Method for processing stainless steel wire by utilizing stainless steel plate rim leftover

A technology of stainless steel wire and stainless steel, which is applied in the field of processing stainless steel plate scraps, can solve the problems that the use value of scraps is not fully utilized, investment and return cannot be balanced, and achieve labor cost saving, simple structure, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The method and special equipment for processing stainless steel wire by using the leftover material of stainless steel plate according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

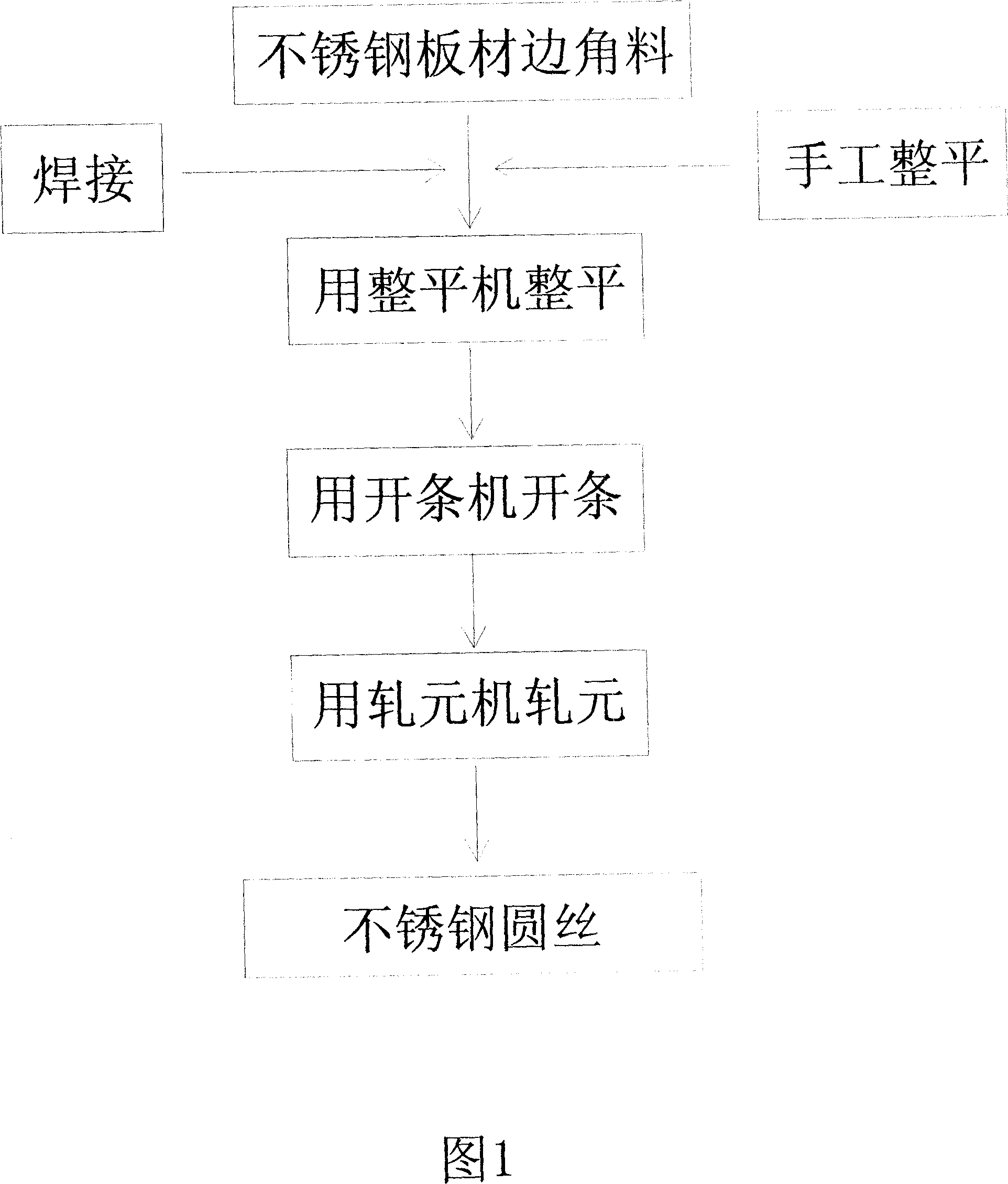

[0049] In order to realize the method that the present invention utilizes the leftover material of stainless steel plate to process stainless steel wire, we have designed three pieces of special equipment of leveling machine, bar opening machine and rolling mill.

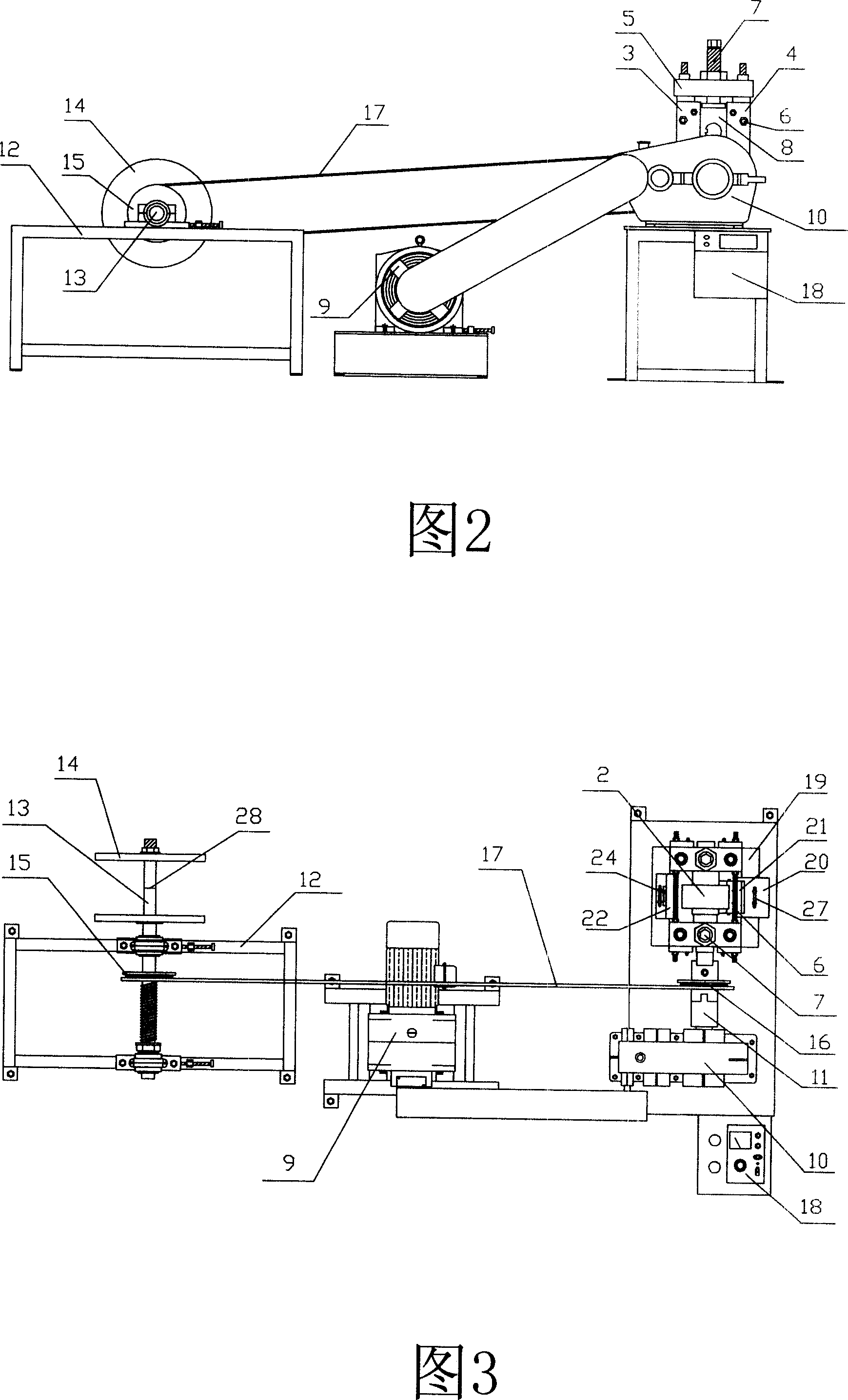

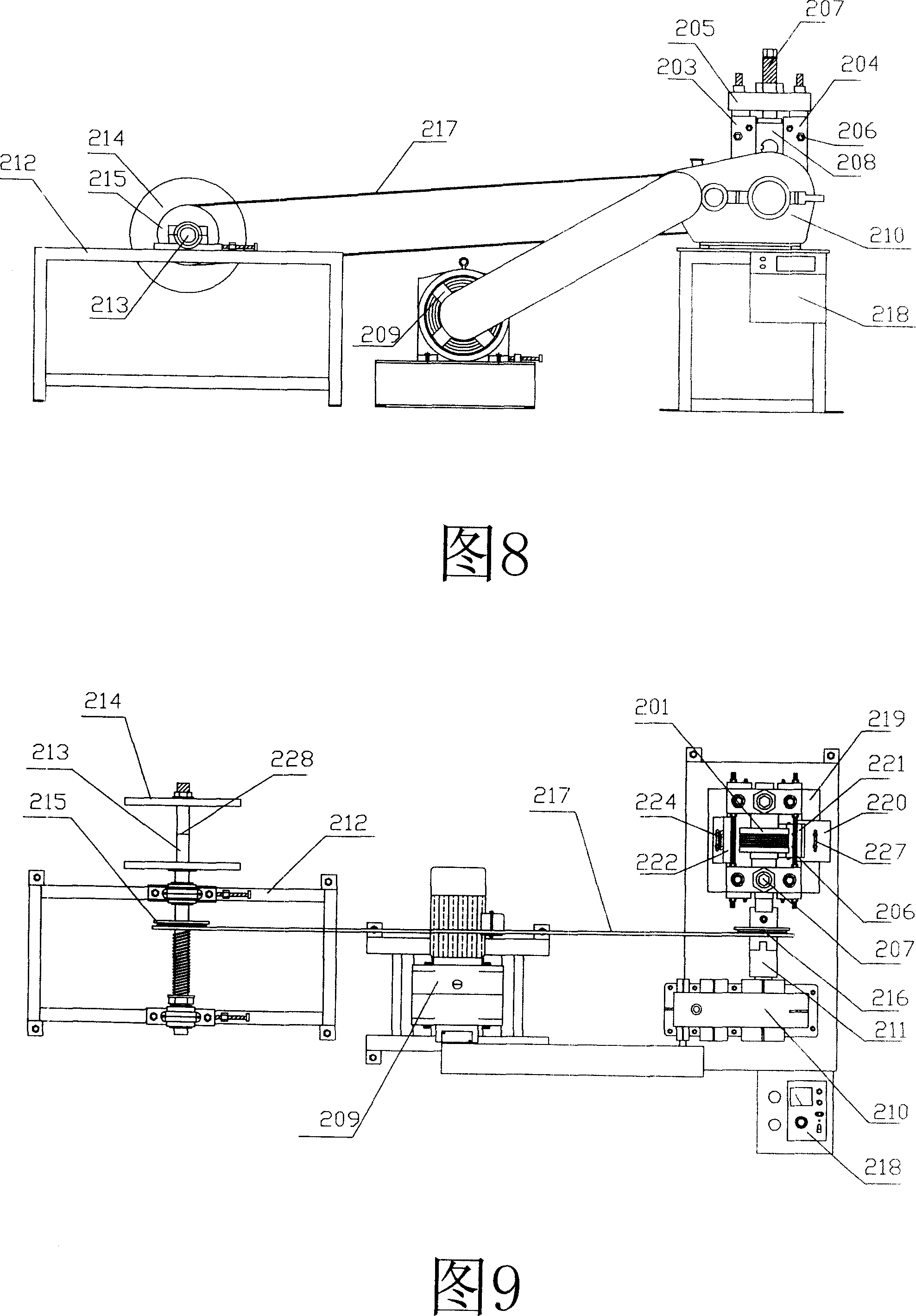

[0050] Figure 2 to Figure 4 show the three views of the stainless steel scrap leveling machine we designed:

[0051] The stainless steel scrap leveling machine comprises leveling dies, feed and discharge clamps (21), (22), speed regulating motor (9), speed reducer (10) and receipt mechanism. The leveling die is a double-drum mechanism, which is composed of a frame and the main and driven rollers (1) and (2) connected to the frame and parallel to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com