Cooler capable of forming flat jet

A cooling device and jet flow technology, applied in the direction of metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of inconsistent cooling effect and defective products of plate materials, so as to avoid casting processing problems, prevent displacement, reduce Effect of device weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

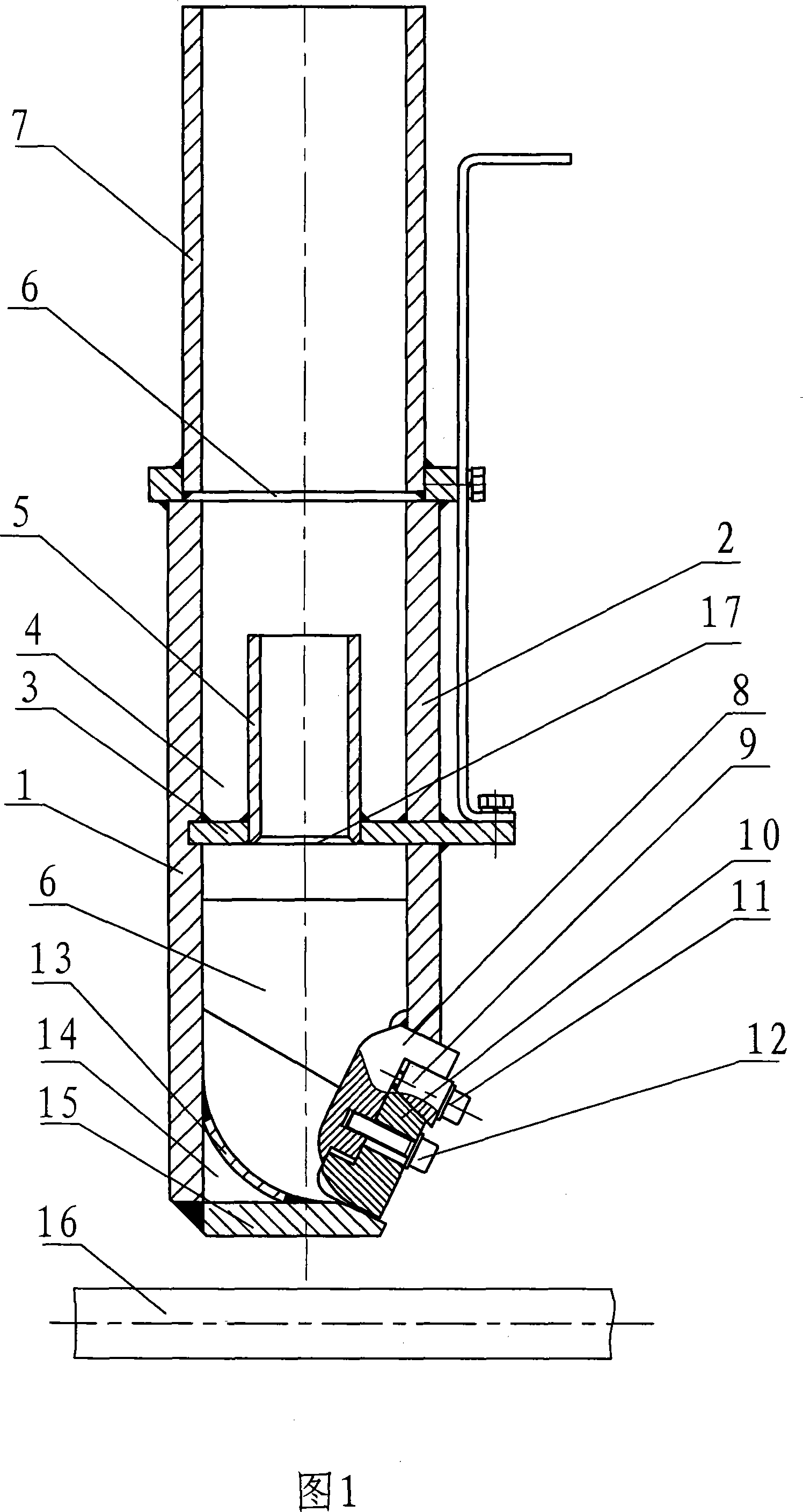

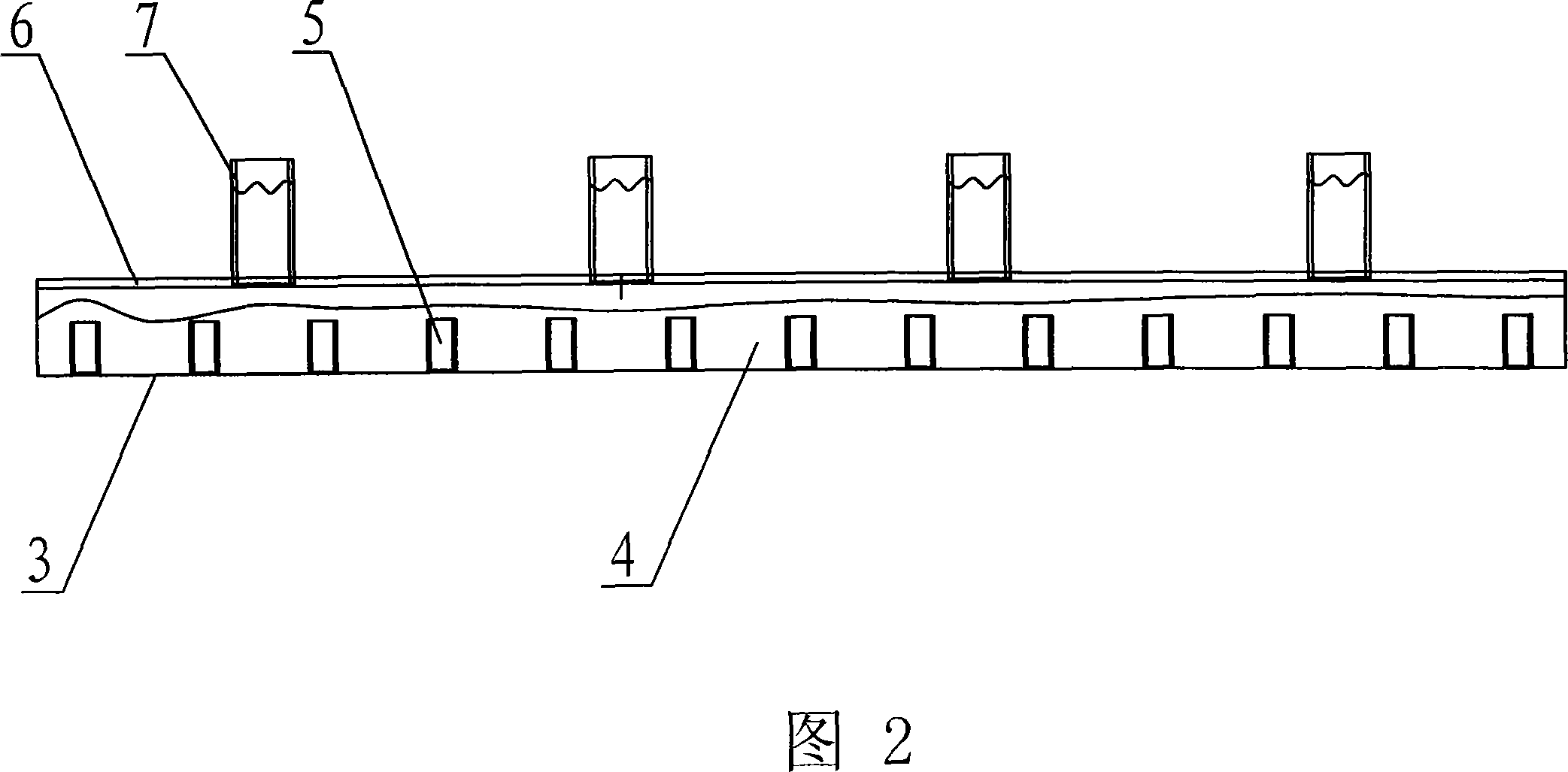

[0008] The cooling device that can form a flat jet flow is wider than the width of the material to be cooled, and is welded by steel plates, as shown in Figure 1: the cooling device is composed of the rear shell 1, the front shell 2, and the rib plate 6, the upper part The input cooling medium interface 7 is connected at a certain distance, and the interface 7 faces the gap between the flow equalizer 5 (the flow equalizer is the abbreviation of the equalizer structure), as shown in Figure 2, which is characterized in that the rear shell 1 and the front shell The clapboard 3 is vertically welded in the body 2, which divides the integrated shell into upper and lower chambers. The clapboard 3 is welded with a plurality of flow equalizers 5 parallel to the shells on both sides at intervals. The flow equalizer 5 is just a cylinder. The base plate 17 has holes, the base plate 17 and the partition plate 3 are in the same plane, and the upper cooling cavity 4 that can make the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com