Control method of hot-rolled steel sheet water-cooling plate

A control method, technology of hot-rolled steel plate, applied in the direction of contour control, etc., to achieve the effect of solving the curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

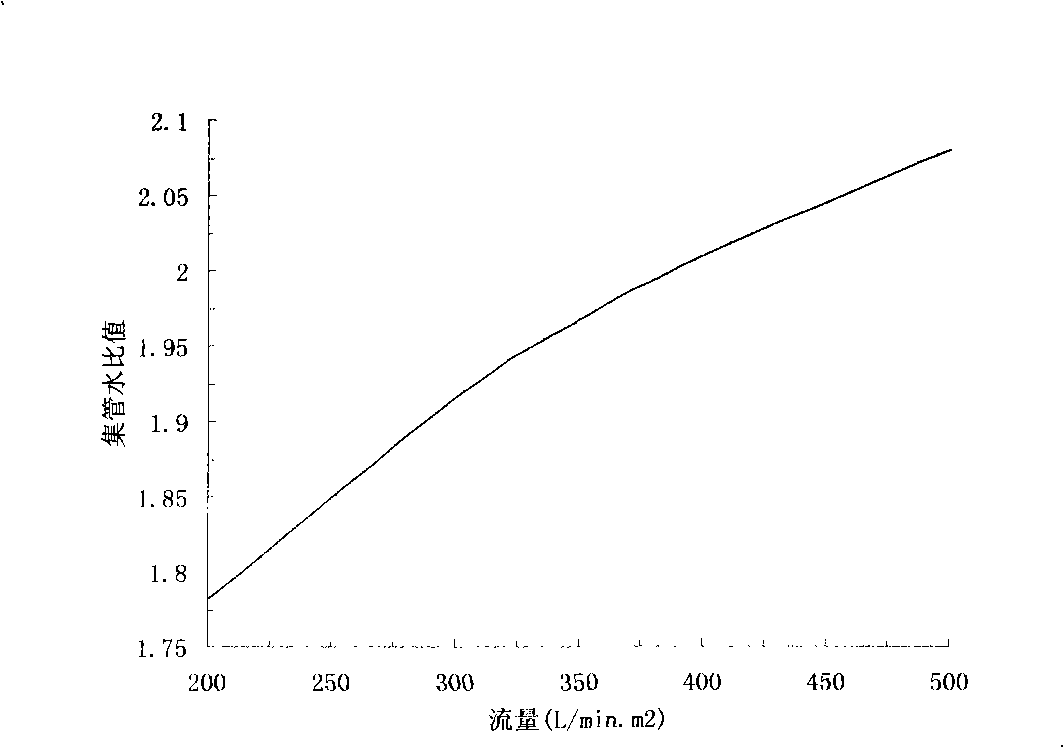

Embodiment 1

[0041] Example 1: A steel plate with a thickness of 22mm has a buckle under the whole plate, and the flow rate of the water-cooled upper header is 300L / m 2 .min, the height of the buckle is about 150mm, then adjust the water ratio, the adjustment amount is ΔR=0.0005*150+0.0015*22=0.108, because the steel plate is bent down, the water ratio should be reduced, the thickness specification 1. The raw water ratio under flow conditions is 1.92, which should be adjusted to R=1.92-0.108=1.812, and the other parameters remain unchanged.

[0042] If the warp only occurs at the head of the steel plate, then the R-water ratio is not adjusted, only the shielding amount of the head is adjusted, and the shielding coefficient adjustment amount is Δm=0.0002*150+0.0015*22=0.063, because what happens on the head is down The curvature of the buckle indicates that the cooling of the upper surface is insufficient, so the shading coefficient of the upper surface can be increased, or the upper surfac...

Embodiment 2

[0044] Example 2: Taking a steel plate with a thickness of 22mm as an example, when the flow rate of the upper header is 300L / m 2 .min, determined according to formula (1):

[0045] R=0.0149*22+0.33*Ln(300)-0.294=1.92

[0046] Therefore, the reasonable lower header flow rate should be 300*1.78=576;

[0047] In the same way, the flow rate of the upper header of the steel plate head is 0.8*300=240, the flow rate of the lower header of the head is 0.7*576=403, the flow rate of the upper header of the tail is 0.9*300=270, and the flow rate of the lower header of the tail is 0.8*576=461.

[0048] If the warp only occurs at the head of the steel plate, then the R-water ratio is not adjusted, only the shielding amount of the head is adjusted, and the shielding coefficient adjustment amount is Δm=0.0002*150+0.0015*22=0.063, because what happens on the head is down The curvature of the buckle indicates that the cooling of the upper surface is insufficient, so the shading coefficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com