Curved-surface screen protector and coating and laminating method and forming method thereof

A molding method and protective film technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of poor product durability, inaccurate alignment, high viscosity of acrylic adhesive, etc., and achieve improved lamination Stability, safe and simple operation, good silicone fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

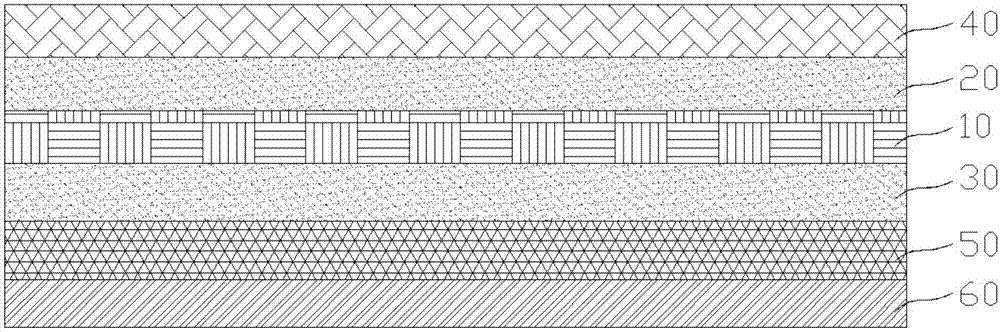

[0080] A curved surface protective film, which is prepared according to the following method:

[0081] 1. Coating and lamination

[0082] The first coating step: take a PET substrate layer with a thickness of 125 μm, and apply polyurethane acrylic resin with a thickness of 18 μm on the top and bottom surfaces of the PET substrate by roller coating, and the coating roller is a ceramic helical tooth pattern Roller, the speed of the coating roller is 40m / min, and the feeding speed of the PET substrate is 30m / min; after the polyurethane acrylic resin is cured, the first hardened layer and the second hardened layer are formed; combined with oven drying and ultraviolet light irradiation successively Two ways of curing treatment, the temperature of the oven is 50-100 ℃, the drying time is 2-4min; the power of the ultraviolet lamp is 80-100W / cm, and the irradiation time is 3-5s;

[0083] The first laminating step: take the first PET release film of acrylic glue type with a thickness ...

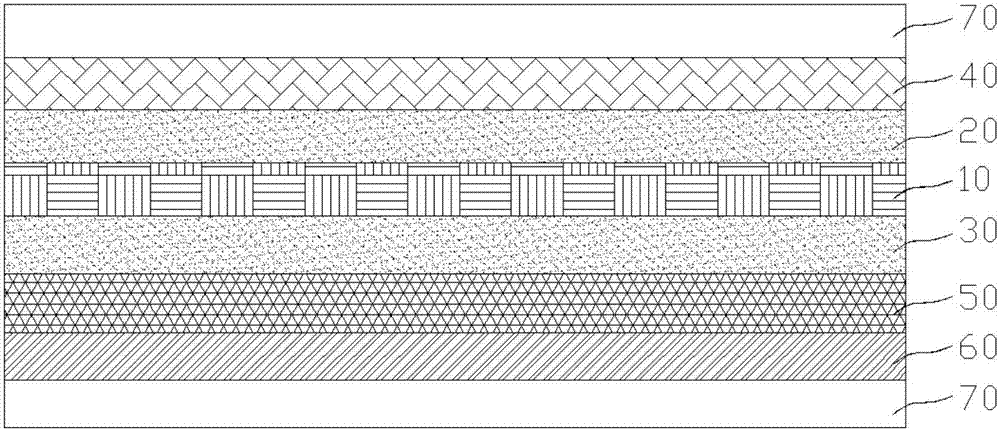

Embodiment 2

[0096] The difference between Example 2 and Example 1 is: the thickness of the first PET release film is 40 μm; the thickness of the PET substrate is 188 μm; the thickness of the first hardened layer is 15 μm, and the thickness of the second hardened layer is 20 μm; The thickness of the fluorinated silicone release layer is 60 μm;

[0097] In the second lamination step, the operation of aging treatment is as follows: standing at 50° C. for 24 hours.

[0098] Others are the same as in Example 1.

Embodiment 3

[0100] The difference between embodiment 3 and embodiment 1 is: in the first coating step, the rotating speed of coating roller is 20m / min, and the feeding speed of PET substrate is 3m / min;

[0101] In the second coating step, the high-viscosity silica gel is cured at 120°C for 150s to form a silica gel layer;

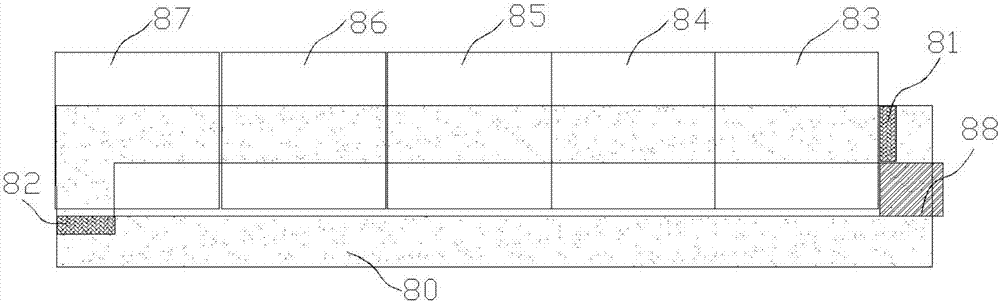

[0102] In the mold heating step, the temperature of the first heating box is 140°C, the temperature of the second heating box is 170°C, and the temperature of the third heating box is 220°C; the storage time of the graphite mold in the first heating box is 15min. The storage time in the second incubator and the third incubator is 5min;

[0103] In the step of pressing down the mold, the pressing speed is 500cm / min, and the pressing time is 2min;

[0104] In the step of cooling the mould, the down-pressing cylinder keeps the pressed state and enters the freezer together with the mold, and the temperature of the freezer is 0° C. for 10 minutes.

[0105] Others are the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com