One-step forming equipment and process of polyolefin polyurethane thermal insulation composite tube

A thermal insulation compounding and forming equipment technology, which is applied in the field of polyolefin polyurethane thermal insulation composite pipe forming, can solve the problem of insufficient bonding force between the working tube and the polyurethane thermal Moderate problems, to achieve the effect of stable and reliable product quality, satisfactory axial shear strength, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

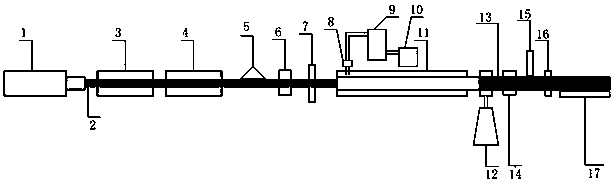

[0025] Such as figure 1 As shown, the polyolefin polyurethane thermal insulation composite pipe one-step molding equipment of the present invention includes a polyolefin inner pipe extruder 1, a vacuum sizing box 3, a spray box 4, and a blast dryer 5 arranged in sequence from left to right , the first haul-off machine 6, plasma processor 7, foaming and setting device, coating extruder 12, the second haul-off machine 14, infrared thickness gauge 15, cutting machine 16 and material turning platform 17; The foaming and setting The device includes a foaming and setting mold 11, a polyurethane high-pressure foaming machine 9 and a mold temperature controller 10; the mold temperature controller 10 is connected with the polyurethane high-pressure foaming machine 9, and the polyurethane high-pressure foaming machine 9 is provided with a high-pressure mixing gun Head 8, the high-pressure mixing gun head 8 is connected with the foaming shaping mold 11.

[0026] The molding equipment of...

Embodiment 2

[0036] The one-step molding process of polyolefin polyurethane thermal insulation composite pipe includes the following steps:

[0037] 1) Add the polyolefin raw material to the polyolefin inner tube extruder 1, and the polyolefin inner tube extruder 1 extrudes the inner tube 2, and the inner tube 2 is pulled downstream by two tractors before and after, and the first tractor 6 The traction speed is S, and the traction speed of the second tractor 14 is S+0.05m / min to ensure that the inner pipe 2 is in a straightened state;

[0038] 2) The inner pipe 2 is successively sized through the vacuum sizing box 3, cooled by the spray cooling box 4 and dried by the blast dryer 5;

[0039] 3) Plasma treatment of the inner tube 2 by the plasma processor 7, so that the outer surface of the inner tube 2 changes from non-polar to polar, and enhances the bonding force between the inner tube 2 and polyurethane;

[0040] 4) Adjust the mold temperature controller 10 to the set temperature, mix p...

Embodiment 3

[0045]To produce pipes with an outer diameter of the inner pipe 2 of dn32, the production speed of the inner pipe 2 is 10-12m / min, and the extrusion rate of the polyolefin inner pipe extruder 1 is 2.78-3.34kg / min. The inner pipe 2 reaches the plasma processor 7 through the vacuum sizing box 3, the spray cooling box 4, the blast dryer 5 and the first tractor 6. Foaming and setting mold 11, the temperature of mold temperature controller 10 is adjusted to 23°C, and the pulling speed of the second downstream pulling machine 14 is adjusted to 10.05-12.05m / min to ensure that the inner tube 2 is in a straightened state, and then the polyurethane A material (combined Polyether) and material B (isocyanate and polyol) are mixed and injected into the pouring die head of the foaming shaping mold 11 through the high-pressure mixing gun head 8, and the inner tube 2 enters the shaping module of the foaming shaping mold 11 to form a 30mm insulation layer, polyurethane foam The pouring amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com