Glasses lens plated non-focusing mobile phone camera

A mobile phone camera and lens technology, applied in the field of mobile phone cameras, can solve the problems of time-consuming and labor-intensive production operations, increase production costs, unfavorable simplification of processes, etc., and achieve the effects of time-saving operation, cost saving, and overall volume reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

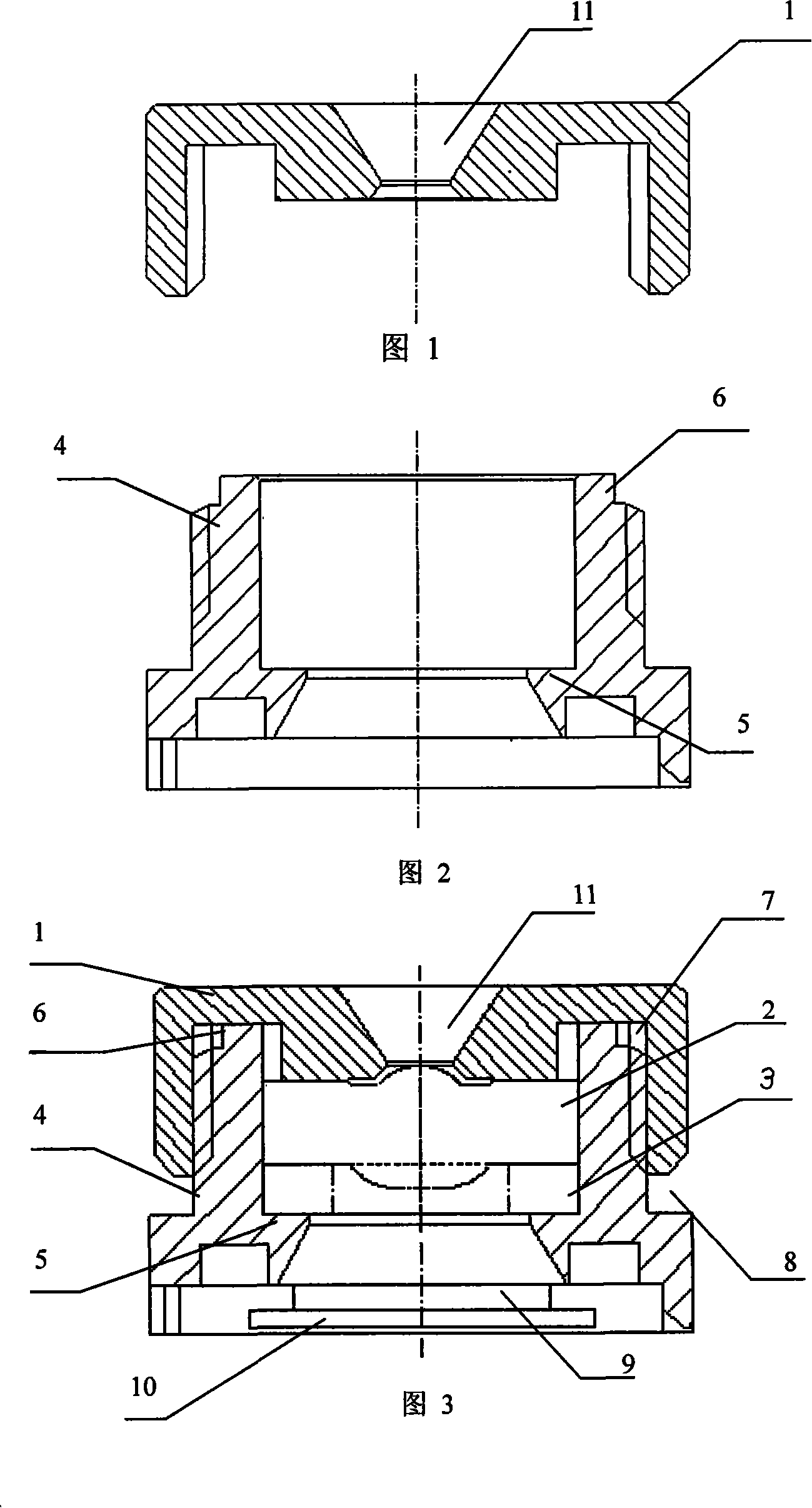

[0012] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

[0013] As shown in Figures 1 to 3, a lens coating non-focusing mobile phone camera includes a lens barrel 4, a lens barrel cover 1 with a light hole 11, and a lens group 2 set in the lens barrel 4, which is characterized in that the surrounding The lower part of the inner wall of the lens barrel 4 is provided with a bracket 5, on which an elastic pressure ring 3 is arranged, and the lens group 2 is placed on the elastic pressure ring 3, and the lens surface of the lens group 2 is coated with an infrared filter film; the lens barrel 4 The top is surrounded by a top platform 6, and the inner surface of the lens barrel cover 1 is tightly pressed with the upper surface of the top platform 6, and the lens group 2 The inner lens is pinched into place and held in place.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com