Stationary phase radio frequency cable shielding layer cutting device

A technology for radio frequency cables and cutting devices, which is applied to the equipment, circuits, electrical components and other directions of dismantling/armoring cables, can solve the problem that the manual cutting method is difficult to meet the requirements of the cutting section, and achieves a simple structure, the cutting section is satisfactory, and the guarantee The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

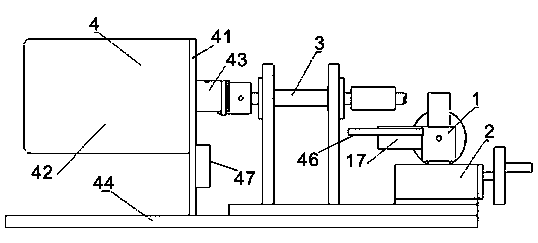

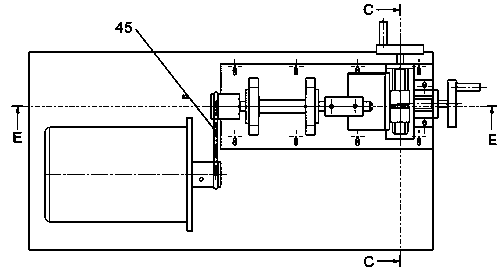

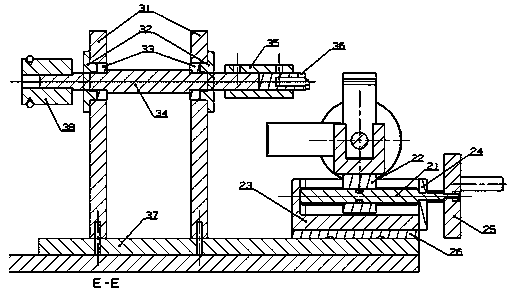

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a phase-stable RF cable shield cutting device includes a clamping module 1 , a feeding module 2 , a transmission bracket module 3 and a power module 4 . Its specific structure is as follows:

[0032] The clamping module 1 comprises a left clamping block 11, a right clamping block 12, a two-way screw rod 13, and a track groove 14. The bottoms of the left clamping block 11 and the right clamping block 12 are placed in the track groove 14, and the two-way spiral Rod 13 vertically passes through the bottom of left clamping block 11 and right clamping block 12, and the top of two-way screw rod 13 passes track groove 14, ends in track groove baffle plate 15; Described two-way screw rod 13 passes track The top of the groove 14 is provided with a clamping rotating hand wheel 16 . Bores are opened at the bottom of the left clamping block 11 and the right clamping block 12, and threads are installed in the holes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com