Intra-cabin and extra-cabin linkage type cabin door lock mechanism

A technology of internal and external linkage and cabin door lock, which is applied in the direction of aircraft accessories, etc., can solve the problems of unreasonable design, inconvenient operation, and large space occupied by the lock mechanism, and achieve the effect of ingenious and reasonable mechanism design, guaranteed reliability, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0022] Best practice:

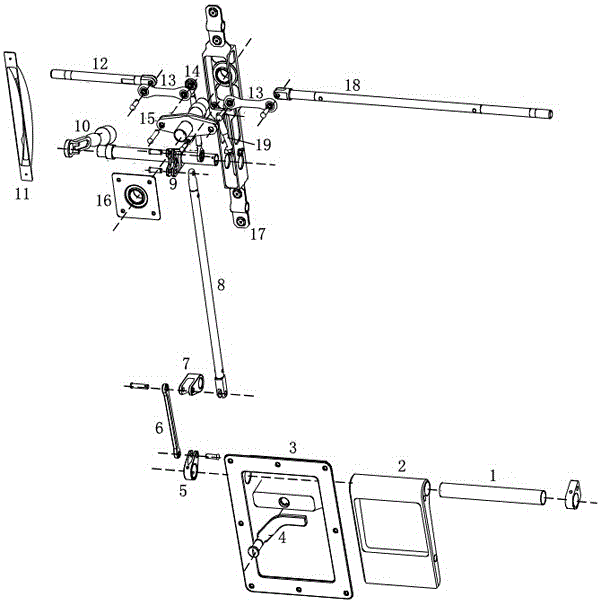

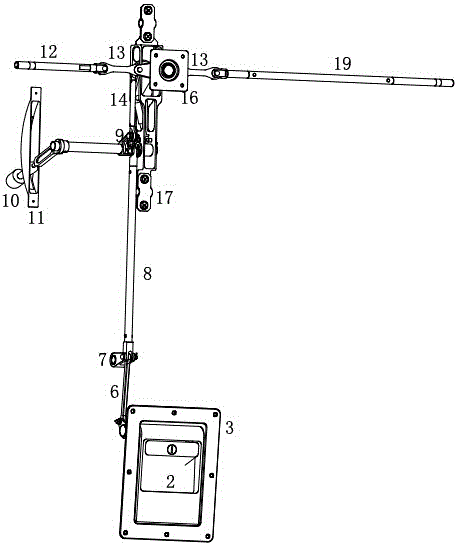

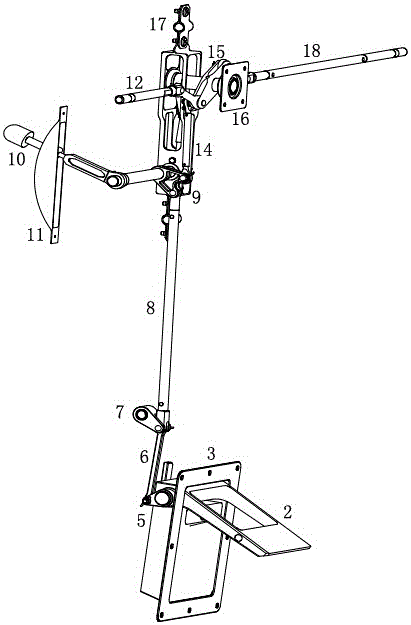

[0023] Such as figure 1 As shown, an internal and external interlocking cabin door lock mechanism includes an external handle 2, an external handle support 3, an external lock 4, a connecting rod I6, a connecting rod II8, an internal handle 10, a left lock pin 12, a connecting rod Rod III 14, lock rocker arm bracket 15, lock mechanism bracket 17 and right lock pin 18.

[0024] The handle support 3 outside the cabin and the rocker arm base 16 are respectively fixed on the cabin door. The handle 2 outside the cabin is connected to the handle support 3 outside the cabin in an embedded form through the rotating shaft 1, and the rotation of the rotating shaft 1 is controlled by the cabin. Outer lock 4 is restricted, one end of the rotating shaft 1 is fixedly hinged with one end of the rotating shaft rocker arm 5, the other end of the rotating shaft rocker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com