Method for preparing continuous fiber multiaxial fabric reinforced thermoplastic composite material

A fabric reinforcement and composite board technology, applied in the direction of chemical instruments and methods, flat products, synthetic resin layered products, etc., can solve problems such as difficulty in threading or mending yarn, difference in resin diversion temperature, and difficulty in mold cavity cleaning, etc., to achieve Effects of improving quality, preventing breakage, and securing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

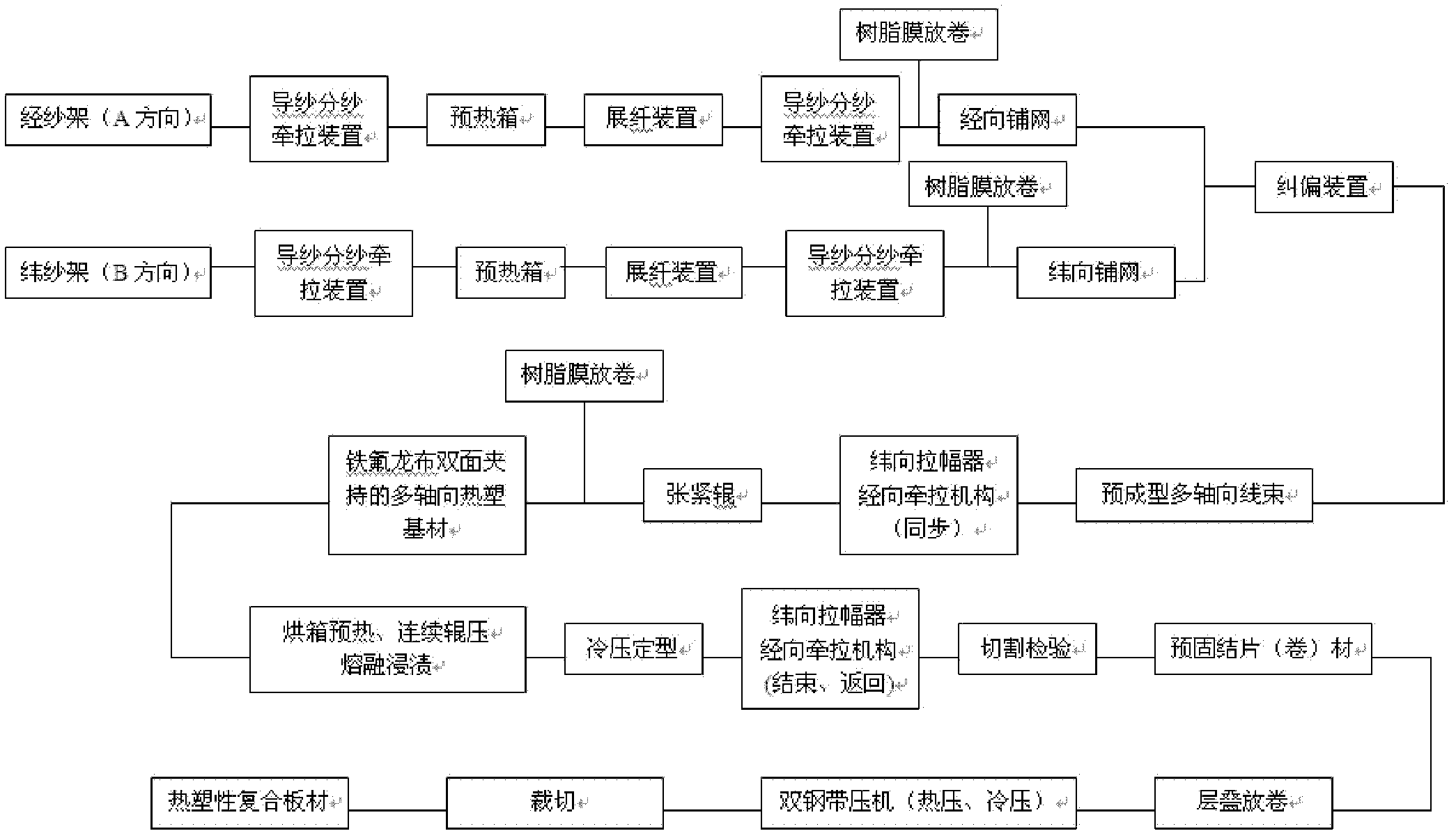

Method used

Image

Examples

Embodiment 1

[0034] The reinforcing material is selected from glass fibers and the thermoplastic resin is selected from polypropylene. Prepare 162Kg of 1100tex glass fiber and 132Kg of PP resin film with an areal density of 100g / m2. The product width is 1250mm, the original width of the single yarn is 4.5mm, and the areal densities of 0° / 90° and ±45° are 131g / m2, 158g / m2, 170g / m2 2 and 170g / m 2 , the widths of each layer of yarn after spreading are 10mm, 8mm, 7.6mm and 7.6mm;

[0035] (1) Draw the yarn in direction A from the creel, pass through the godet roller and the dividing reed in turn, and then control the tension of the yarn through the pulling roller to ensure the stability and parallel arrangement when it is drawn out, and then import it into the oven Preheating in the middle, the preheating temperature range is 200°C, and the yarn in the A direction is spread into a wide, straight and evenly distributed monofilament ribbon-shaped material with a certain width, which is a strai...

Embodiment 2

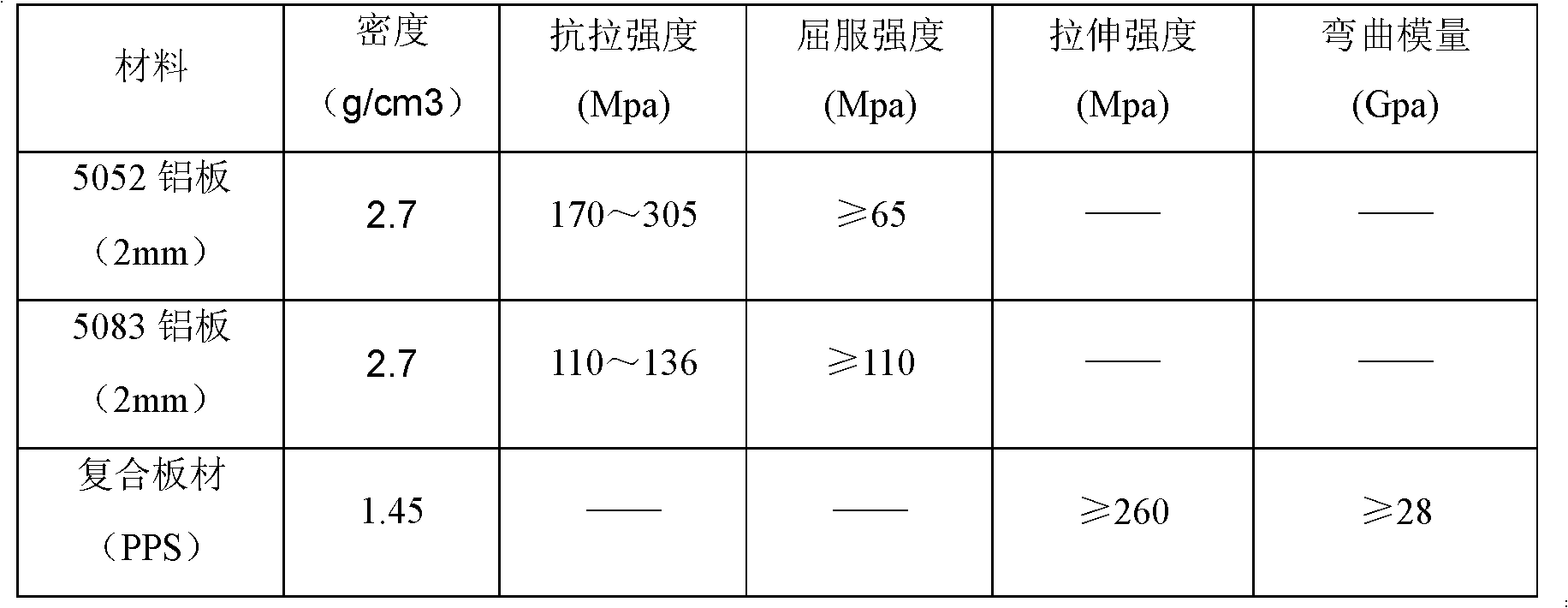

[0047] The reinforcing material is selected from glass fiber, the thermoplastic resin is selected from polyphenylene sulfide, prepare 112Kg of glass fiber of 1100tex and 65Kg of polyester PPS resin film with surface density of 100g / m2, the width is 2450mm, and the original width of single yarn is 4.5mm. The surface density in direction and latitudinal direction is 178g / m respectively 2 and 212g / m 2 , calculated by the process, the warp density and weft density are 3.8 threads / inch and 4.5 threads / inch respectively, and the widths after stretching in the warp and weft directions are 6.8mm and 5.8mm respectively;

[0048] (1) Draw the yarn in direction A from the creel, pass through the godet roller and the dividing reed in turn, and then control the tension of the yarn through the pulling roller to ensure the stability and parallel arrangement of the yarn when it is drawn out, and then import it into the oven Preheating in the middle, the preheating temperature range is 300°C,...

Embodiment 3

[0063] The reinforcing material is selected from glass fiber, and the thermoplastic resin is selected from polyphenylene sulfide. Prepare 800tex glass fiber 100Kg and area density 100g / m 2 The polyester PPS resin film is 50Kg, the width is 1650mm, the original width of single yarn is 4.5mm, and the surface density in warp direction and weft direction is 170g / m respectively 2 and 206g / m 2 , Calculated by the process, the warp density and weft density are 3.2 threads / inch and 4.0 threads / inch, respectively, and the widths after stretching in the warp and weft directions are 6.5mm and 5.5mm, respectively.

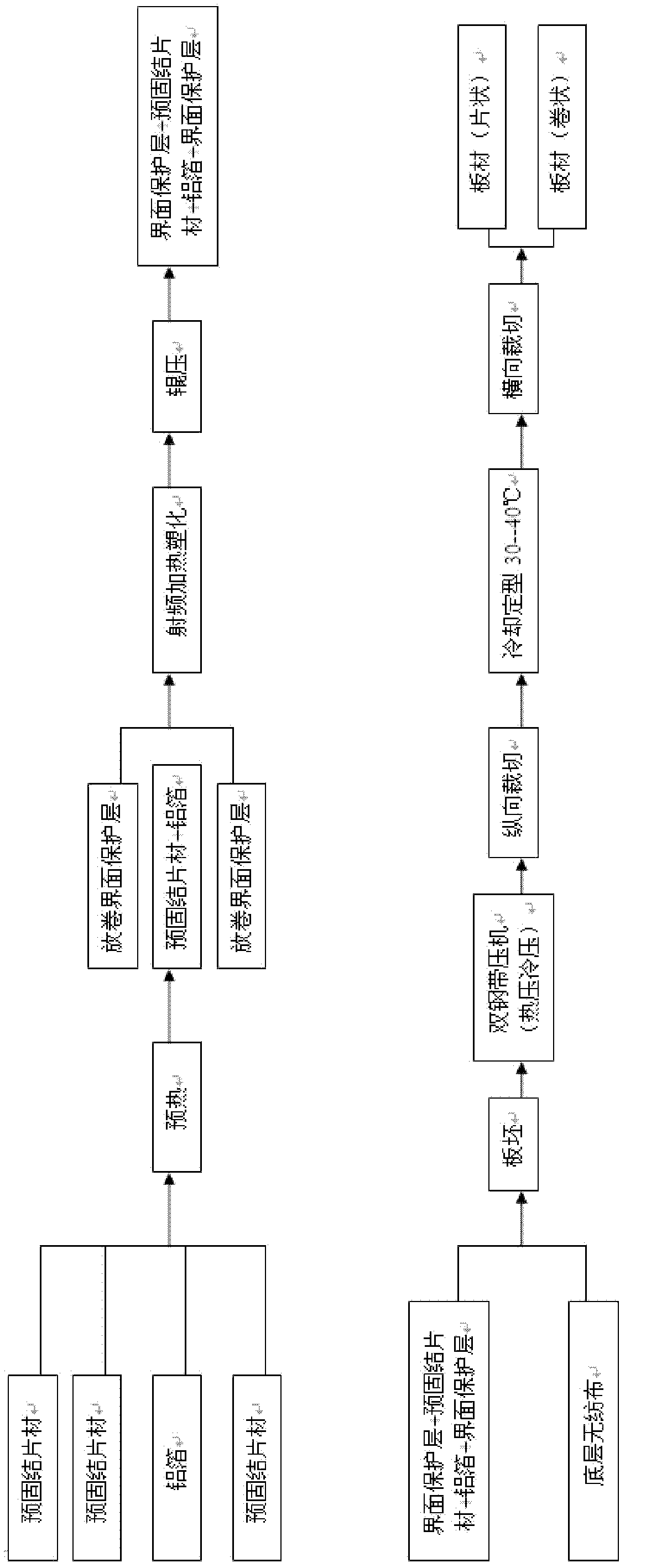

[0064] Four layers of multi-axially reinforced pre-consolidated sheets are compositely laminated to form a composite sheet with a thickness of 2mm; as the material for the upper and lower interfaces of the product in this example, the core structure in the middle of the sheet is selected from aluminum honeycomb coils, (the expansion ratio of Thickness 20mm), prepare a high-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com