Engine material rest

An engine and material rack technology is applied to the material rack where the engine is placed, and the crop material rack is the field of transportation auxiliary devices, which can solve the problems of unable to fully fix the engine, inaccurate positioning of the positioning device, unable to install the engine, etc. Simple installation and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

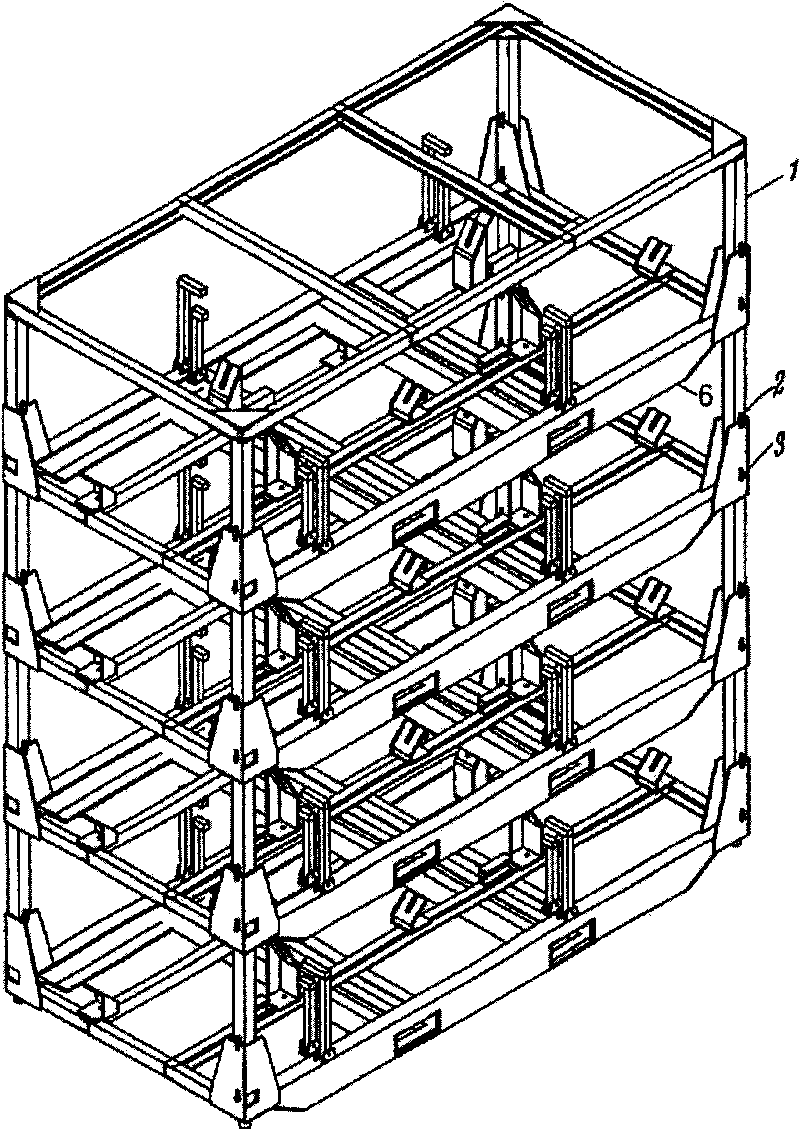

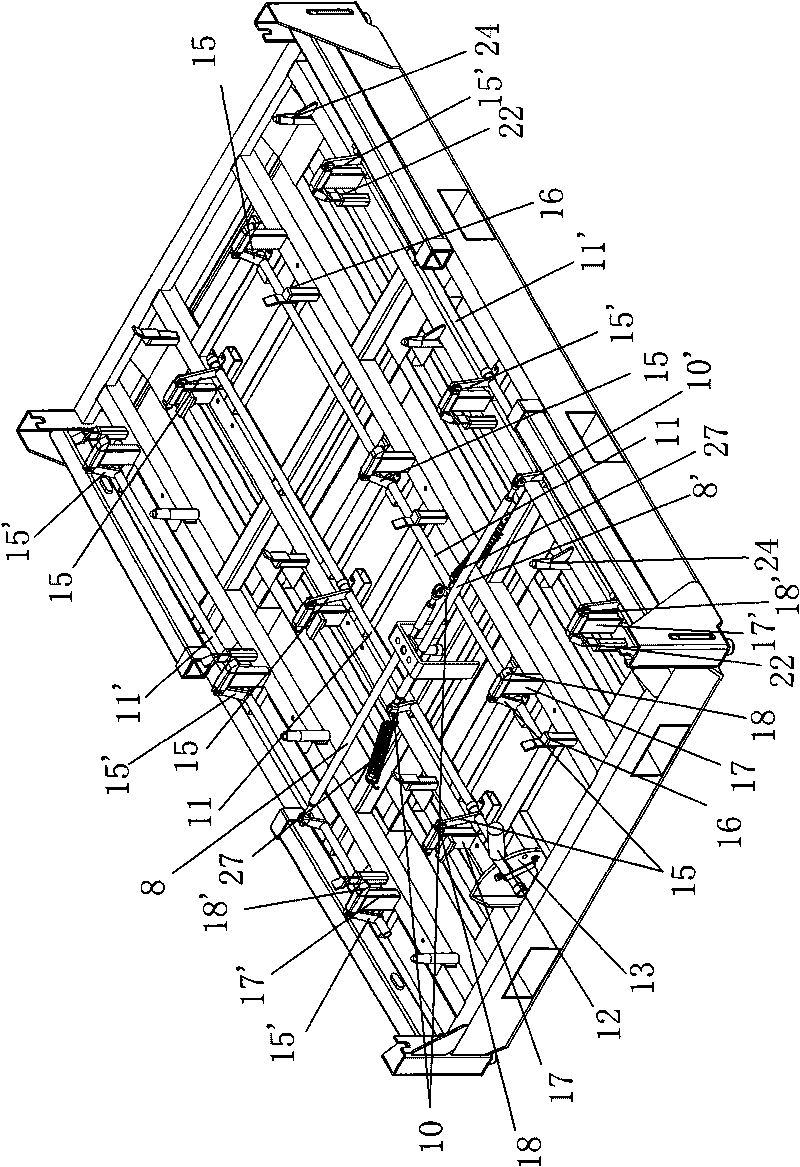

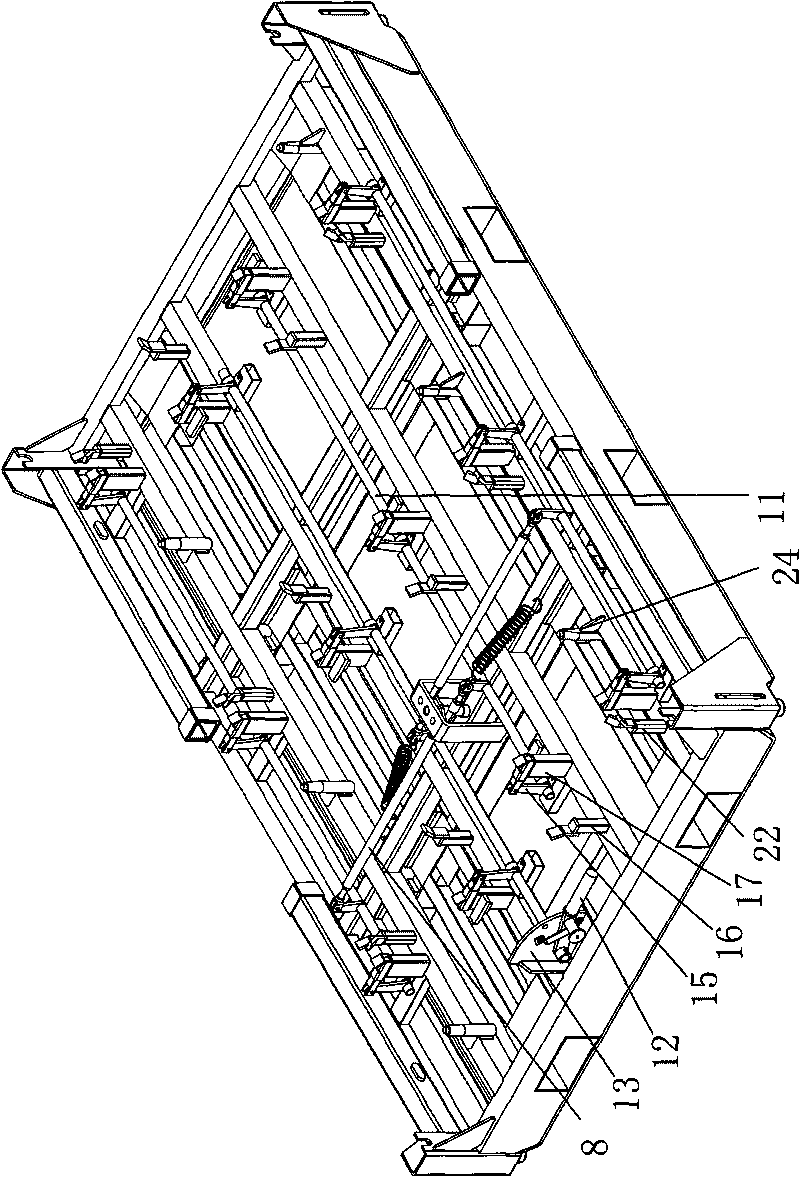

[0045] Such as figure 2 , Shown in 3, the present embodiment includes - material rack body 1, is provided with 6 engine placement stations on it. All comprise two fixed support frames 16 ( Figure 9 ),twenty two( Figure 7 ) and a fixed positioning pin 24 ( Figure 8 ), two fixed support frames 16,22 are relatively installed. Such as Figure 7 , Shown in 9, also comprise two movable briquetting block positioning frames 17,17 ', each activity is equipped with a movable briquetting block 18,18 ' on it.

[0046] The above are the positioning and supporting mechanisms of the engine, corresponding to the positioning parts of the engine, and corresponding adjustments are made according to the different positioning parts of the engine bottom. Put the engine on the rack, and lock the engine after everything is placed.

[0047] Such as figure 2 , Shown in 3, the present embodiment is also provided with an engine locking / opening mechanism, including a handle 12, on which a hand...

Embodiment 2

[0061] Such as Figure 11 Shown, the present embodiment comprises two fixed support frames 16,23 (equivalent to 22 in embodiment 1) on the engine station ( Figure 12 ) and a fixed positioning bracket pin 24, wherein two fixed support frames 16,23 are relatively installed. The rest of the structure is the same as that of Embodiment 1 and will not be repeated here.

Embodiment 3

[0063] Such as Figure 13 Shown, present embodiment comprises two fixed supports 16,22 ( Figure 7 ) and a fixed positioning bracket pin 25 (equivalent to 24 in embodiment 1) ( Figure 8 ), wherein the fixed support frame 22 is relatively installed with the fixed positioning bracket pin 25. Also comprise three movable briquetting block locating frames 17,17 ', 17 ", each activity is equipped with a movable briquetting block 18,18 ', 18 " on it. The two movable briquetting block positioning frames 17, 17" are installed on one side, and the movable briquetting block locating frame 17' is installed on the other side. The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com