Inbuilt method for distributed type sensing cable in foundation pile

A sensor optical cable, distributed technology, applied in the direction of basic structure test, basic structure engineering, construction, etc., can solve the problems of protection and easy damage, and achieve the effect of improving survival rate, accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

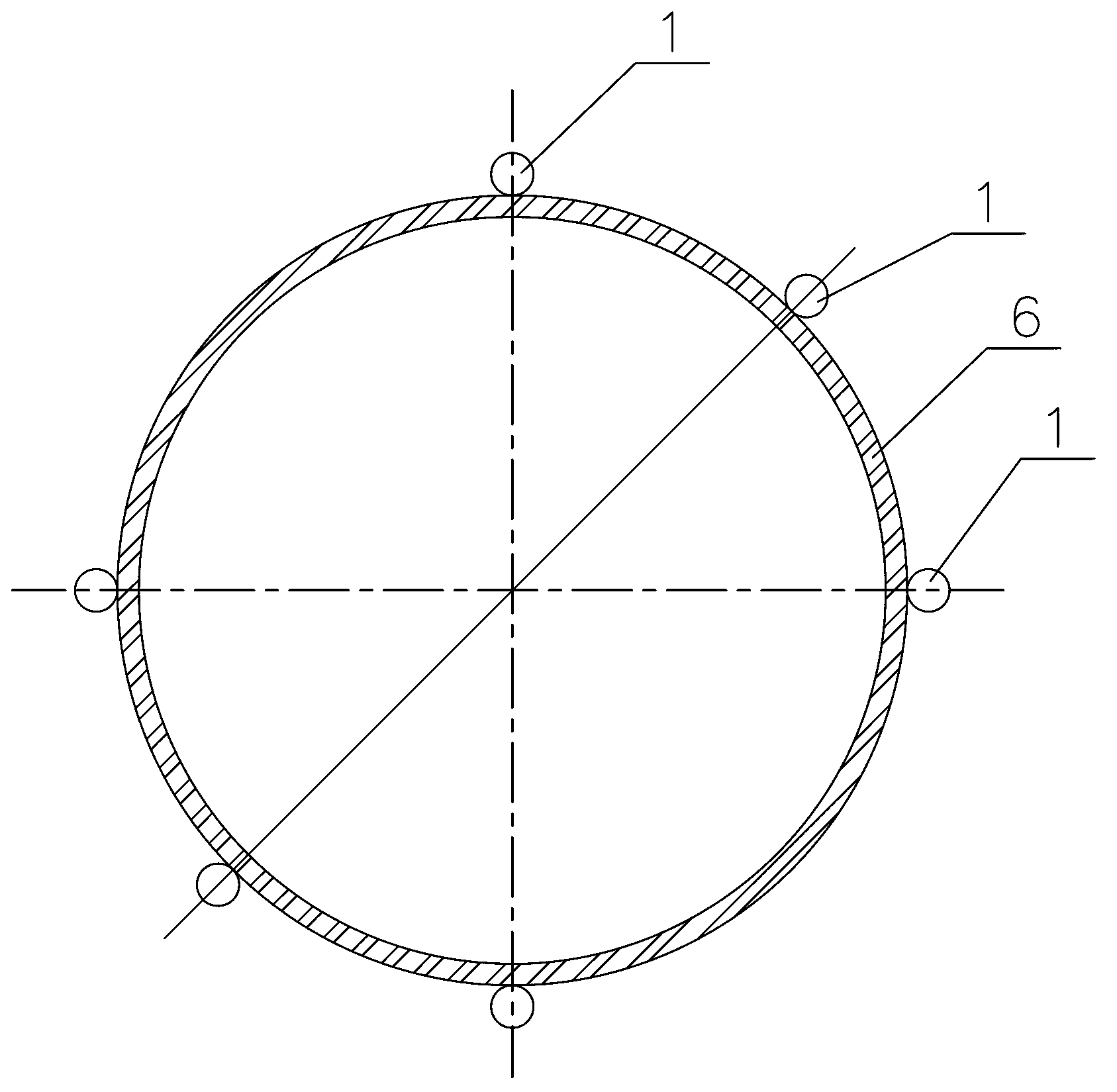

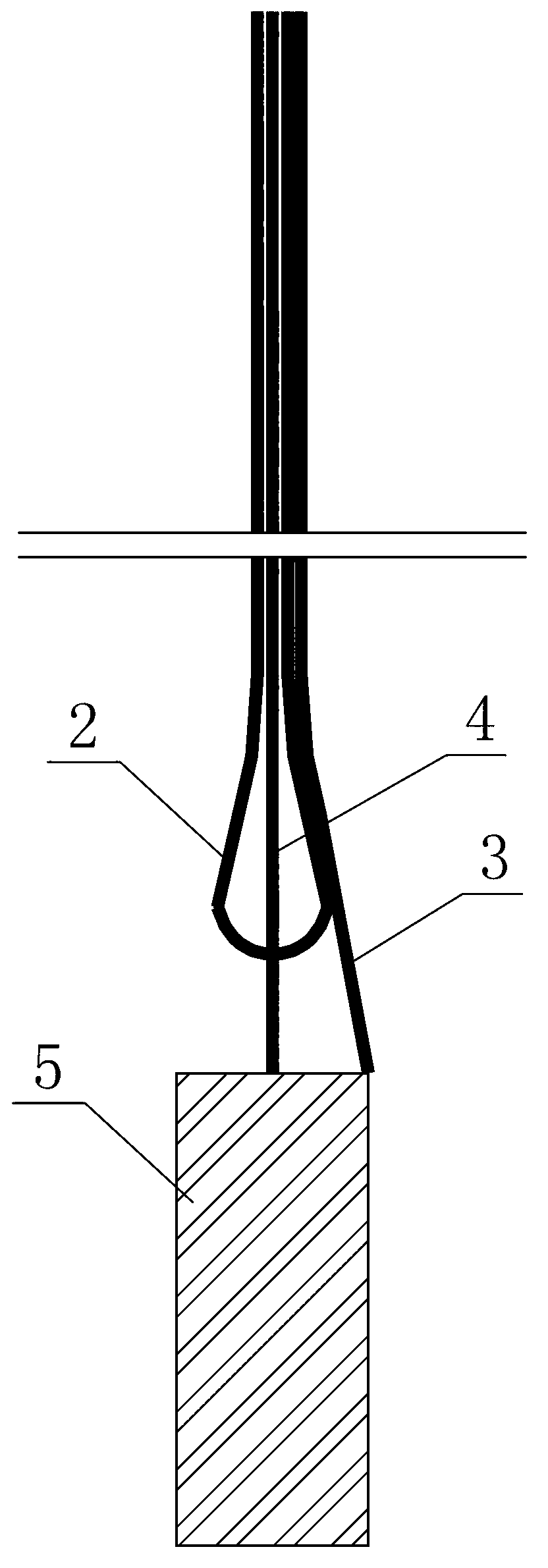

[0032] Embodiment 1: as figure 1 As shown, the foundation pile in this embodiment is a steel pipe pile 6, that is, the embedding process of the distributed sensing optical cable in the steel pipe pile, and the steps are as follows:

[0033] 1.1. Weld a group of pre-embedded steel pipes 1 parallel to its axis and arranged symmetrically with the axis as the center line on the outer wall or inner wall of the steel pipe pile 6, and ensure that both ends of each pre-embedded steel pipe 1 protrude from each section of steel pipe Both ends of the pipe pile 6; in this example, the outer diameter of the embedded steel pipe 1 is 50-110mm.

[0034] 1.2. Carry out the steel pipe pile 6 driving construction. During the construction process, set a bottom cover at the bottom of the pre-embedded steel pipe 1 at the bottom to prevent soil from entering the pre-embedded steel pipe 1 during the construction process; if the pile needs to be connected during the construction process , align the p...

Embodiment 2

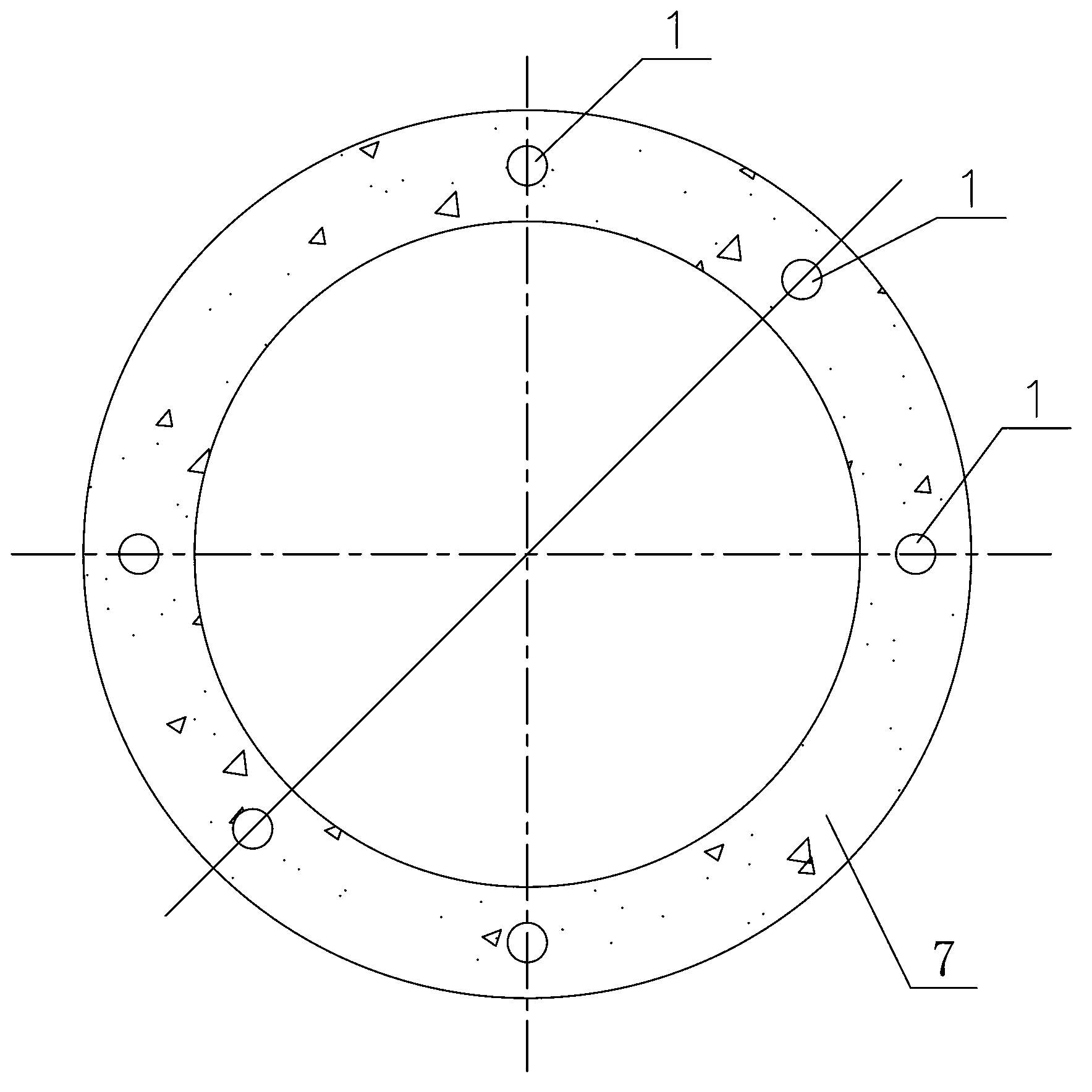

[0040] Embodiment 2: as image 3 As shown, the foundation pile in this embodiment is a reinforced concrete prefabricated pile 7 (the cross section is circular, that is, the embedding process of the distributed sensing optical cable in the reinforced concrete prefabricated pile, the steps are as follows:

[0041]2.1. When making the reinforcement cage of the reinforced concrete prefabricated pile 7, the pre-embedded steel pipe 1 is bound on the reinforcement cage, and then the construction of the reinforced concrete prefabricated pile 7 is carried out according to the conventional method, so that the pre-embedded steel pipe 1 is pre-embedded in the reinforced concrete prefabricated At the same time, ensure that the two ends of each pre-embedded steel pipe 1 extend out of the two ends of each section of reinforced concrete prefabricated pile 7, and each pre-embedded steel pipe 1 is parallel to the axis of reinforced concrete prefabricated pile 7, and take this axis as Center lin...

Embodiment 3

[0044] Embodiment 3: as Figure 4 As shown, this embodiment is basically the same as Embodiment 2, except that the cross section of the reinforced concrete prefabricated pile 7 of this embodiment is square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com