Retracting and releasing device for chain

A technology of retractable device and chain, which is applied to the parts of the binding machine, etc., can solve problems such as ramming and safety hazards, and achieve the effect of improving stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

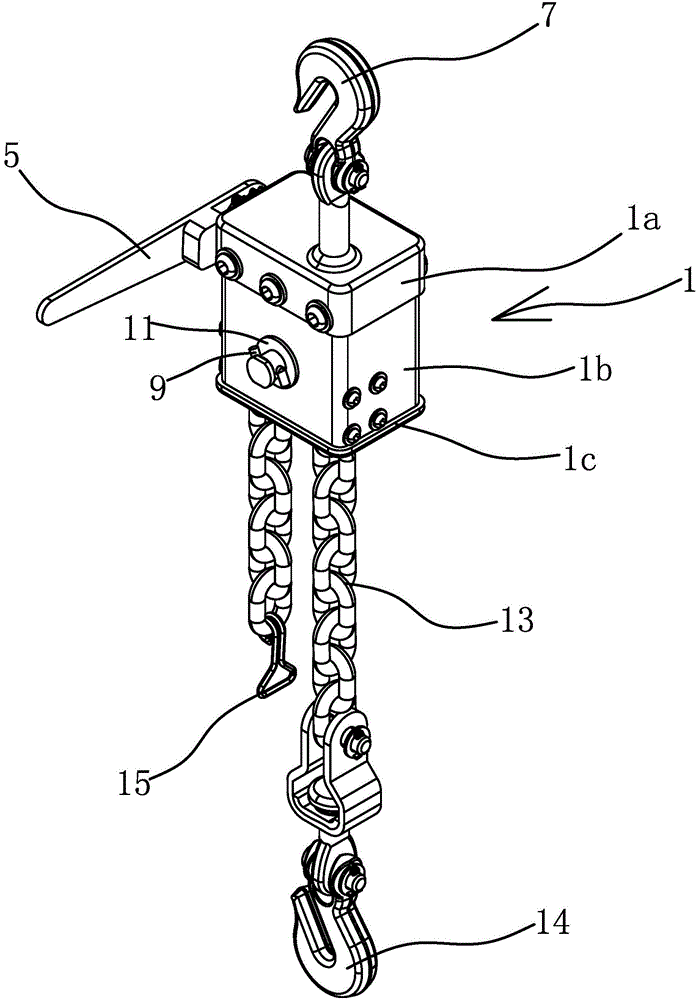

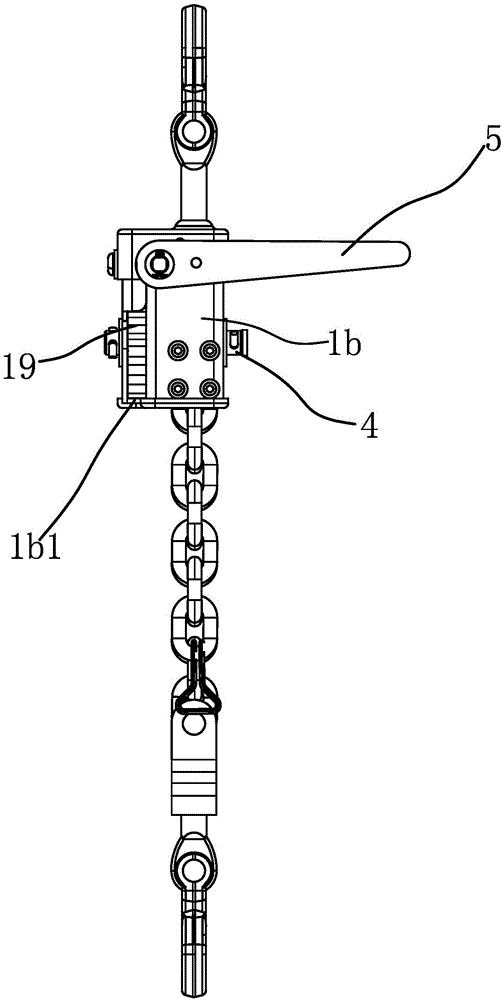

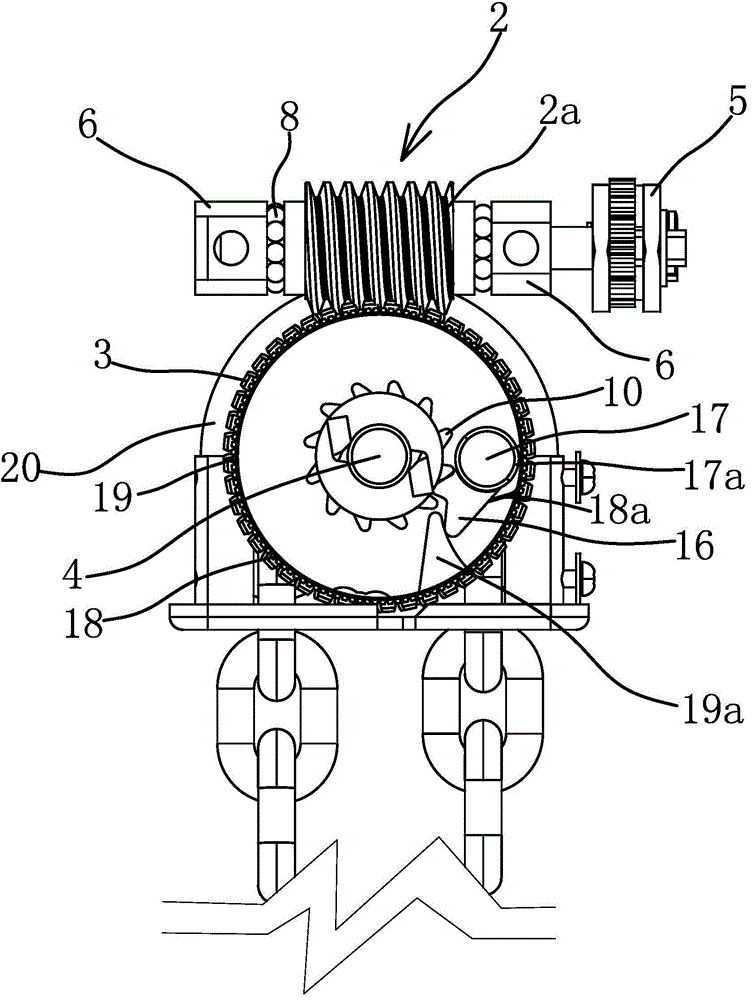

[0053] like figure 1 , figure 2 and image 3 As shown, the retractable device of this chain consists of a housing 1 with a cavity inside, a worm 2, a worm wheel 3, a rotating shaft 4, a pawl 16, an elastic piece, and a ratchet handle 5 {see: Two-way ratchet 10 wrench [Application No.: 201120164696.3; Authorization Announcement No.: CN202129748U]} etc.

[0054] Among them, such as figure 1 As shown, the casing 1 includes an upper casing 1a, a middle casing 1b and a lower casing 1c which are fixedly connected to each other. The inner side of the upper end of the middle casing 1b is provided with a support 6, and the number of the supports 6 is two and the positions are opposite. The fasteners pass through the upper shell 1a and the middle shell 1b and are fixed on the support 6, and the other side of the support 6 is also fixed on the upper end of the middle shell 1b through the fasteners, which can be bolts, screws and other mechanical fasteners. The top of the upper cas...

Embodiment 2

[0071] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the elastic member is a torsion spring, and the torsion spring is sleeved on the gear shaft 17, one end of the torsion spring acts on the pawl 16, and the other end is fixed Connected to the side of the worm gear 3. And under the action of the torsion spring, the pawl 16 always has a tendency to be embedded in the ratchet teeth of the ratchet wheel 10 .

Embodiment 3

[0073] The structure and principle of this embodiment are basically the same as those of the first embodiment, the difference is that the toggle member is a pressure plate, the pressure plate is hinged on the worm wheel 3 and located on this side of the ratchet wheel 10, and the pressure plate rotates around the hinge point and can be away from the contact The first part 16a or the first contact part 16a abuts against and overcomes the elastic force of the elastic member so that the second contact part 16b is separated from the ratchet 10 . The surface of the casing 1 has a circular opening, the pressing plate includes a grip portion and a contact portion for contacting with the ratchet teeth of the pawl 16 , and the grip portion partially protrudes from the opening. The handle part extends out of the opening, and the hand holds the part of the handle part outside the casing to facilitate the rotation of the pressing plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com