A processing technology for producing special-shaped cross-section brass strips

A processing technology and special-shaped section technology, applied in the field of special-shaped cross-section brass strip manufacturing technology, can solve the problems of poor surface quality, long idle time of equipment, low material utilization rate, etc. The effect of packaging and product surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

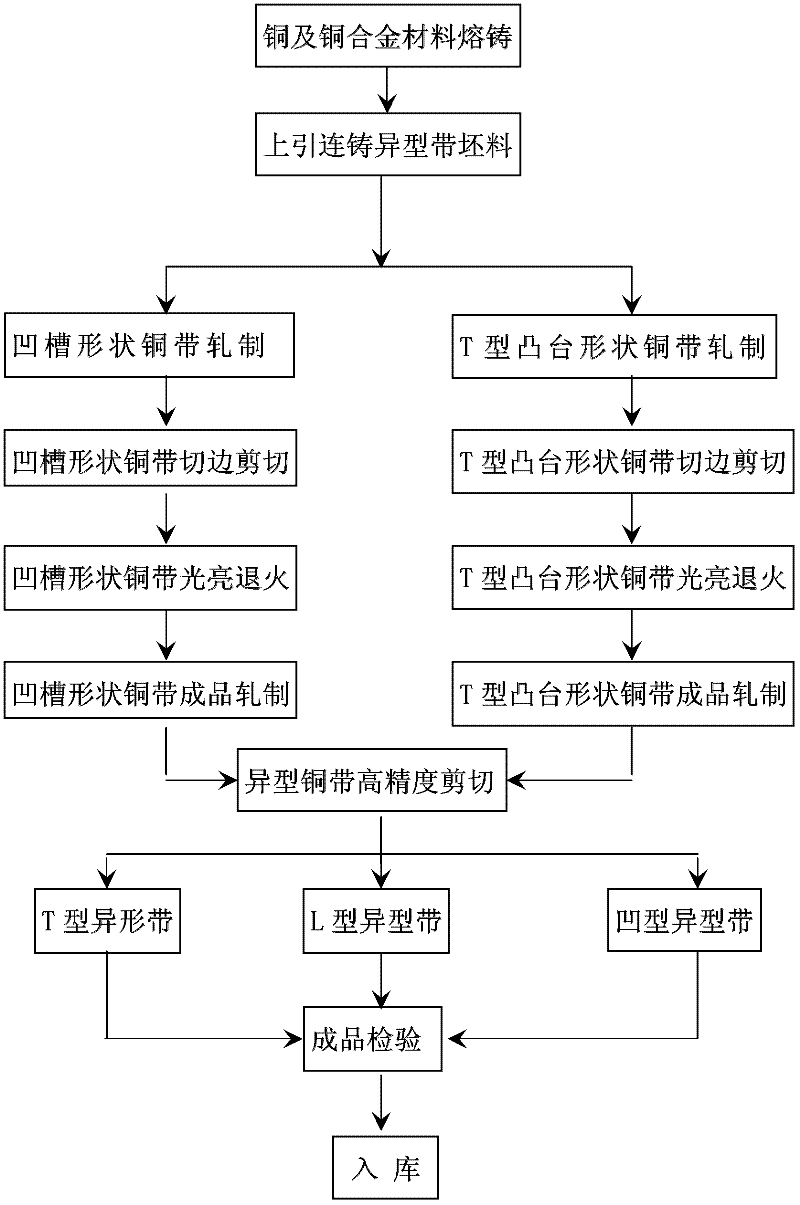

Method used

Image

Examples

Embodiment 1

[0033] It is required that the material of the high-precision special-shaped copper strip is H65, the weight of each roll is ≥120Kg, and the section of the copper strip is in the shape of a middle groove. See the appendix for its cross-sectional shape requirements Figure 4 Medium U type, the size requirements are T=1.46±0.02, t=0.6±0.02, C=13.6±0.05, W=61.5±0.1; the physical properties of the product are required to be state (Y), surface hardness HV=120--160 , the tensile strength (Rm / MPa) is 410--540Mpa, and the elongation after breaking (A11.3 / %) reaches 13%; its production process is: melting---upward continuous casting-high precision rolling-high precision Shearing-bright annealing-product rolling-high-precision finished product shearing-inspection-finished product storage; in the finished product rolling process or the final high-precision shearing process, the material is divided into the required reel weight, 100-300Kg / reel.

[0034] 1. Smelting: Strictly follow the c...

Embodiment 2

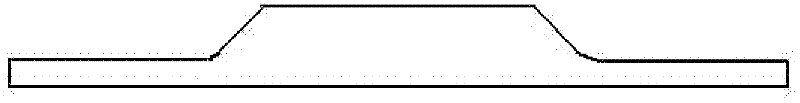

[0044] The material of high-precision special-shaped copper strip is required to be H62, the weight of each roll is ≥120Kg, and the cross-section of the copper strip is as follows figure 2 T-Boss shape shown. Its production process is: smelting --- upward continuous casting special-shaped section billet-high-precision rolling-high-precision shearing-bright annealing-product rolling-high-precision finished product shearing-inspection-finished product storage; during processing According to the actual situation, the high-precision shearing before bright annealing can be omitted, and the intermediate material is divided into the required reel weight in the finished product rolling process or the final high-precision shearing process, 100-500Kg / reel.

[0045] 1. Melting: Strictly follow the chemical composition requirements of H62. Adding materials: Cu60.5-63.5wt% Zn36.5-39.5wt%; PBi Sb Pb and other impurities should be less than 0.5wt%; use medium frequency induction melting fur...

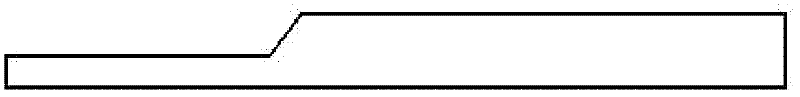

Embodiment 3

[0055] It is required that the material of high-precision special-shaped copper strip is brass, the weight of each roll is ≥120Kg, and the cross-section of the copper strip is as follows image 3 The L-shaped shaped copper strip shown. Its production process is: smelting---upward continuous casting-high-precision rolling-high-precision shearing-bright annealing-product rolling-high-precision finished product shearing-inspection-finished product storage; In some cases, the high-precision shearing before bright annealing is omitted, and the intermediate material is divided into the required reel weight in the finished product rolling process or the final high-precision shearing process, 100-500Kg / reel.

[0056] As mentioned above in the process of examples 1 and 2, the corresponding copper alloy raw materials are selected, and through smelting, upward continuous casting, groove-shaped / T-shaped special-shaped copper blanks, high-precision rolling, and high-precision shearing for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com