Large-scale portal frame

A gantry, large-scale technology, applied in the direction of hoisting equipment braking devices, load suspension components, cranes, etc., can solve the problem of not finding large-scale gantry public information, etc., to achieve smooth movement, labor-saving operation, and enhanced bending resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

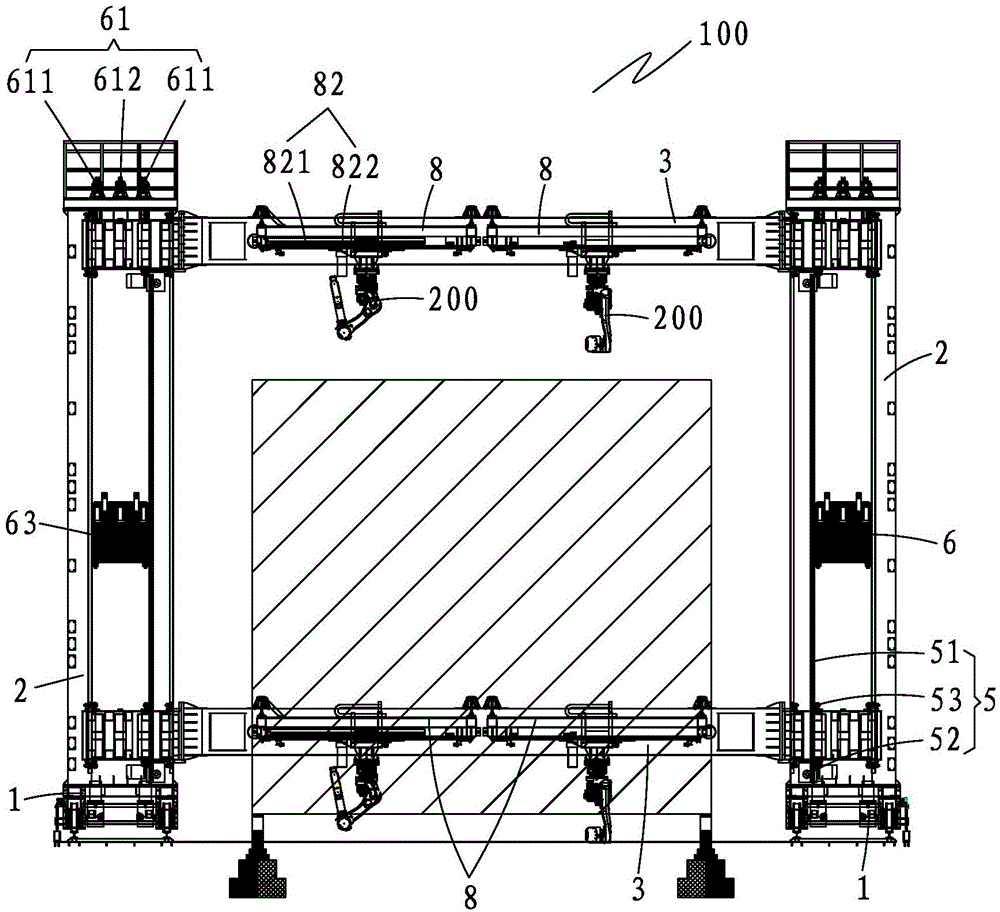

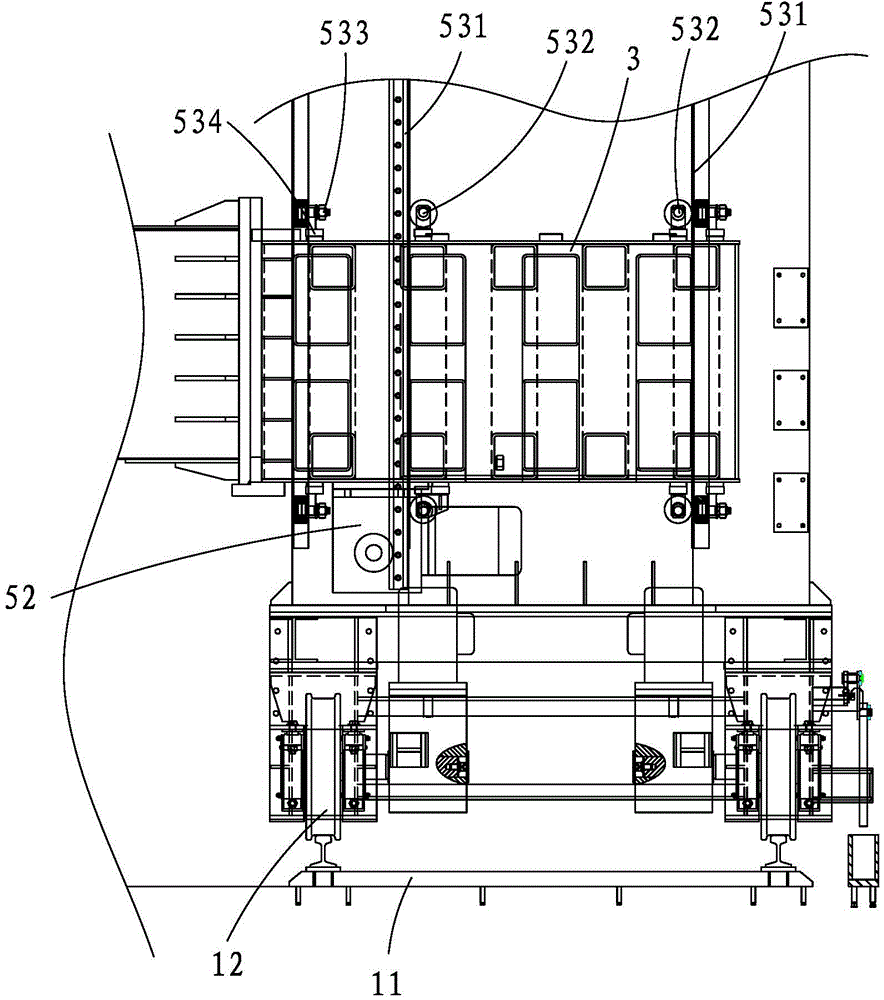

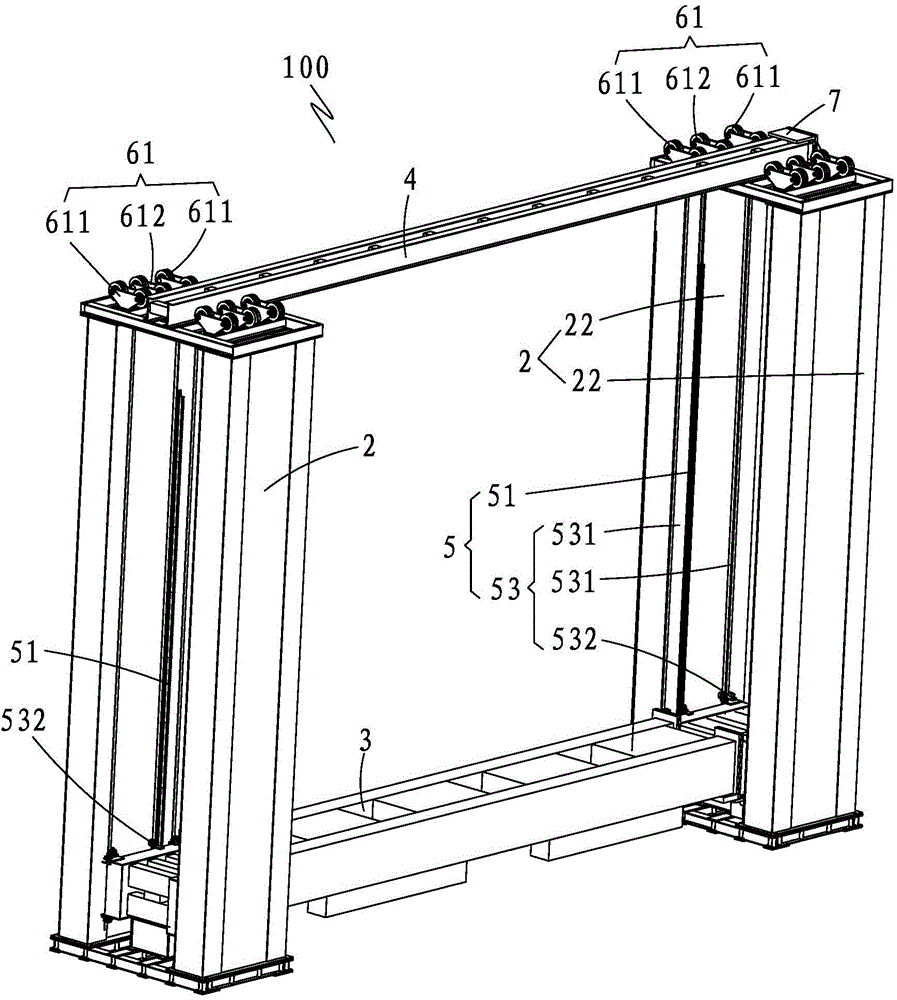

[0041] Such as Figure 1 to Figure 13 As shown, the large-scale gantry 100 of the present invention includes two rails 11, two trolleys 12, two columns 2, a movable main beam 3 and a connecting beam 4; , the two trolleys 12 are erected on one of the rails 11 respectively and can move along the rails 11; the two ends of the movable main beam 3 are respectively erected on a column 2 and connected to a lifting device 5. The upper ends of the two columns 2 are connected by the connecting beam 4; wherein: at least two counterweight mechanisms 6, a connecting beam adjusting mechanism 7 and two suspension beams 8 for fixing the manipulator 200 are also included;

[0042] mainly as Figure 5 with Figure 5a As shown, any of the counterweight mechanisms 6 includes a guide wheel set 61, a sling 62 and a counterweight 63, the guide wheel set 61 is fixed on the top of the column 2, and the sling 62 is wound around the guide wheel. The weights 63 and the movable main beam 4 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com