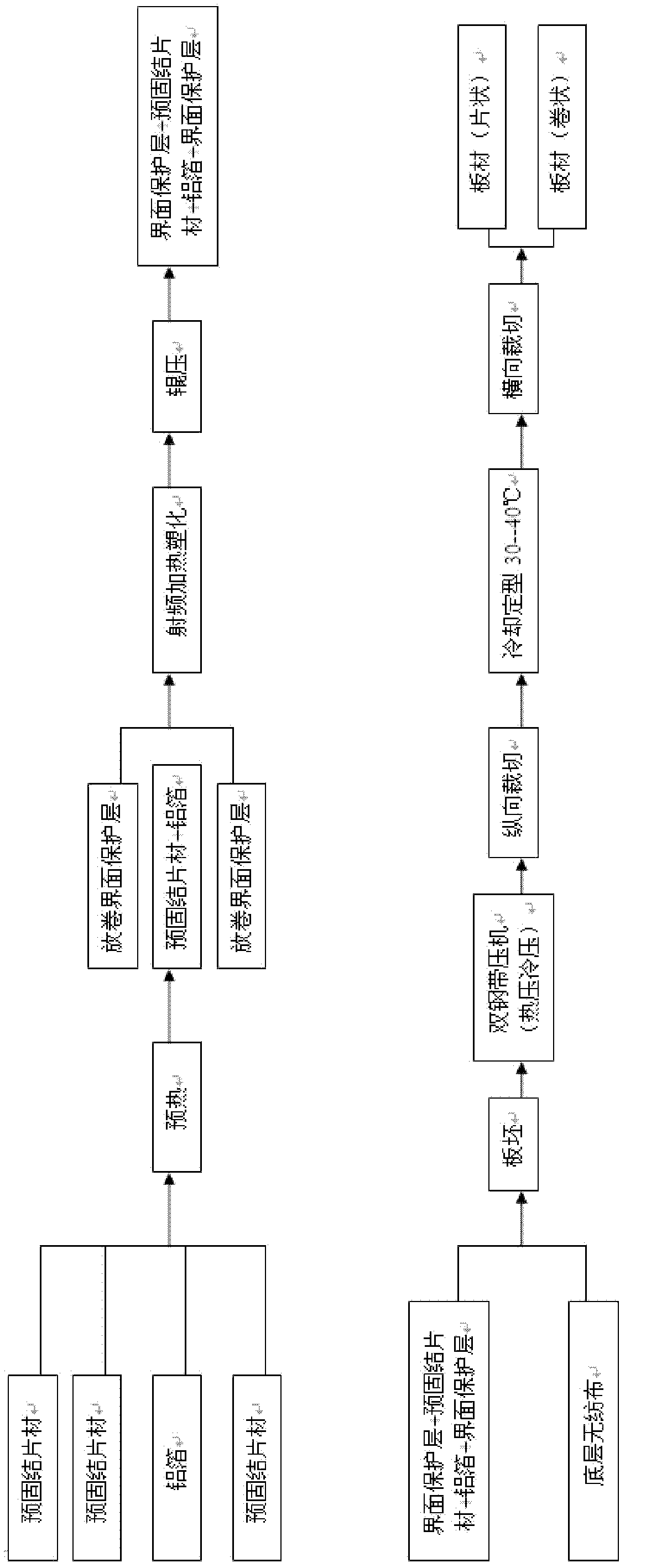

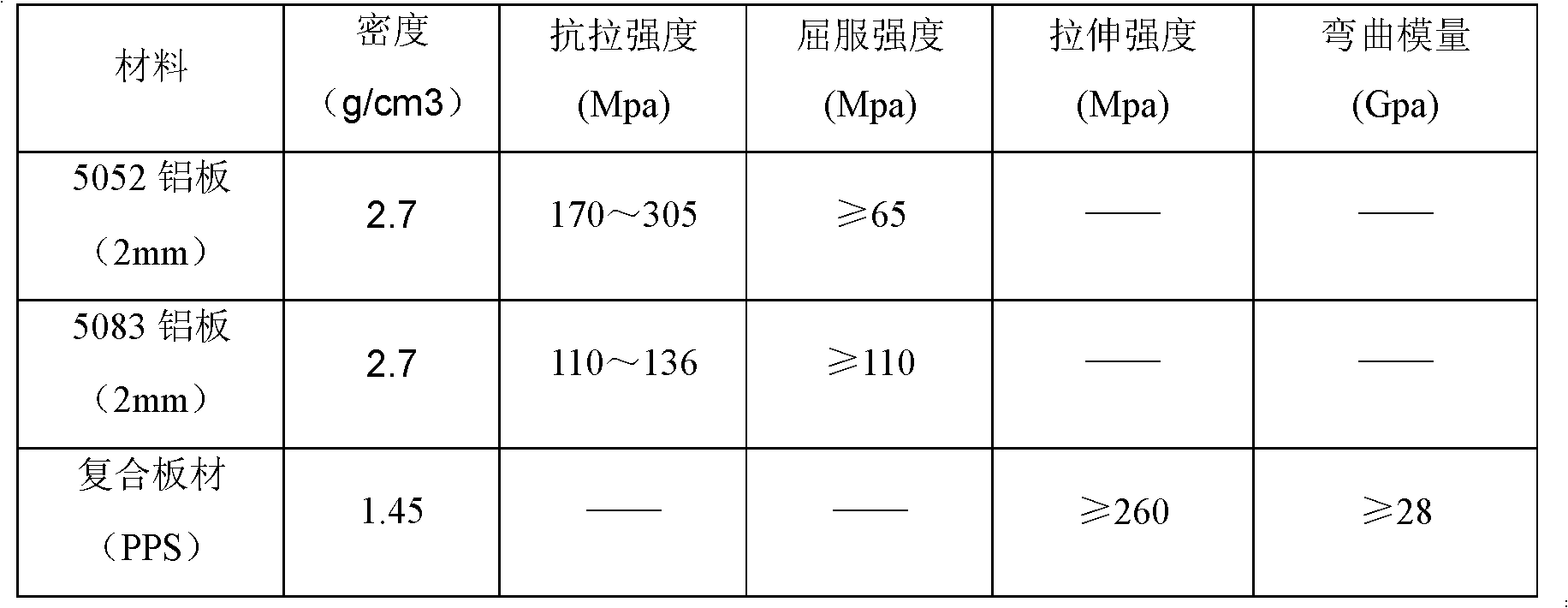

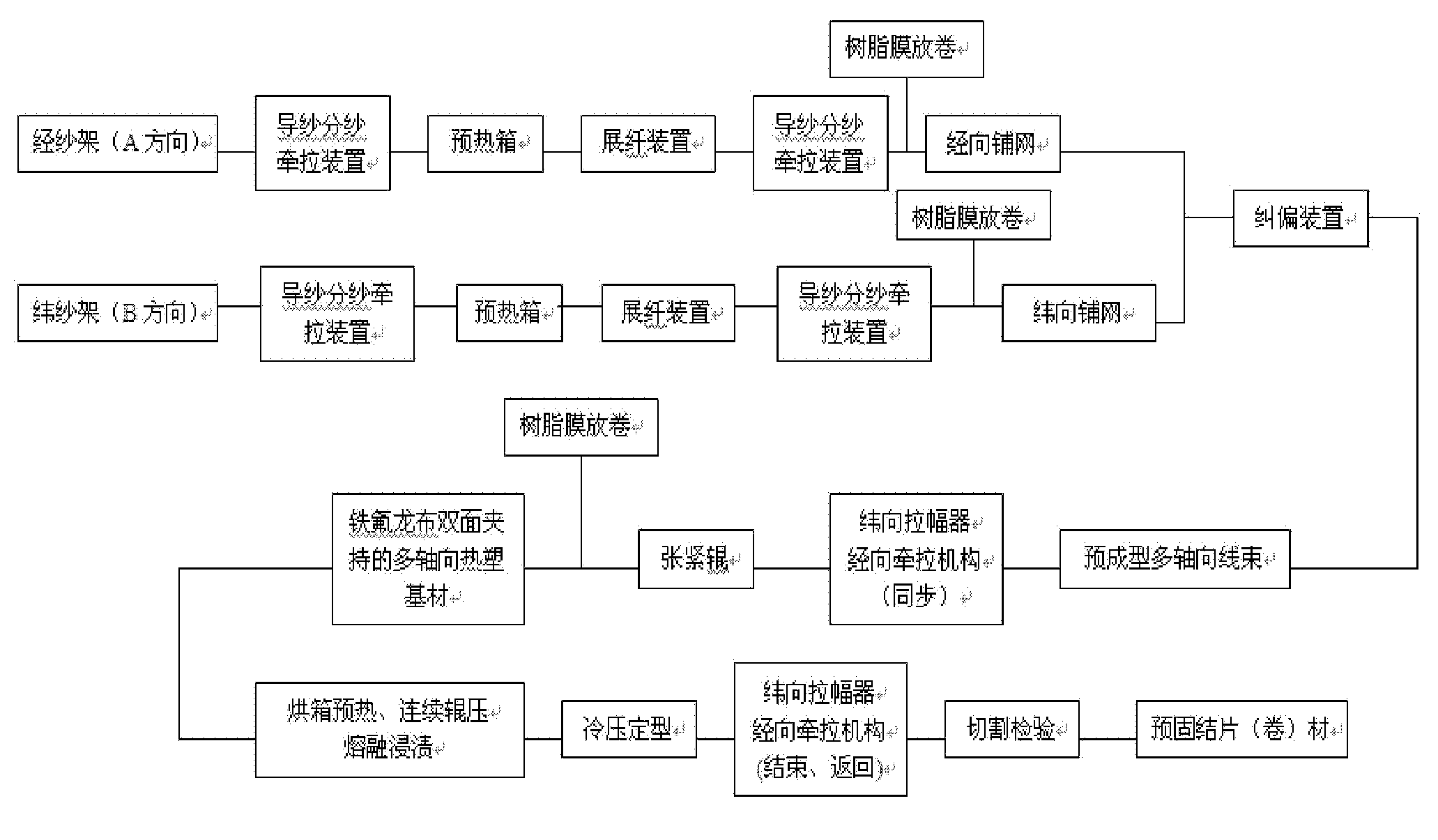

Method for preparing continuous fiber multiaxial fabric reinforced thermoplastic composite material

InactiveCN102218828AGuaranteed to be straightAvoid breakingSynthetic resin layered productsLaminationAviationHoneycomb

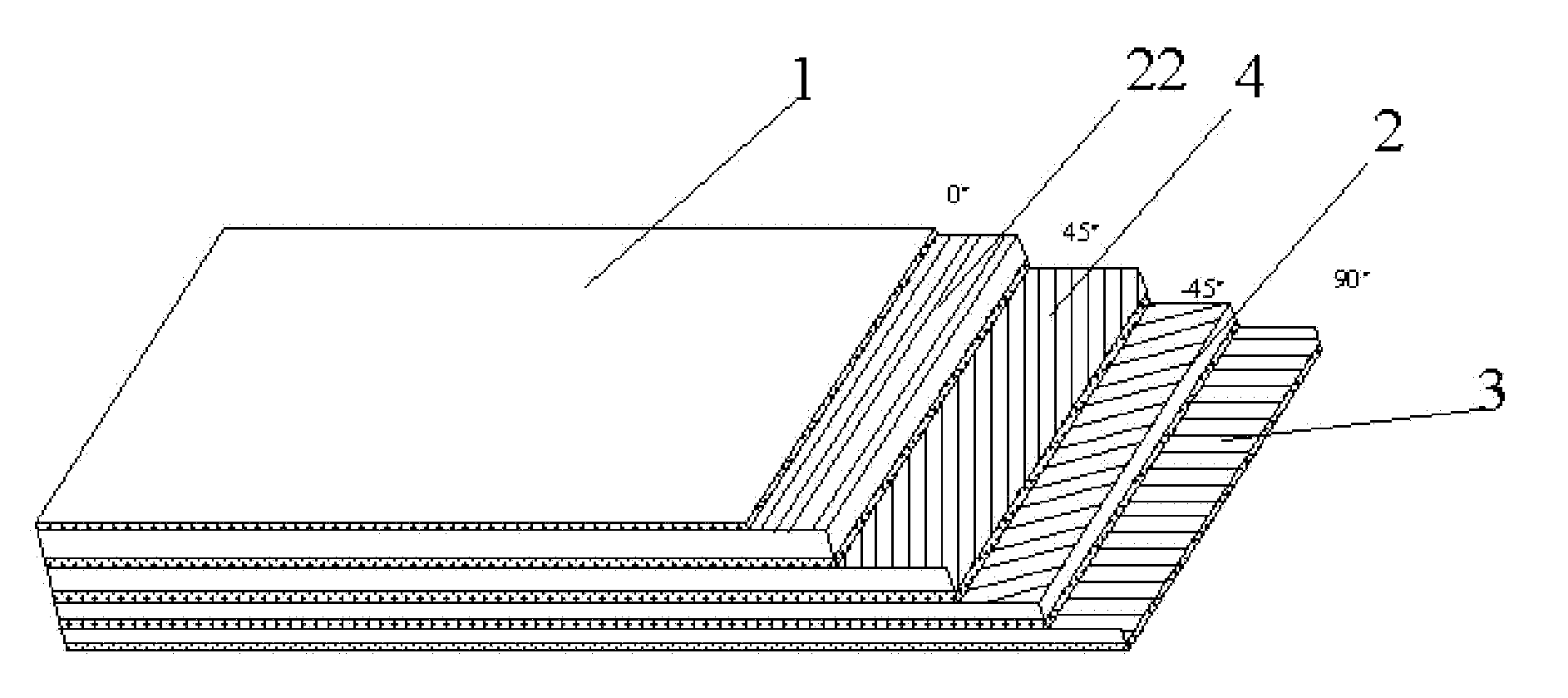

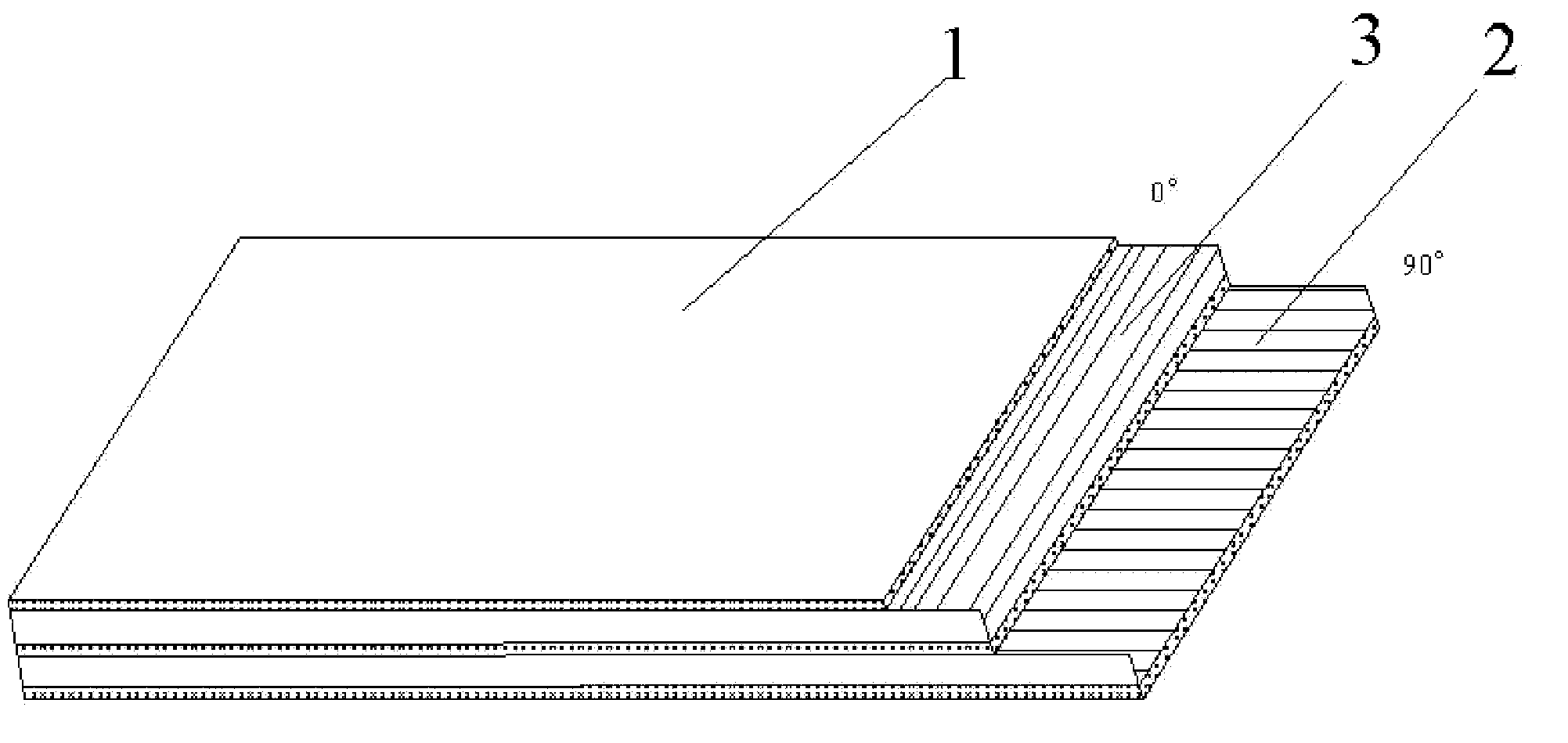

The invention discloses a method for preparing a continuous fiber multiaxial fabric reinforced thermoplastic composite material. The prepared continuous fiber multiaxial reinforced thermoplastic preconsolidating material is taken as a base material of the composite board, and combined with other functional materials for forming a novel material system which can be used for producing multiaxial fabric reinforced thermoplastic composite materials for different industries and solving the technical bottleneck that different materials have different composite bonding difficulties. According to the invention, the prepared composite material is constructed by continuous fiber multiaxial direaction; materials have the characteristics of resilience and uniform stressing on different directions. In addition, light sandwich panel formed by a honeycomb core material provides higher impact strength of materials, which is suitable for preparing structural parts and interior decorative parts in the field of railway car containers of navigation and aviation. The product of light-weight flame retardant can be recovered and used, and is more suitable for industrialization scale production of the warp knitting industry organization.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

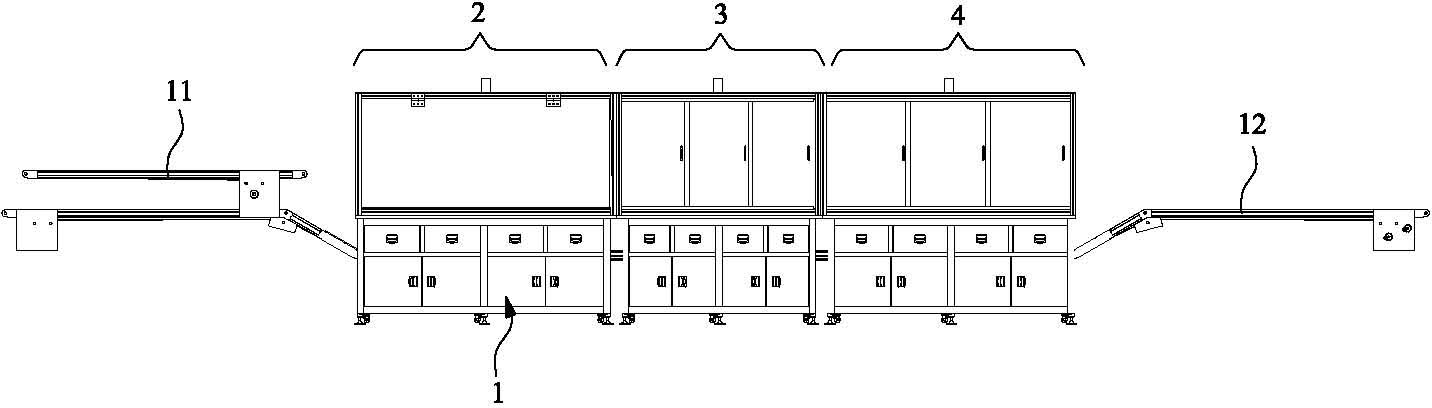

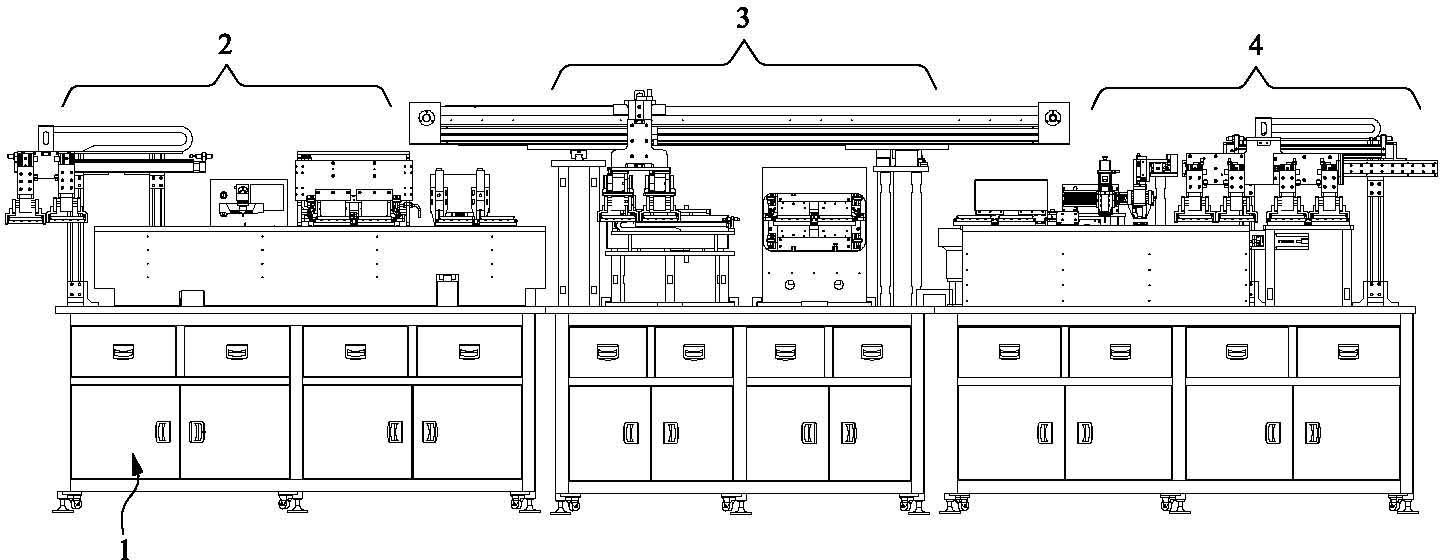

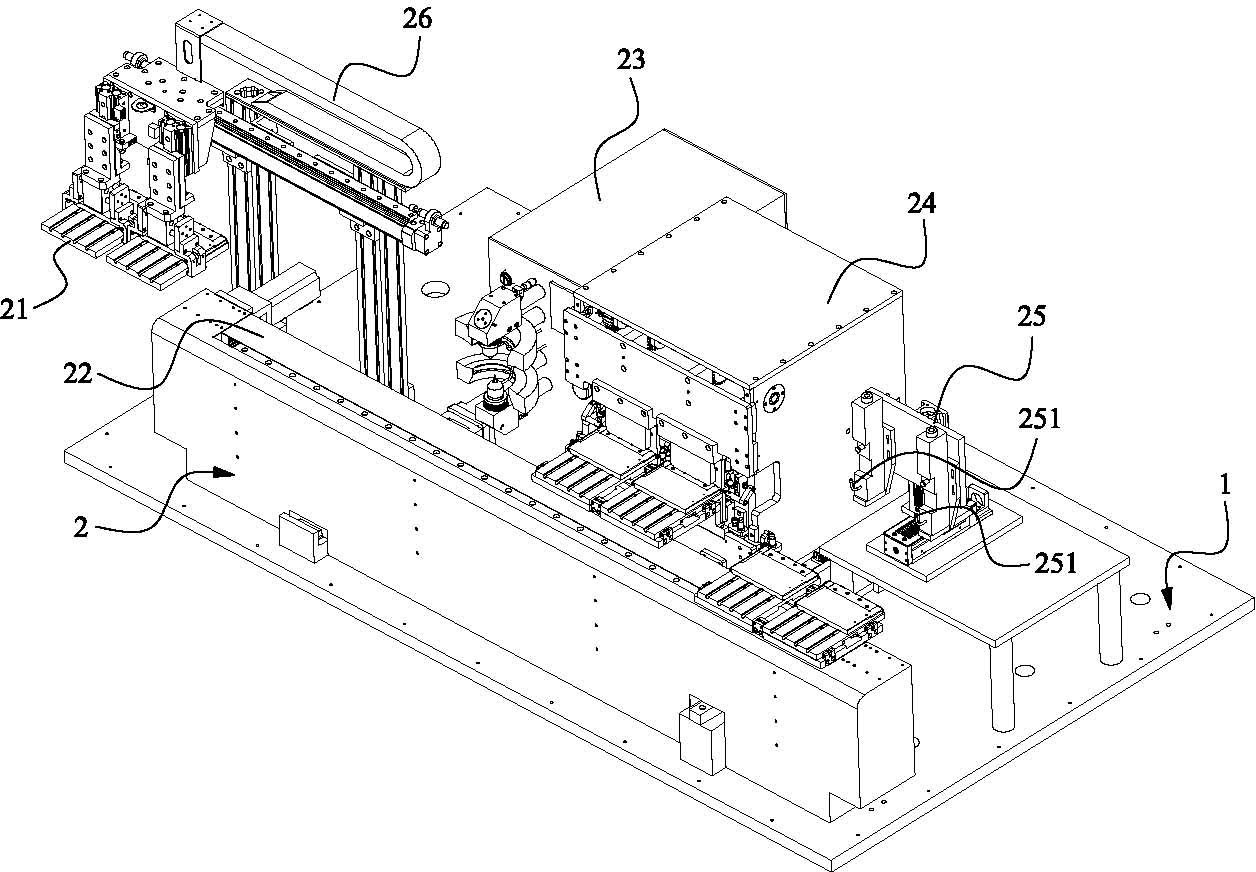

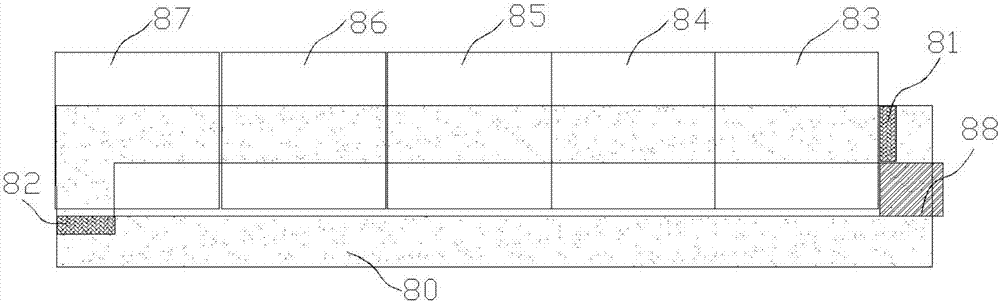

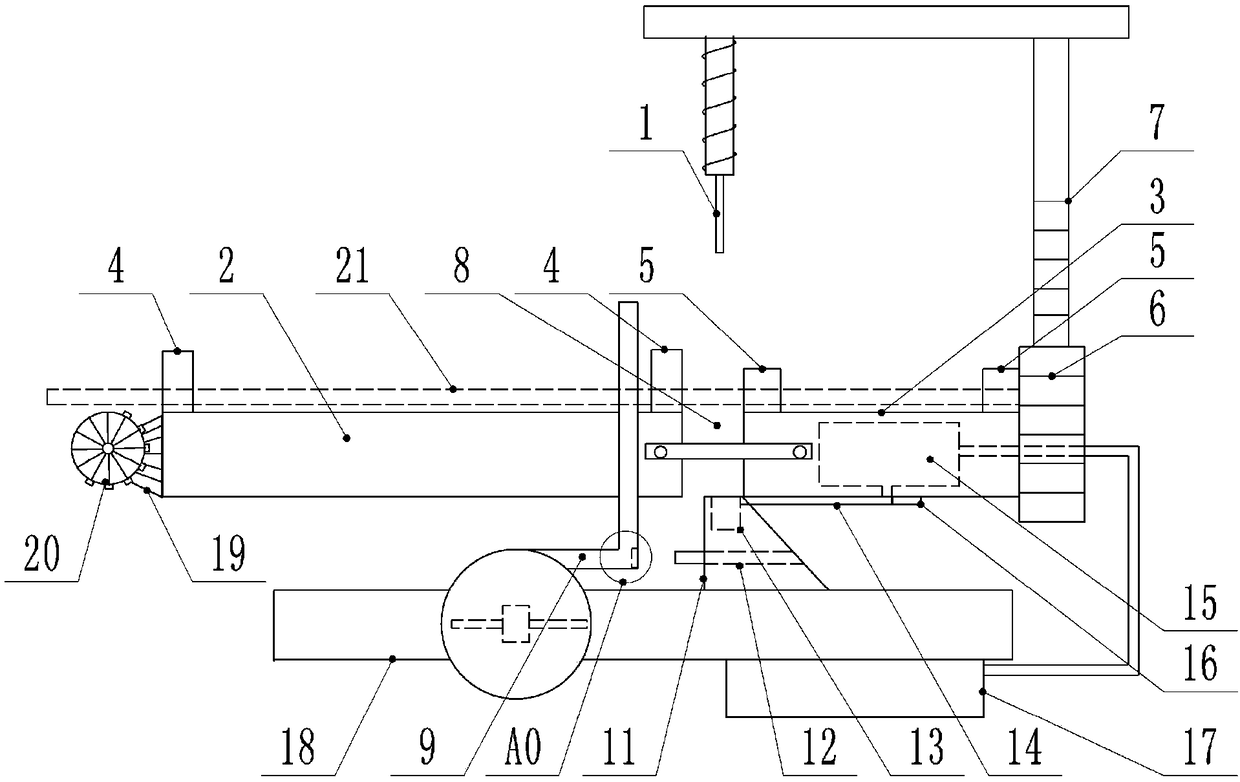

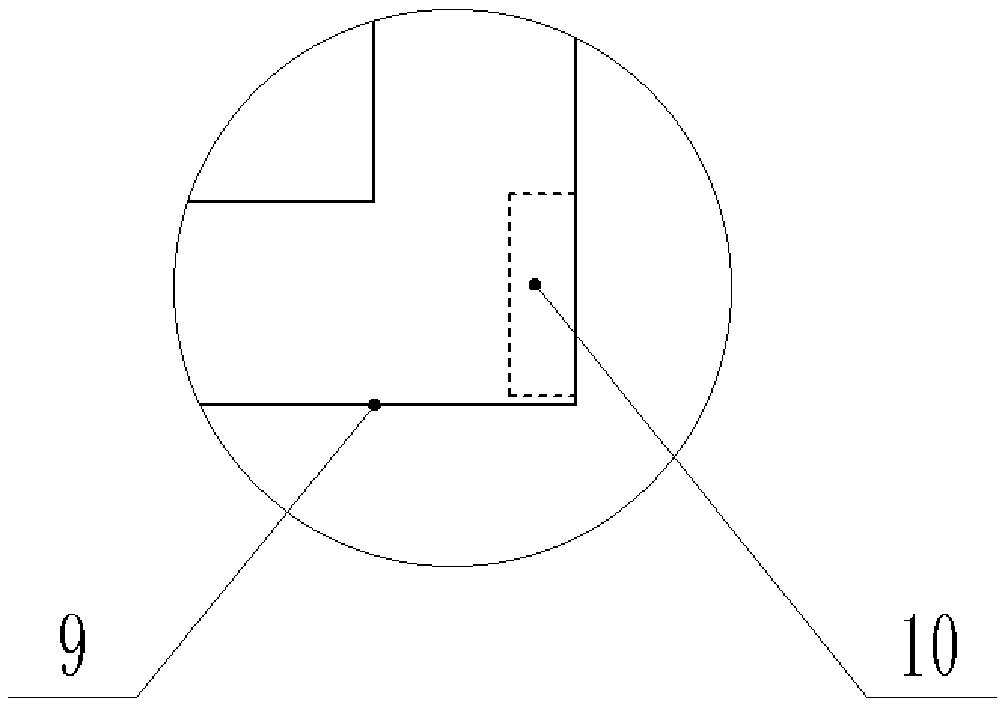

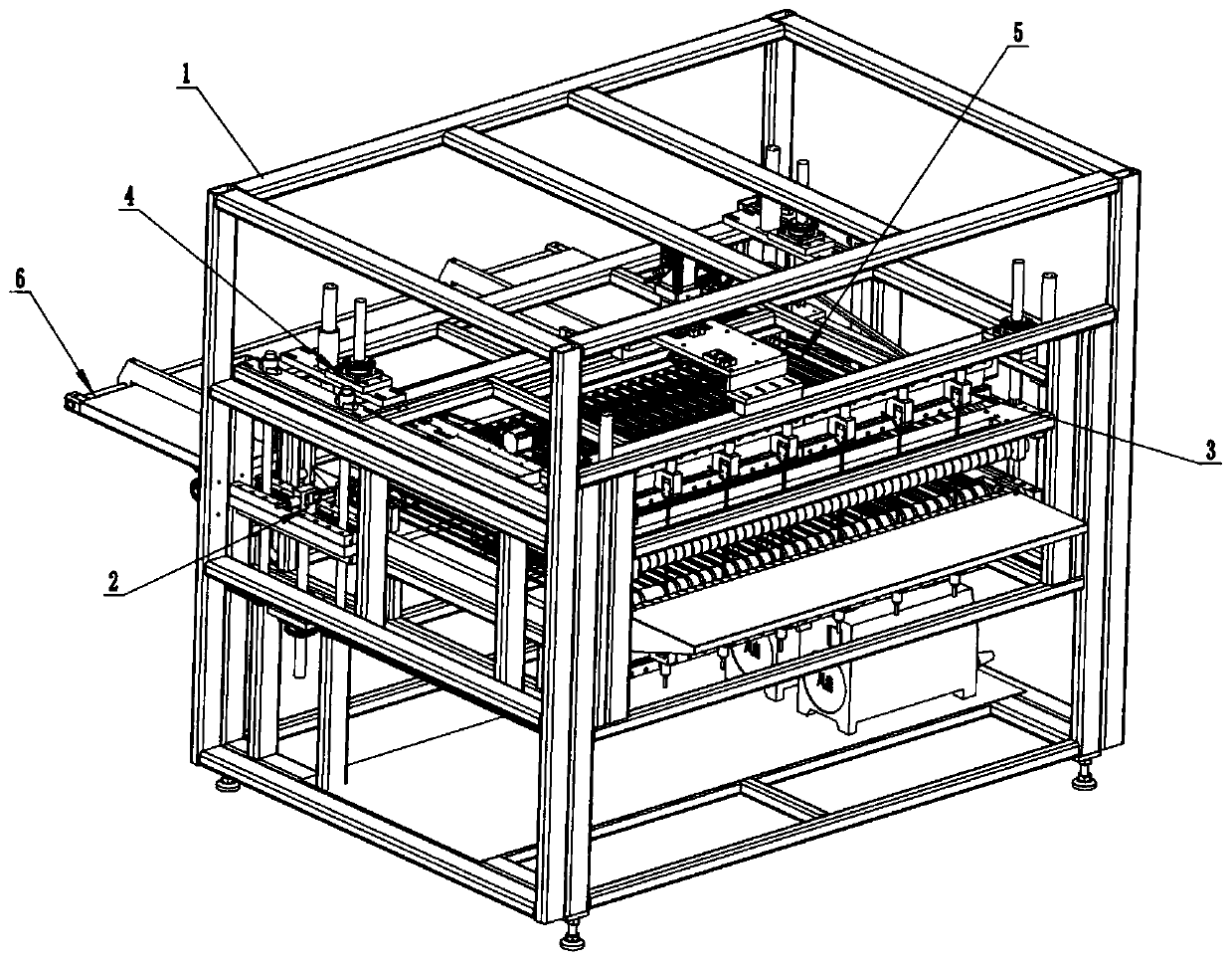

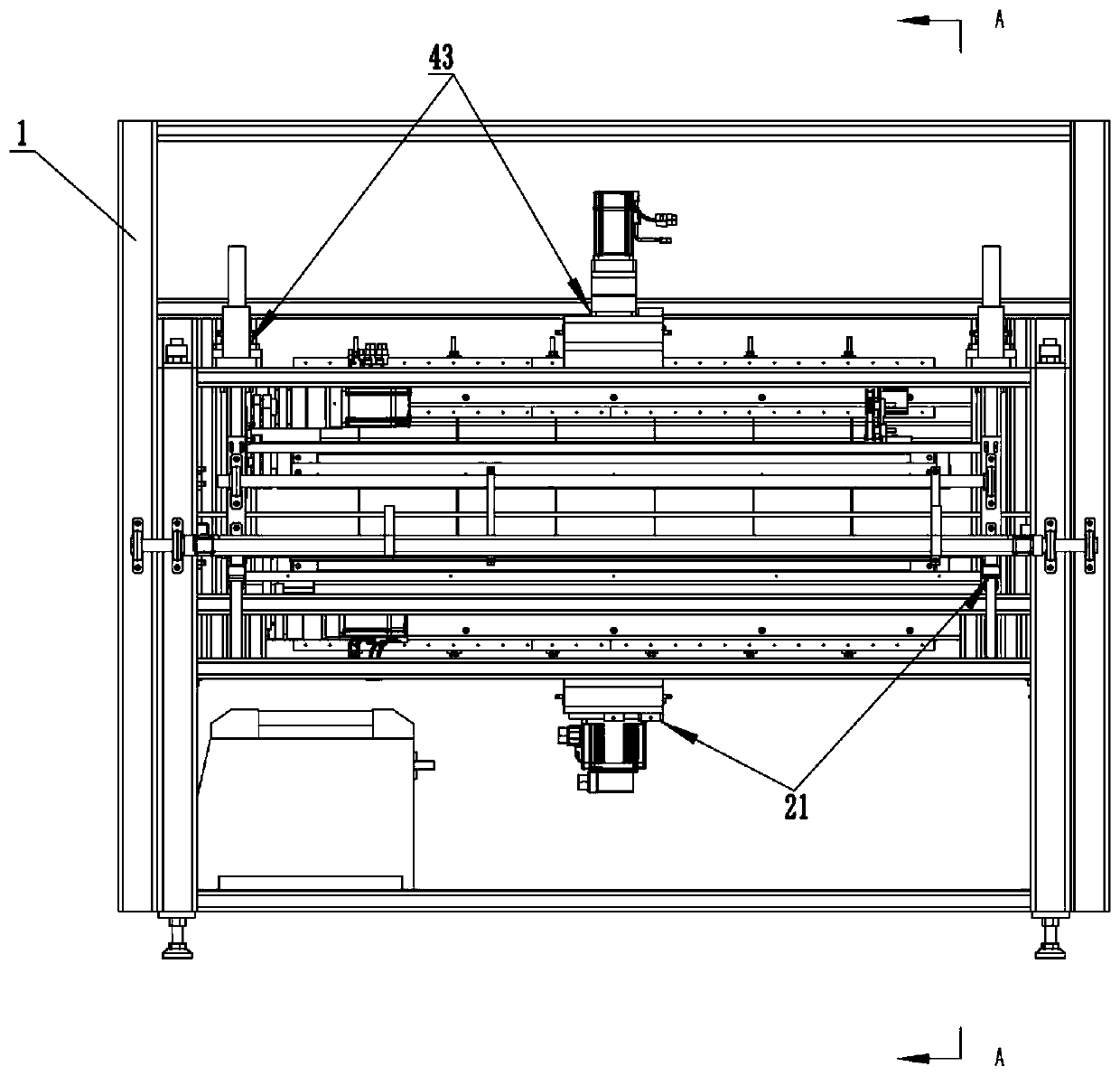

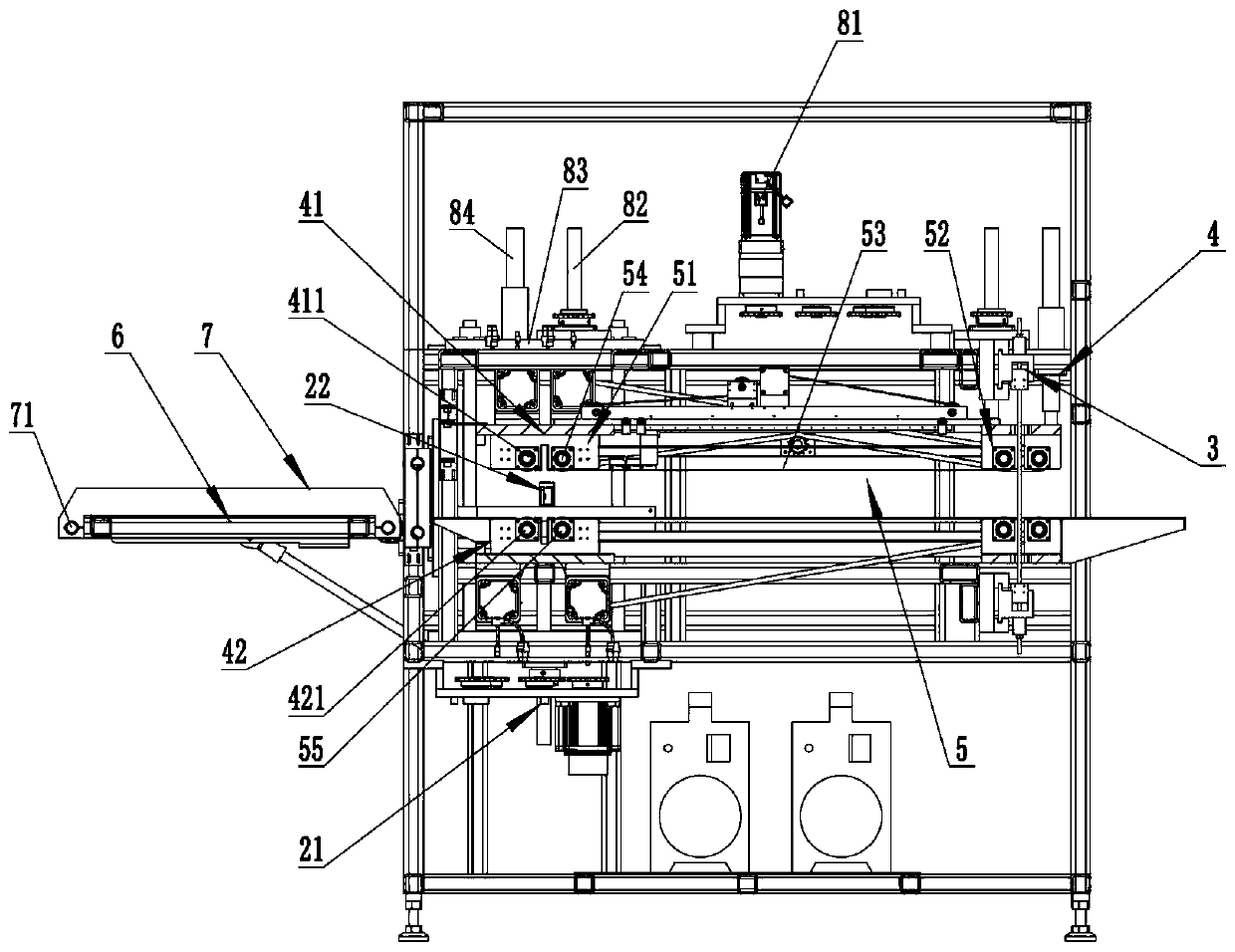

Automatic cable and connector processing, welding and assembling machine

InactiveCN102637988AEliminate weldsEliminate quality problemsLine/current collector detailsEconomic benefitsEngineering

The invention discloses an automatic cable and connector processing, welding and assembling machine, comprising a rack as well as a laser peeling module, an adhered tin trimming module and a plug welding module sequentially arranged on the rack, wherein the laser peeling module comprises a jig, a first transmission device, a laser device, a peeling device and a flux spraying device; the adhered tin trimming module comprises a clamping-jaw feeding device, a tin pot and a trimming device; and the plug welding module comprises a soldering device, a plugging device, a welding device and a clamping-jaw laying-off device. Therefore, the automatic machining on a cable is finished by virtue of the laser peeling module and the adhered tin trimming module, the laser peeling module, the adhered tin trimming module and the plug welding module are matched to weld and connect a connector and the cable together, and a core wire of the cable is kept to be straight in processes of processing and welding the core wire, so that the quality problems of insufficient soldering, leaving out of welding, short circuit and the like during the connection between the cable and the connector are eliminated, and the unmanned automatic processing, welding and assembling procedures are realized to effectively improve the production efficiency of products and to bring more economic benefits to enterprises.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

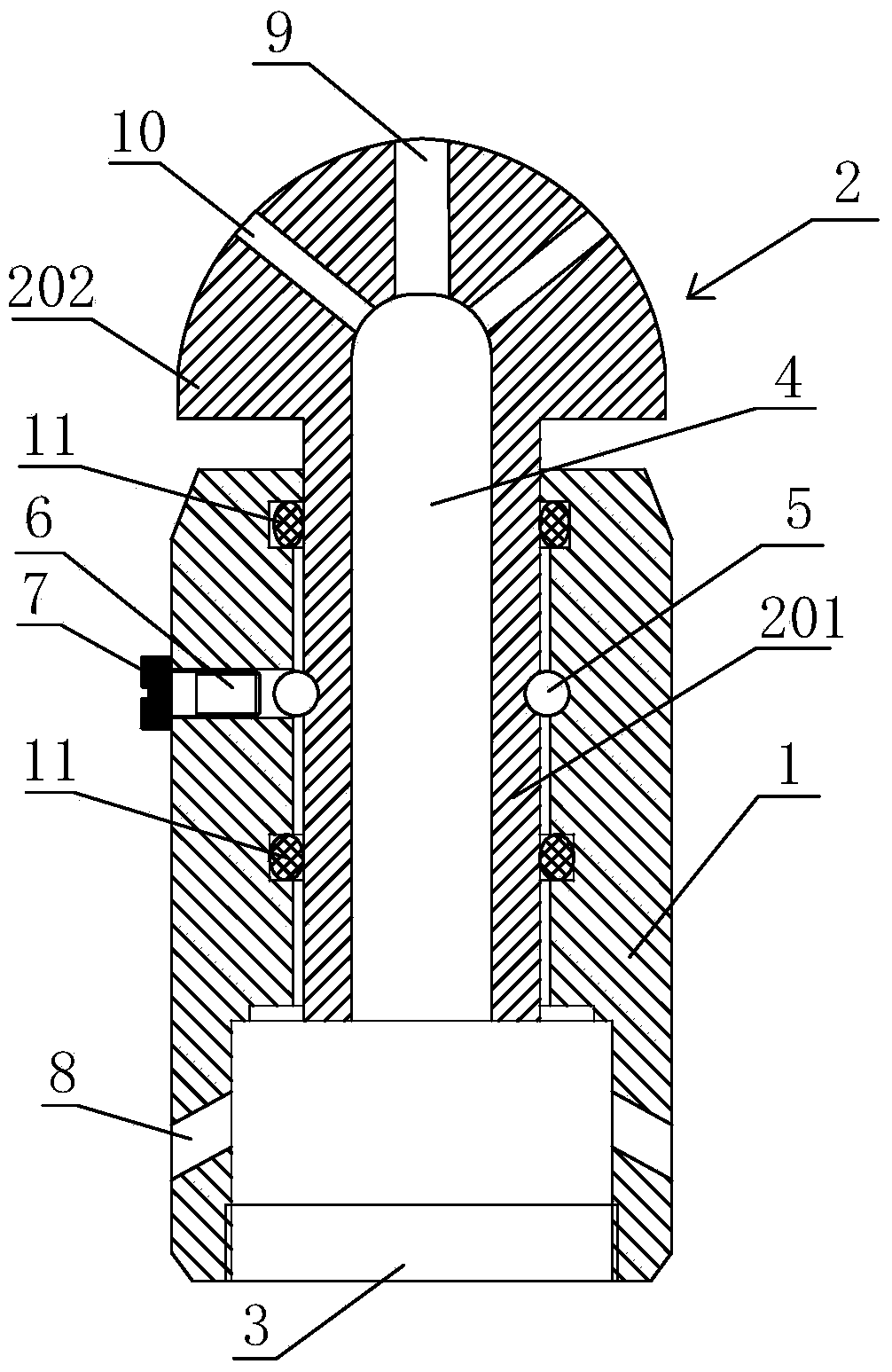

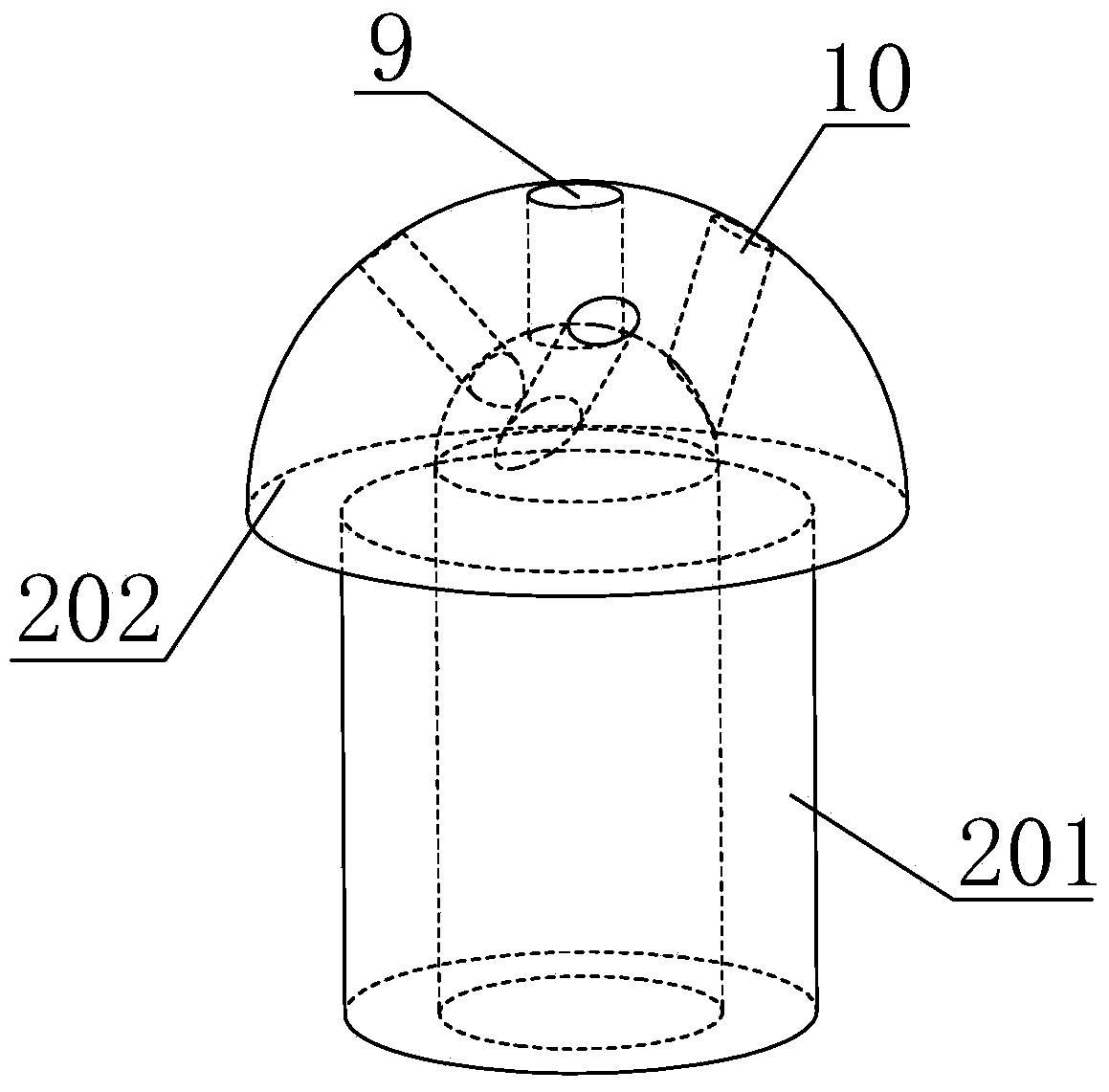

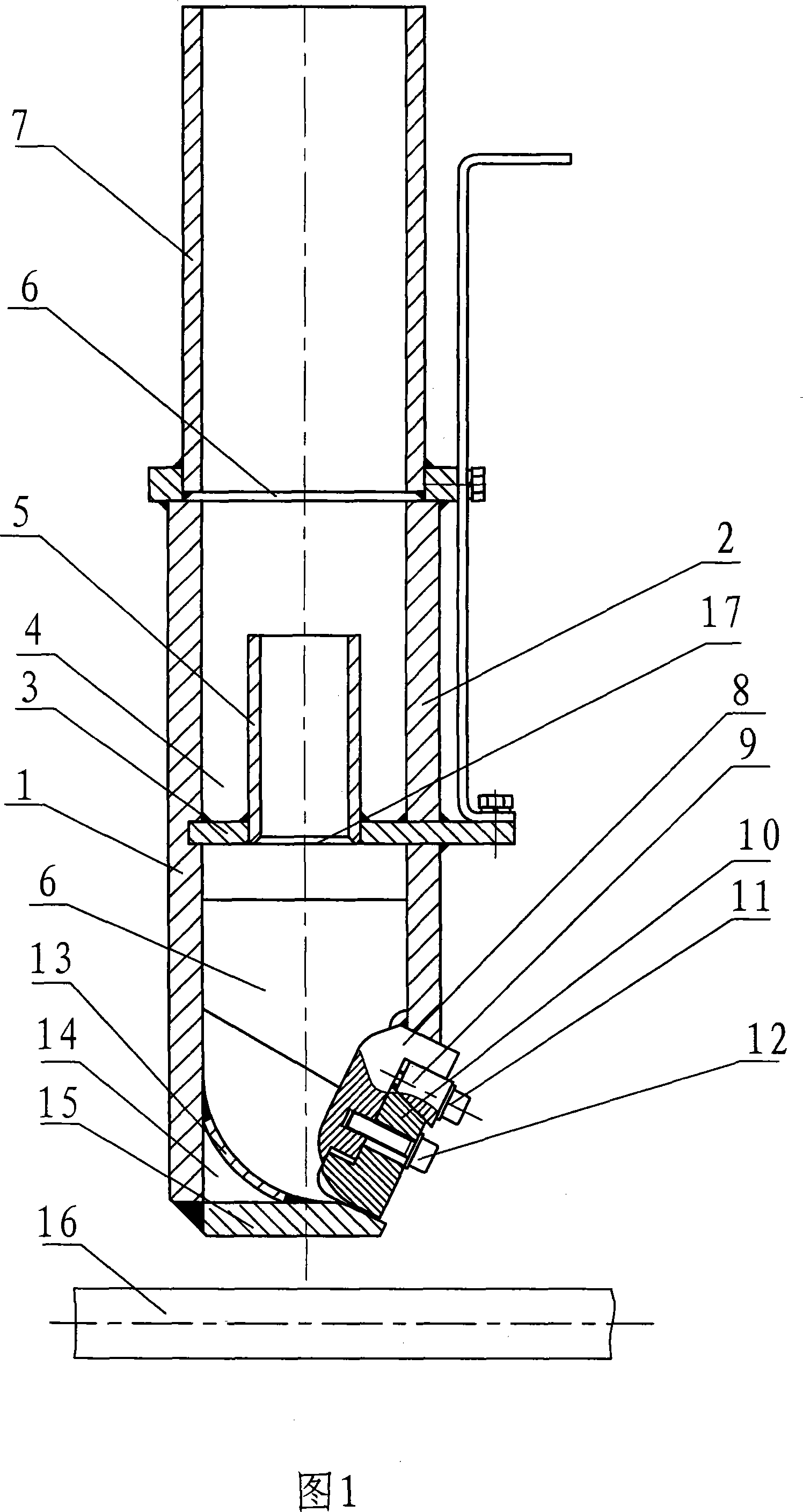

Radial sidetrack drilling rotating self-propelled porous jet flow drill bit

The invention relates to a radial sidetrack drilling rotating self-propelled porous jet flow drill bit, which mainly comprises a casing, a rotating drill bit body, a gear type slide ring type combined seal, an opening sealing screw, steel balls and the like, wherein a water inlet is processed at the tail end of the casing; a backward spray nozzle is processed on the casing; a forward spray nozzle and a center spray nozzle are processed on the rotating drill bit body; semicircular grooves are respectively processed in the casing and the rotating drill bit body; the steel balls are placed in the grooves formed between the casing and the rotating drill bit body; the rotating drill bit body is positioned through the steel balls and can rotate around the self axial line; the gear type slide ring type combined seal is adopted between the rotating drill bit body and the casing; through holes are formed at the lateral side of the casing; the steel balls are placed into the grooves through the through holes; and after the steel balls are placed into the grooves, the through holes are sealed through the opening sealing screws. The radial sidetrack drilling rotating self-propelled porous jet flow drill bit can effectively solve the problems of poor jet flow drill bit reaming capability, poor rock breaking hole smooth roundness, bent tracks of hydraulic jet hoses and the like of the hydraulic jet radial sidetrack drilling tiny drill hole technology, and can be widely applied to the hydraulic jet radial horizontal well technology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Cooler capable of forming flat jet

InactiveCN101020196AReduce the temperatureStable work structureWork treatment devicesMetal rolling arrangementsSheet steelArchitectural engineering

The cooler capable of forming flat jet is formed through welding steel plates and features that inside the welded casing, there are vertical partition boards, flow homogenizing tubes welded between partition boards, arched plate in the lower part, etc to form the outer coolant circulating cavity, water guiding structure, and adjustable flat jet slot. The cooler is made through spot welding plus intermittent welding, annealing to eliminate stress, and straightening. The present invention has less heat deformation, low manufacture cost, high use effect and long service life.

Owner:辽宁省轧制工程技术中心

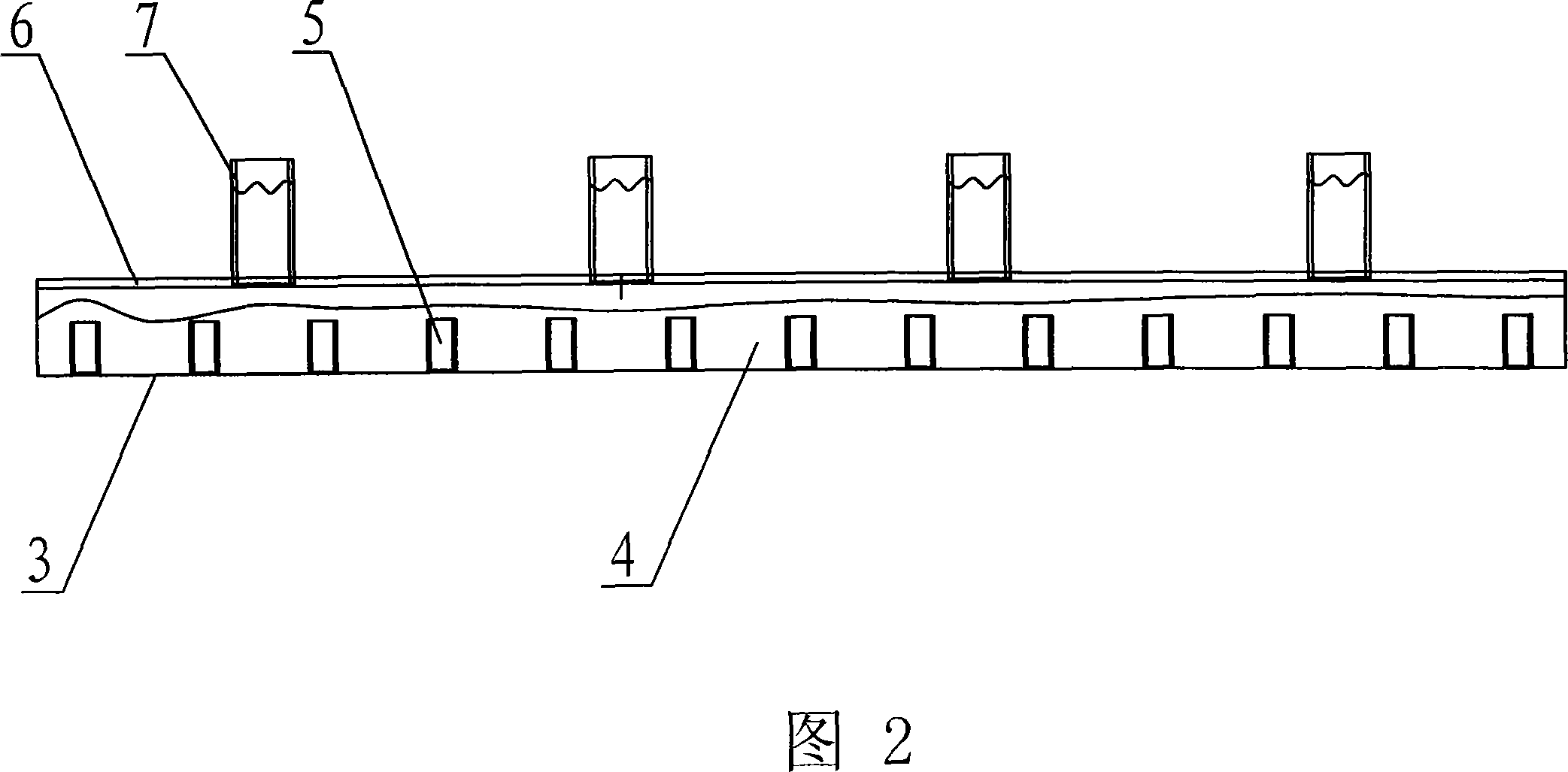

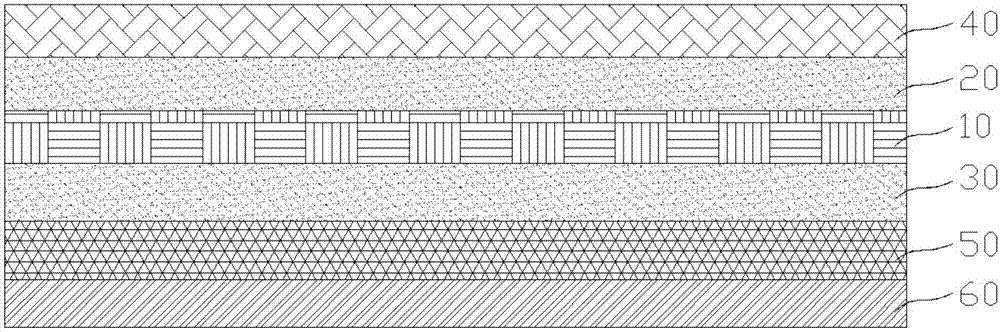

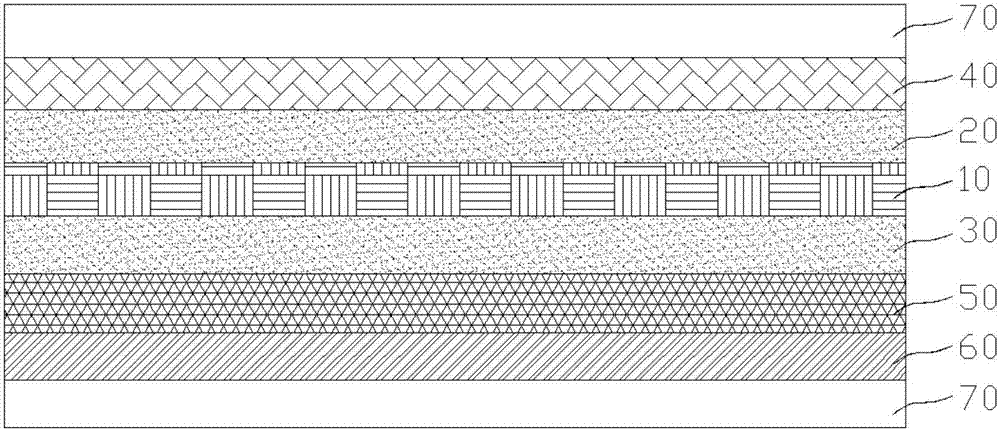

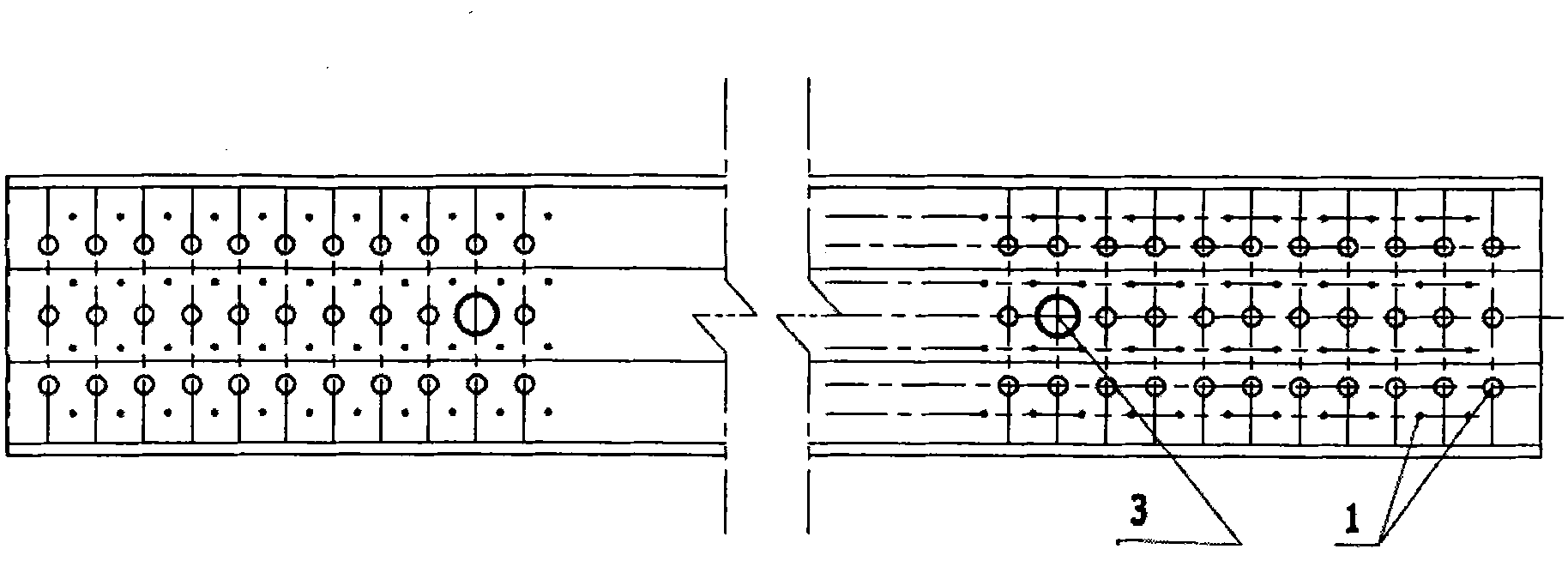

Continuous fiber multi-axial enhanced thermoplasticity preconsolidation sheet and preparation method thereof

InactiveCN102218831AGuaranteed to be straightAvoid breakingSynthetic resin layered productsLaminationPorosityEngineering

The invention discloses a preparation method of a continuous fiber multi-axial enhanced thermoplasticity preconsolidation sheet. Warp direction and weft direction yarns are respectively led out from a creel to be expanded after being preheated by a drying oven, and then the yarns are conveyed to a weaving and overlaying net system by a traction roller. Under the control of a tension system, nets are overlaid in a cross mode to prepare multi-axial wiring harness sheets. The upper layer, the lower layer and the middle layer of the fabric sheet are respectively overlaid with the modified thermoplasticity resin film to prepare preformed thermoplasticity base material. The base material is introduced into the drying oven to be plastified at high temperature, and the sheet is subjected to cold pressing and shaping after continuous roll-in melting dipping to prepare the multi-axial enhanced preconsolidation sheet. According to the warp knitting wiring harness and the tentering dipping technology disclosed by the invention, the fabric wiring harness structure is kept, the dry fiber zone in material is eliminated, the compactness of the material is improved, and the porosity of the material is lowered; the fabric fibers of different directions construct higher specific strength of the thermoplasticity composite material; and the new technology breaks through the technical bottleneck that high-performance fiber fabric is difficult to dip.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Control method of hot-rolled steel sheet water-cooling plate

InactiveCN101406902AGuaranteed to be straightSolve problemsProfile control deviceThermodynamicsEngineering

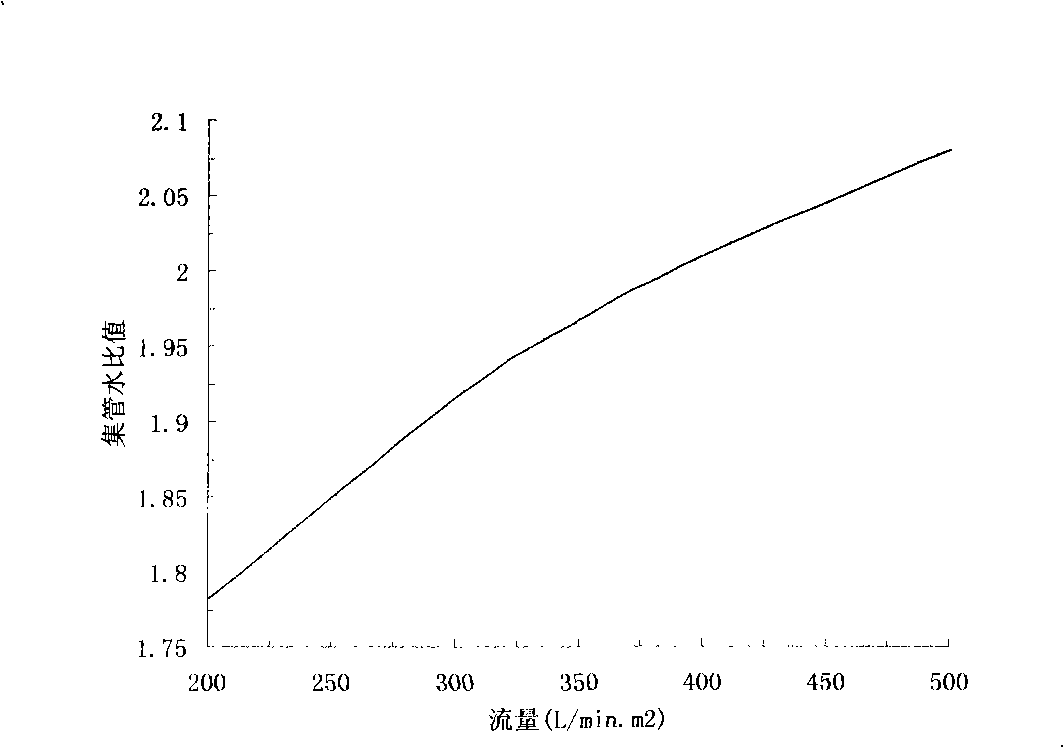

The invention relates to a water cooled shape control method for a hot rolled steel plate. The top bottom water ratio and the head tail shielding parameter design and regulation process for the steel plate are determined by the heat exchange characteristic and the volume deformation feature during accelerated cooling process of the hot rolled steel plate. The quantitative relationship between the surface heat load of the steel plate and the flow rate of headers is established; and an upper and lower header initial water ratio function changing with the flow rate and thickness specifications is established based on the quantitative relationship. A reasonable lower / upper header flow ratio R is determined according to the functional relationship: R=0.0149xh+0.33Ln(F)-0.294. Therefore, the upper and lower surfaces of the steel plate are evenly cooled down by water. The technology is suitable for the after-rolling laminar flow water cooled shape technological parameter optimization of a medium and heavy plate and hot continuous rolling band steel, and can quickly and effectively solve the problem of water-cooled bend of the steel plate.

Owner:SHOUGANG CORPORATION

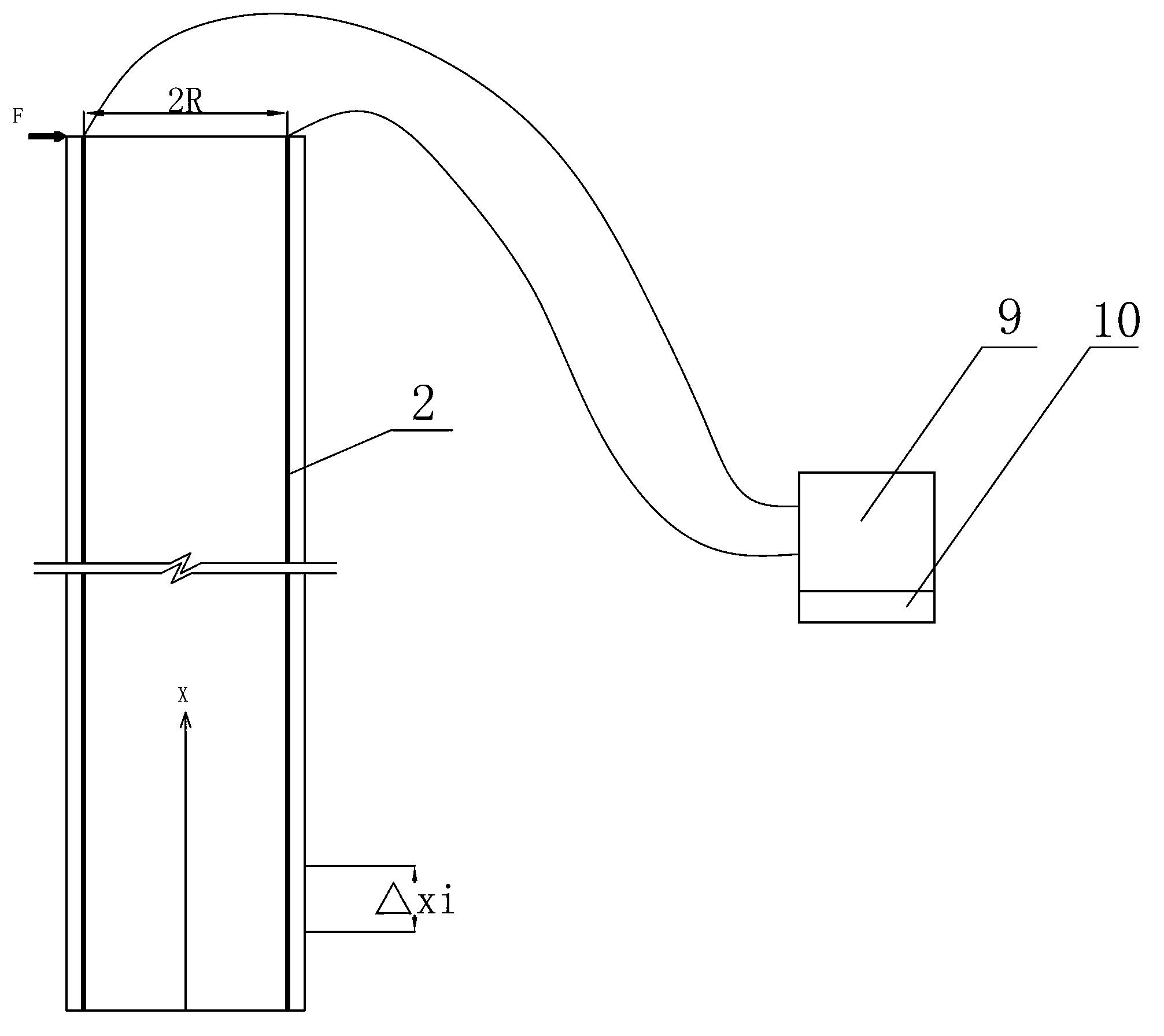

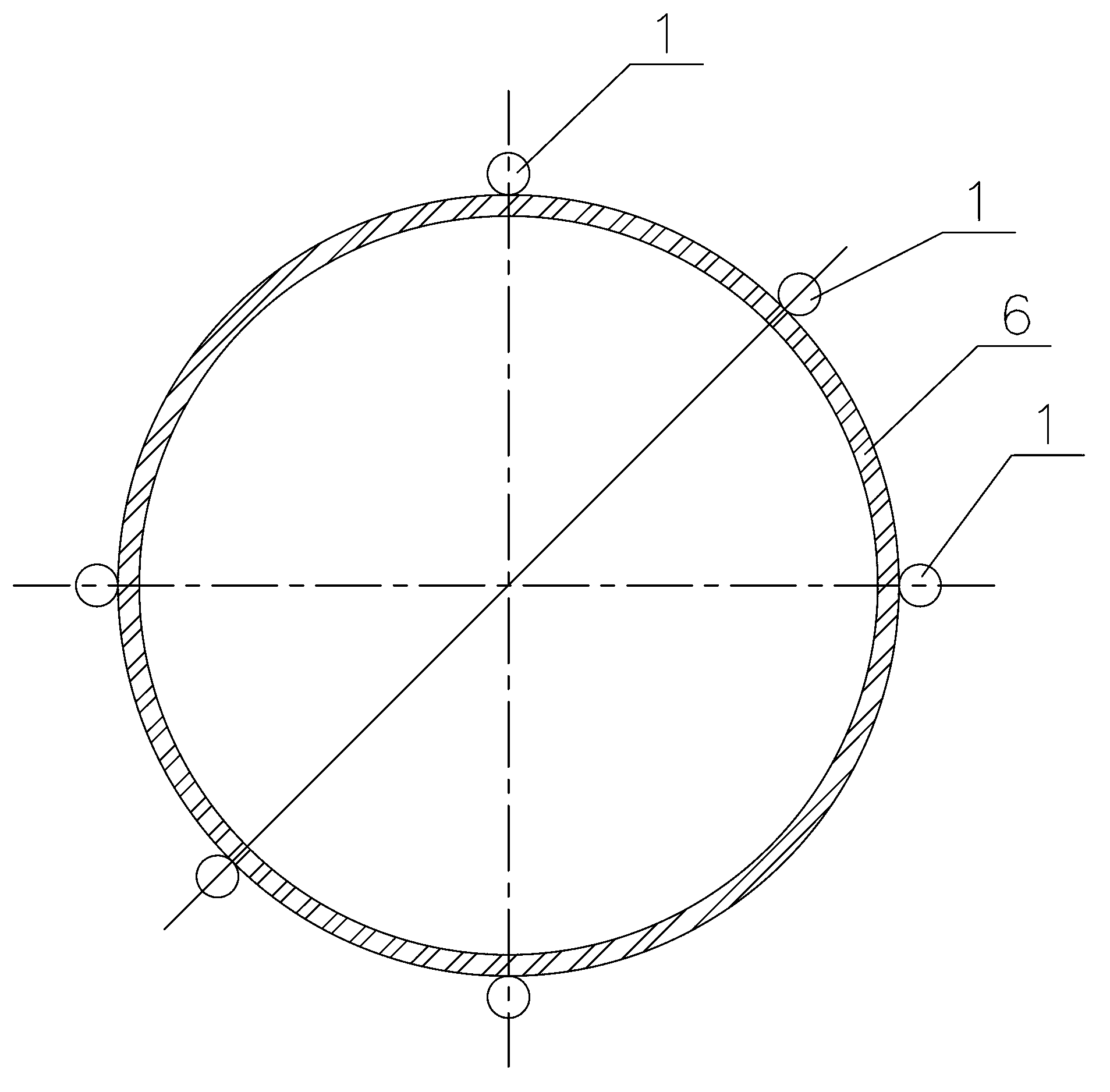

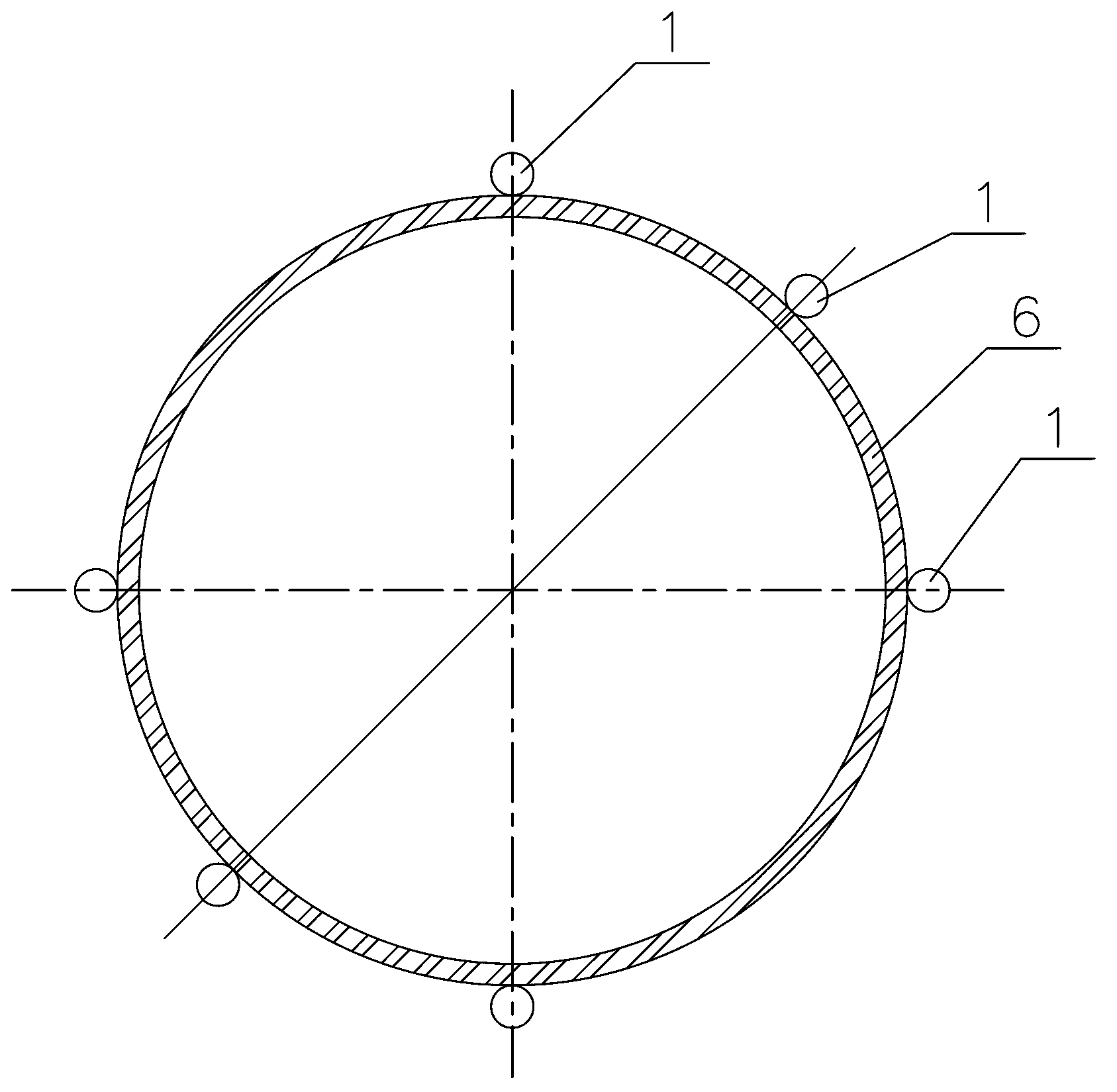

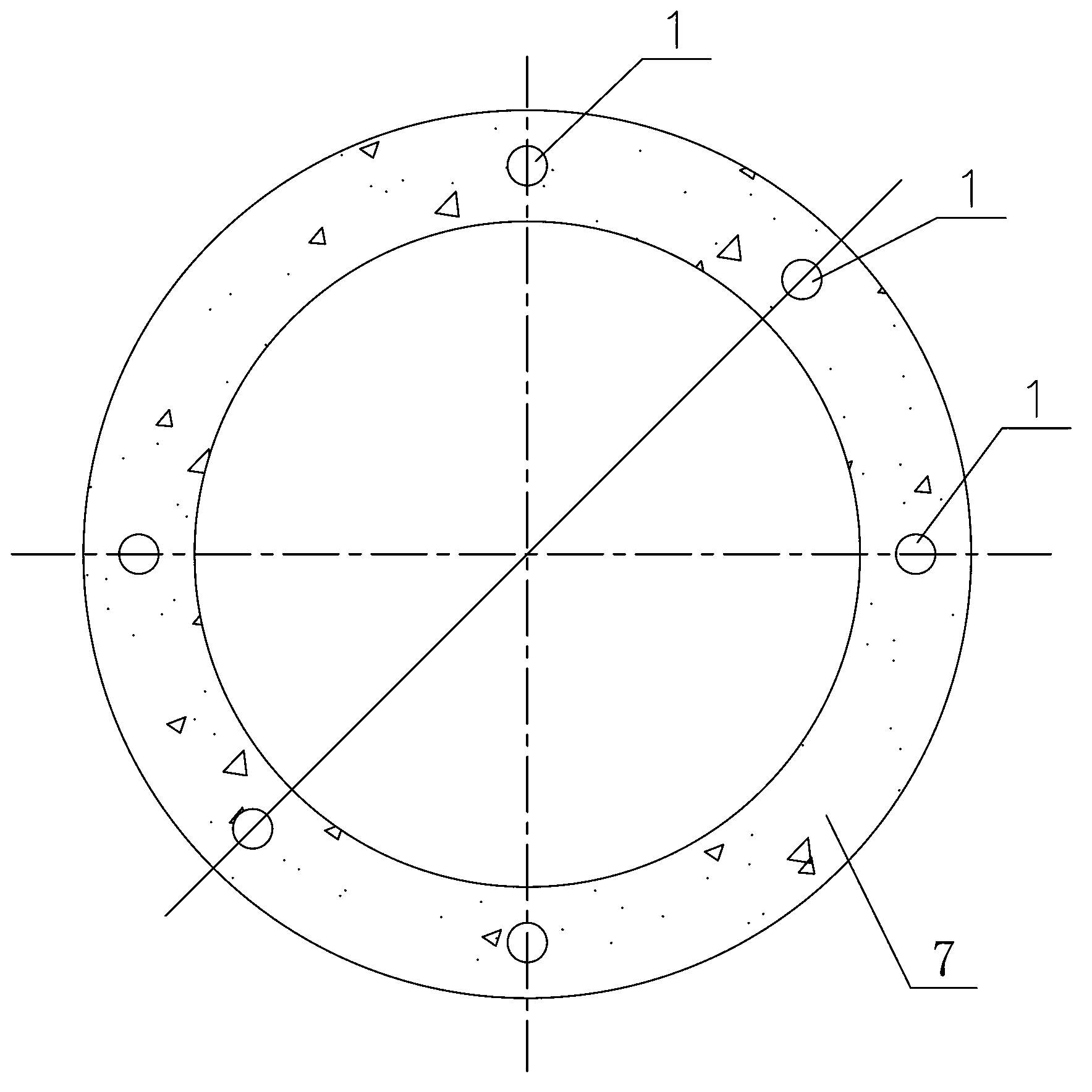

Foundation pile deflection measurement method based on distributed fiber sensing technique

The invention relates to a foundation pile deflection measurement method based on a distributed fiber sensing technique. According to the foundation pile deflection measurement method based on the distributed fiber sensing technique, pile body deflection of a foundation pile can be obtained in real time, and stability of the foundation pile is monitored. The foundation pile deflection measurement method based on the distributed fiber sensing technique is characterized by comprising the following steps: (a) a group of sensing optical cables which are parallel to the axis of the foundation pipe and symmetrically arranged based on the axis serving as a center line are arranged on edges of the foundation pile; (b) by means of a Brillouin demodulation technique, compression strain and tensile strain of each section of the foundation pile under the action of horizontal load can be measured in real time; and (c) according to a formula, deflection of each section of the foundation pile can be calculated. The method is used for the pile body deflection measurement of a steel pipe pile, a reinforced concrete precast pile, a reinforced concrete bored pile and other foundation piles.

Owner:ZHEJIANG HUADONG SURVEYING MAPPING & GEOINFORMATION

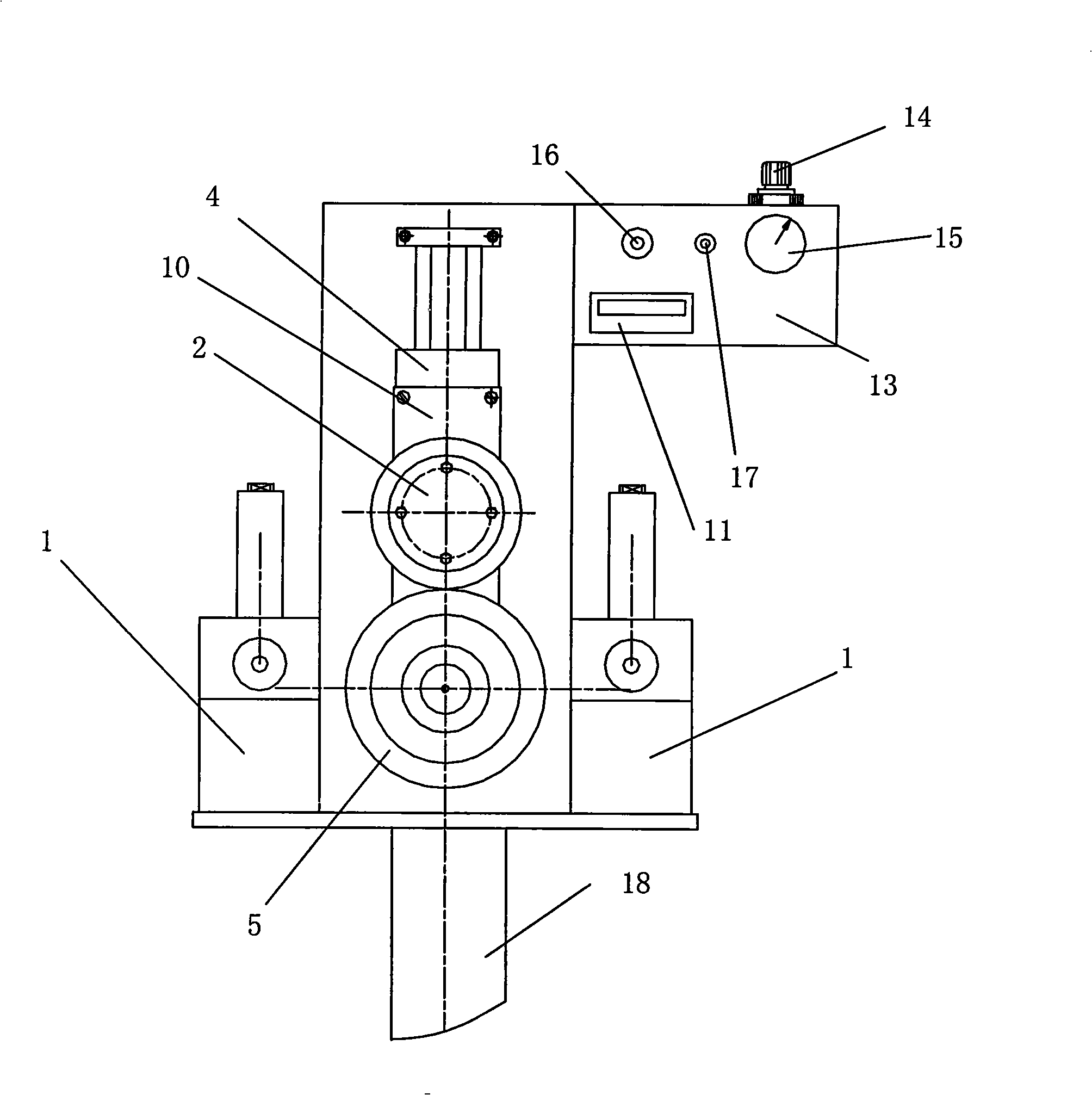

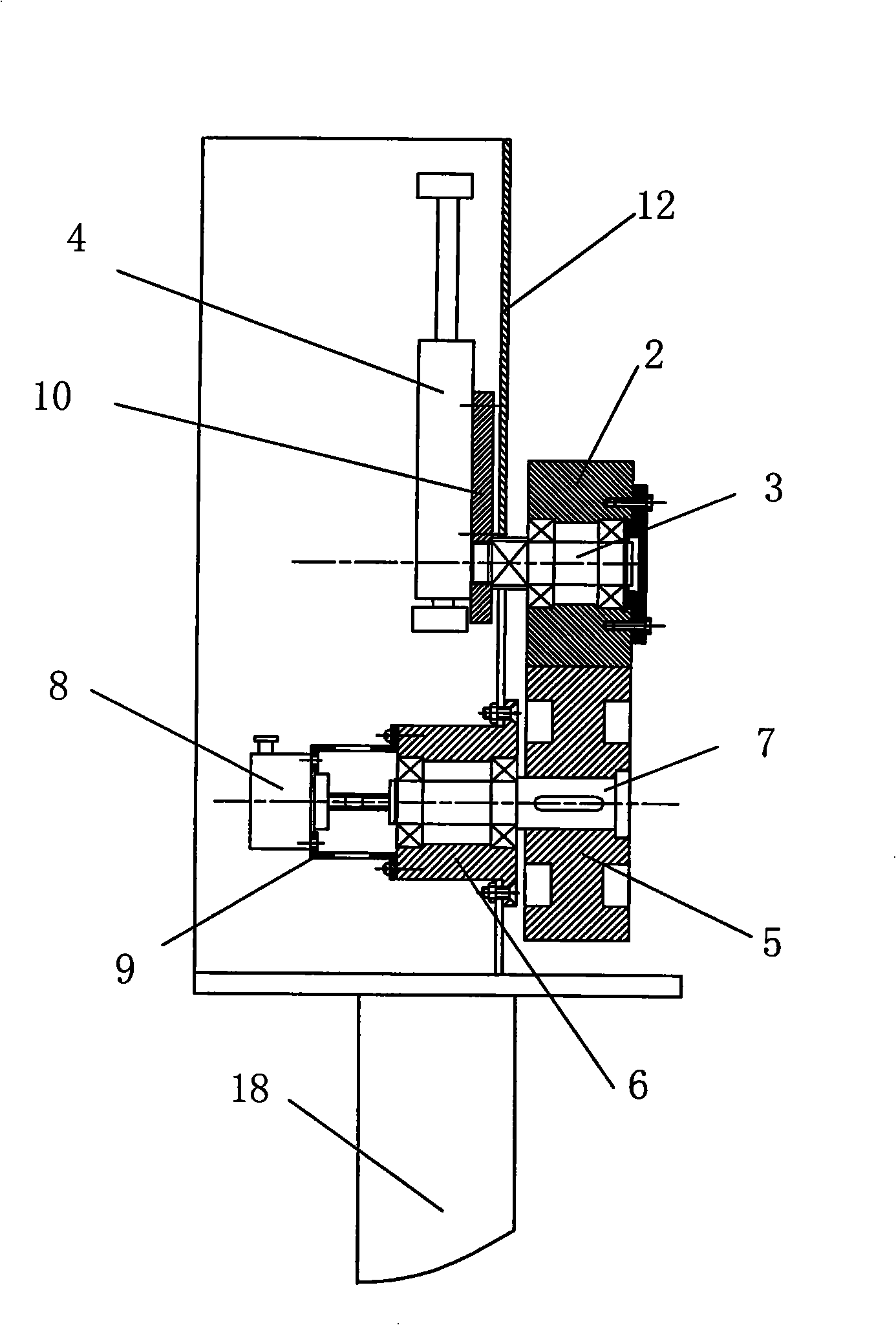

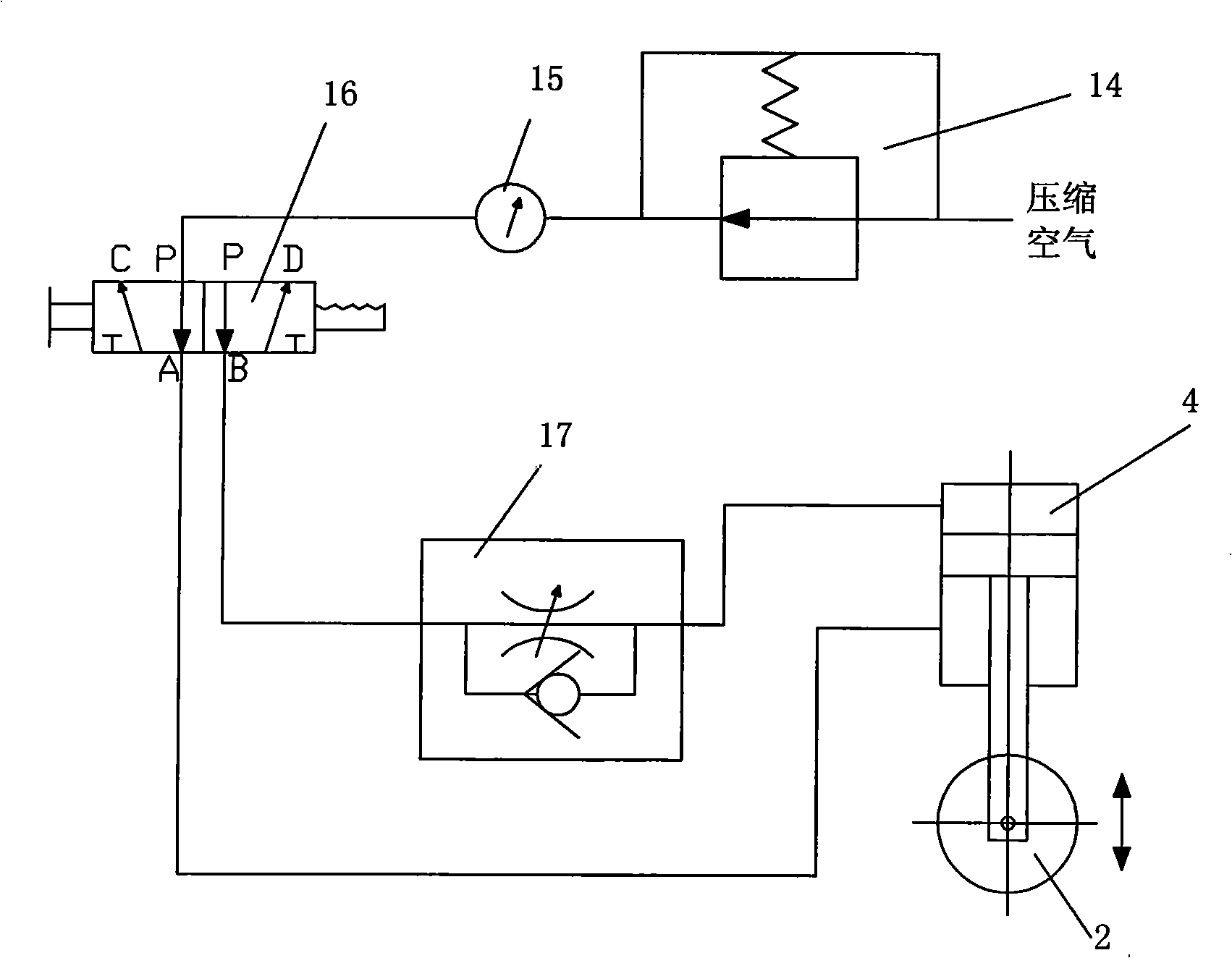

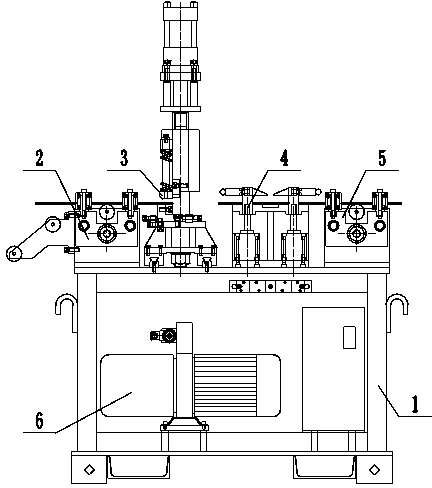

Pneumatic metering device for cable

InactiveCN101334272AGuaranteed to be straightKeep it straightUsing fluid meansEngineeringControl valves

The invention relates to a metering device of cables and discloses a pneumatic metering device used for cables. The device comprises a bracket, an upper clamping roller, and a lower supporting roller and a coder which are arranged on the bracket. The device is characterized in that a pneumatic slide valve and a corresponding gas control valve are arranged on the bracket, an upper clamping roller axis is fixed on the piston rod of the pneumatic slide valve, an upper clamping roller bearing is connected with the upper clamping roller axis, an upper clamping roller body is fixed on the upper clamping roller bearing, an upper supporting roller body is over against a lower supporting roller body up and down, and the gas control valve controls the piston rod of the gas control valve to move linearly up and down.

Owner:CHINA XIDIAN GRP CO LTD

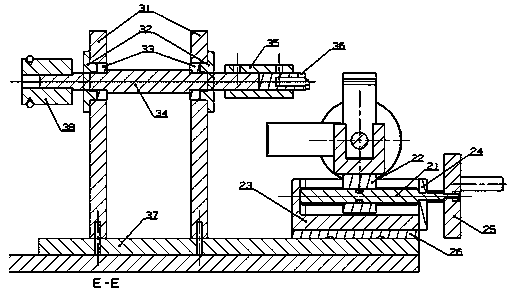

Cutting and welding working table

ActiveCN103737330AImprove work efficiencyAvoid damageWelding/cutting auxillary devicesArc welding apparatusProduction lineButt welding

A cutting and welding working table on a rolling production line comprises a working table body, a front guide assembly, a material cutting assembly, a butt welding material press assembly and a rear guide assembly. The front guide assembly, the material cutting assembly, the butt welding material press assembly and the rear guide assembly are sequentially installed above the working table body, the working planes of the assemblies are located on the same plane, and the working center lines are located on the same straight line. The working table is level in belt material cutting end and good in butt welding quality, avoids damage to roller wheels caused by poor butt welding thickness and greatly improves working efficiency due to the fact that cutting and butt welding can be conducted in a line production mode.

Owner:柳州凌云汽车零部件有限公司

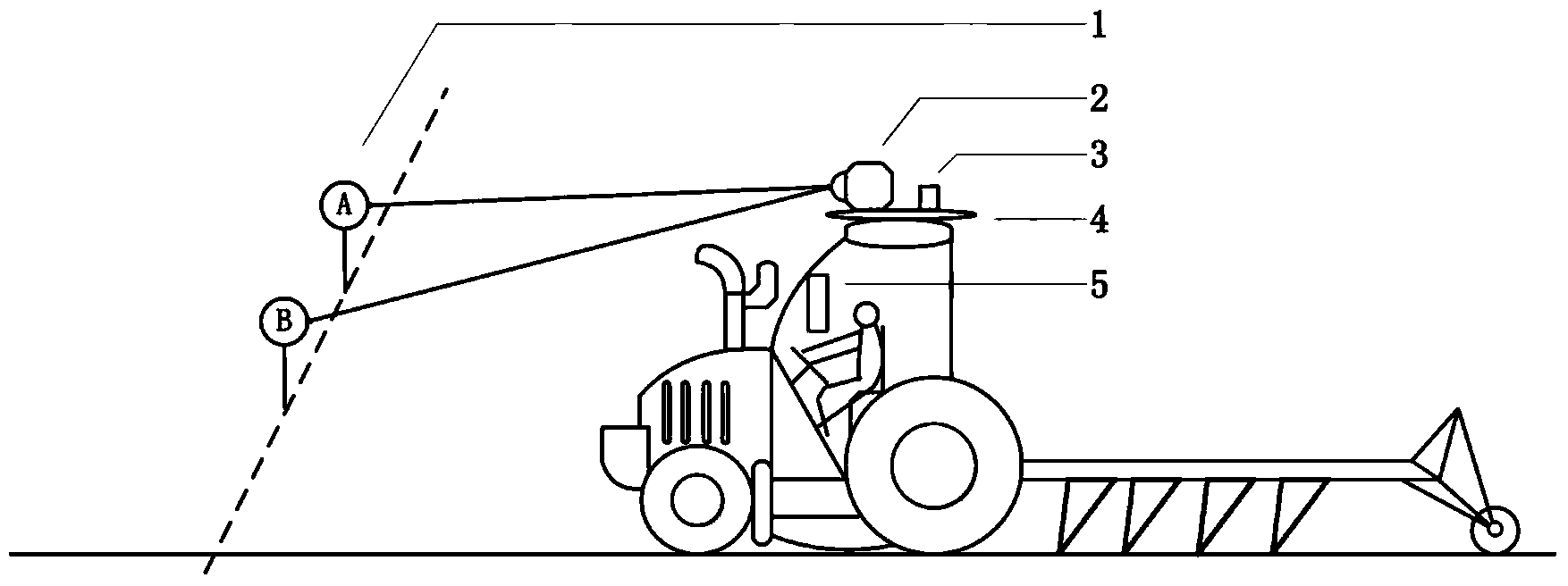

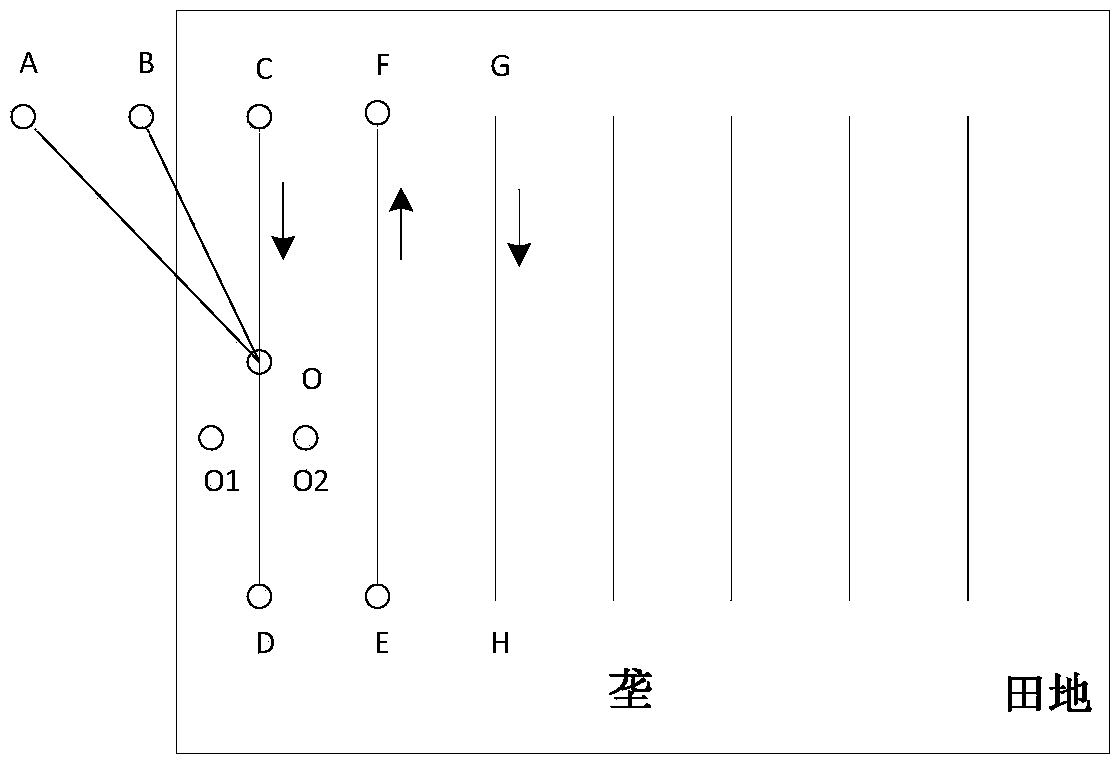

Agricultural machine navigation system and method applied to small and medium-sized farmland

InactiveCN104133192APosition real-time observationSimple structurePosition fixationFailure rateMaintainability

The invention discloses an agricultural machine navigation system and method applied to small and medium-sized farmland. The navigation system comprises a distance measurement device, an intelligent camera, a vehicle-mounted computer, a farmland target and a display device. According to the navigation system, the distance between an agricultural machine and the farmland target is obtained through the distance measurement device, distance information is converted into the information of the actual position of the agricultural machine and the relative position of a preset rail through the vehicle-mounted computer, the information is sent to the display device at last, an agricultural machine operator can observe the relative position of the agricultural machine in real time through the display device, and the agricultural machine is controlled to return to the preset position if deviating from the preset rail. The agricultural machine navigation system has the advantages of being simple in structure, higher in maintainability, lower in failure rate, low in cost and the like.

Owner:XIDIAN UNIV

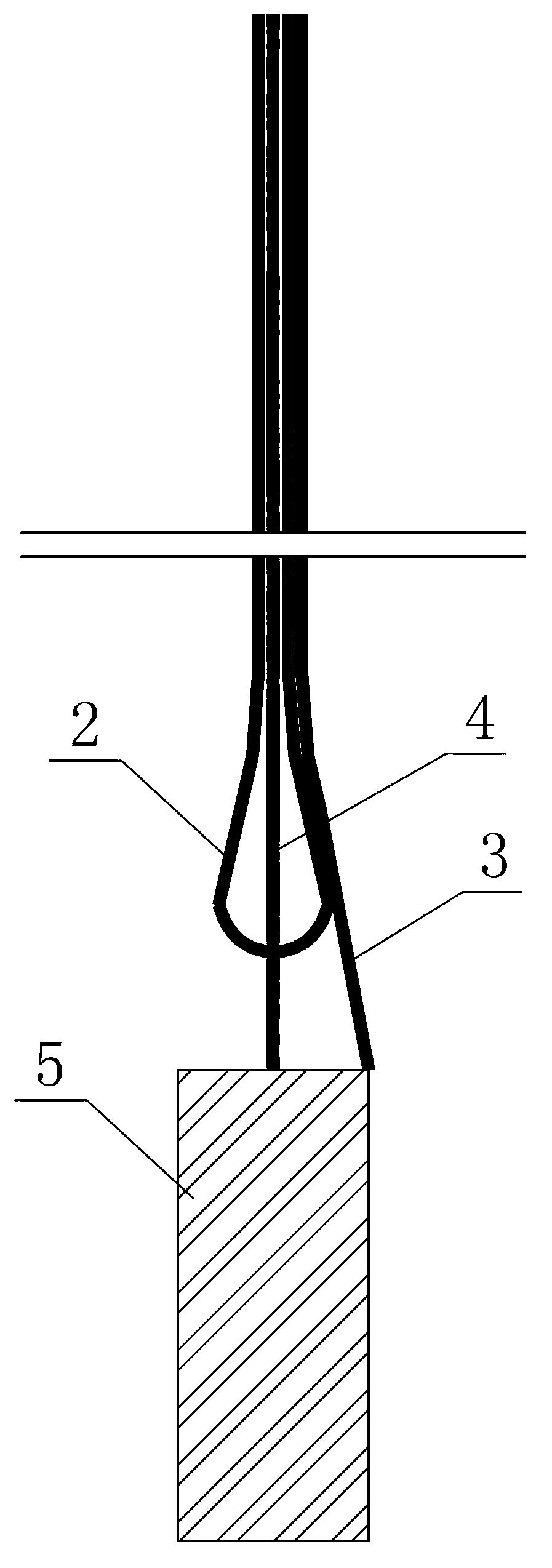

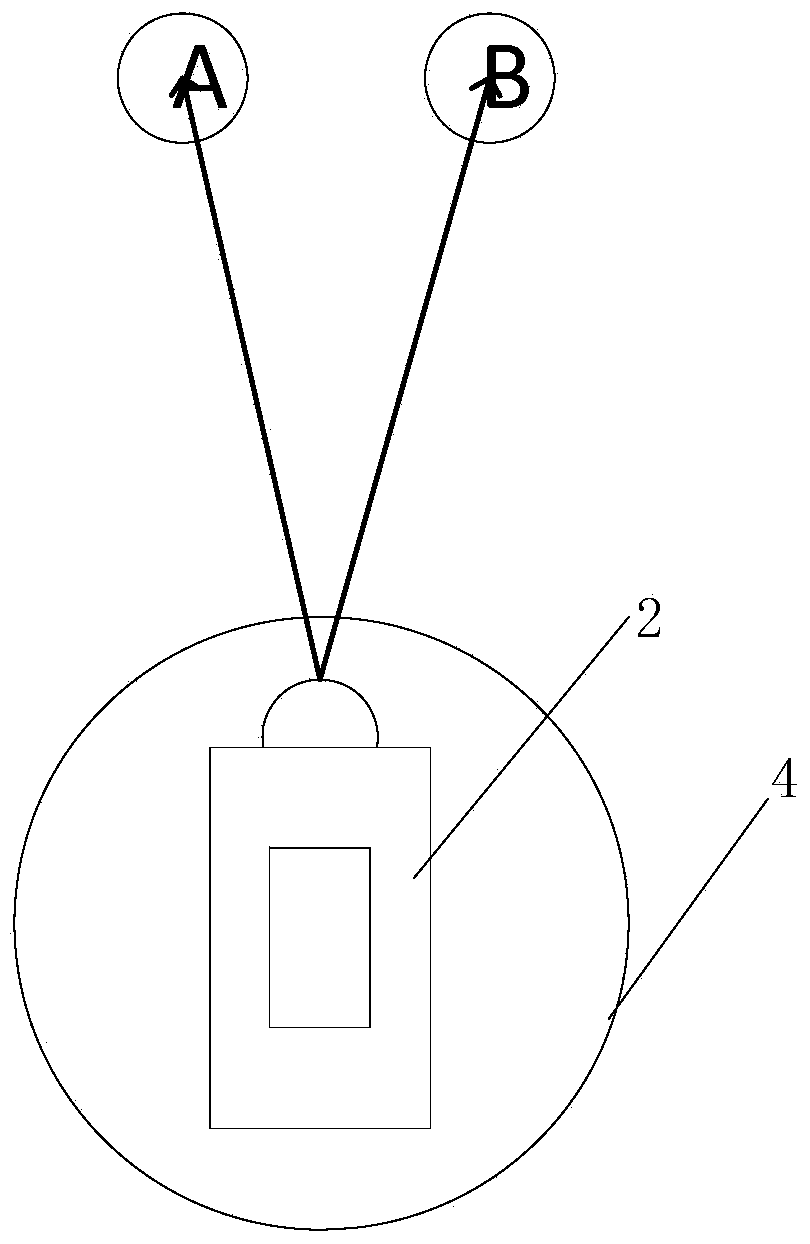

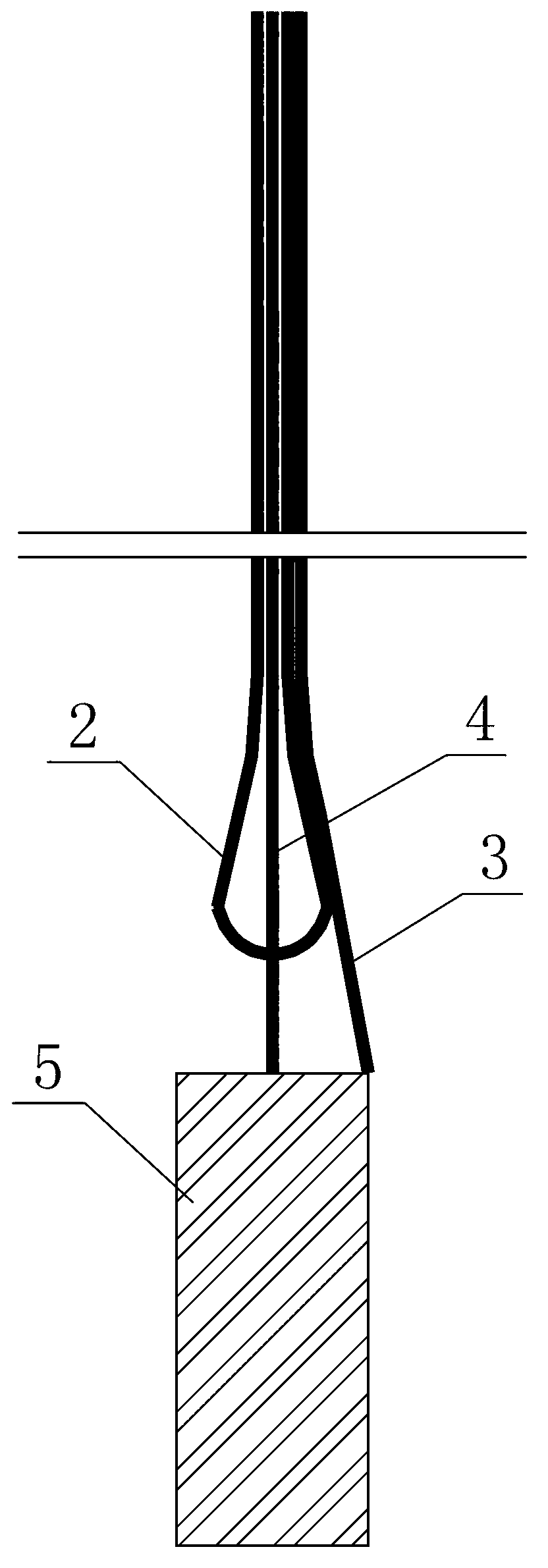

Inbuilt method for distributed type sensing cable in foundation pile

ActiveCN103215975AAvoid damageGuaranteed to be straightFoundation testingFiber strainArchitectural engineering

The invention relates to an inbuilt method for a distributed type sensing cable in a foundation pile. The invention aims at providing the inbuilt method for the distributed type sensing cable in the foundation pile to achieve a goal of reducing or avoiding damage to the sensing cable in a foundation pile construction process, thus improving the survival rate of an optic fiber strain sensor. The technical scheme is that for a driven pipe, the inbuilt method includes the steps: 1.1. arranging a group of pre-buried steel pipes on the foundation pile; 1.2. conducting foundation pile driving-in construction; 1.3. bending the sensing cable from the middle of the cable by 180 degrees, and fixing the bent portion on a metal support and conducting smooth transition on the bent portion; 1.4 placing the sensing cable and grouting flexible pipe together in each pre-buried steel pipe after a pilling rest period until the bent portion of the sensing cable extends to the bottom of the pre-buried steel pipe; and 1.5. grouting to the pre-buried steel pipe through the grouting flexible pipe until thick liquid comes out of the opening of the pipe, and completing the burying of the sensing cable after the thick liquid in the pipe is solidified.

Owner:ZHEJIANG HUADONG SURVEYING MAPPING & GEOINFORMATION

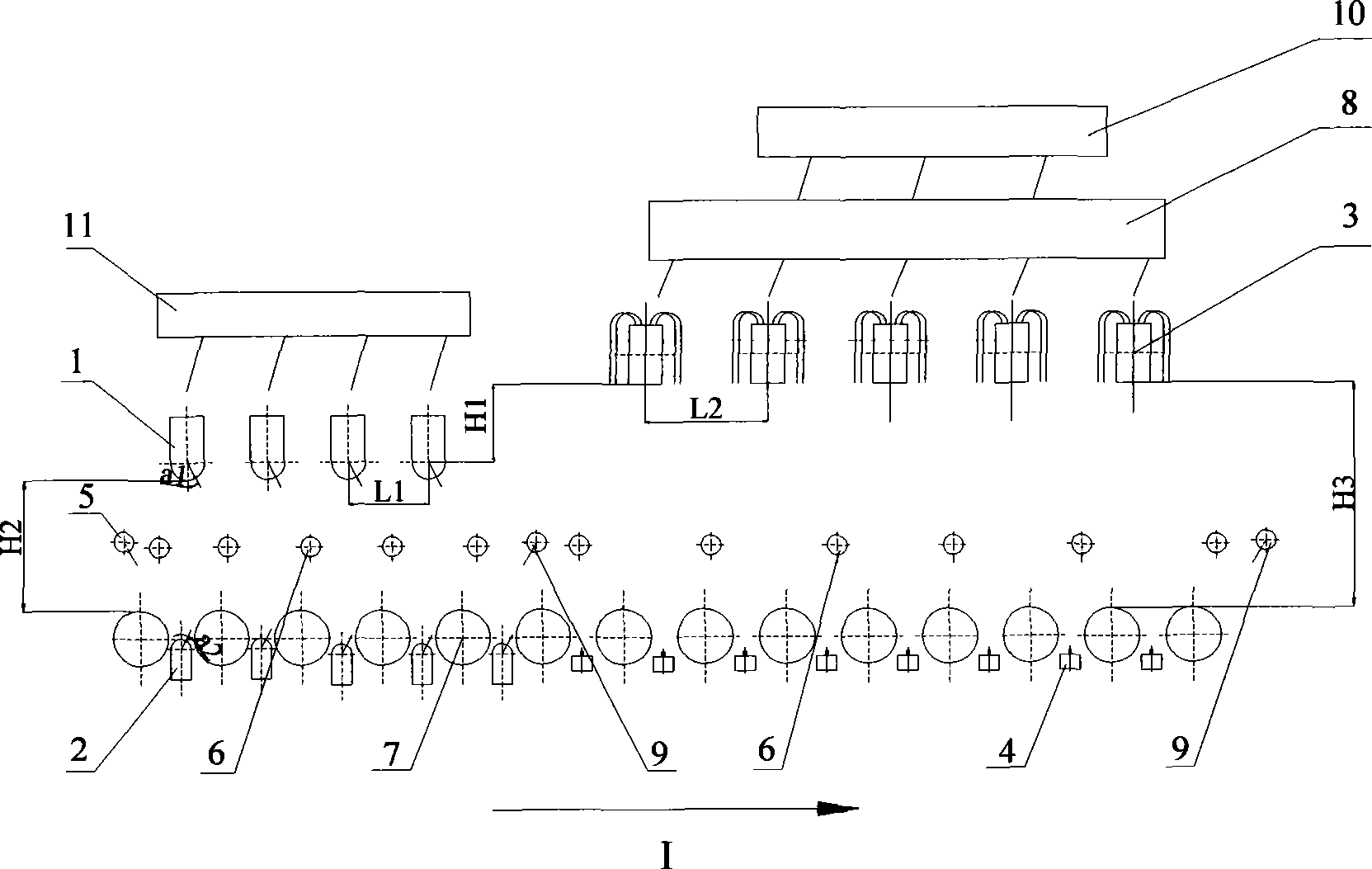

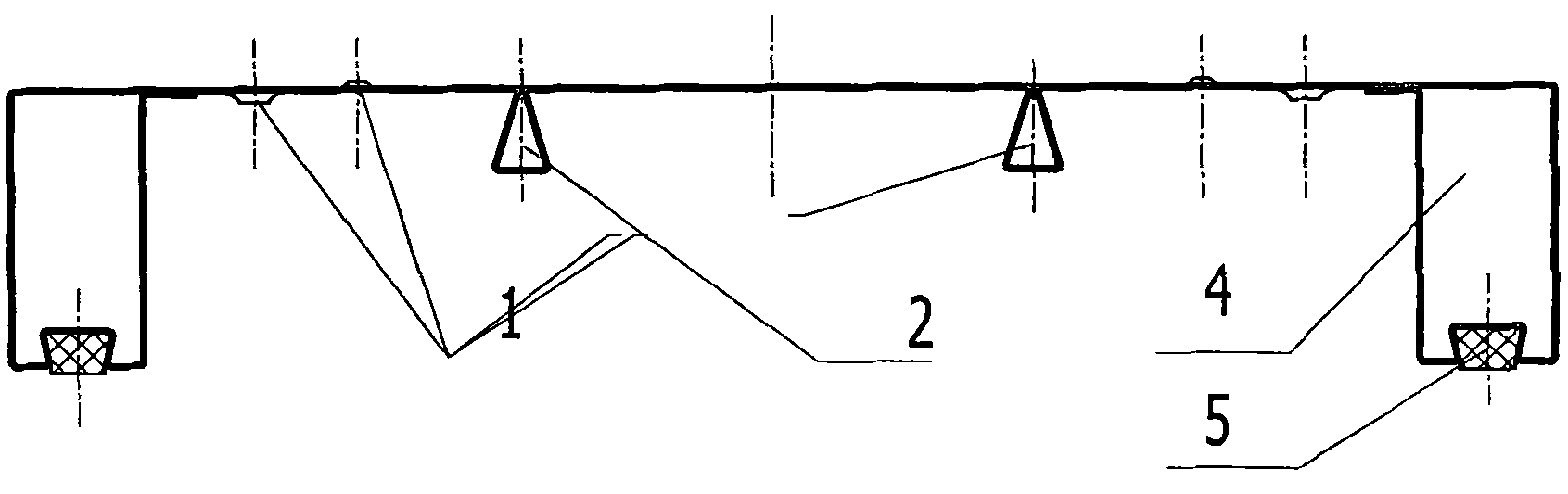

Cooling device used for hot-rolled strip production line

InactiveCN101518788AAchieve high-intensity coolingSolve the lack of cooling capacityWork treatment devicesMetal rolling arrangementsProduction lineUltra fast

The invention discloses a cooling device used for a hot rolled strip production line which comprises a roller way on which hot rolled sheets to be cooled are placed. The cooling device comprises an ultra-fast cooling device and a laminar flow cooling device, wherein the ultra-fast cooling device comprises a plurality of ultra-fast cooling water spraying upper collecting pipes and a plurality of ultra-fast cooling water spraying lower collecting pipes; the ultra-fast cooling water spraying upper collecting pipes are arranged sequentially and are perpendicular to the hot rolled strip production line; the ultra-fast cooling water spraying lower collecting pipes are arranged in the gaps of the roller way; the laminar flow cooling device comprises a high cistern, a shunting and collecting pipe, a laminar flow cooling upper collecting pipe and a laminar flow cooling lower collecting pipe; the high cistern and the shunting and collecting pipe are arranged up and down; and the high cistern, the shunting and collecting pipe, the laminar flow cooling upper collecting pipe and the laminar flow cooling lower collecting pipe are connected with each other through distribution pipes. The cooling device used for the hot rolled strip production line can cool hot rolled sheets quickly and evenly to meet the production demands of special steel grades, is beneficial to form industrial scale and has significant productive practice meaning.

Owner:TIANJIN DONGDA JINFENG ROLLING TECH

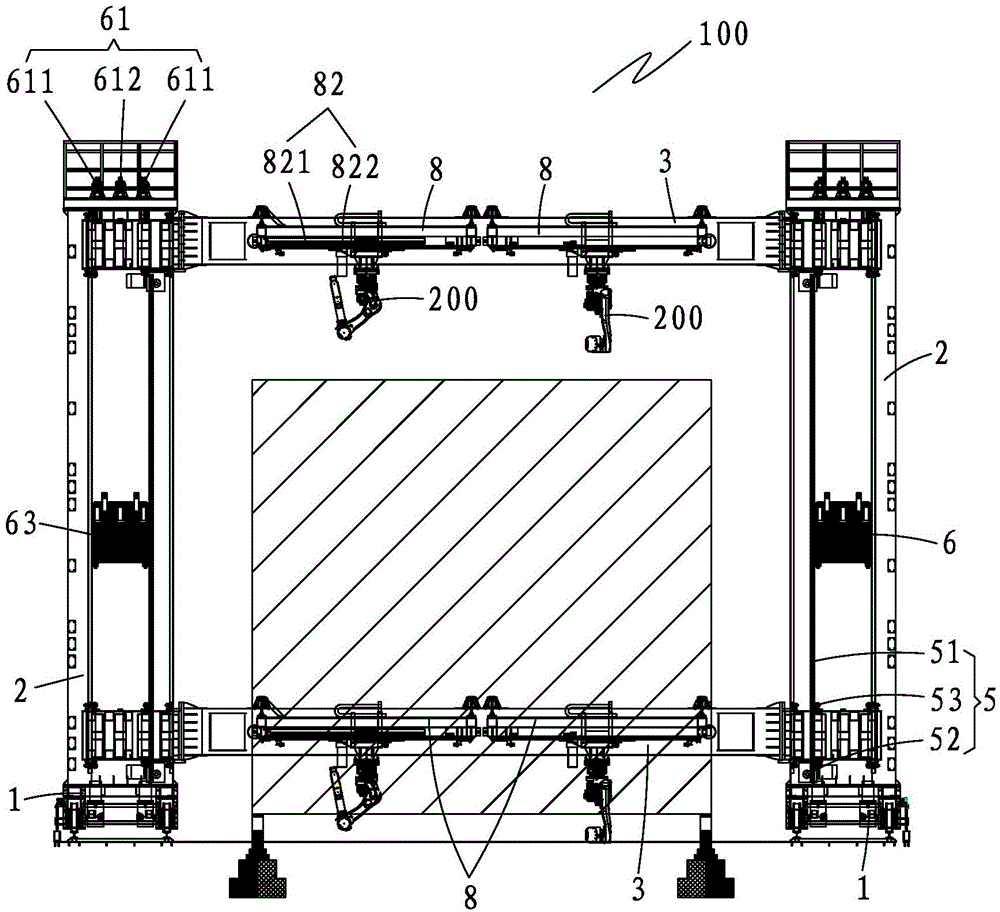

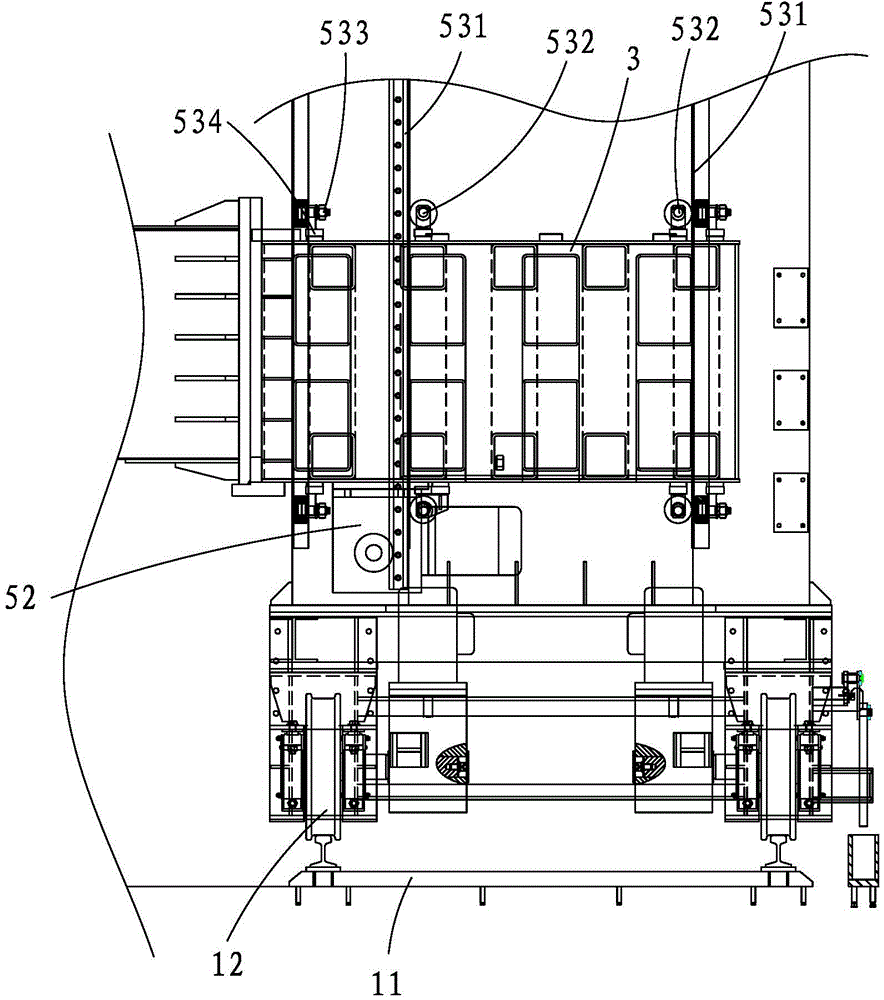

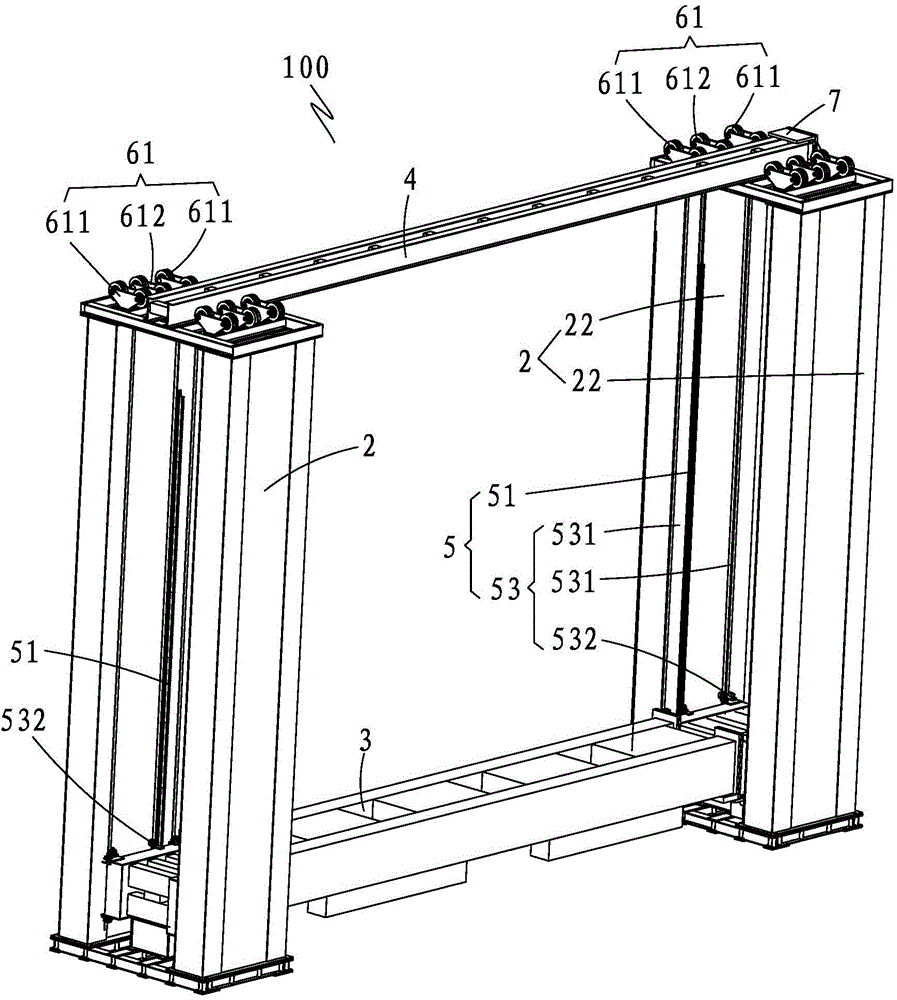

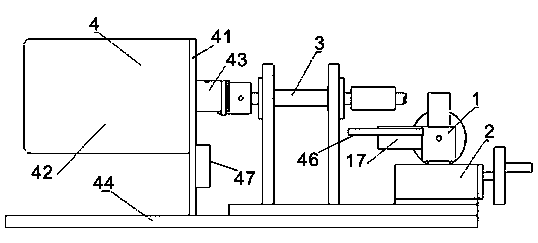

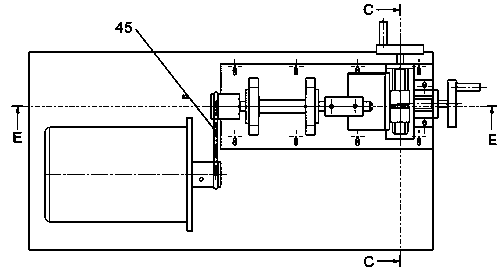

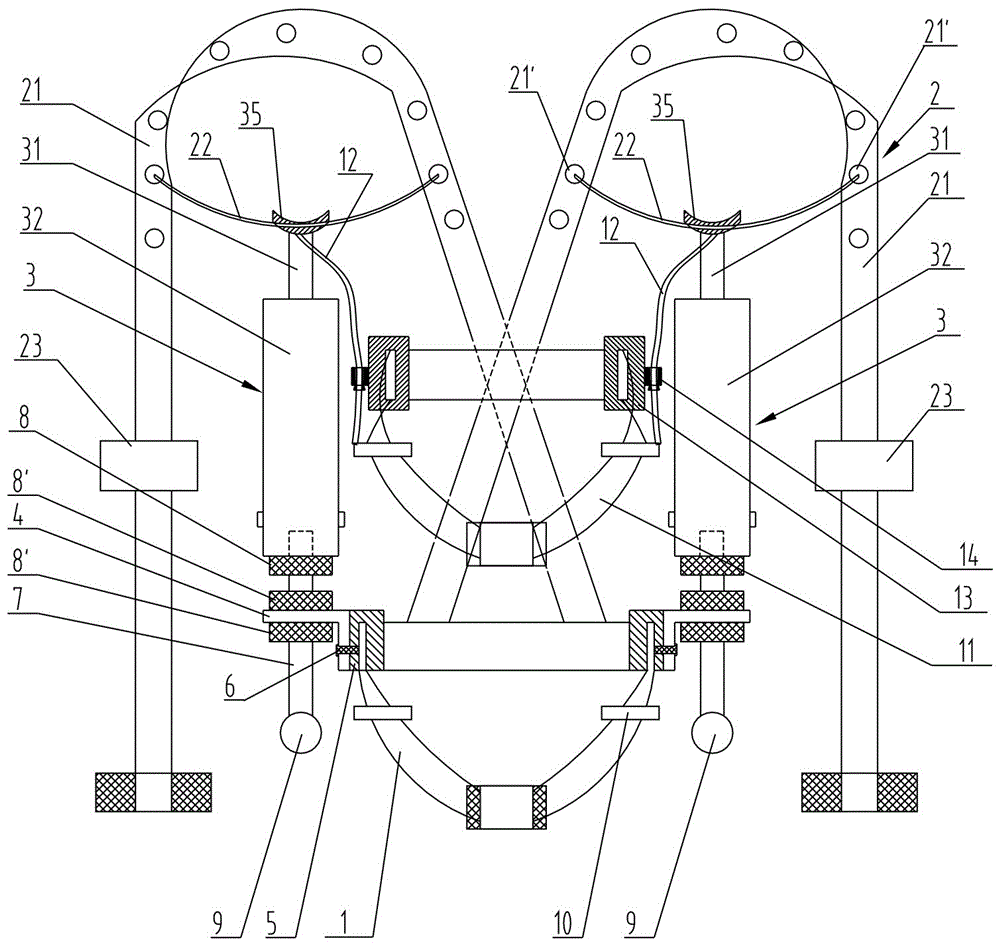

Large-scale portal frame

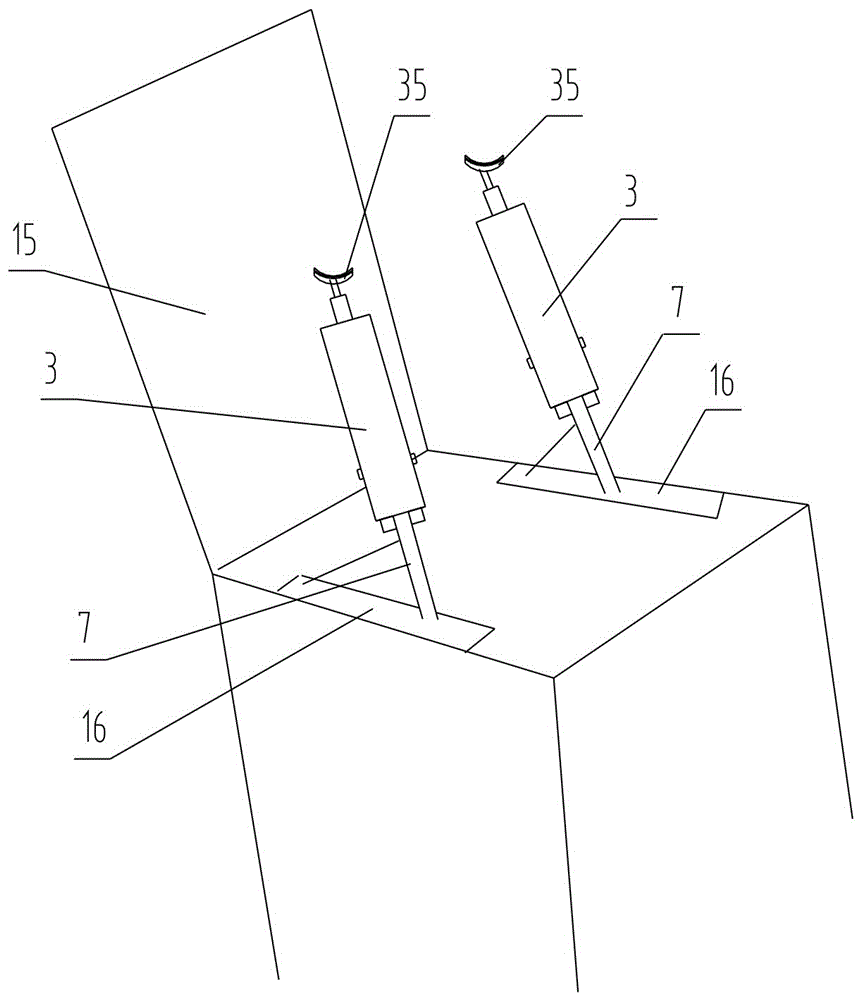

ActiveCN104370209ALabor-saving operationStrengthen the degree of bending resistanceBase supporting structuresBraking devices for hoisting equipmentsManipulatorPortal frame

The invention provides a large-scale portal frame. The large-scale portal frame comprises two rails, two trolleys, two stand columns, a movable main beam and a connection beam. Two ends of the movable main beam are respectively erected on the stand columns and are connected to a lifting device. Upper ends of the two stand columns are connected by the connection beam. The large-scale portal frame also comprises at least two counterweight mechanisms, a connection beam adjustment mechanism and two suspention beams for fixing manipulators. The counterweight mechanism comprises a guide wheel group, a suspension cable and a counterweight block. The connection beam adjustment mechanism comprises at least one adjusting nut, at least one adjusting screw and an adjusting seat. The two suspention beams are symmetrically fixed to the movable main beam, one end of each one of the suspention beams is close to the center of the movable main beam and any one of the suspention beams is provided with a horizontal movement mechanism. The manipulators are connected to the suspention beams by the horizontal movement mechanisms. The large-scale portal frame satisfies span and height requirements and is suitable for 3D printing building extruding head arrangement.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

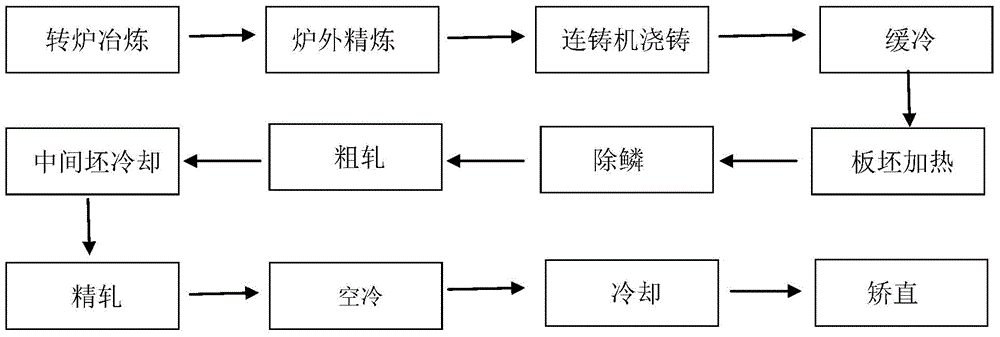

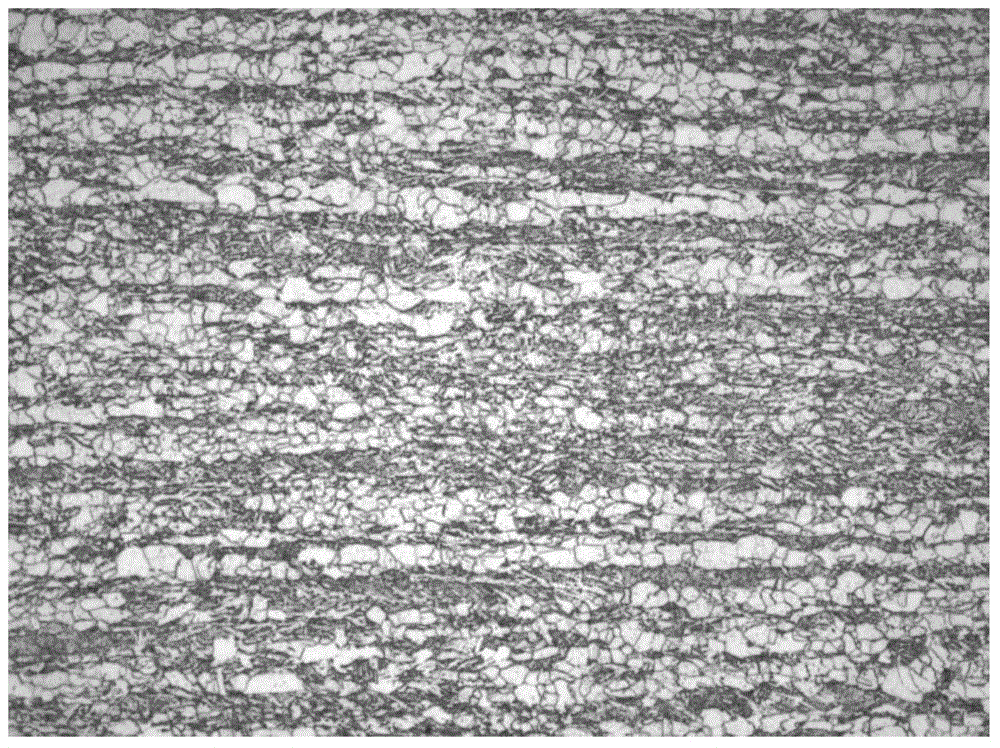

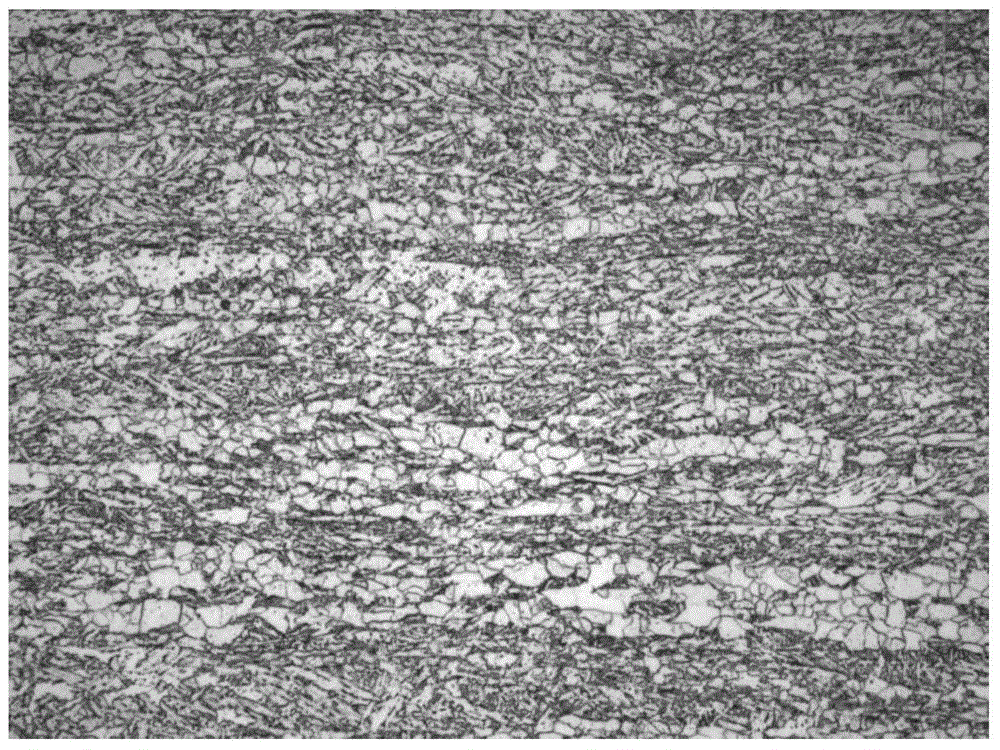

X80 pipeline steel with high stress ratio and high arrest toughness and preparation method and application of X80 pipeline steel

The invention specifically relates to X80 pipeline steel with the high stress ratio and high arrest toughness and a preparation method and application of the X80 pipeline steel. The X80 pipeline steel is composed of, by weight, 0.03% to 0.08% of C, 0.15% to 0.35% of Si, 1.50% to 2.00% of Mn, not larger than 0.010% of P, not larger than 0.003% of S, 0.04% to 0.08% of Nb, 0.015% to 0.025% of Ti, 0.015% to 0.025% of Zr, not larger than 0.03% of Mo, not larger than 0.35% of Cu, not larger than 0.30% of Ni, not larger than 0.30% of Cr and the balance Fe and inevitable impurities. Zirconium is added to promote precipitation of proeutectoid ferrite, the banded structure level is reduced, and the stress ratio and the arrest toughness of a steel plate are effectively improved. The heating temperature is strictly controlled, and the recrystallization deformation temperature section in a rough rolling stage and the rolling reduction and the temperature of the last phase of rough rolling are reasonably matched, so that the austenite grain size is reduced to the maximum degree; and a rough-rolled intermediate billet is cooled, so that grain growth generated after recrystallization deformation is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

Curved-surface screen protector and coating and laminating method and forming method thereof

ActiveCN107187128AGuaranteed to be straightHigh hardnessFlexible coversWrappersTectorial membraneHardness

The invention discloses a curved-surface screen protector. The curved-surface screen protector comprises a first PET release film, a first hardening layer, a base material layer, a second hardening layer, a silica gel layer and a fluorinated organosilicone release layer which are stacked sequentially from top to bottom, wherein the first PET release film comprises a PET release film body and a first adhesive layer arranged below the PET release film body. The curved-surface screen protector is high in hardness, high in stability after fitting a curved mobile phone, capable of fitting a curved-surface screen perfectly, durable, resistant to scratch and easy in sticking and offers more stable, effective and comprehensive protection for the curved-surface screen. The invention further discloses a coating and laminating method and a forming method of the curved-surface screen protector. The coating and laminating method is simple in technology, fewer in step and safe to implement. The forming method is simple in technology, safe and simple to implement and low in cost.

Owner:GUANGZHOU EHANG ELECTRONICS CO LTD

610Mpa high-strength steel plate for low-yield-ratio petroleum reserve tank and manufacturing method thereof

InactiveCN104451386ASave the process of quenching + temperingShort production cycleBatch productionSheet steel

The invention belongs to the field of low alloy steel production processes, and specifically relates to a 610Mpa high-strength steel plate for a low-yield-ratio petroleum reserve tank and a manufacturing method thereof. The 610Mpa high-strength steel plate for the low-yield-ratio petroleum reserve tank comprises the following components in percentage by mass: 0.07-0.13% of C, 0.15-0.35% of Si, 1.45-1.60% of Mn, less than 0.015% of P, less than 0.005% of S, less than 0.030% of Nb, 0.03-0.05% of V, 0.010-0.020% of Ti, 0.08-0.18% of Mo, 0.15-0.35% of Ni, less than 0.008% of N and the balance of Fe and inevitable impurities. The method is capable of overcoming the limitation that the yield ratio is difficult to reduce in the traditional production and manufacturing method, simplifying the production process, shortening the production flow and reducing energy consumption, suitable for industrial batch production, and capable of ensuring a low yield ratio while meeting the requirements of strength, toughness and welding performance indexes.

Owner:SHANDONG IRON & STEEL CO LTD

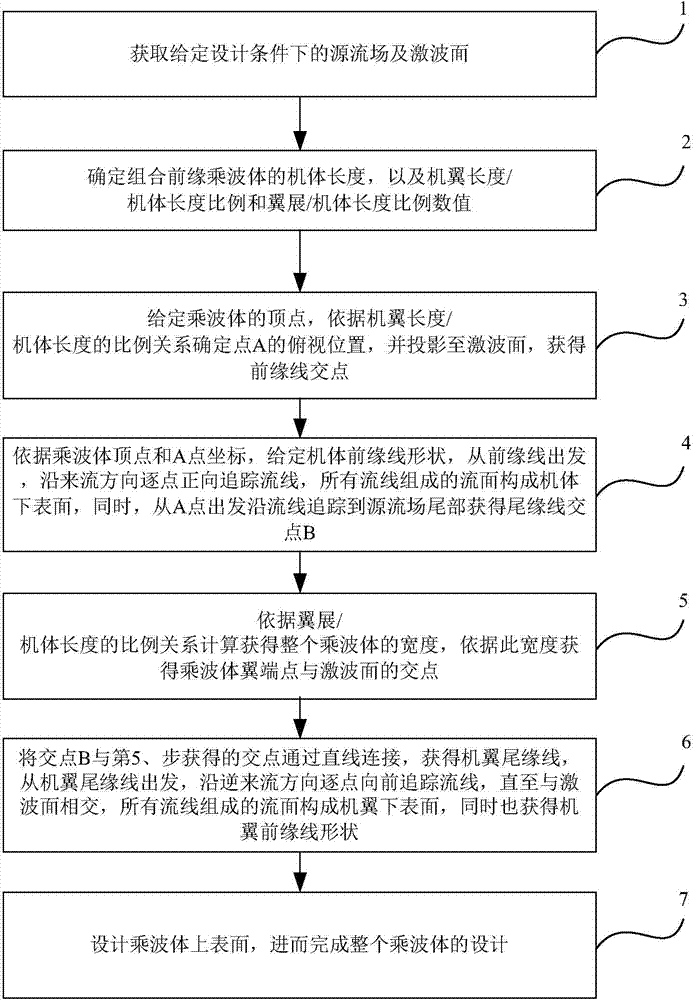

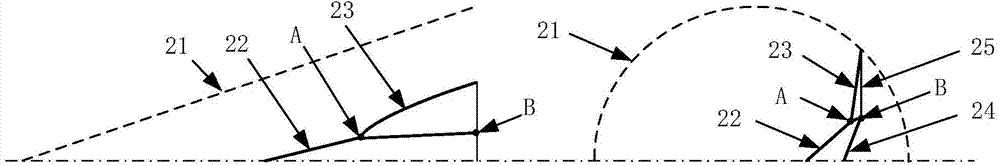

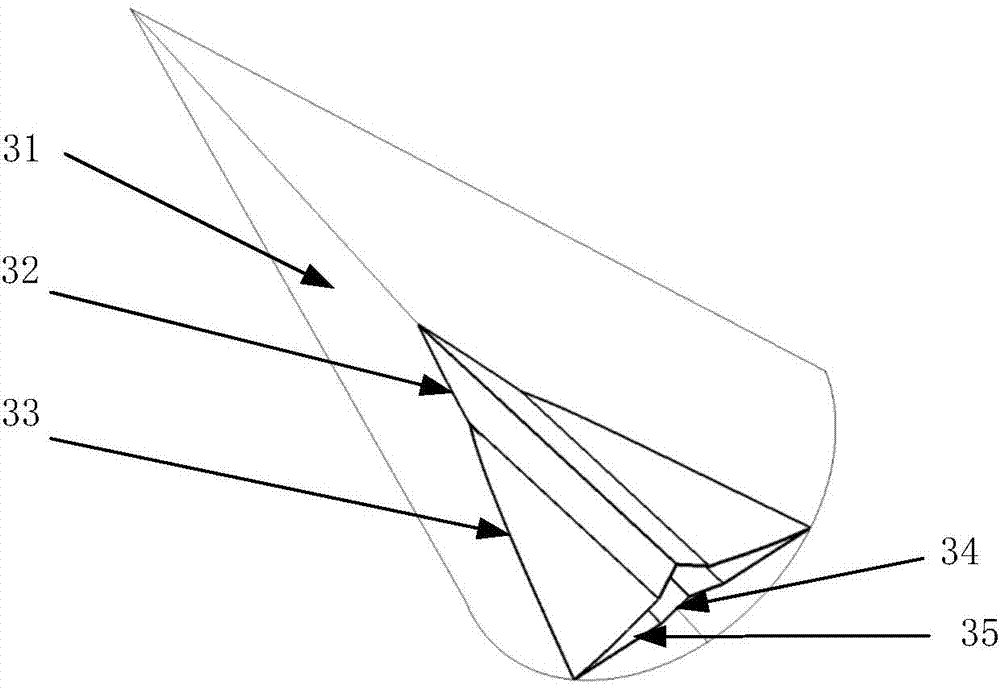

Combined front-edge wave rider design method and combined front-edge wave rider

ActiveCN104724281AGuaranteed to be straightFlexible and adjustable aspect ratioAir-flow influencersShock waveConfiguration design

The embodiment of the invention provides a combined front-edge wave rider design method and a combined front-edge wave rider. According to the method, the appearance of the wave rider is divided into two parts, namely an engine body and a wing, and then the method of defining a front / rear edge curve is adopted, so that the design flexibility of the wave rider can be effectively improved, and the appearance more close to the actual can be acquired. The lower surface of the wing is intersected with a shock wave surface so as to form a wing front-edge line, and then the combined front-edge line of the wave rider is obtained; when the method is used for designing, not only can the features of the wave rider be guaranteed, but also the length-width ratio is flexible and the straightness of the tailing edge is guaranteed, the design method is more suitable for the actual aircraft. The lower surface of the engine body can be designed by using a positive filament line tracing method for giving the front-edge line, the lower surface of the wing can be designed by using an adverse filament line tracing method for riving the tailing-edge line. The main application range of the design method provided by the embodiment of the invention is configuration design for various hypersonic aerocrafts, and the design method is particularly suitable for designing future hypersonic aircrafts or gliding type aircrafts.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

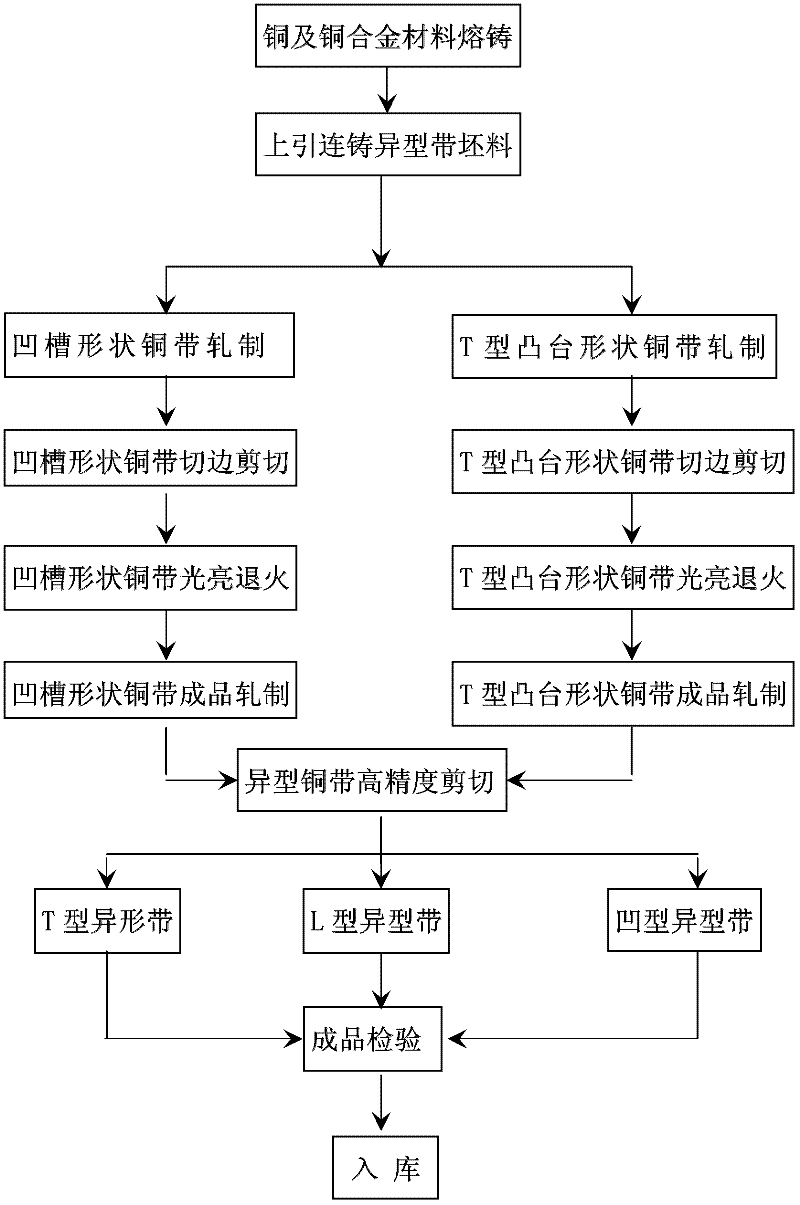

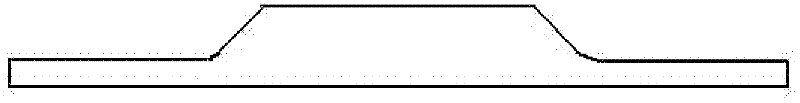

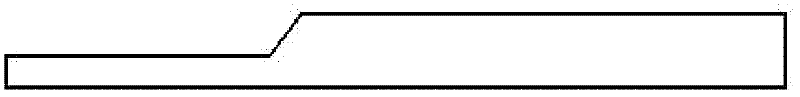

A processing technology for producing special-shaped cross-section brass strips

A processing technology for producing brass strips with special-shaped cross-sections, comprising the following steps: melting, casting, high-precision rolling, bright annealing, finished product rolling, and finished product shearing, characterized in that the casting adopts upward continuous casting to prepare billets , and the round crystallizer tooling equipped with graphite molds used for wire rod production by upward continuous casting was transformed into a design cross-section crystallizer tooling for strip production. Compared with the original processing method for producing brass strips with special-shaped cross-sections, it has the characteristics of low manufacturing cost and cheap tooling molds. The surface of the blank obtained by the invention is bright, the crystal texture is uniform, and the surface milling is not required in the subsequent processing. At the same time, the method has low energy consumption, and is a high-efficiency, low-cost method for producing brass strip blanks with special-shaped cross-sections.

Owner:赤峰京铜铜业有限公司 +1

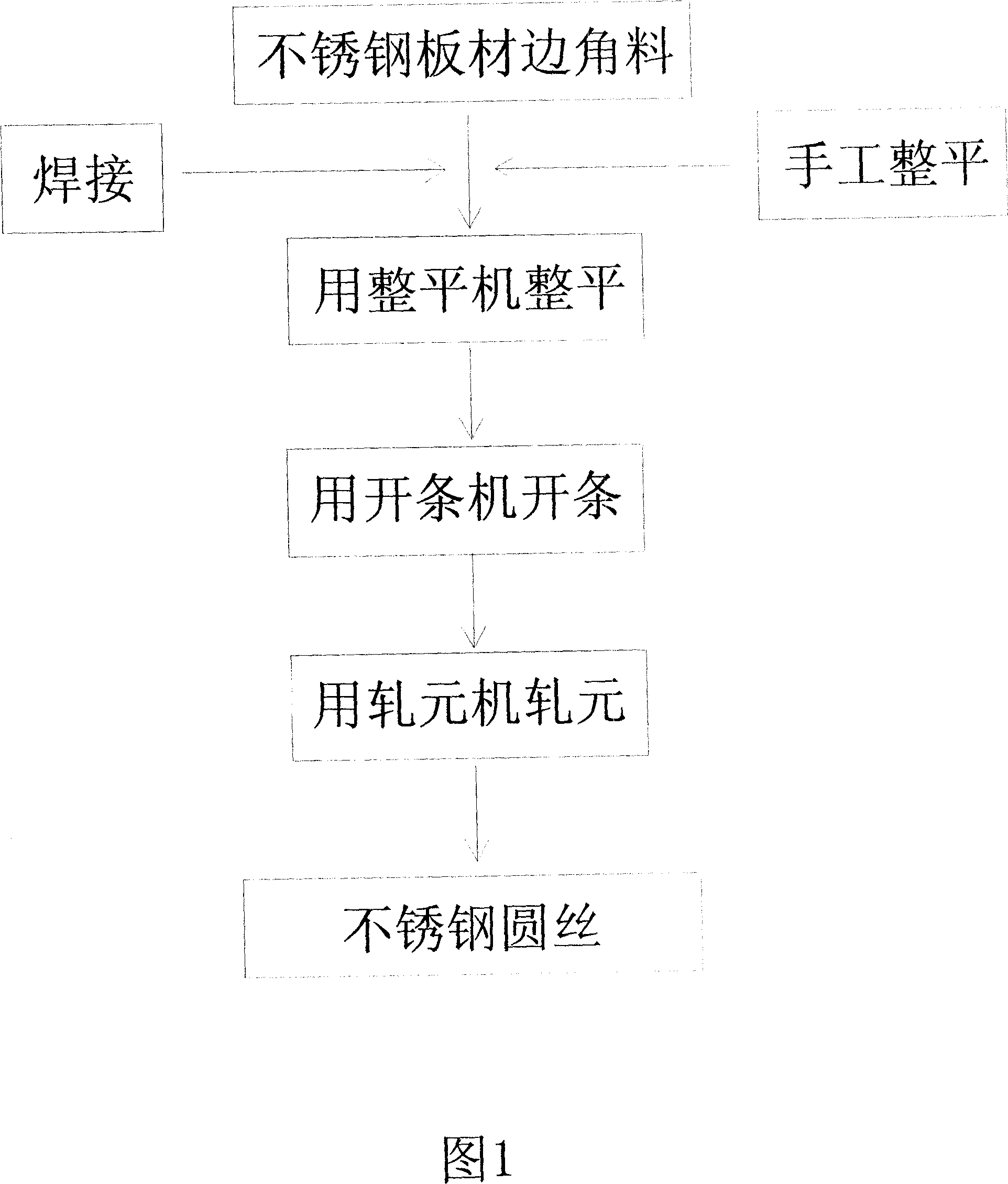

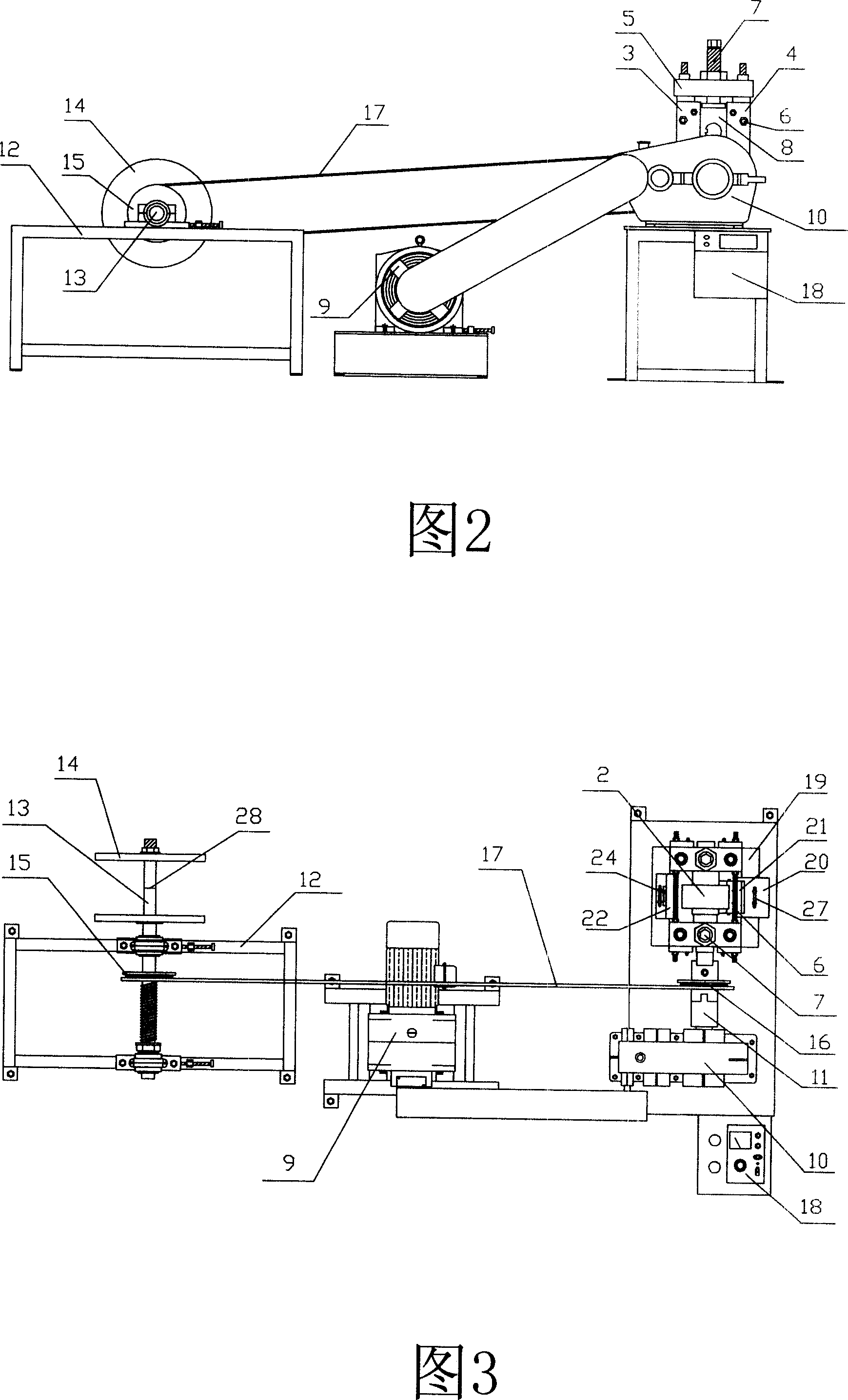

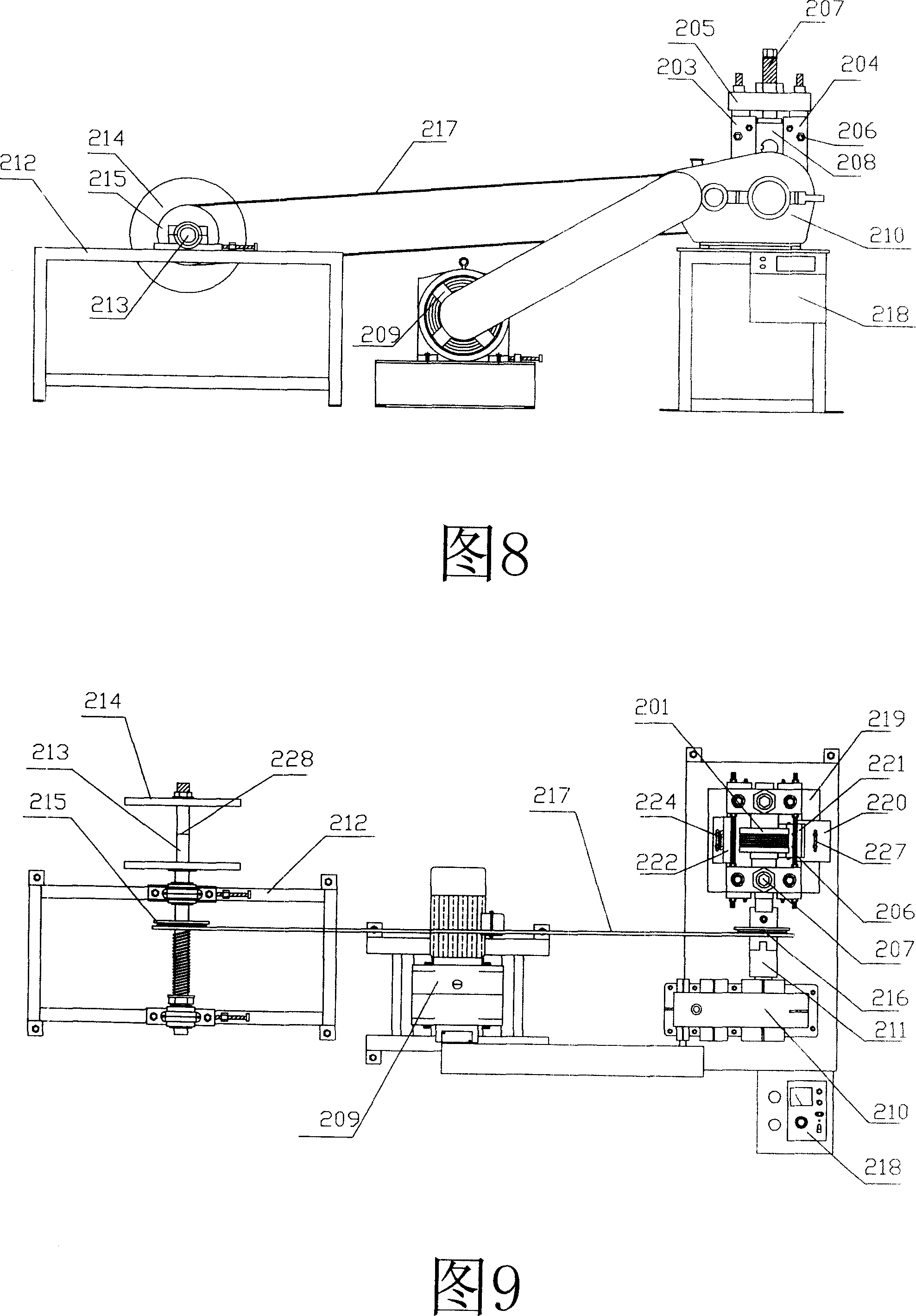

Method for processing stainless steel wire by utilizing stainless steel plate rim leftover

InactiveCN101015834AEnergy savingReduce labor costsMetal-working feeding devicesMetal rolling stand detailsSteel platesScrap

A method for using edge and corner materials of stainless steel plate to process stainless steel wires, is characterized in that first using flatten machine to process the edge and corner materials into stainless steel bars, then using opening machine to open bars, using coiler to coil the bars into round wires. The invention can save material and energy with low cost.

Owner:张文波

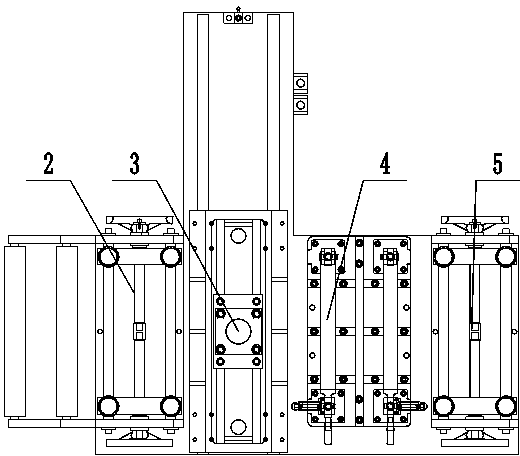

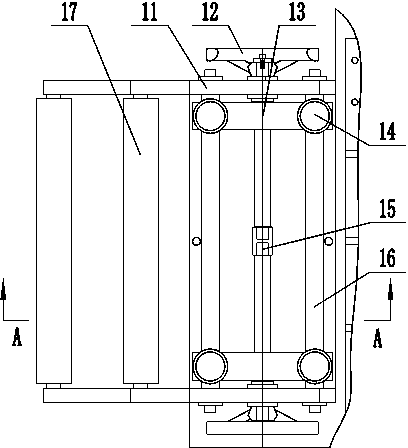

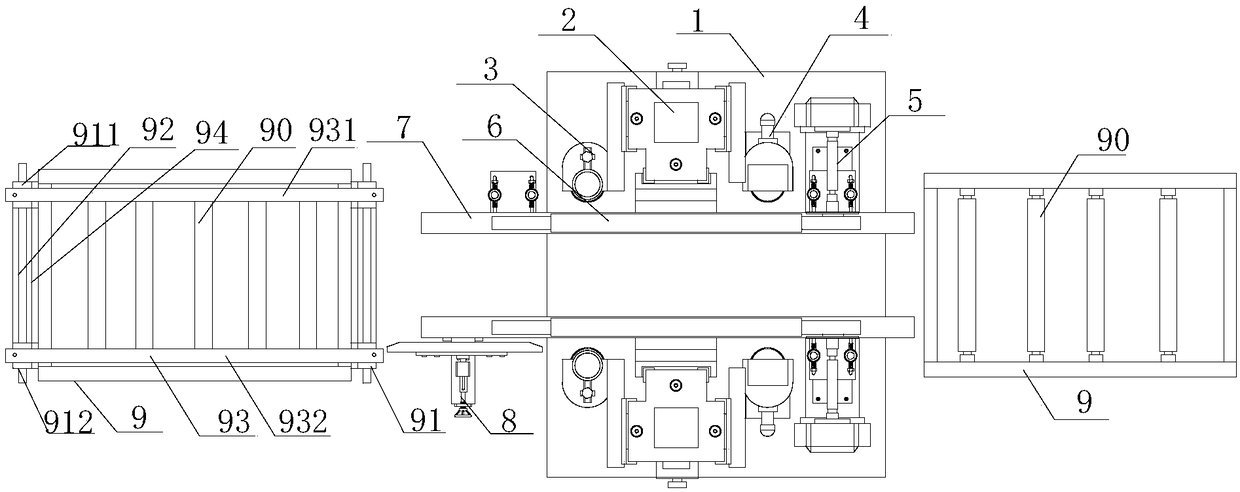

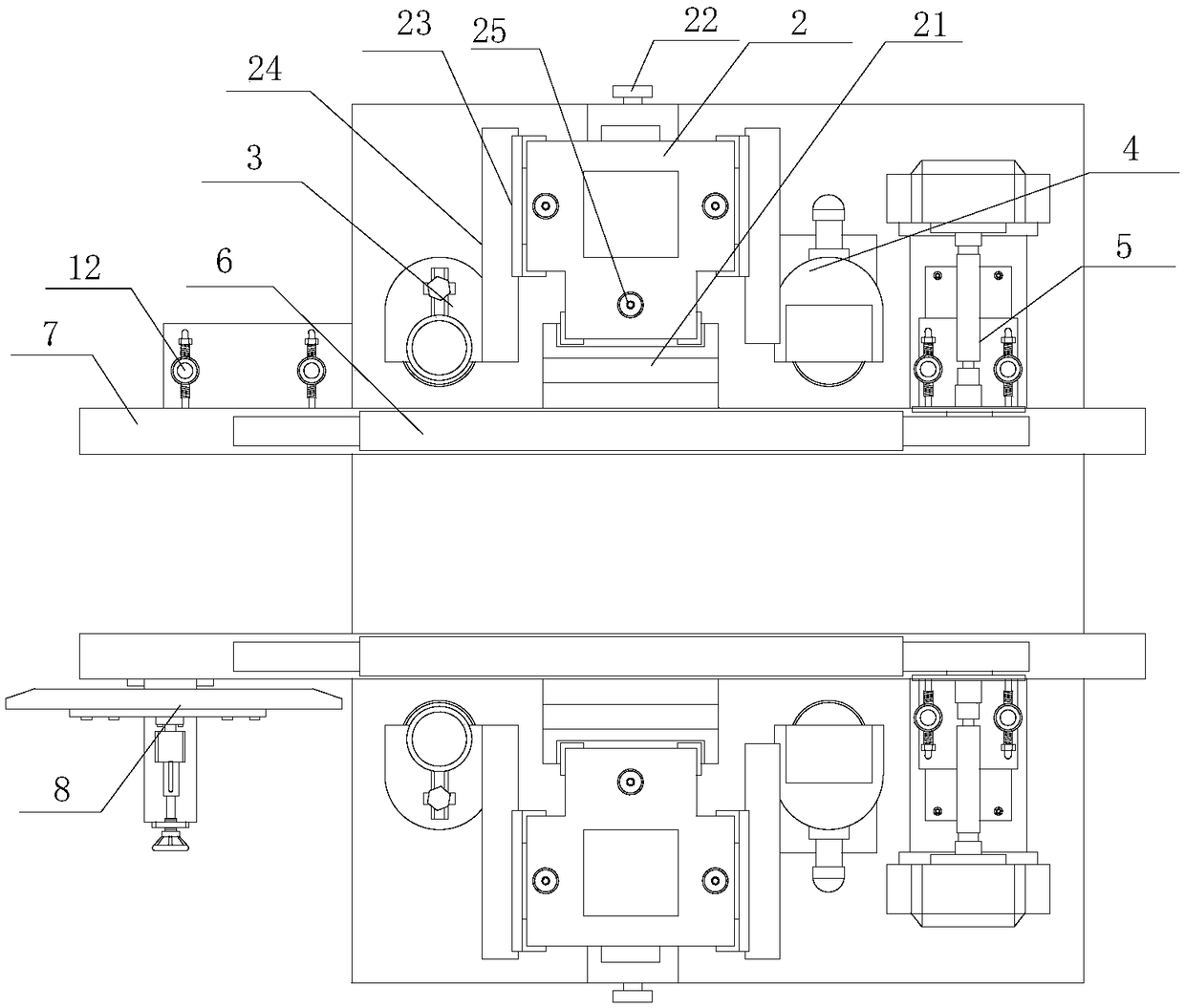

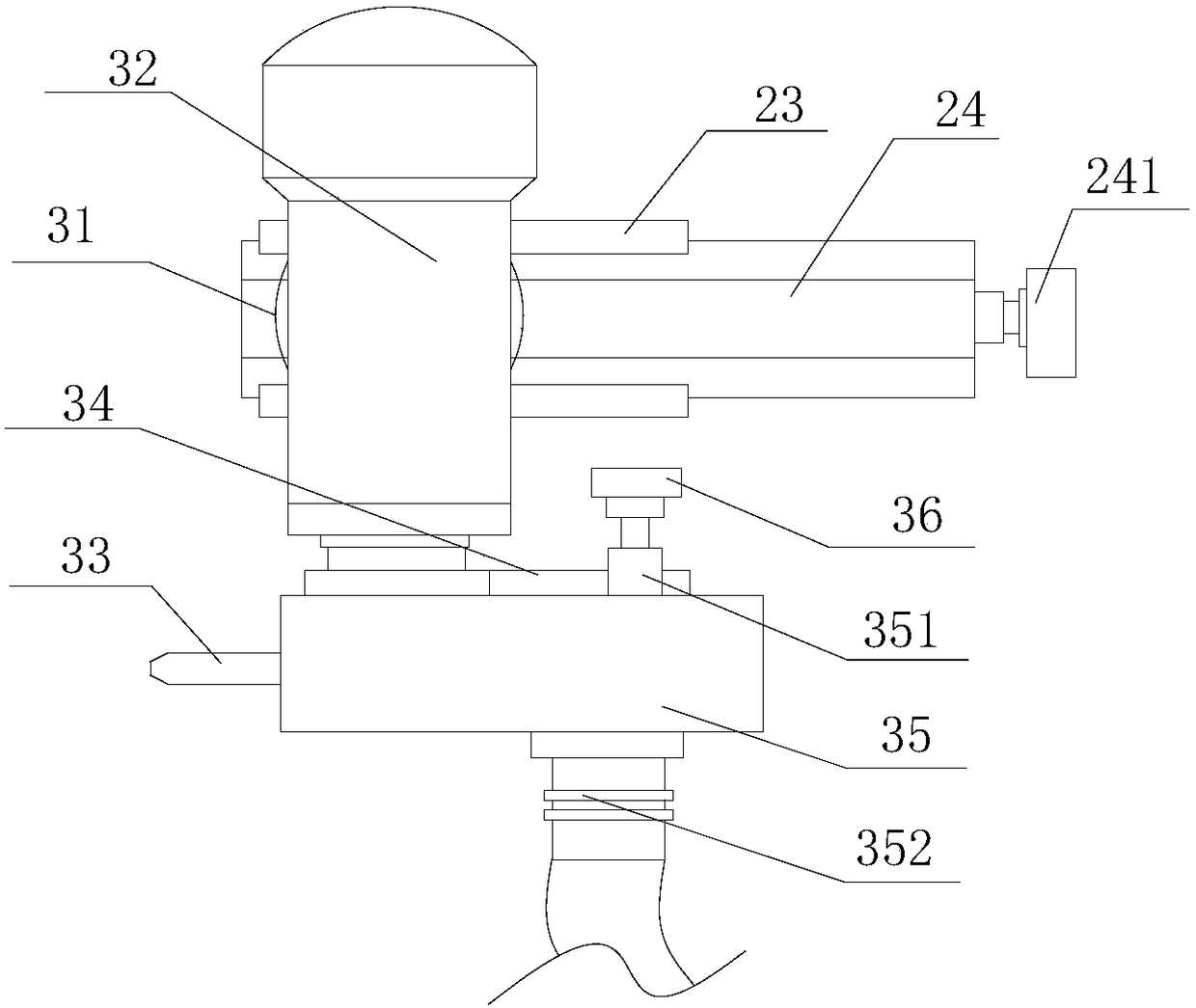

Wallboard straightening device

PendingCN108500800AGuaranteed to be straightQuality improvementEdge grinding machinesGrinding carriagesDrive wheelConveyor belt

The invention provides a wallboard straightening device. The wallboard straightening device comprises a rack, adjusting pedestals, a first polishing mechanism, a second polishing mechanism, a conveyorbelt drive mechanism, a material pressing conveyor belt, a material supporting conveyor belt, an auxiliary material blocking mechanism and a roller supporting conveying frame. The two sides of the rack are symmetrically provided with the adjusting pedestals. One side of each adjusting pedestal is provided with a first supporting frame, and the material supporting conveyor belt is arranged on thefirst supporting frames. The material pressing conveyor belt is provided with a drive wheel. The two ends of each adjusting pedestal are symmetrically provided with supporting installation arms. The first polishing mechanism and the second polishing mechanism are installed on the supporting installation arms correspondingly. One side of the rack is provided with the auxiliary material blocking mechanism. Material blocking backing parts are symmetrically distributed on the two sides of the roller supporting conveying frame, the straightness of a wallboard needing to be straightened can be ensured, the wallboard straightening device can straighten the wallboard with the bad straightness on the two sides, exceeded parts are polished, and the straightness of the whole wallboard is guaranteed.

Owner:JIAXING YUNMU ENVIRONMENTAL PROTECTION TECH CO LTD

Diode pin cutting mechanism

ActiveCN109127956ASolve the problem of easy splashing aroundFacilitate orderly processingMetal stripsEngineering

The invention relates to the field of semiconductor device pin cutting machining, and discloses a diode pin cutting mechanism. The diode pin cutting mechanism comprises a cutter and a cutting platform, the cutting platform comprises a conveying platform and a rotating platform which are fixedly connected, a gap is formed between the conveying platform and the rotating platform to form a cutting seam, grooves used for containing metal strips are formed in the conveying platform and the rotating platform, a fixing plate is arranged over the groove of the conveying platform in a crossed mode, anarc-shaped plate is arranged over the groove of the rotating platform in a crossed mode, the arc-shaped plate and the fixing plate are both used for fixing the metal strips, and a rotating platform driving mechanism is connected to the rotating platform. According to the diode pin cutting mechanism, the problem that splashing occurs after a pin is cut by the cutter can be solved.

Owner:泸州龙芯微科技有限公司

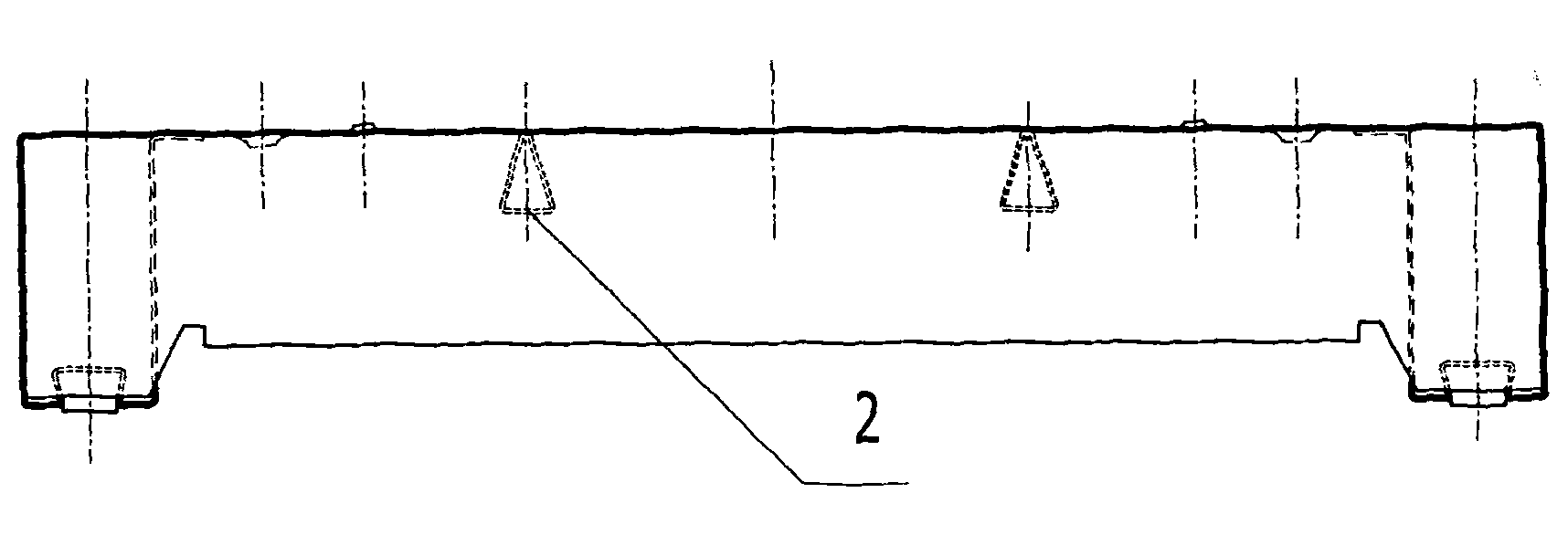

Lightweight galvanized steel springboard and processing process thereof

InactiveCN101956453AReasonable structureGood strengthVessel partsScaffold accessoriesWeld strengthGalvanization

The invention discloses a lightweight galvanized steel springboard and a processing process thereof, relating to the fields of building construction and ship building devices. The lightweight galvanized steel springboard of the invention uses steel SGC570, the steel springboard has a reverse-concave cross section, supporting feet at both sides are in a box-shaped structure, grooves are arranged at the bottoms of the supporting feet, end plates are arranged at both ends of the steel springboard, transverse rib plates are alternately arranged on the bottom of the steel springboard, and cold-extrusion punch holes are arranged on the surface of the steel springboard. The supporting feet and longitudinal ribs of the lightweight galvanized steel springboard of the invention are formed together with the body through once cold bending and pressing, which avoids the processing defects of the product, avoids the welding strength requirement, increases the strength, ensures the sheet smoothness and improves the whole bearing capability. According to the invention, the steel thickness can be reduced to 1 / 2.4 by substituting steel SGC570 for steel Q235, thus the consumption of iron ore and the waste of energy are reduced, the needs of practical use by reasonable design can be met.

Owner:白龙浩

Method for preparing large-specification thin-composite-layer nickel-based alloy and pipeline steel composite plate

ActiveCN107185961AGuaranteed bonding strengthGuaranteed stretching effectRoll force/gap control deviceTemperature control deviceReduction ratioAlloy

The invention discloses a method for preparing a large-specification thin-composite-layer nickel-based alloy and pipeline steel composite plate. The method comprises the following steps that 1, a nickel-based alloy plate serving as a composite layer and a pipeline steel plate serving as a base layer are composited to prepare composite board blank through explosion welding; 2, a leveling treatment is carried out on the composite board blank, and then a heating treatment is carried out on the composite board blank; 3, a cooling treatment is carried out on the heated composite board blank; and 4, the composite board blank which is subjected to the cooling treatment is fed into an asynchronous rolling mill for asynchronous rolling to obtain the nickel-based alloy and pipeline steel composite plate, wherein the shearing strength of the nickel-based alloy and pipeline steel composite board is not less than 210 MPa, the total rolling reduction ratio of asymmetrical rolling is 50%-90%, and the different speed ratio of each pass of the asynchronous rolling mill is 1.05-1.30. According to the method for preparing the composite plate, the corrosion resistance of the nickel-based alloy plate serving as the composite layer is ensured, and the tensile property and the impact toughness of the pipeline steel plate serving as the base layer are ensured; and the bonding strength and other properties of the composite plate can meet the requirements specified in the NB / T47002.2 standard, and even the requirement for rolling force of the rolling mill is reduced.

Owner:XIAN TIANLI CLAD METAL MATERIALS

Transversal-vertical slitting machine for pearl wool

PendingCN110576474AGuaranteed to be straightHigh precisionMetal working apparatusEngineeringElectrical and Electronics engineering

The invention relates to the technical field of pearl wool processing, and particularly relates to a transversal-vertical slitting machine for pearl wool. The transversal-vertical slitting machine forthe pearl wool comprises a rack as well as a transversal slitting device, a vertical slitting device and a feeding guide roll device which are installed on the rack, wherein the transversal slittingdevice comprises a transversal slitting lifting mechanism and a transversal slitting heat knife group, the transversal slitting heat knife group is installed on the transversal slitting lifting mechanism and used for lifting movement, the vertical slitting device comprises a vertical slitting translation support and a plurality of groups of vertical slitting heat knife groups, and the plurality ofgroups of vertical slitting heat knife groups are movably installed on the vertical slitting translation support; and the feeding guide roll device comprises a first guide roll mechanism and a secondguide roll mechanism, and the first guide roll mechanism and the second guide roll mechanism are arranged at the upper side and the lower side of a charge direction. The transversal-vertical slittingmachine for the pearl wool further comprises a charge induction mechanism arranged on the rack. The transversal-vertical slitting machine for the pearl wool is conducive to increasing the cutting accuracy for the pearl wool, reducing the cutting deviation, ensuring more accurate dimensions of the cut pearl wool, and increasing the cutting efficiency.

Owner:广州千宝机械实业有限公司

Stationary phase radio frequency cable shielding layer cutting device

ActiveCN103441457ASimple structureReasonable structureLine/current collector detailsApparatus for removing/armouring cablesStructural engineeringRadio frequency

The invention discloses a stationary phase radio frequency cable shielding layer cutting device which comprises a clamping module, a feeding module, a transmission support module, and a power module. The clamping module comprises a left clamping block, a right clamping block, a double-direction screw rod, and a rail groove. The bottom of the left clamping block and the bottom of the right clamping block are arranged in the rail groove. The double-direction screw rod vertically penetrates through the bottom of the left clamping block and the bottom of the right clamping block. The top of the double-direction screw rod penetrates through the rail groove and abuts against the inside of a baffle of the rail groove. The feeding module comprises a feeding screw rod, a sliding block, and a feeding rail groove. The sliding block is fixed with the bottom of the rail groove of the clamping module. The feeding screw rod vertically penetrates through the sliding block with inner threads. The top of the feeding screw rod penetrates through the rail groove, and the two ends of the top of the feeding screw rod abut against the inside of a baffle of the feeding rail groove. The feeding screw rod rotates to drive the sliding block to drive the clamping module to be in transverse forward or backward linear motion. In the utilization process, the stationary phase radio frequency cable shielding layer cutting device can ensure the straightness of the cutting section of a cable and ensure cutting accuracy.

Owner:CHENGDU SIWI HIGH TECH IND GARDEN

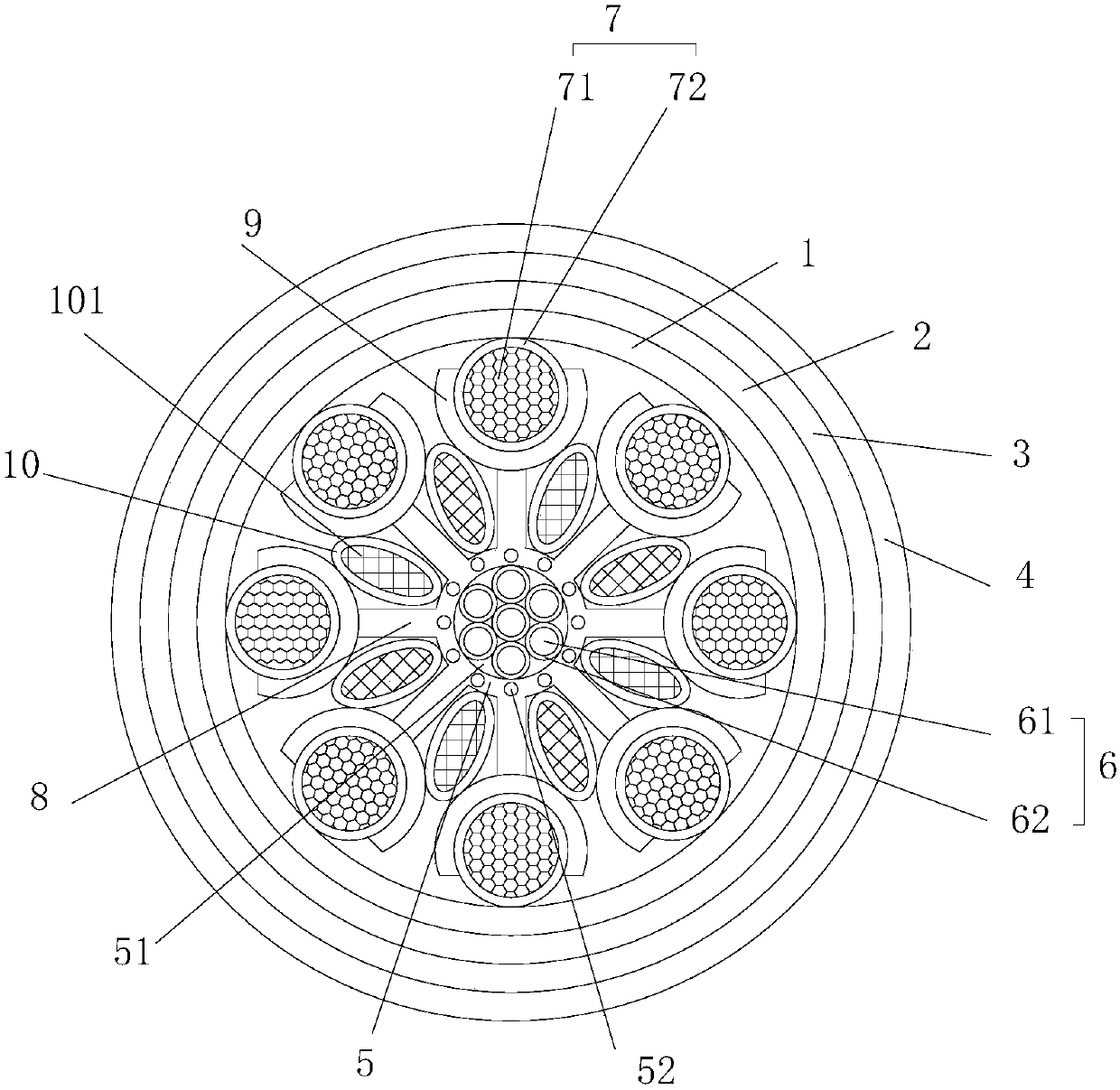

Elastic anti-bending control cable

InactiveCN107731385AGuaranteed tightnessGuaranteed to be straightInsulated cablesInsulated conductorsPower flowCopper wire

The invention provides an elastic anti-bending control cable, which comprises a cable core, a flame-retardant band wrapping layer, an inner sheath, a tinned copper wire braided shielding layer and anouter sheath, wherein the flame-retardant band wrapping layer, the inner sheath, the tinned copper wire braided shielding layer and the outer sheath are wrapped outside the cable core in sequence. A center support pipe is peripherally provided with a plurality of rigid supports distributed in the radial direction of a cable; the end, away from the center support pipe, of each of the plurality of rigid supports is provided an elastic support member; a plurality of external control cores are arranged in the plurality of elastic support members respectively; a center control core is arranged in the center support pipe; and the inner sides of the plurality of external control cores are abutted against the inner circle surfaces of the plurality of elastic support members and the outer sides ofthe plurality of external control cores are abutted against the flame-retardant band wrapping layer respectively, thereby ensuring tightness of the control cable. When the cable is bent due to external force, the elastic support members and a plurality of elastic tubes deform to achieve a buffer effect for bending of the control cable; and when the bending force fades away, the elastic support members and the plurality of elastic tubes recover under the resilience actions thereof, thereby ensuring that the whole cable is smooth and straight, and not influencing current or signal transmission quality.

Owner:JINYUAN ELECTRIC GRP

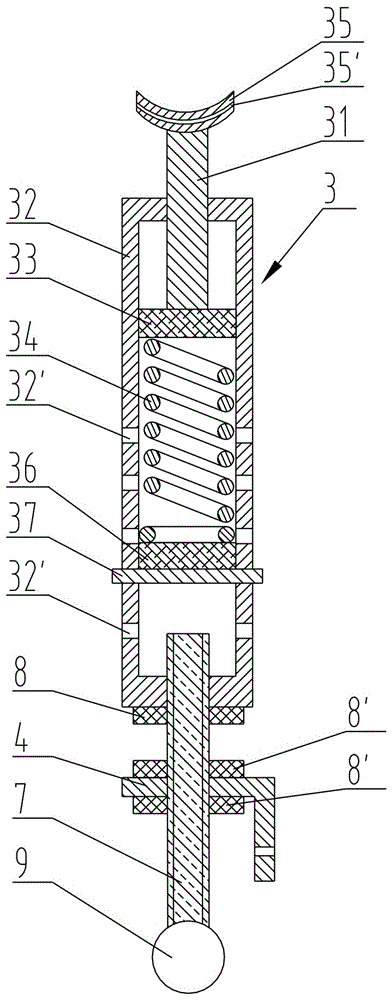

Lumbar vertebra support device

The invention provides a lumbar vertebra support device. The lumbar vertebra support device comprises a waist support belt, axilla stabilizing belt assemblies and two sets of same expansion and contraction devices, wherein each set of expansion and contraction device comprises a piston rod, a cylinder barrel, a piston and expansion and contraction springs positioned in the cylinder barrel, the top of each piston rod extends out of each corresponding cylinder barrel and is provided with an axilla support, the bottom of the piston rod is fixed to the upper end surface of the piston, and the top ends of the expansion and contraction springs push against the lower end surface of the piston; the cylinder barrels of the two sets of expansion and contraction devices are respectively connected to the waist support belt, and the axilla supports are connected with the axilla stabilizing belt assemblies. The lumbar vertebra support device can be used for correcting the sitting position of the human body, so that the diminution of vision caused by the too close distance between the eyes and the observed object is avoided, meanwhile, the extrusion from the gravity of the human upper body to the lumbar vertebra is alleviated, so that the stress applied to the lumbar vertebra of the lumbar vertebra patient is alleviated, and the lumbar vertebra support device has the adjuvant therapy and health effects for the lumbar vertebra patient.

Owner:刘茂生

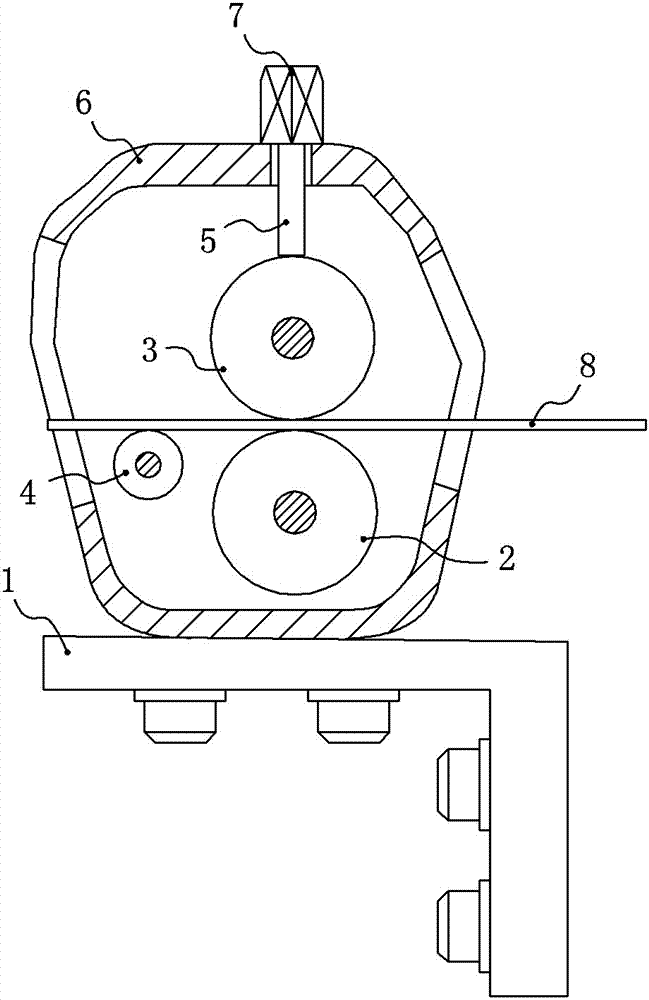

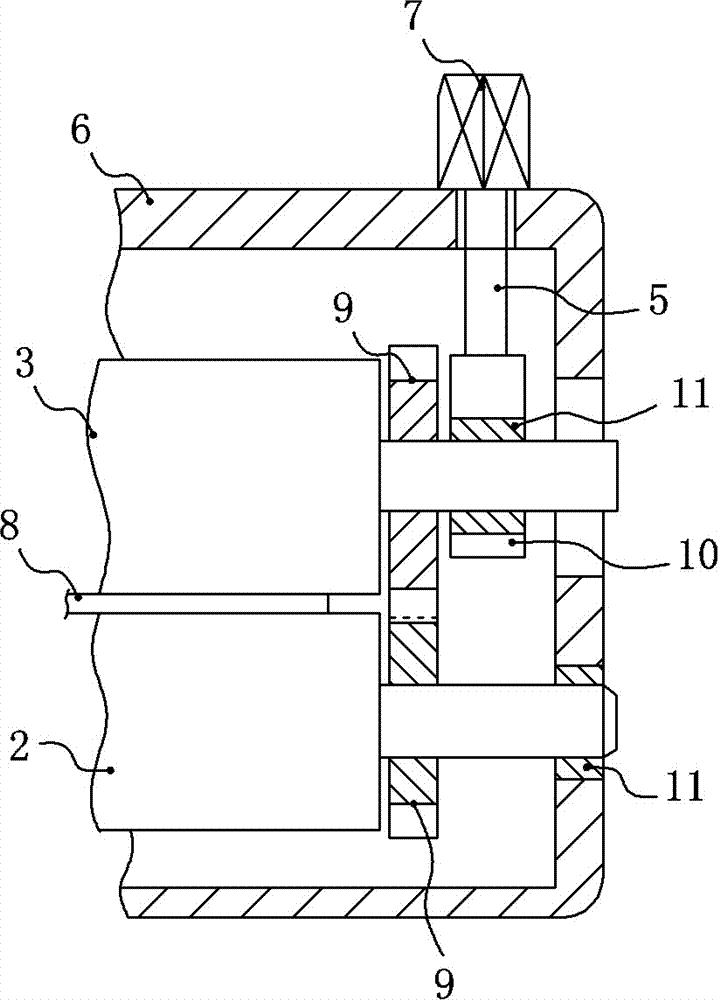

Roller synchronous feeding device

InactiveCN104226839AGuaranteed to be straightMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention belongs to the field of feeding of workpieces related to stroke of dies or tools, and particularly relates to a roller synchronous feeding device. The device comprises a machine frame, a shell, a driving roller and a driven roller. The shell is arranged on the machine frame, the driving roller is driven by a motor, and the two ends of the driving roller are connected with the shell through bearings. The roller synchronous feeding device further comprises adjusting mechanisms, each adjusting mechanism comprises an adjusting rod, an adjusting nut and an adjusting base, the two sides of the driven roller are respectively provided with one adjusting mechanism, the two sides of the driven roller are connected with the adjusting bases of the adjusting mechanisms through bearings, the adjusting rods are connected with the adjusting bases, and ascending and descending of the adjusting bases are controlled through matching of the adjusting nuts; the driving roller and the driven roller are respectively provided with a gear, and the gears are meshed. In the roller synchronous feeding device, stress on the upper side of a conveyed plate and stress on the lower side of the conveyed plate are approximately equal, so that it is guaranteed that the conveyed plate is flat and straight.

Owner:重庆腾田科技发展有限公司

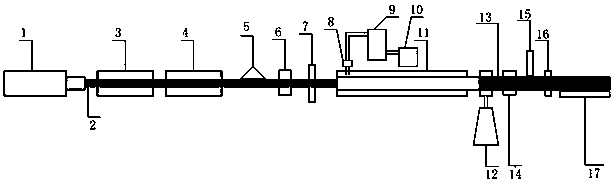

One-step forming equipment and process of polyolefin polyurethane thermal insulation composite tube

PendingCN109551776AImprove adhesionGuaranteed to be straightTubular articlesPolyolefinThermal insulation

The invention discloses one-step forming equipment of a polyolefin polyurethane thermal insulation composite tube. The equipment comprises a polyolefin inner tube extruding machine, a vacuum sizing box, a spraying cooling box, a blowing dryer, a first traction machine, a plasma processor, a foaming and shaping device, a coating extruder and a second traction machine, and the foaming and shaping device comprises a foaming and shaping mold, a polyurethane high-pressure foaming machine and a mold temperature controller. The invention further discloses a one-step forming process of the polyolefinpolyurethane thermal insulation composite tube. Compared with an existing two-step method, the tube length can be customized, the production efficiency is improved, and the product quality is guaranteed; and compared with an existing one-step method, bonding force between an inner tube and a polyurethane heat preservation layer is improved, the axial shearing strength meets the standard requirements, and the product quality is stable and reliable; and the polyurethane heat preservation layer and an outer protection layer are in direct contact, so that the bonding force is guaranteed, the two traction machines are arranged on the upstream and the downstream correspondingly, and differential traction of the two traction machines is carried out, so that the straightness and centering of the inner tube are ensured.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Production method of high straightness super-strength steel

The invention discloses a production method of high straightness super-strength steel. A steel production process route comprises the following steps: pretreatment of molten iron, converter smelting,LF external refining, VD vacuum treatment, continuous casting, heating, rolling, straightening, quenching, tempering, finishing, performance inspection, and flaw detection. The high straightness super-strength steel is characterized by being prepared from the following chemical components in percentage: 0.15 to 0.20 percent of C, 0.15 to 0.35 percent of Si, 1.0 to 1.50 percent of Mn, smaller thanor equal to 0.012 percent of P, smaller than or equal to 0.003 percent of S, 0.010 to 0.030 percent of Nb, 0.015 to 0.040 percent of V, 0.010 to 0.025 percent of Ti, 0.020 to 0.045 percent of Als, 0.040 to 0.60 percent of Cr, 0.10 to 0.30 percent of Mo, 0.20 to 0.50 percent of Ni, 0.0008 to 0.0025 percent of B, smaller than or equal to 0.60 percent of CEV and the balance of Fe and inevitable impurities. The super-strength steel has the characteristics that the production thickness is 6 to 25 mm, the width is 1,500 to 3,800 mm, the yield strength of a steel plate is greater than or equal to 1,100 MPa, the tensile strength is greater than or equal to 1,200 MPa, the elongation percentage is greater than or equal to 11 percent, the impact work at -40 DEG C below zero is greater than or equal to 50 J and the straightness in any direction of the steel plate is smaller than or equal to 3 mm / m.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com