Semi-product display module and assembly method

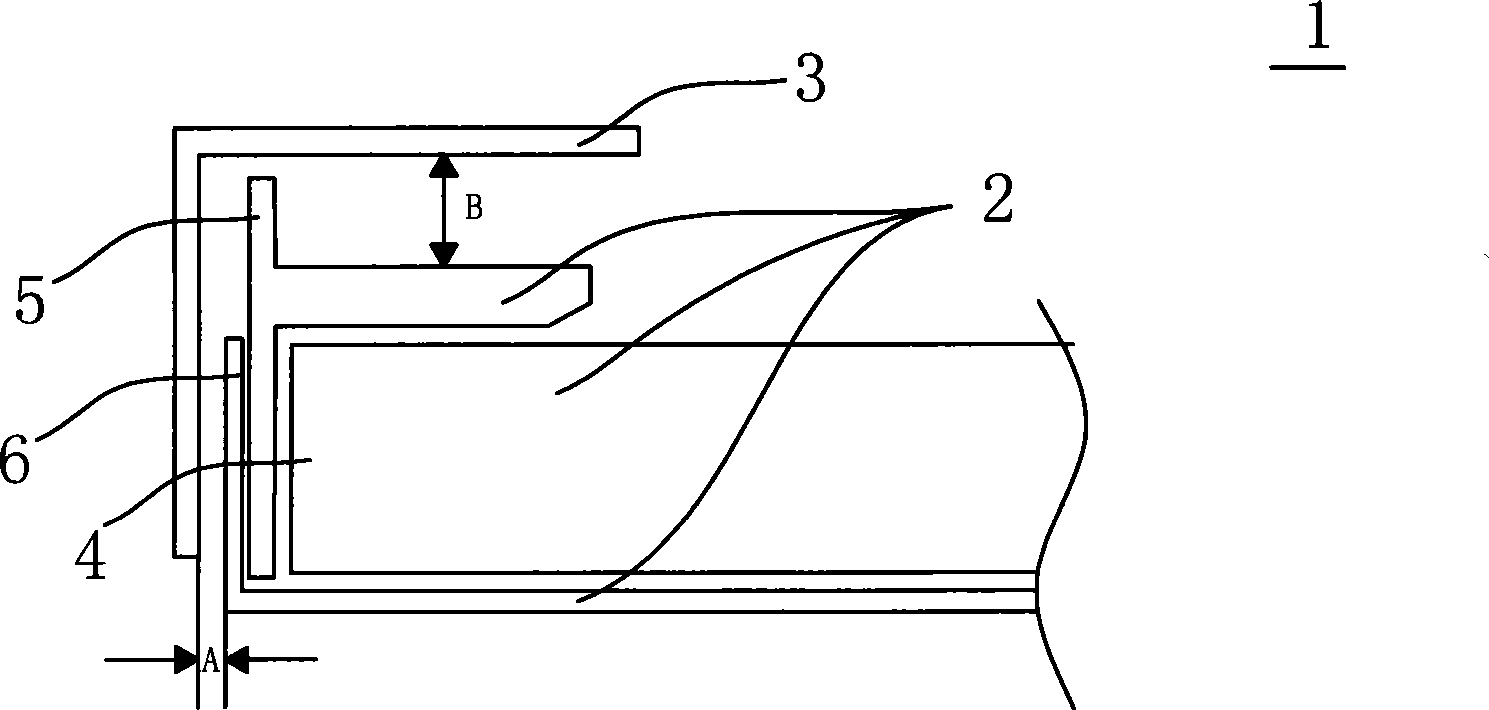

A technology for displaying modules and assembling methods, which is applied to identification devices, nonlinear optics, instruments, etc., and can solve problems such as wear of the plastic frame 5, deformation of the front iron frame 3, and increased defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

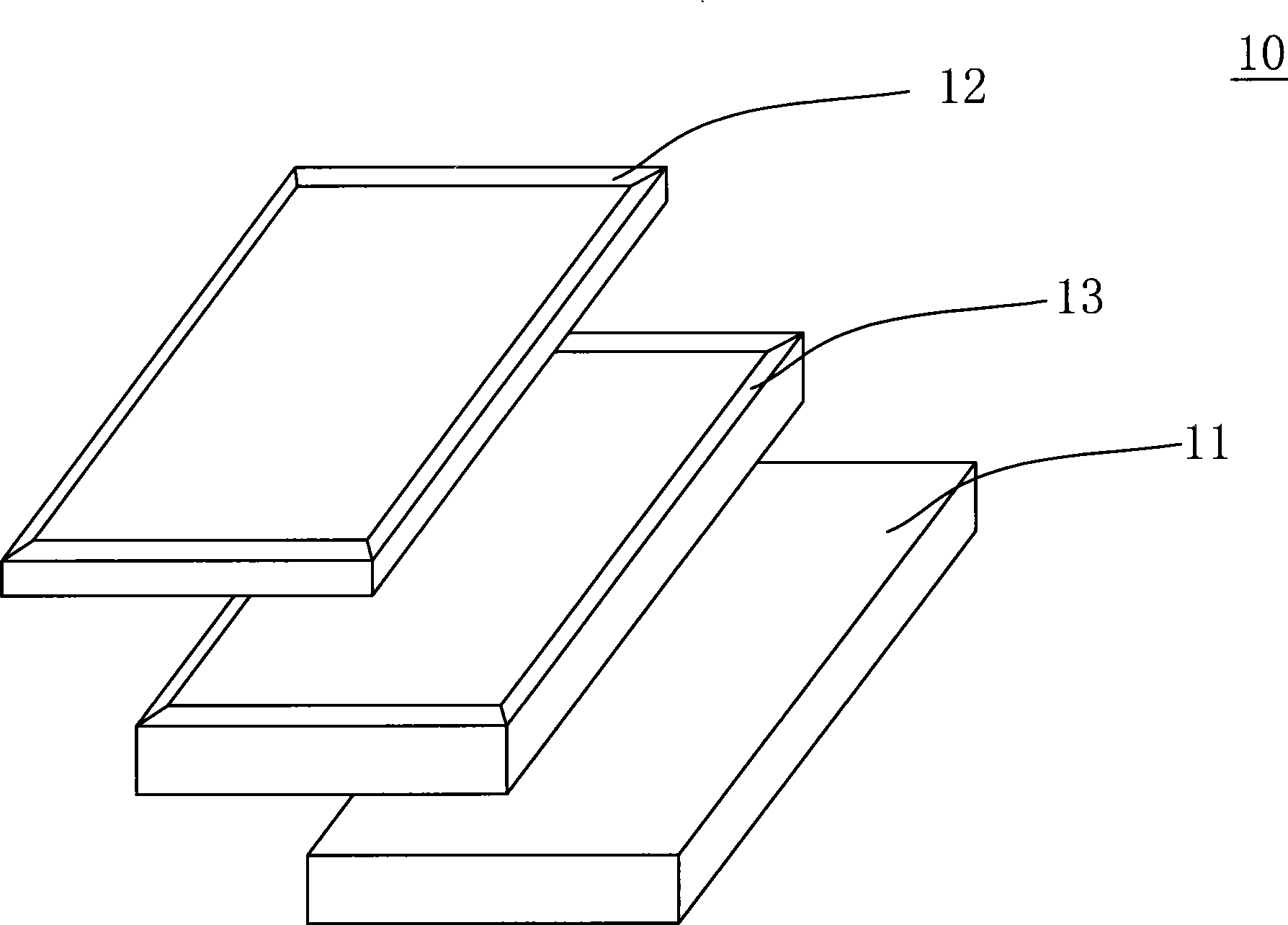

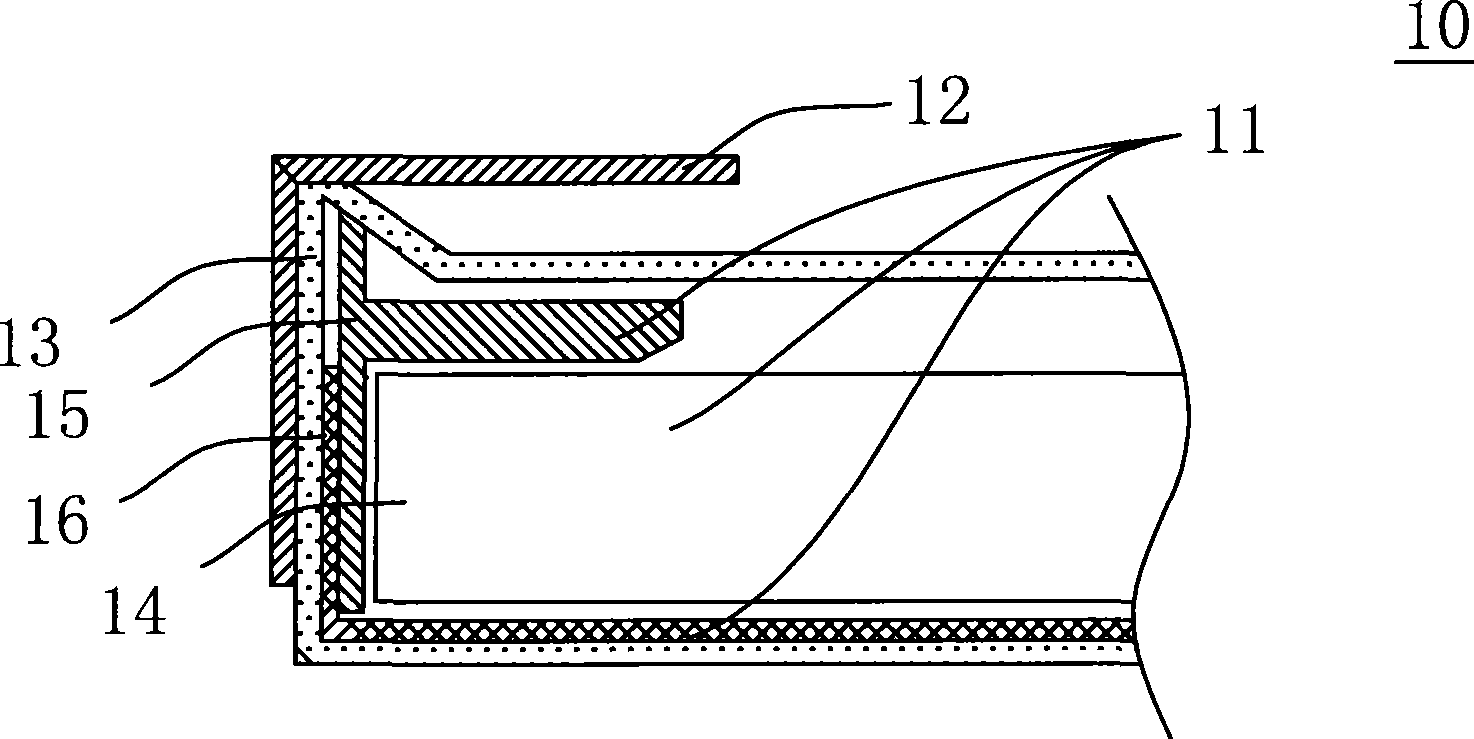

[0021] See figure 2 and image 3 , figure 2 Shown is an exploded schematic diagram of a semi-finished display module according to the present invention, image 3 Shown is a schematic diagram of the assembly of the semi-finished display module according to the present invention. The invention provides a semi-finished display module. The semi-finished display module is a display module without a display panel. In this embodiment, the display module is a liquid crystal display module as an example, and the semi-finished display module 10 includes a backlight module 11 , a first frame body 12 and a buffer member 13 . In the liquid crystal display module, the backlight module 11 is used to provide a light source for the liquid crystal display panel of the liquid crystal display device. The backlight module 11 includes a backlight assembly 14 , a second frame 15 and a third frame 16 . The third frame body 16 and the second frame body 15 are respectively disposed on two sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com