Cutting and welding working table

A workbench and butt welding technology, applied in shearing devices, manufacturing tools, welding equipment, etc., can solve the problem of the inability to guarantee the smoothness of the splicing butt welding seam, the effect of the gap change of the roller group, and the uneven ends of the strip, etc. problems, to achieve the effect of reducing the volume of the workbench, eliminating the need for complex pipeline installation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

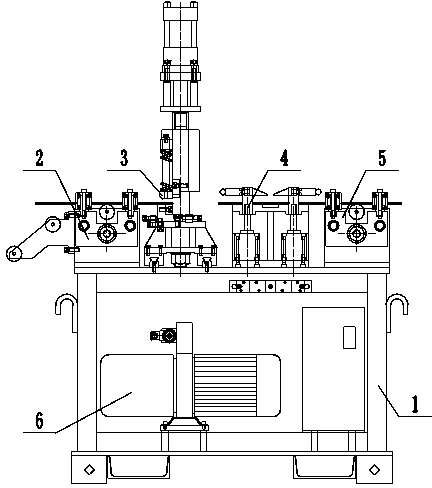

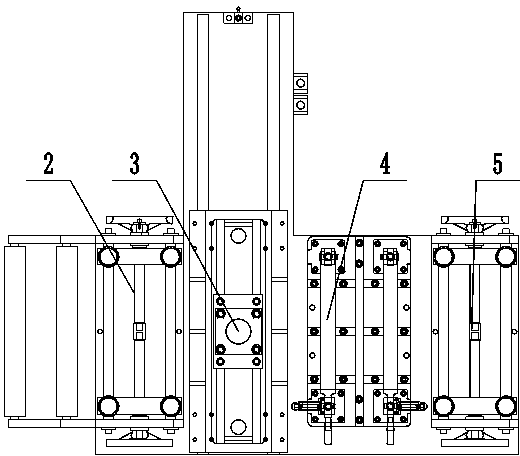

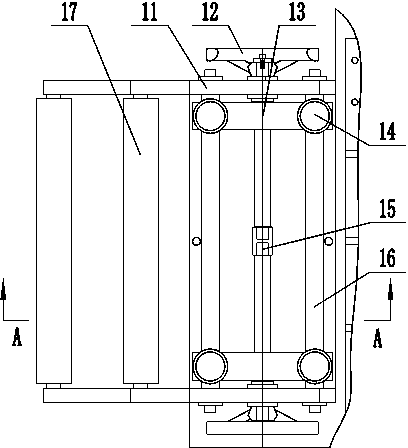

[0034] Describe structure of the present invention below in conjunction with accompanying drawing and working process thereof.

[0035] see as figure 1 and figure 2 As shown, the present invention includes a workbench 1, a front guiding component 2, a trimming component 3, a butt welding pressing component 4, a rear guiding component 5 and a gas-hydraulic power unit 6, the front guiding component 2, the trimming component 3 , Butt welding pressing assembly 4 and rear guiding assembly 5 are sequentially installed above the workbench 1 and the working plane is on the same plane, and the working center line is on the same straight line; the gas-hydraulic power unit 6 is installed in the lower abdominal space of the workbench 1 .

[0036] When working, the strip material is fed and guided from the front guide component 2, the end is cut off at the trimming component 3 and the section is straight, and the butt welding pressing component 4 is aligned with the front material and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com