Patents

Literature

38results about How to "Eliminate cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

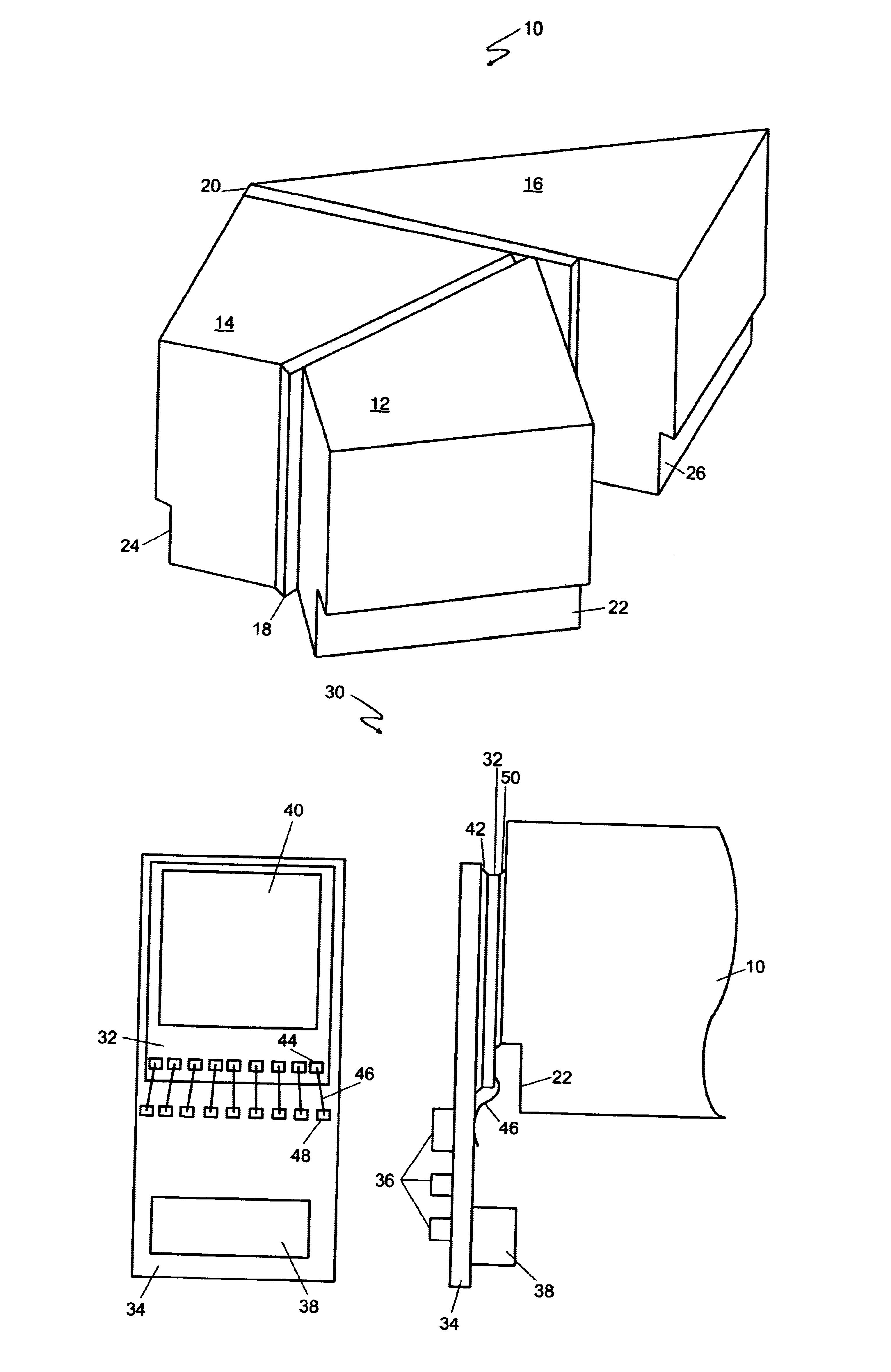

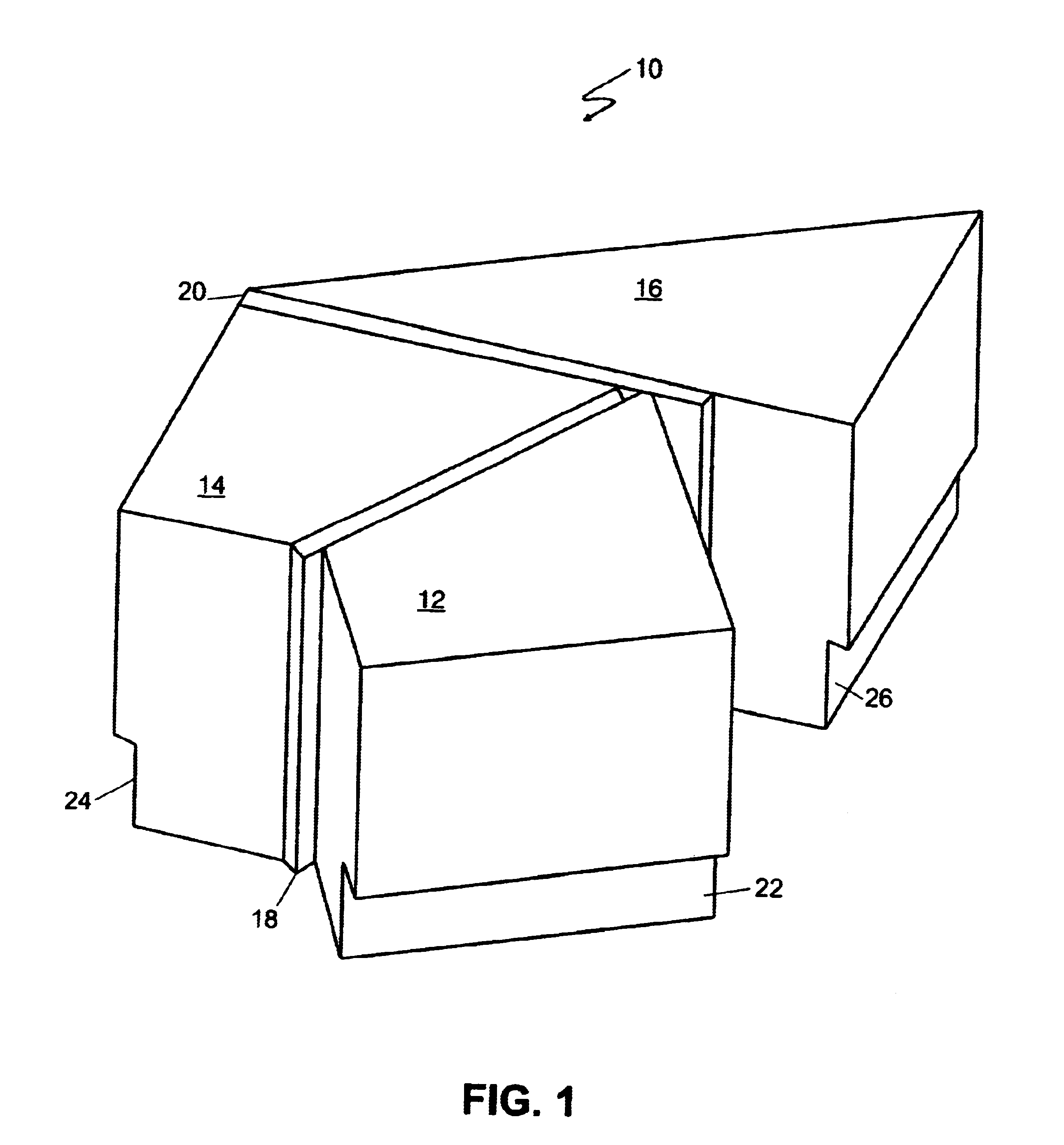

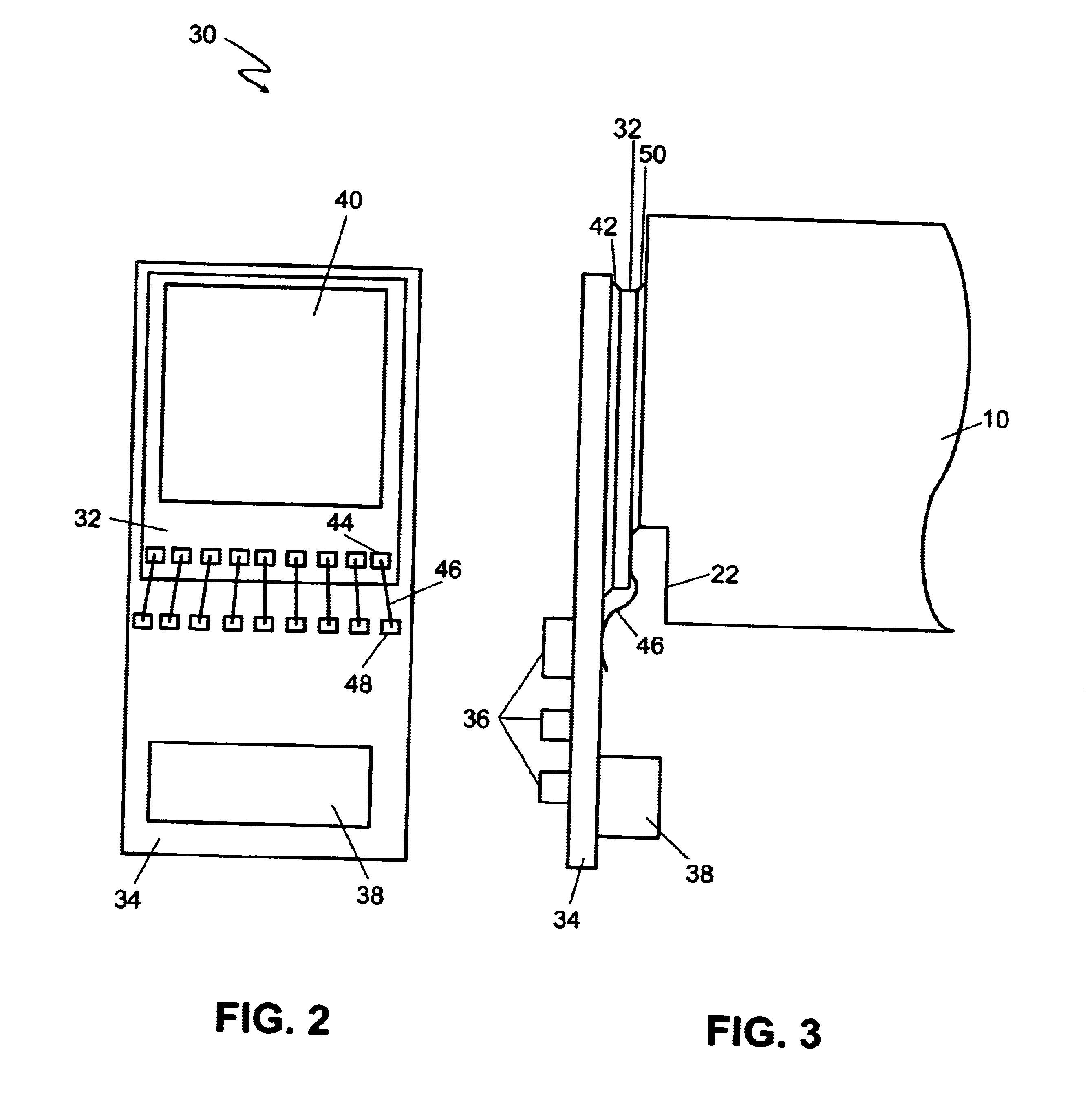

System apparatus and method for hosting and assigning domain names on a wide area network

InactiveUS6687746B1Eliminate costCost reductionData processing applicationsDigital data processing detailsManagement systemData mining

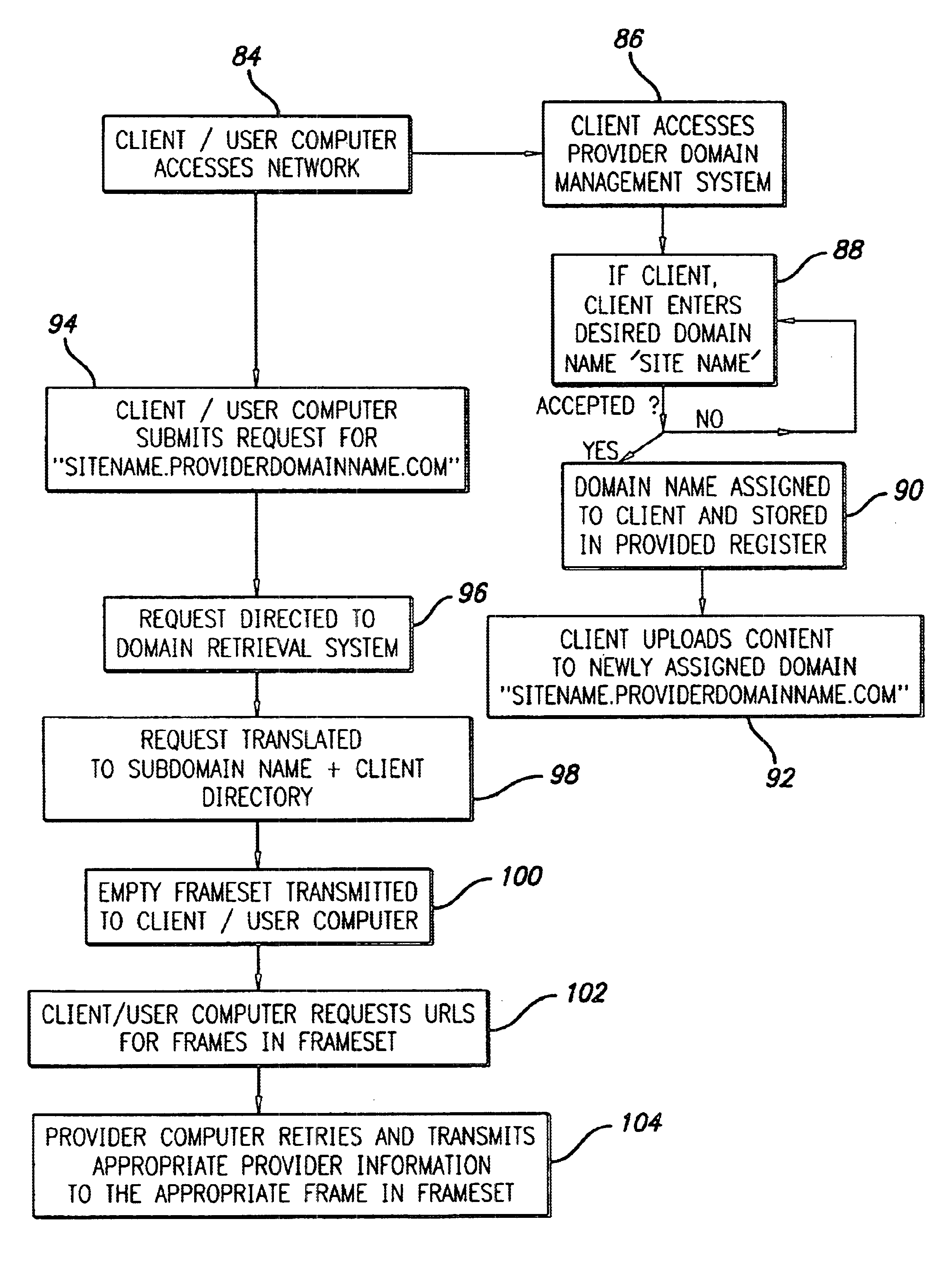

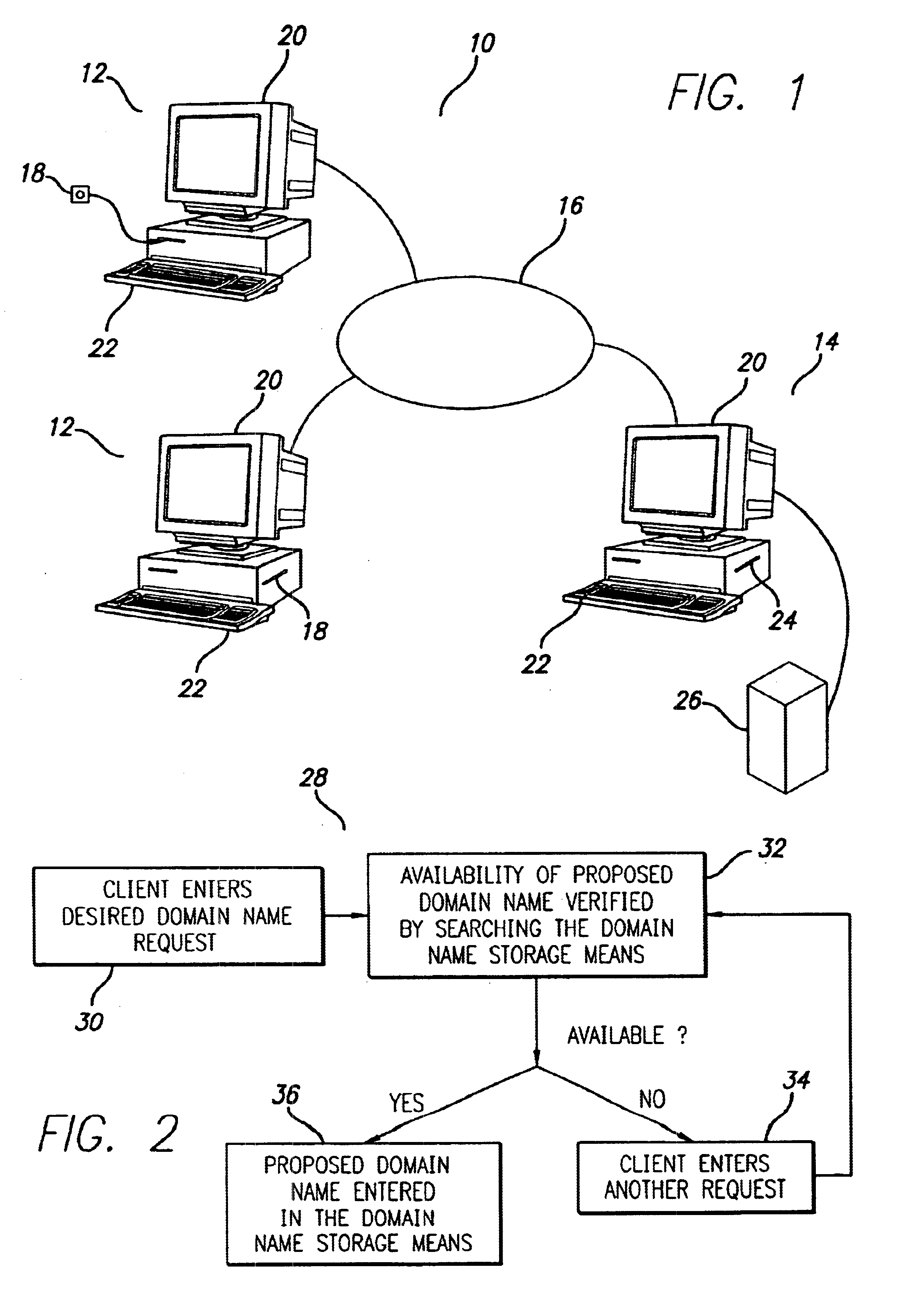

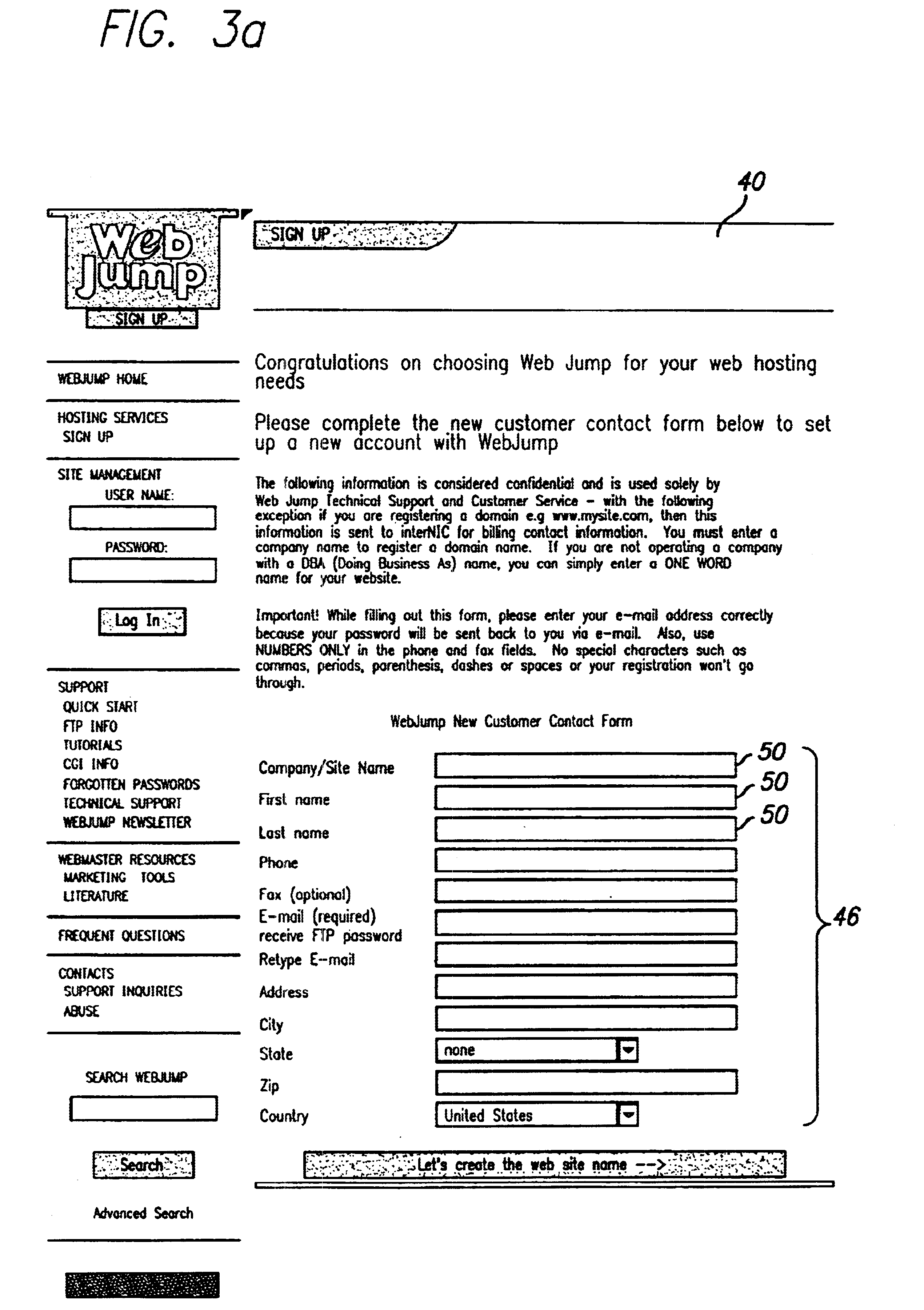

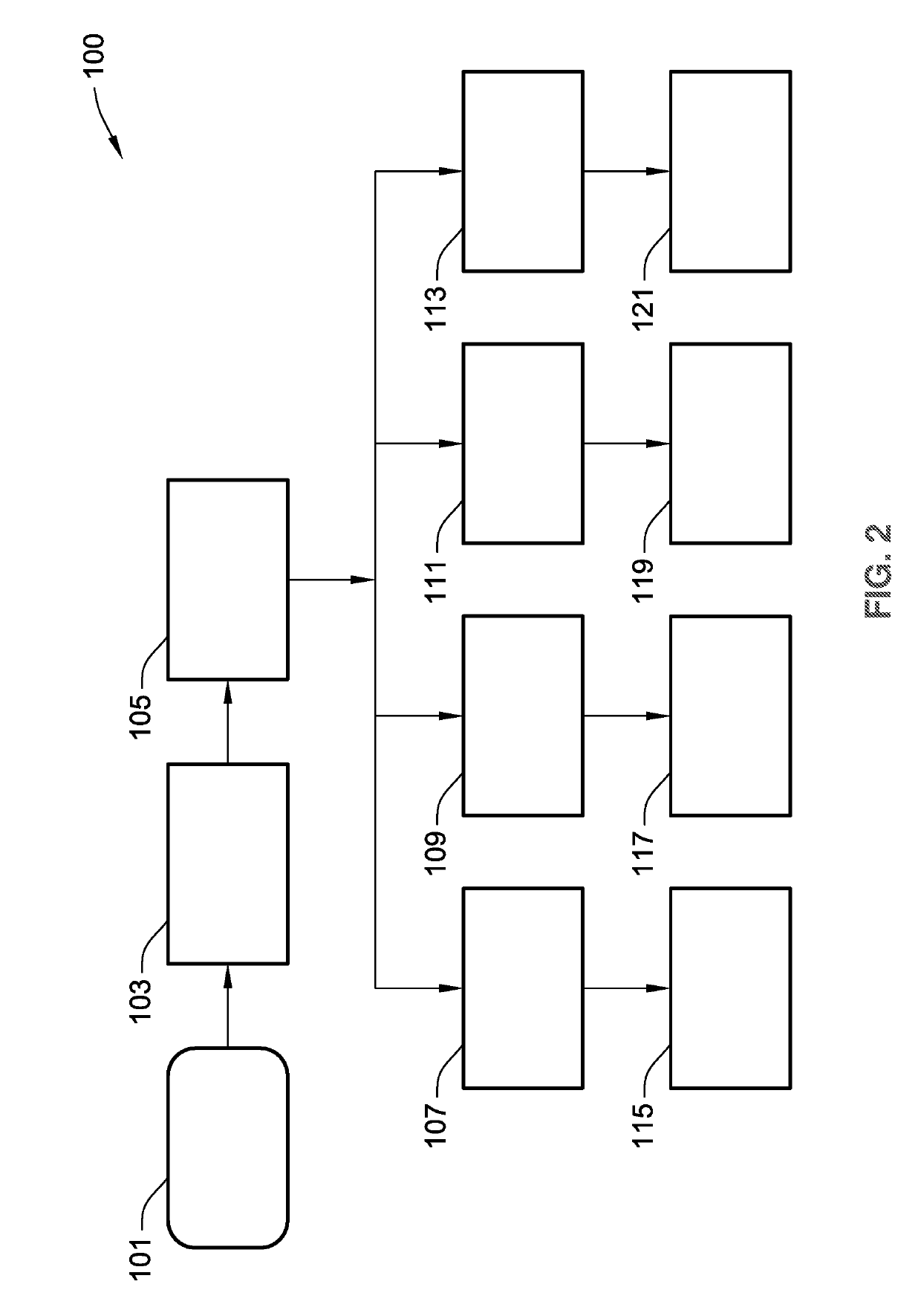

Embodiments of the instant invention are directed to a domain management system, apparatus and method for hosting and assigning domain names. Embodiments of the domain management system comprise a name assignment system and a hosting system, wherein the hosting system comprises a domain retrieval system and a data storage apparatus. The name assignment system verifies availability and assigns domain names to requesting clients. The name assignment system comprises an input component, a confirmation mechanism and a name storage means. Preferred embodiments of the domain retrieval system comprise a scheduler, a parsing member having a plurality of redirectors and a plurality of servers. The domain retrieval system locates the domain referenced by the domain name by parsing header information and utilizing a wildcard DNS. Once the domain is located, the domain retrieval system forwards the domain to the user computer.

Owner:FAR NORTH PATENTS LLC

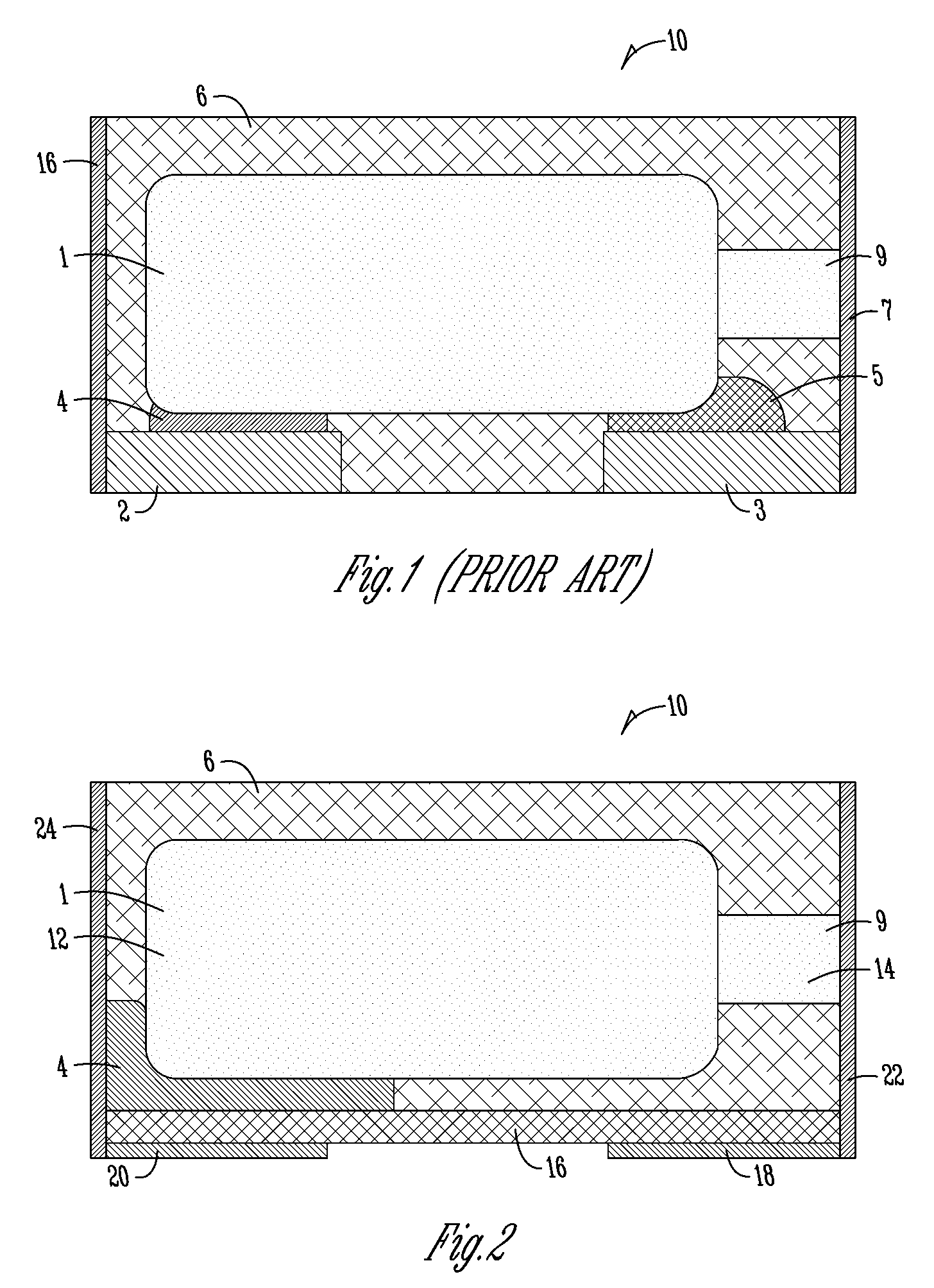

Capacitor with improved volumetric efficiency and reduced cost

InactiveUS20080247122A1Eliminate costGood conditionSolid electrolytic capacitorsFixed capacitor terminalsCapacitanceEngineering

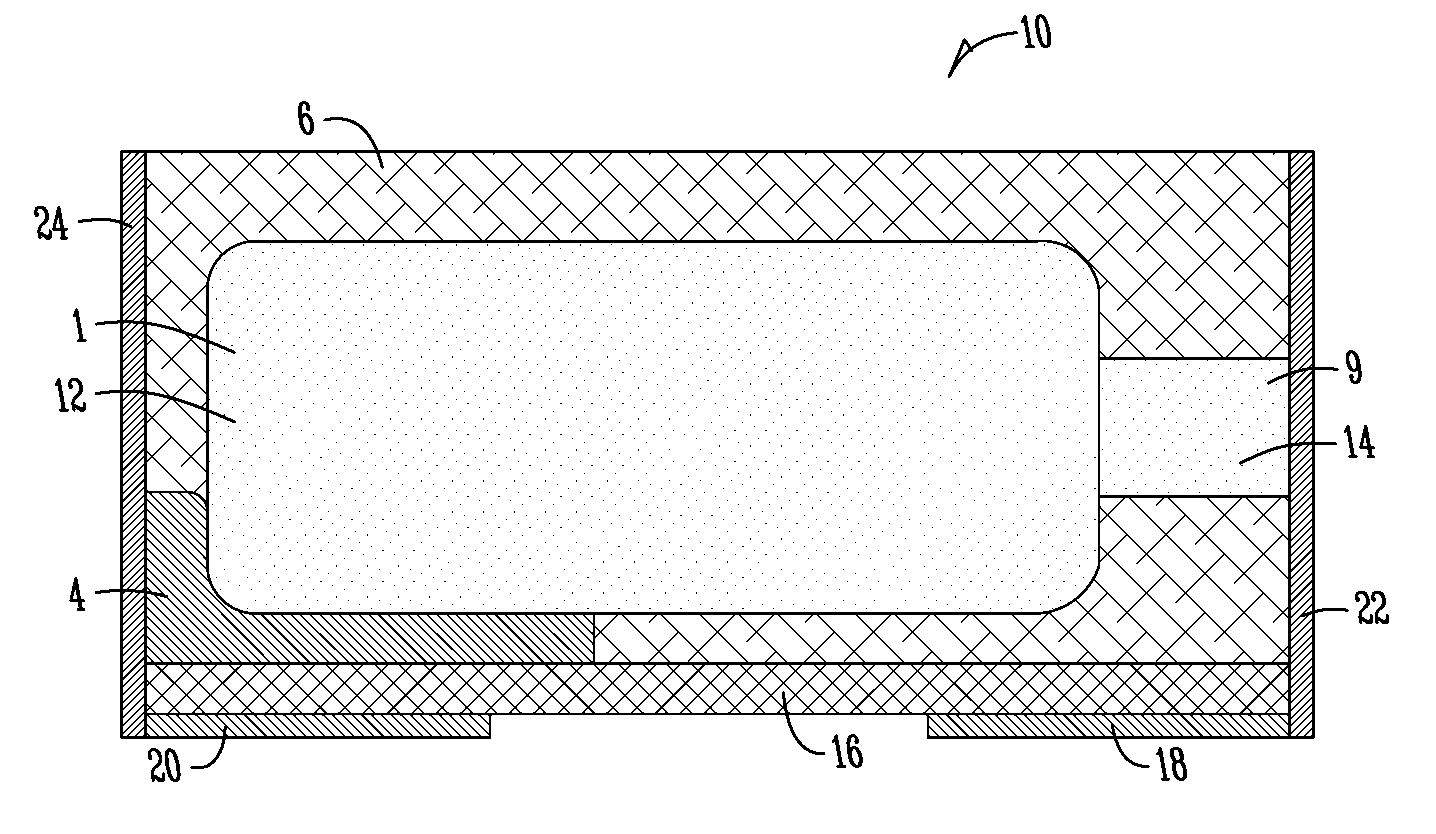

A surface mount capacitor is provided. The surface mount capacitor includes a capacitive element including an anode and a cathode, the anode having an exposed portion, an encapsulation material partially surrounding the capacitive element, a non-conductive substrate in contact with the encapsulation material, an anode termination connected to the non-conductive substrate, a cathode termination connected to the non-conductive substrate, and a first conductive path between the exposed portion of the anode and the anode termination comprising a first external conductive connection on a first external surface of the capacitor. The capacitor may also include a second conductive path between the cathode and the cathode termination. The second conductive path includes a second external conductive connection on a second external surface of the capacitor. The second conductive path may further include a conductive adhesive between the cathode and the second external conductive connection.

Owner:VISHAY SPRAGUE

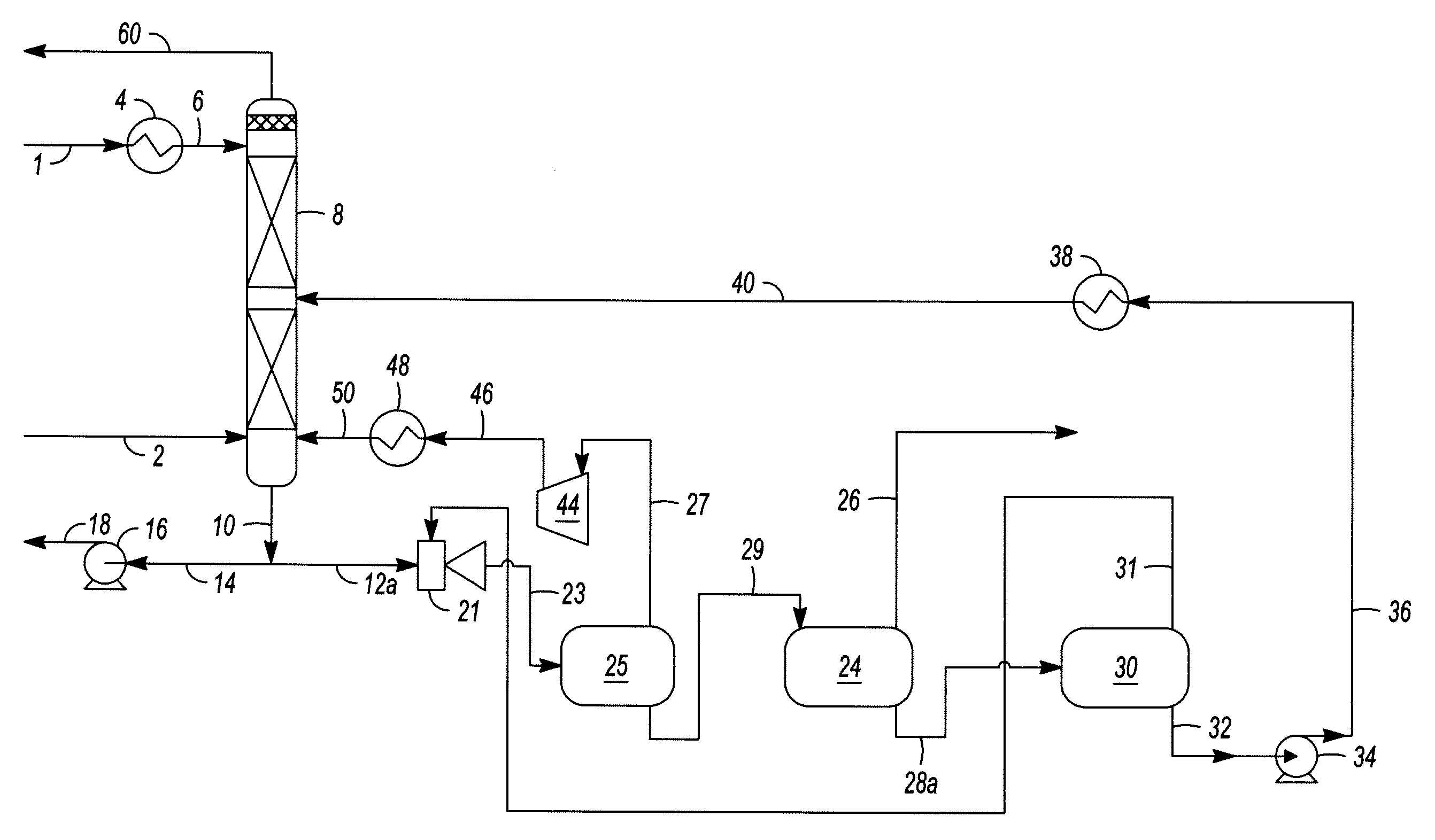

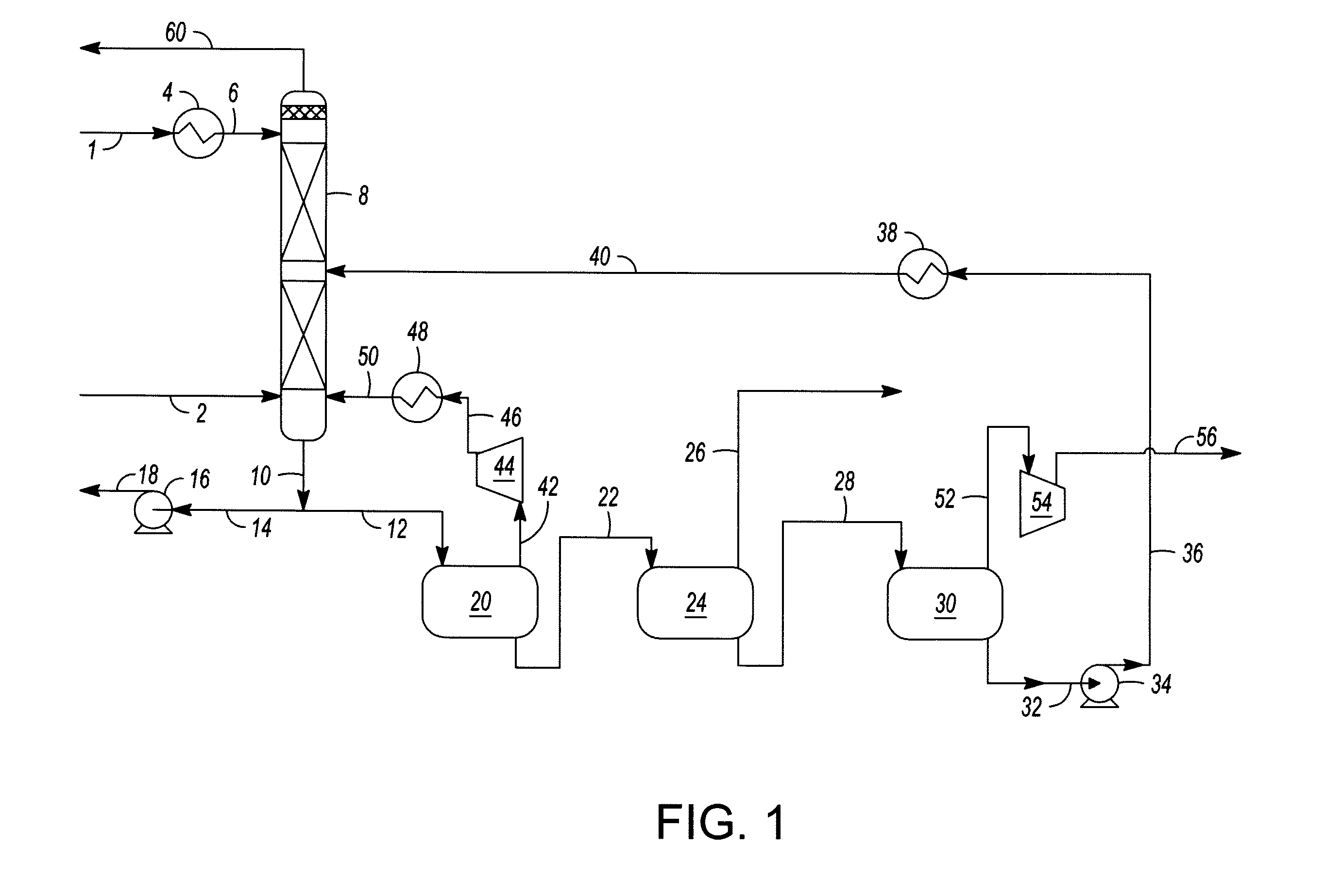

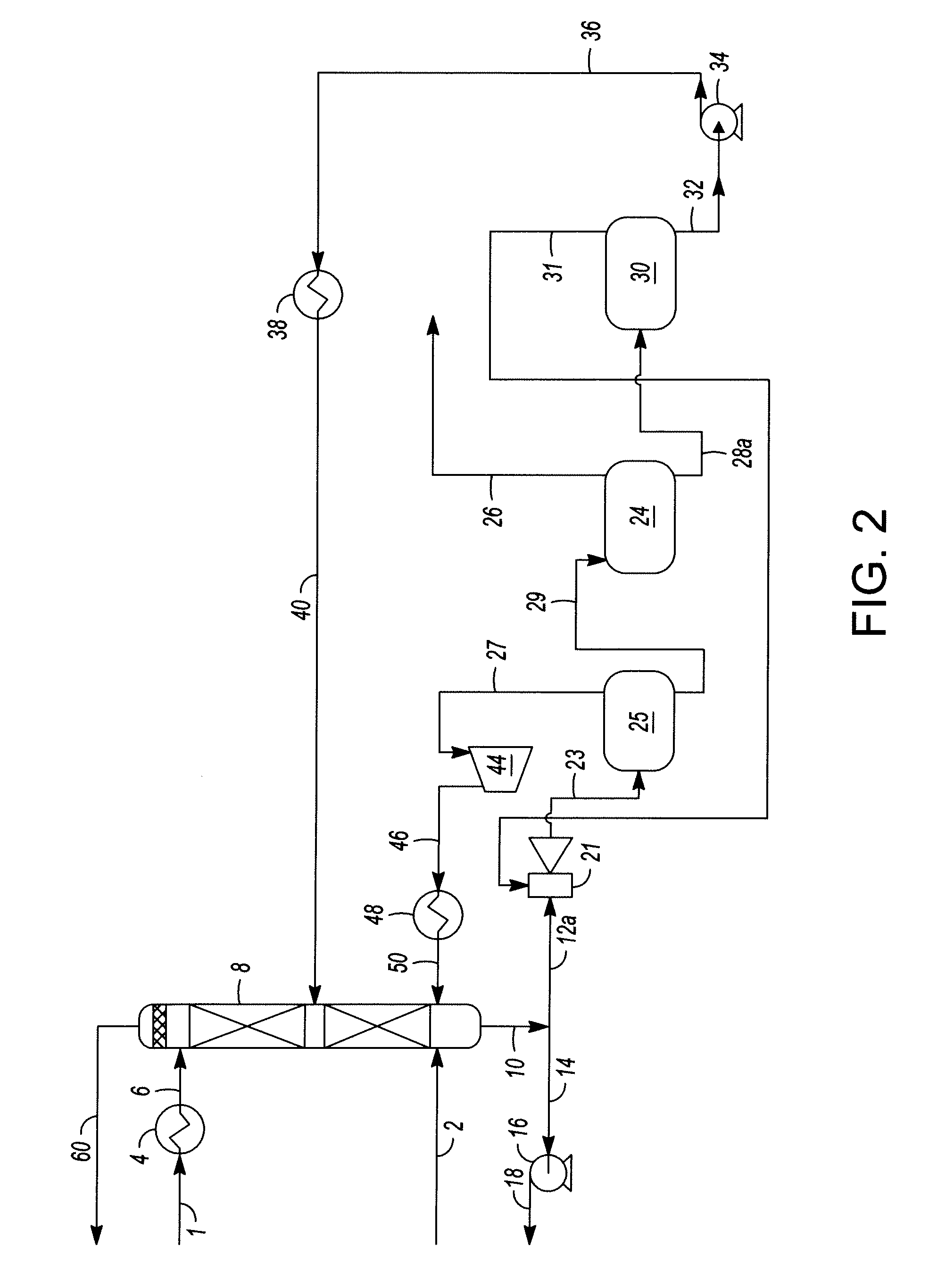

Use of Solvent Stream as Motive Fluid in Ejector Unit for Regenerating Solvent for Absorption Unit

The invention provides a process and system for regenerating a solvent used to remove carbon dioxide from feed gases, such as natural gas and synthesis gas. The process and system employs an eductor or ejector as an alternative to the prior art's vacuum compressor that is placed on the vapor stream from a vapor flash. This process and system saves substantial capital and operating costs over the prior art.

Owner:UOP LLC

Color separation prisms having solid-state imagers mounted thereon and camera employing same

InactiveUS6614478B1Eliminate costUndesired reflectionTelevision system detailsPrismsOptical pathImage sensor

A method for attaching imagers to color-separation prisms includes the steps of: arranging three solid-state array image sensor integrated circuits behind and in close proximity to the output faces of a color-separating prism having substantially equal optical path lengths for the three paths, the three solid-state array image sensor integrated circuits each having a solid-state array image sensor and bonding pads for electrical connections disposed on a top face thereof; aligning the three sensors such that the images traversing the three paths are coincident within a pixel dimension of the image sensors; filling the space between each output face of the prism and the top face of the corresponding image sensor with index-matched adhesive; and causing the index-matched adhesive to become rigid while maintaining the alignment of the three image sensors.

Owner:FOVEON

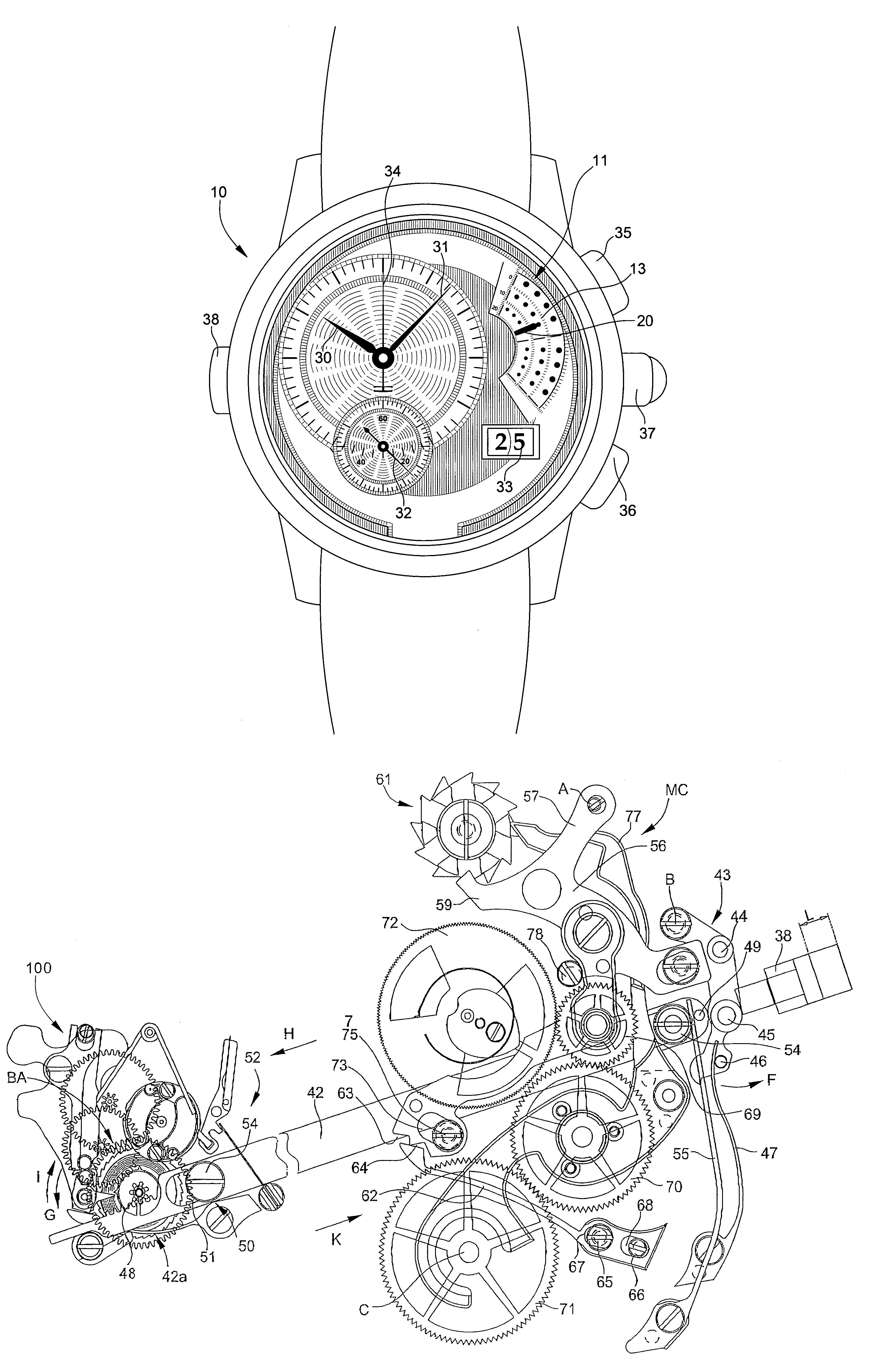

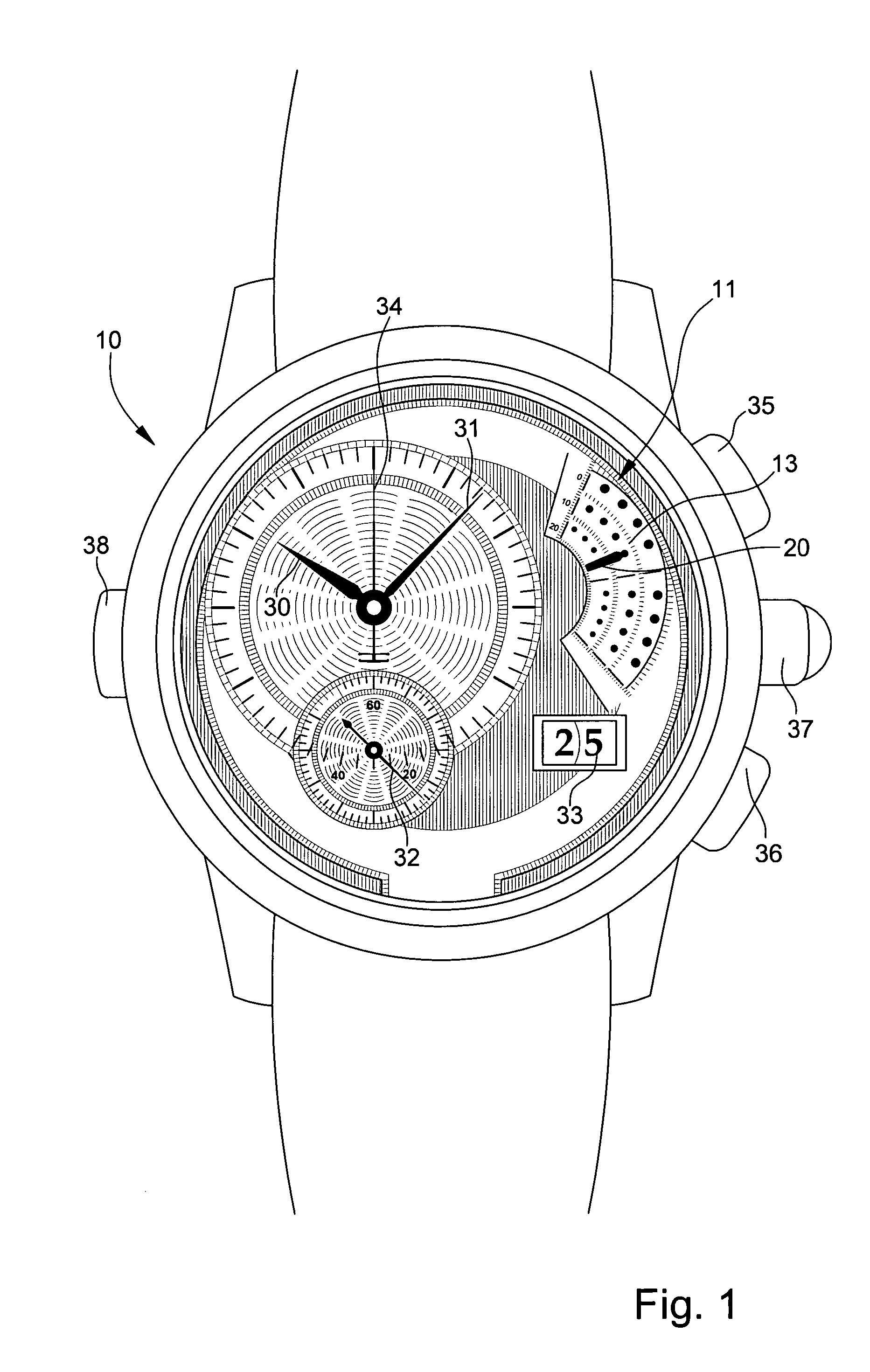

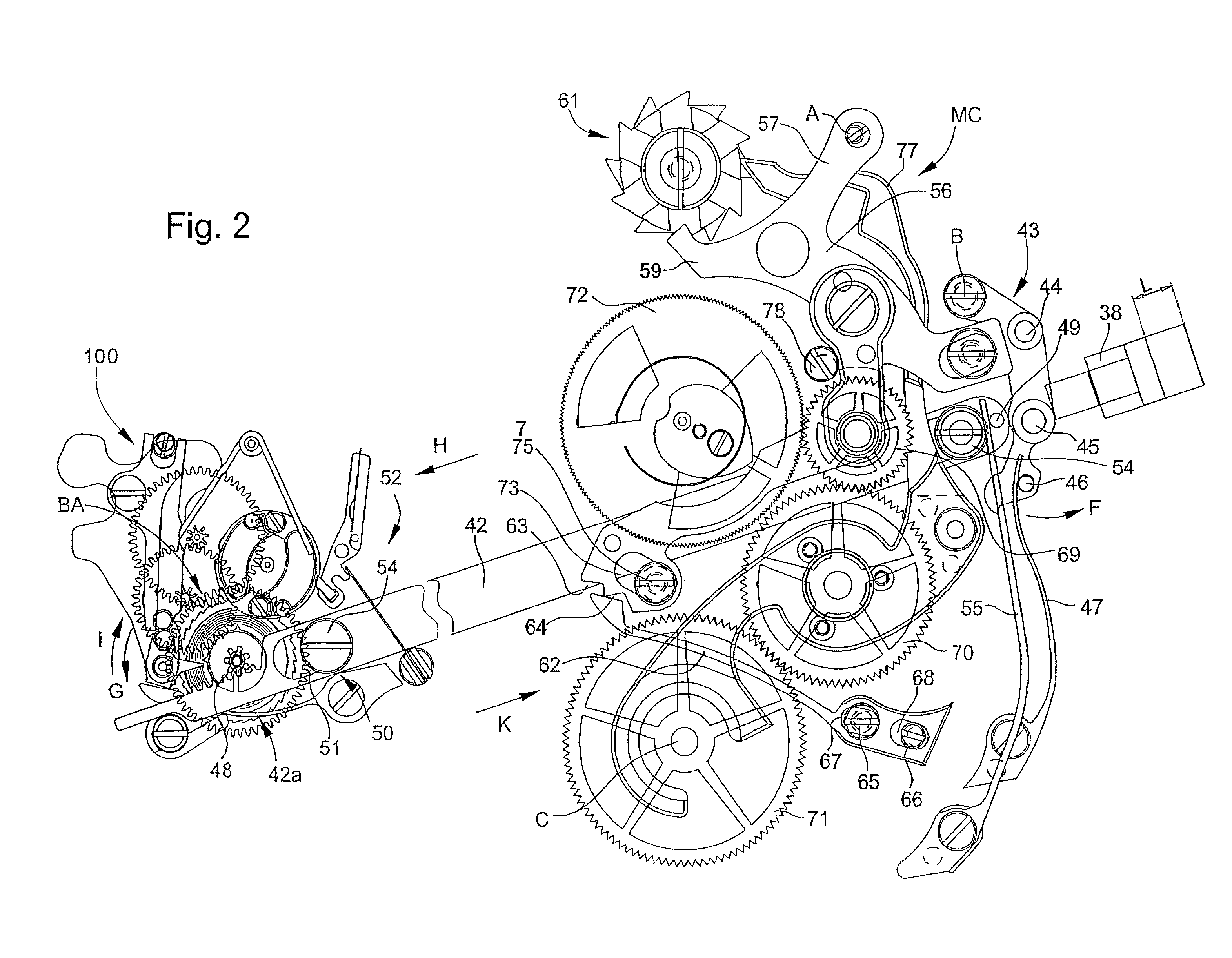

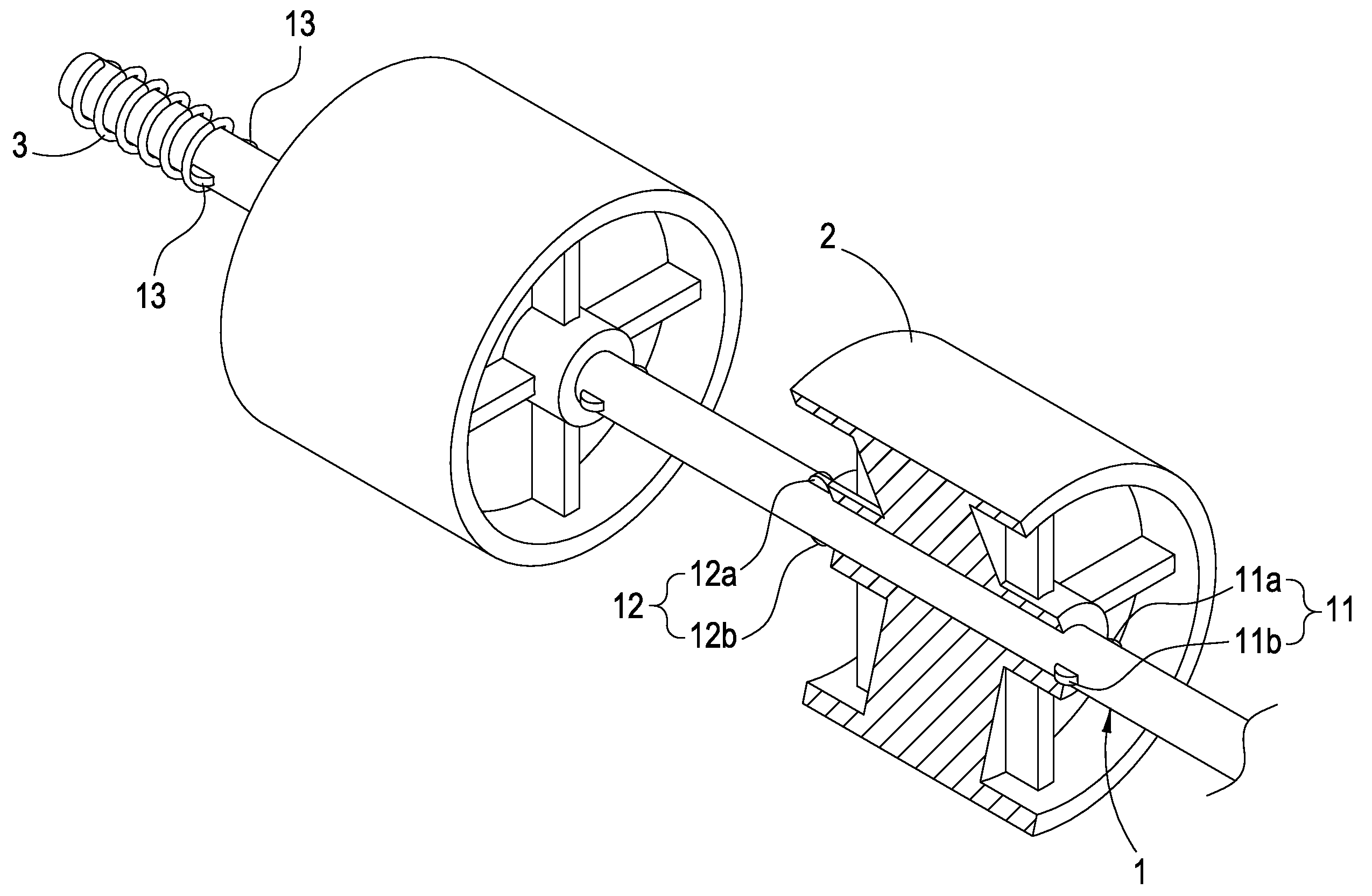

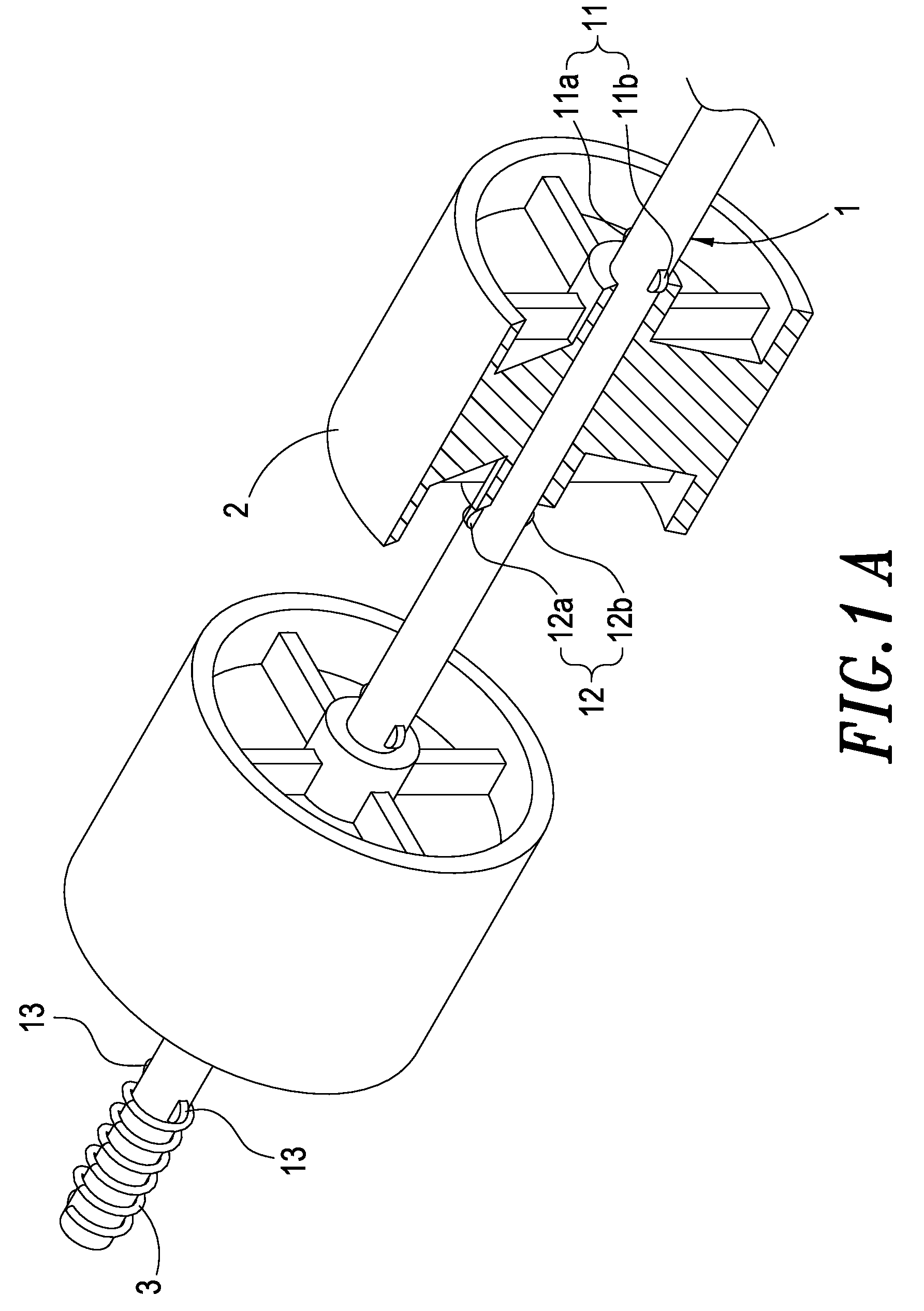

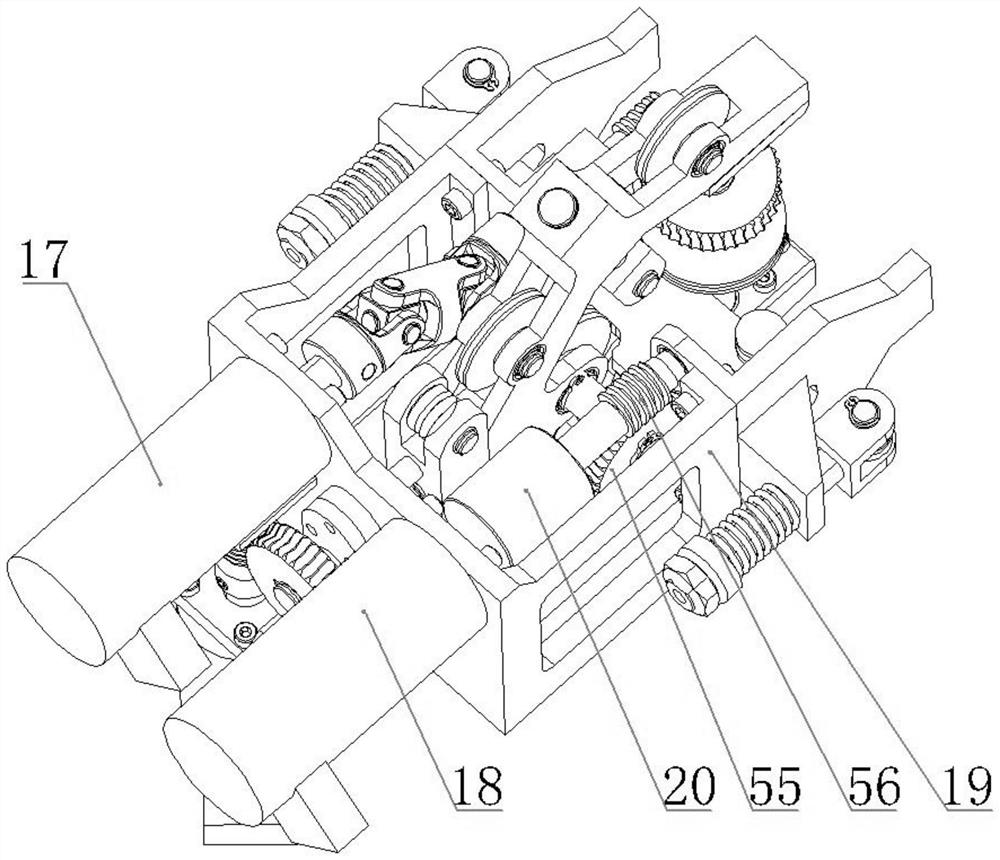

Timepiece including a mechanism for triggering a time-related function and simultaneous winding of a barrel spring

InactiveUS7192181B2Simplifies manufactureEliminate costMechanical unknown time interval measurementElectric windingEngineeringConductor Coil

The invention concerns a timepiece component comprising a watch movement provided with a main barrel acting as power source for a timekeeping device of the watch movement and an auxiliary barrel designed to supply mechanical power to an additional device, and mechanical control means capable of being manually actuated to trigger said additional device, characterised in that said control means are arranged to simultaneously trigger the additional device and wind the auxiliary barrel.

Owner:GLASHUETTER UHRENBETRIEB GMBH

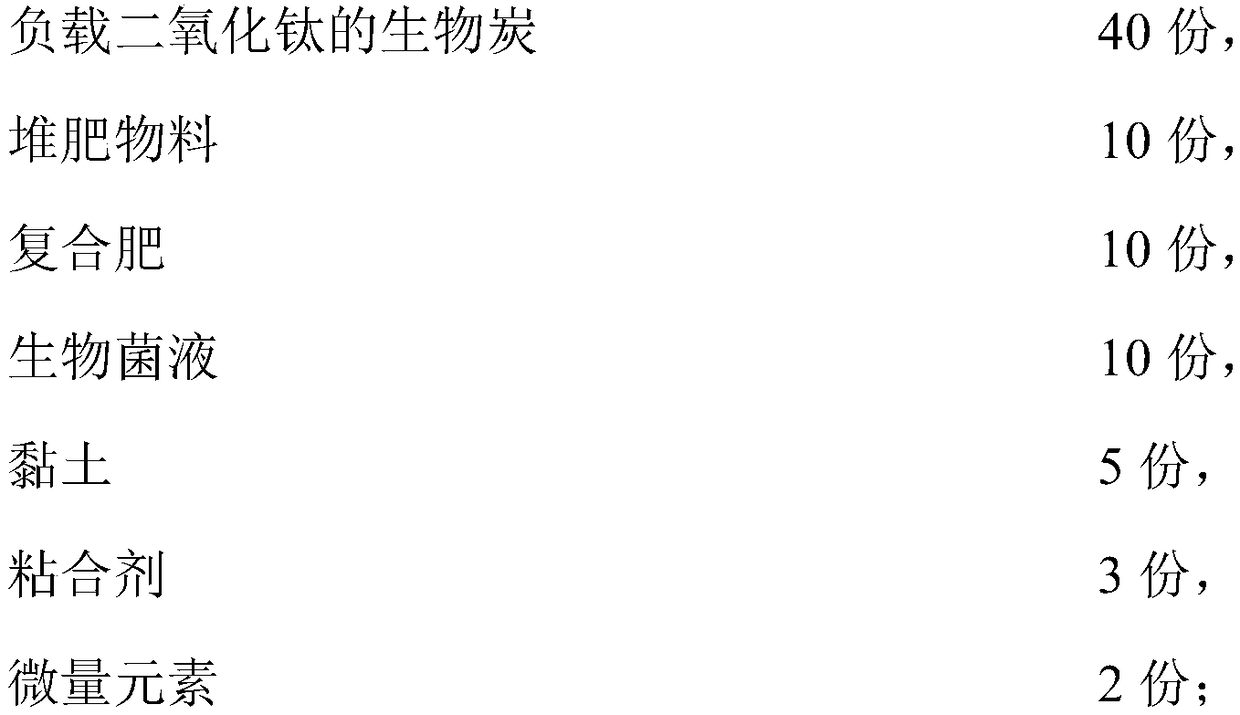

Biochar soil remediation agent and preparation method thereof

InactiveCN108640791AImprove organic matterIncrease microbial contentSuperphosphatesAlkali orthophosphate fertiliserMicroorganismSoil remediation

The invention discloses a biochar soil remediation agent and a preparation method thereof. The biochar soil remediation agent is prepared from titanium dioxide supported biochar, compost materials, compound fertilizer, a biological bacteria solution, clay, a binder and microelements; the preparation method of the biochar soil remediation agent comprises steps as follows: preparation of titanium dioxide supported biochar, preparation of the compost materials, preparation of the biological bacteria solution, preparation of the clay, preparation of a mixed material coated with biochar, pelletizing and drying. The preparation process is environmentally friendly and simple to operate, the raw materials are widely sourced, the prepared soil remediation agent not only can adsorb and degrade pollutants in soil, but also increases content of organic matter and microorganisms in the soil, and accordingly, economic benefit and environmental benefit are remarkably increased.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

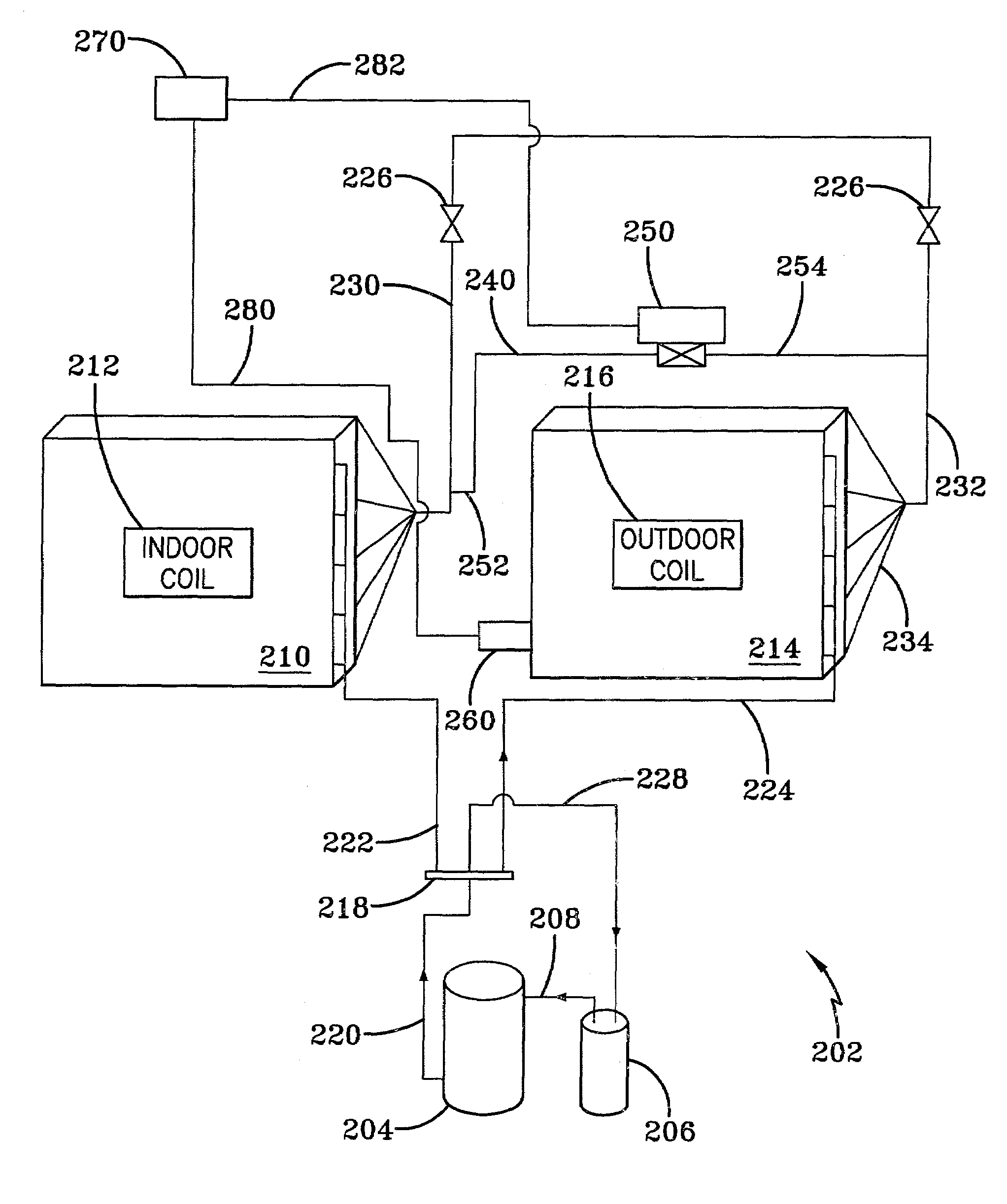

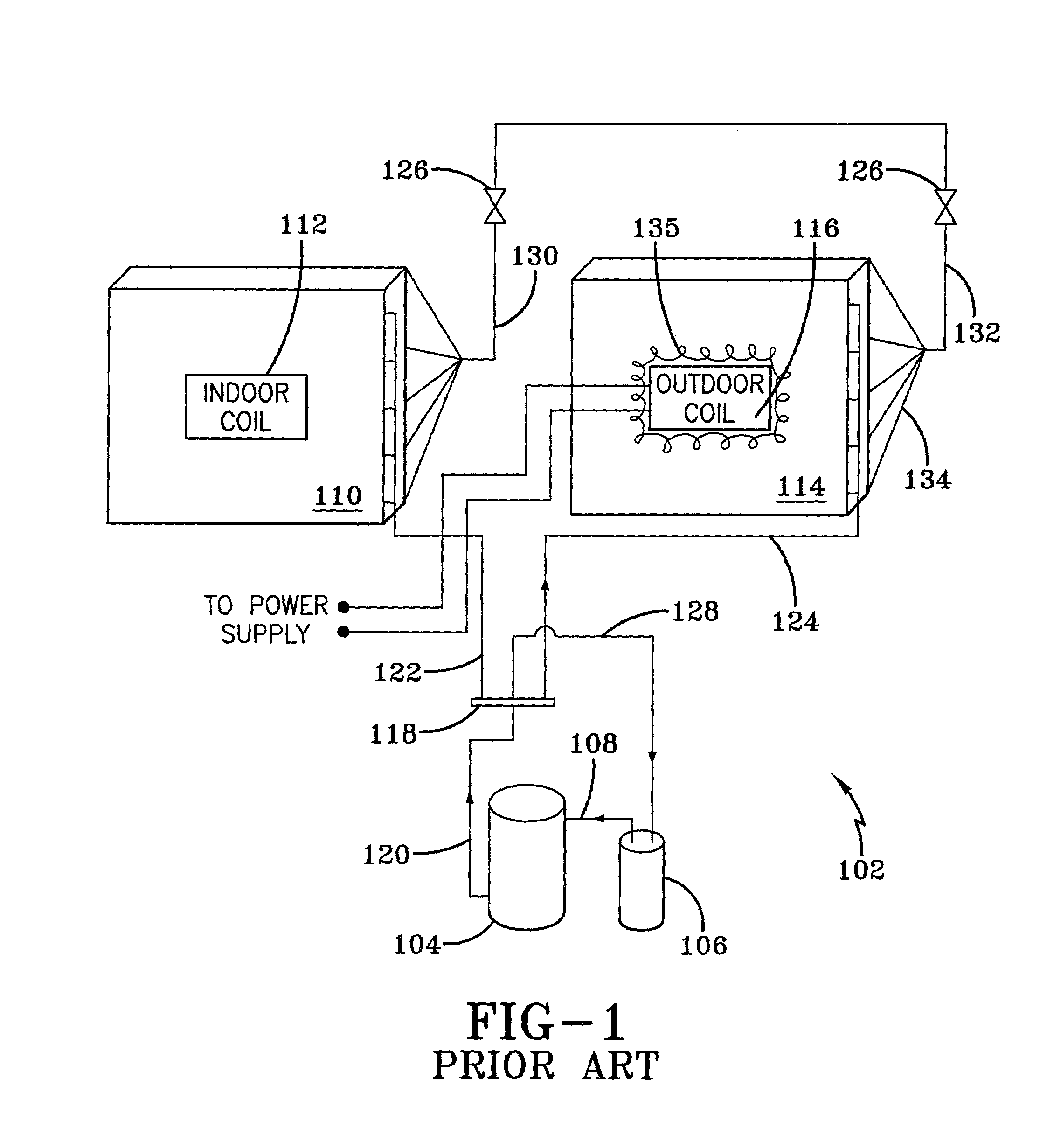

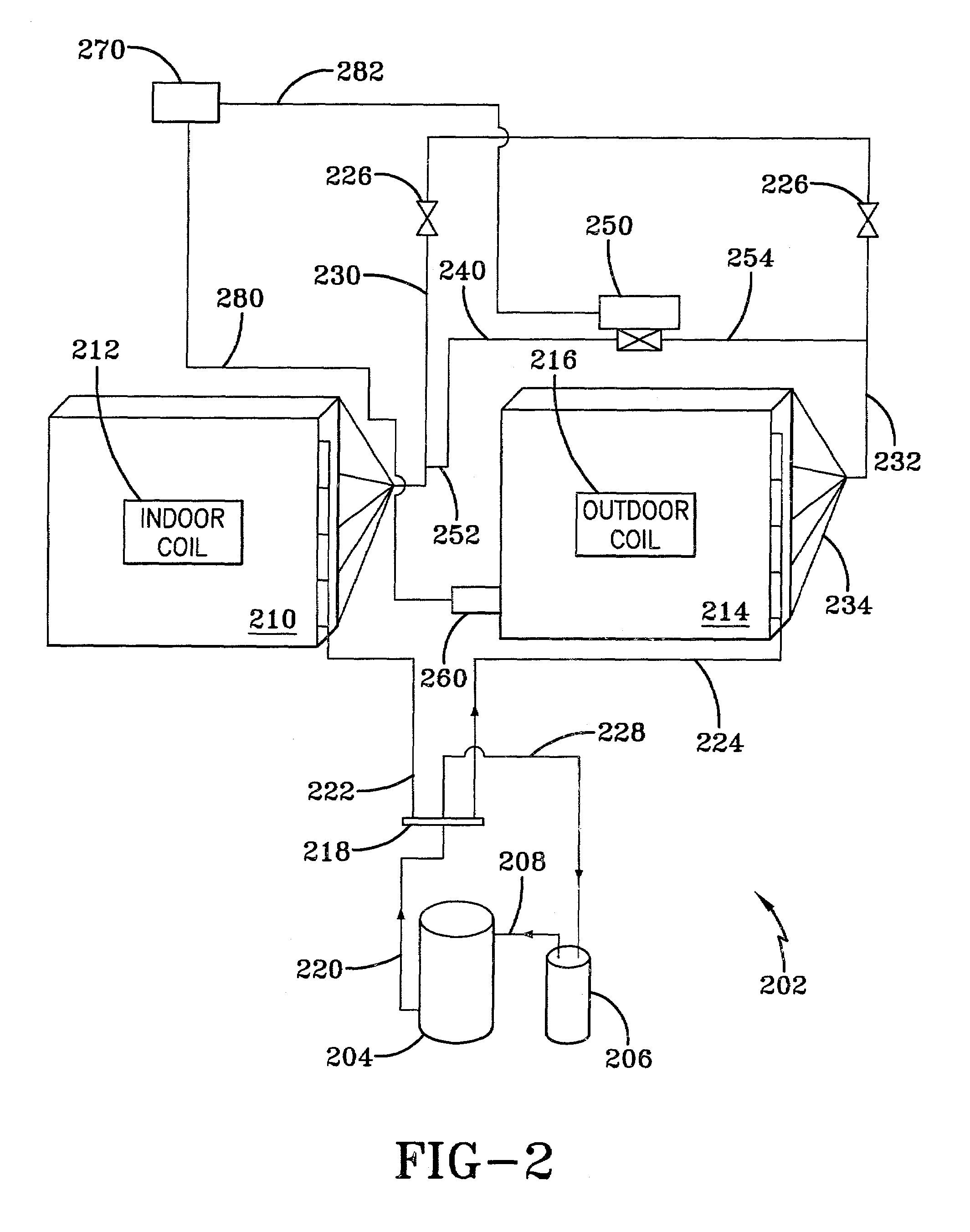

Air-to-air heat pump defrost bypass loop

InactiveUS7004246B2Eliminate costReduce operating costTemperatue controlAir heatersRefrigerantSet point

An improvement in defrosting an air-to-air heat pump system when in the heating mode. A bypass loop transfers refrigerant at a higher temperature and pressure than is normally cycled through the outdoor unit to an outdoor coil to defrost ice on the outdoor coil, The bypass loop includes a valve movable between closed and open positions. A sensor monitors a preselected condition indicative of outdoor coil performance. A controller communicates with the valve and the sensor. Once the controller determines that a preselected set point of a preselected condition indicative of deteriorating performance has been reached, based on received sensor signals, the controller sends a signal to open the valve, allowing warm refrigerant to bypass expansion valves and flow to the outdoor unit to defrost the outdoor unit. Once defrosting is accomplished, the valve can be moved to a closed position to resume normal operation of the heat pump unit.

Owner:YORK INT

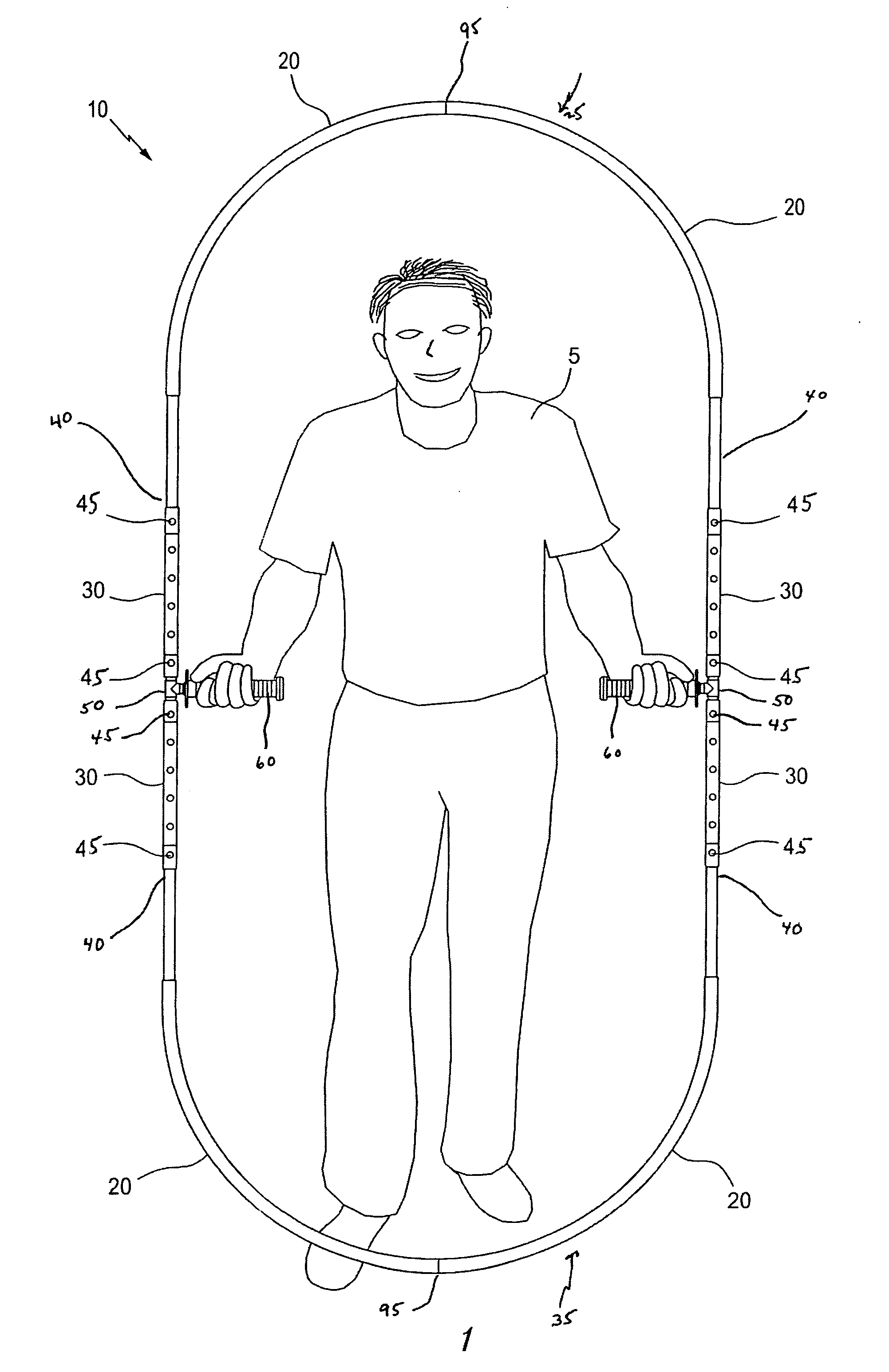

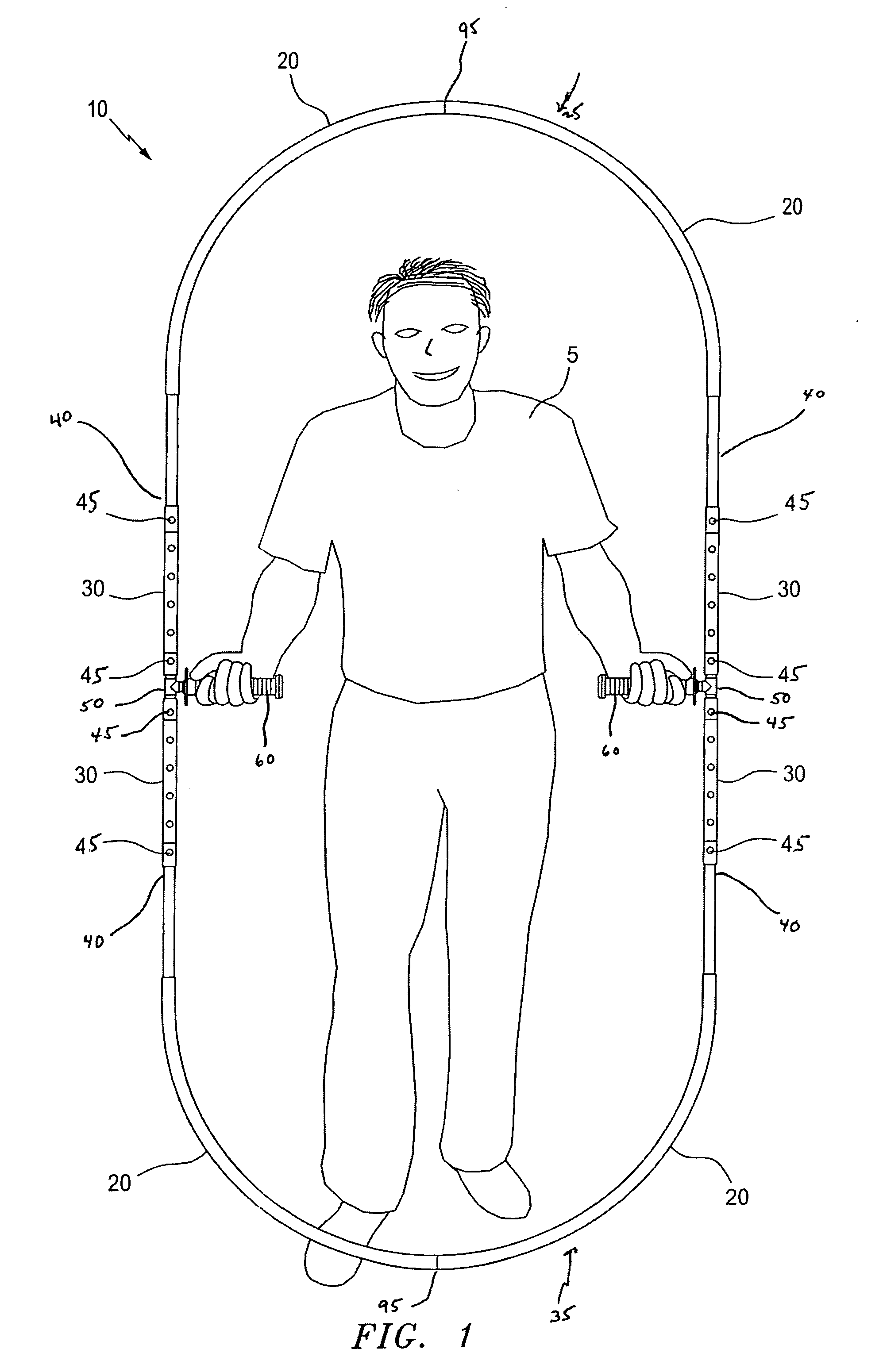

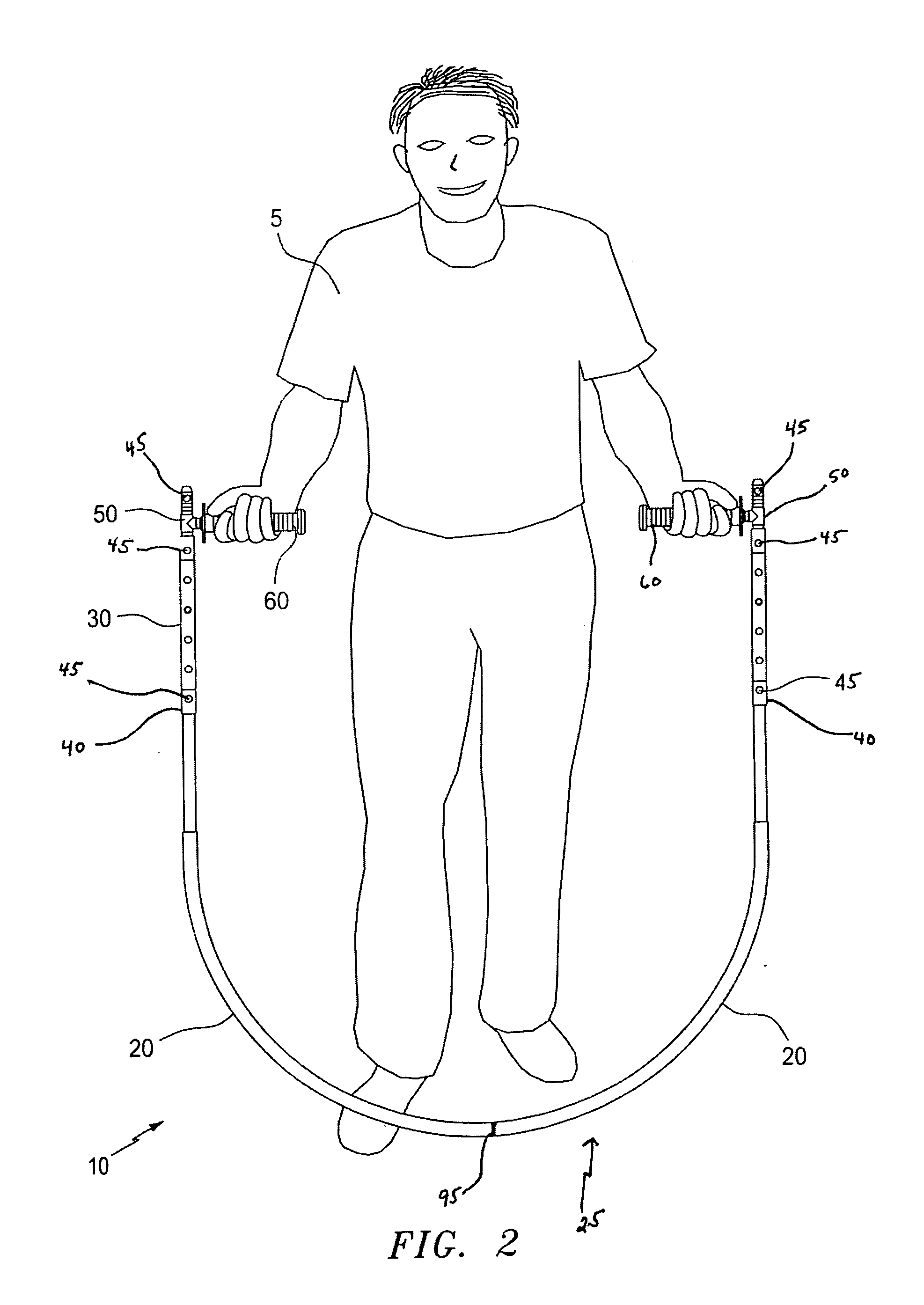

Jump hoop device

A jump hoop device is provided to assimilate all benefits of a conventional jump rope without use of rope which can become entangled in a user's feet or become worn with frequent use. The present jump hoop device is especially beneficial towards improvement in the areas of exercise, fitness, therapy, rehabilitation and sports training or for enjoyment at home by both children and adults. The apparatus of the invention provides quick and easy adjustment in height and width by an improved adjustment means which does not require use of bolts, pins, nuts or other means. The present apparatus can be used as a double hoop assembly providing double jumping per rotation or as a single hoop assembly like the conventional jump rope. A counter device and means of providing music or other sound recordings are attached to a pair of handle assemblies respectfully, for providing added entertainment or instructional purposes.

Owner:HEINRICH CARL C

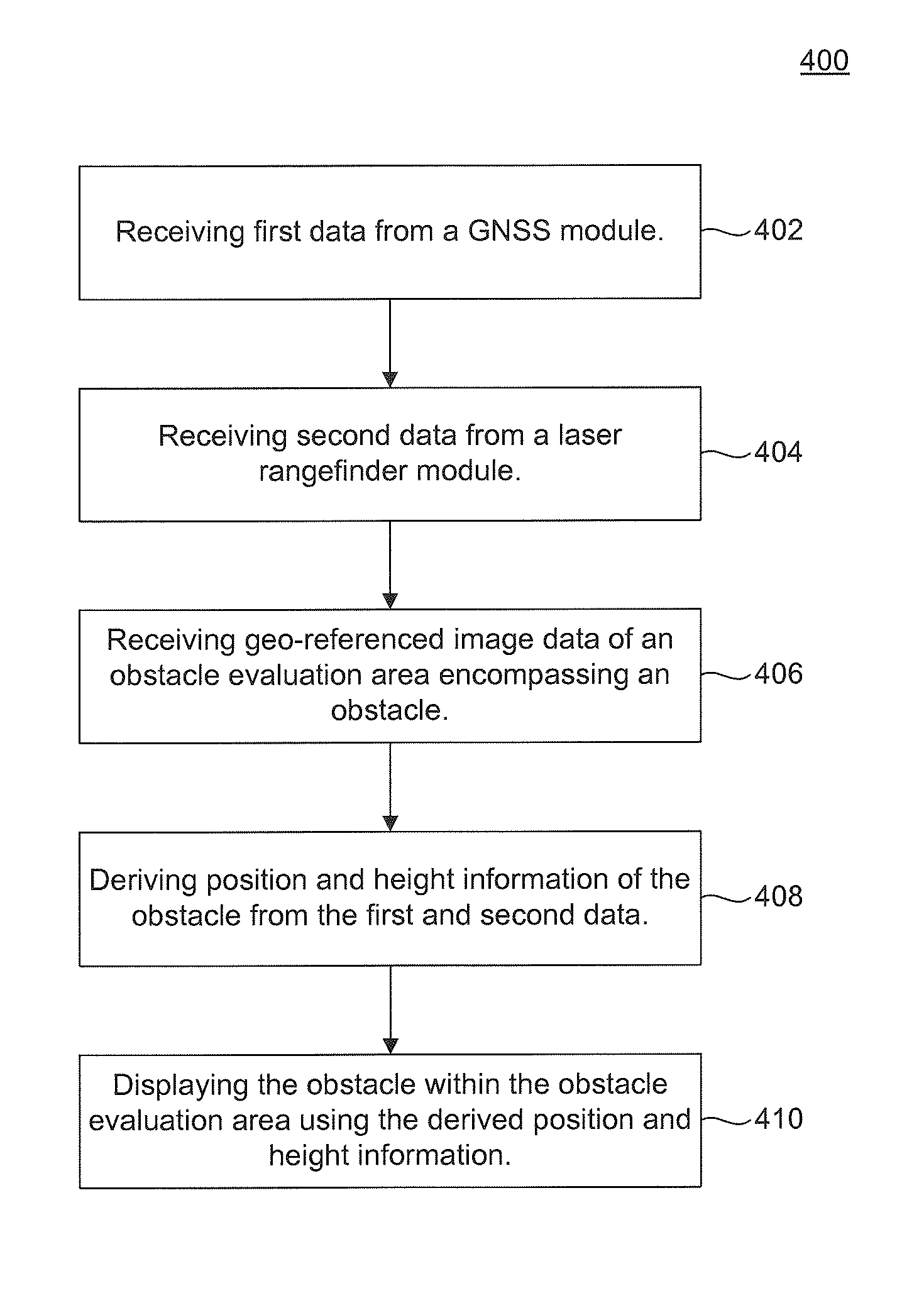

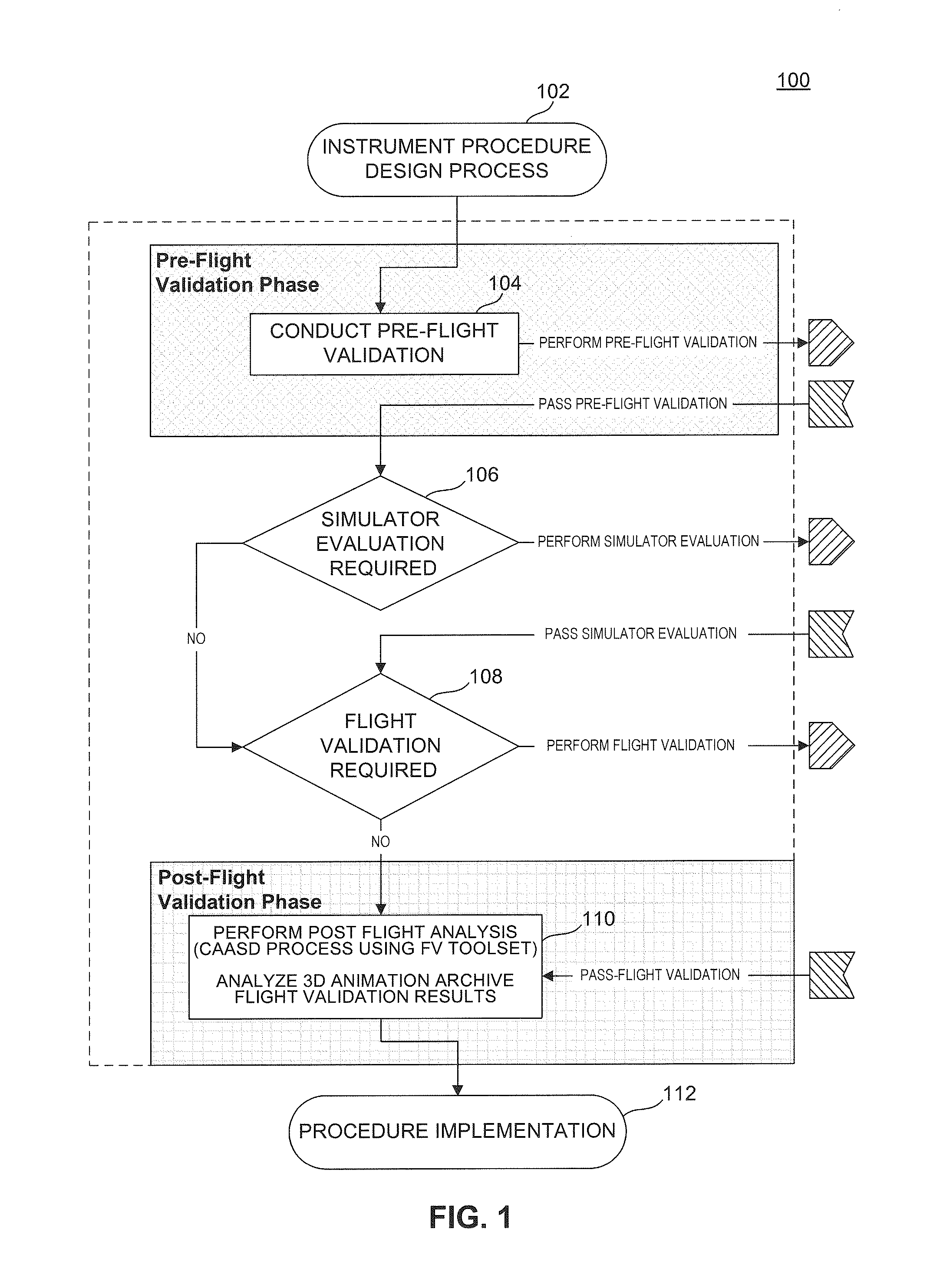

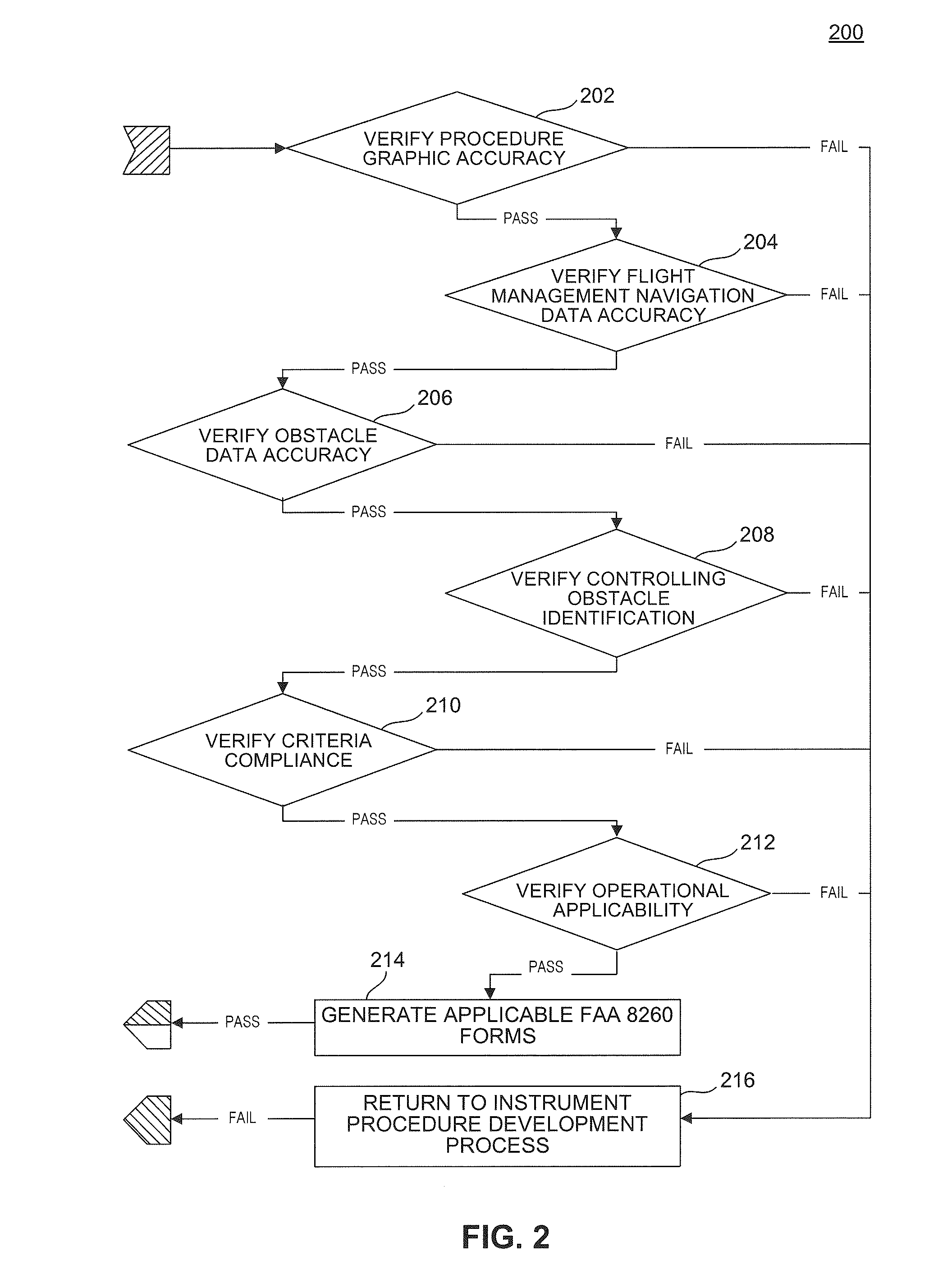

Systems, Methods, and Computer Program Products of Flight Validation

ActiveUS20120053832A1Eliminate costSuitable for operationInstruments for road network navigationRoad vehicles traffic controlComputer programmingRoute generation

Systems, methods, and computer program products for flight validation (FV) are provided. Embodiments implement the requirements of FAA Notice 8260.67 as they relate to FV. Embodiments enable FV to be performed in its entirety, including flight and / or ground obstacle assessment, and on-course / on-path flight evaluation. Embodiments enable a post-flight validation phase, which provides post flight analysis and archiving capabilities. Using embodiments, a person of minimal skill and training can perform FV as prescribed by FAA requirements. Accordingly, significant costs associated with hiring professional surveyors and air crews to perform obstacle assessment and flight evaluation can be eliminated. Embodiments can be implemented using commercial off-the-shelf (COTS) and relatively inexpensive hardware, making them suitable for large-scale FV operations. Embodiments may also be integrated with existing instrument flight procedure design tools, including, for example, the TARGETS (Terminal Area Route Generation Evaluation & Traffic Simulation) tool developed by the MITRE Corporation.

Owner:MITRE SPORTS INT LTD

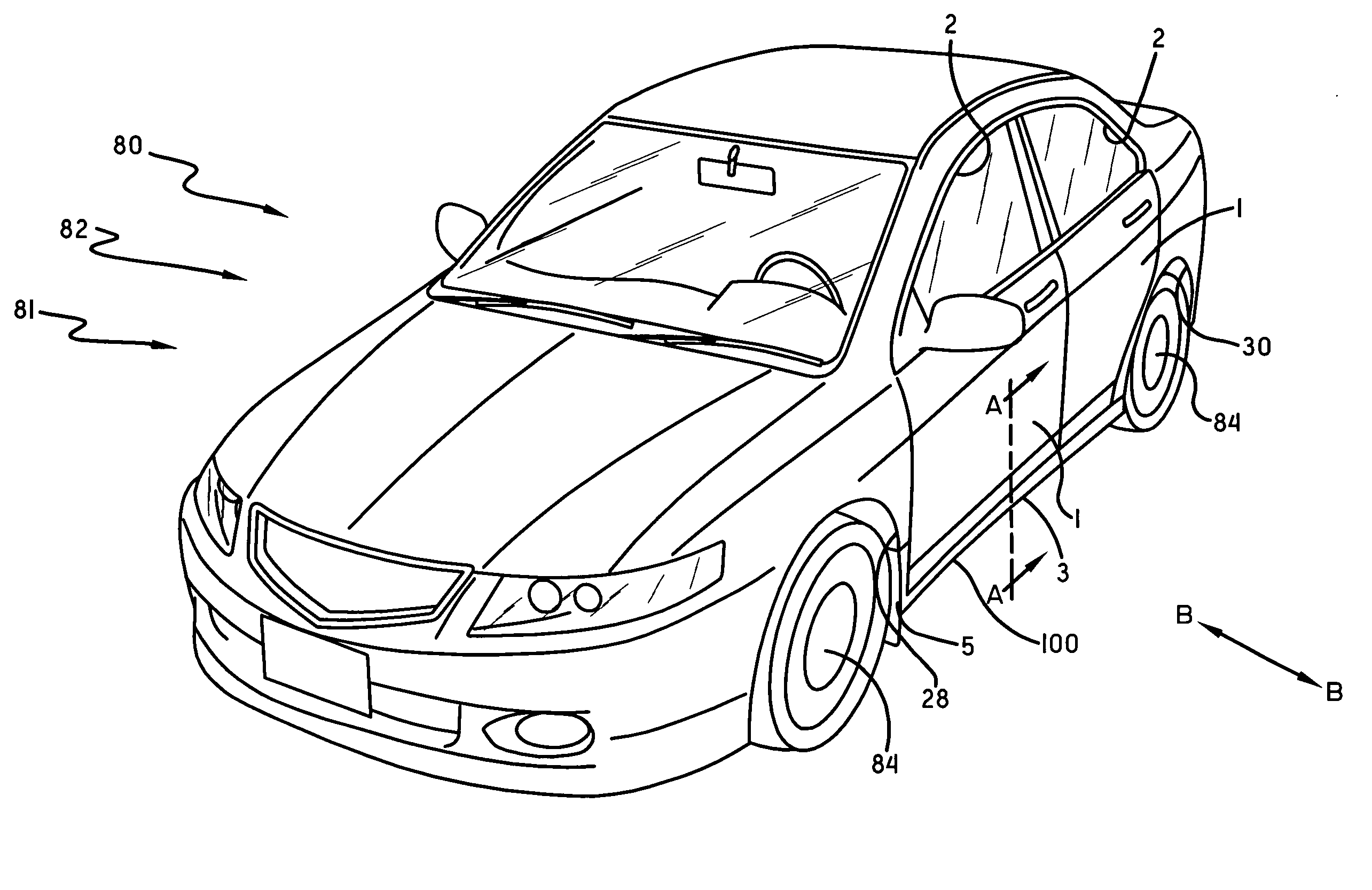

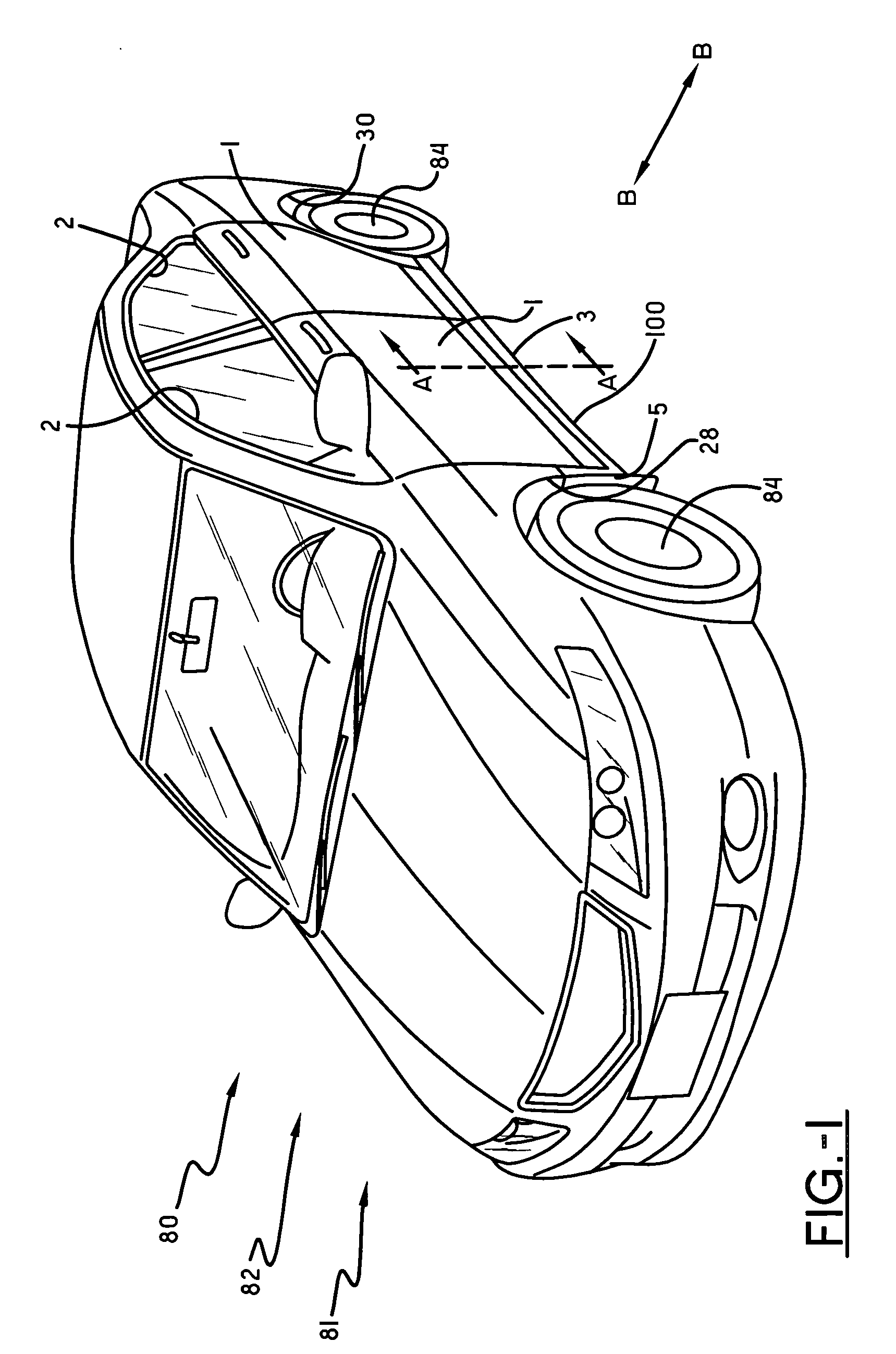

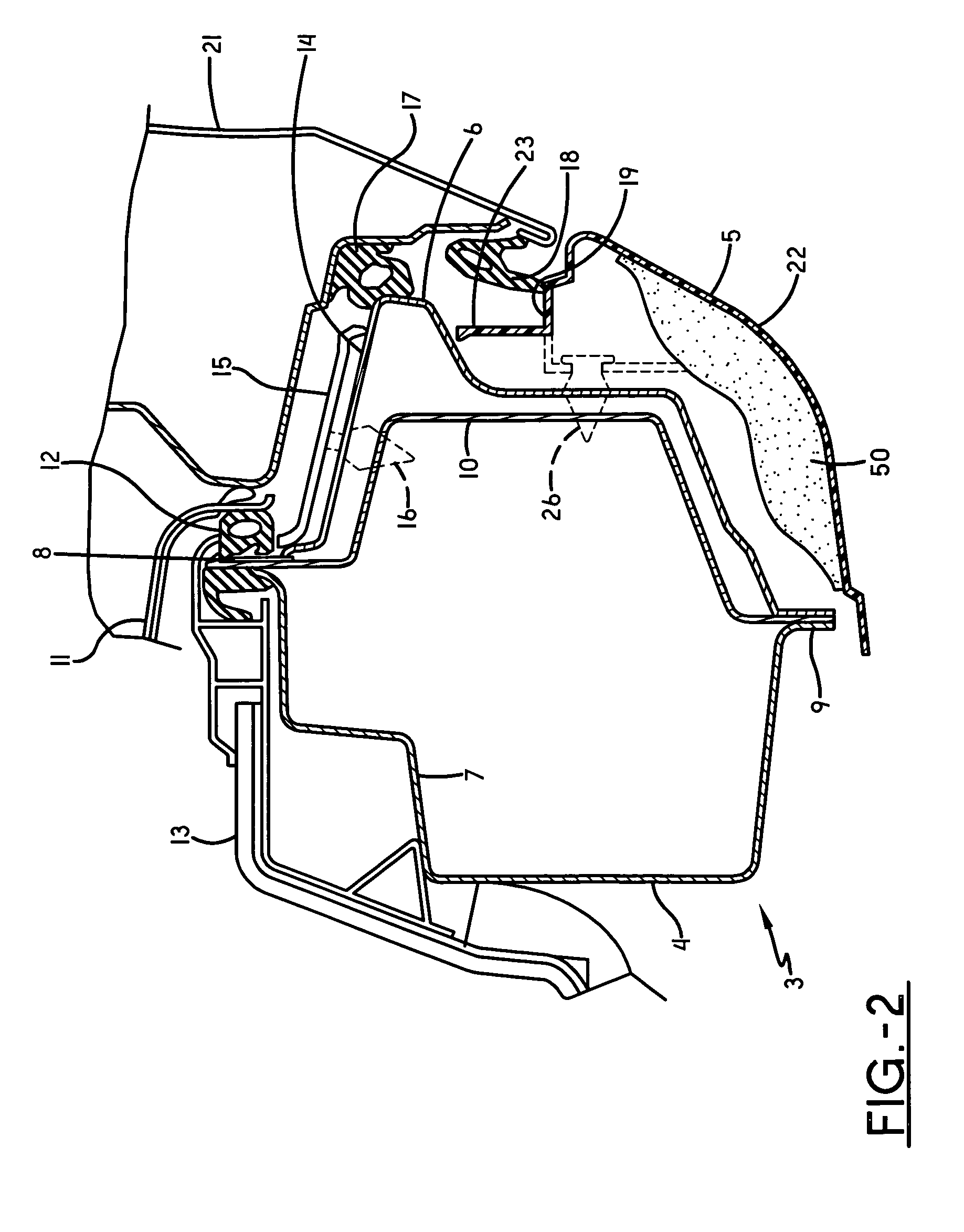

Single piece side-sill-garnish and mudguard

InactiveUS20090167010A1Eliminate costReduce tooling costsVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

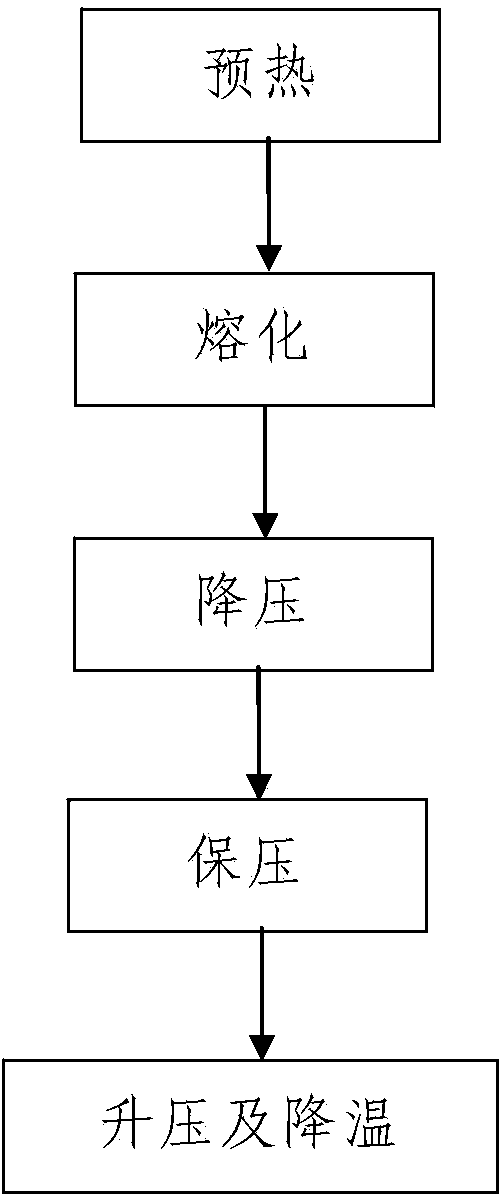

Polycrystalline silicon ingot casting molten material and impurity removing process

InactiveCN103741206AReasonable designThe process steps are simplePolycrystalline material growthFrom frozen solutionsCrucibleIngot casting

The invention discloses a polycrystalline silicon ingot casting molten material and an impurity removing process. The process comprises the following steps: 1, preheating: adopting an ingot furnace to preheat a silicon material filled in a crucible, and gradually raising the heating temperature of the ingot furnace to T1; the preheating time is 6-10h, and T1=1165-1185 DEG C; 2, melting: the melting temperature is T1-T5; T5=1540-1560 DEG C; in the melting process, filling insert gases into the ingot furnace, and keeping air pressure in the furnace in Q1, and Q1=550-650mbar; 3, removing impurities: the process is as follows: the 11th step, reducing pressure: the air pressure of the ingot furnace is reduced from Q1 to Q2, and the pressure reducing time is 8-12min, and Q2=350-450mbar; the 12th step, maintaining pressure; the 13th step, boosting pressure and lowering temperature. The process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect, can discharge gas containing carbon in the furnace in time, and increases the polycrystalline silicon ingot casting quality.

Owner:XIAN HUAJING ELECTRONICS TECH

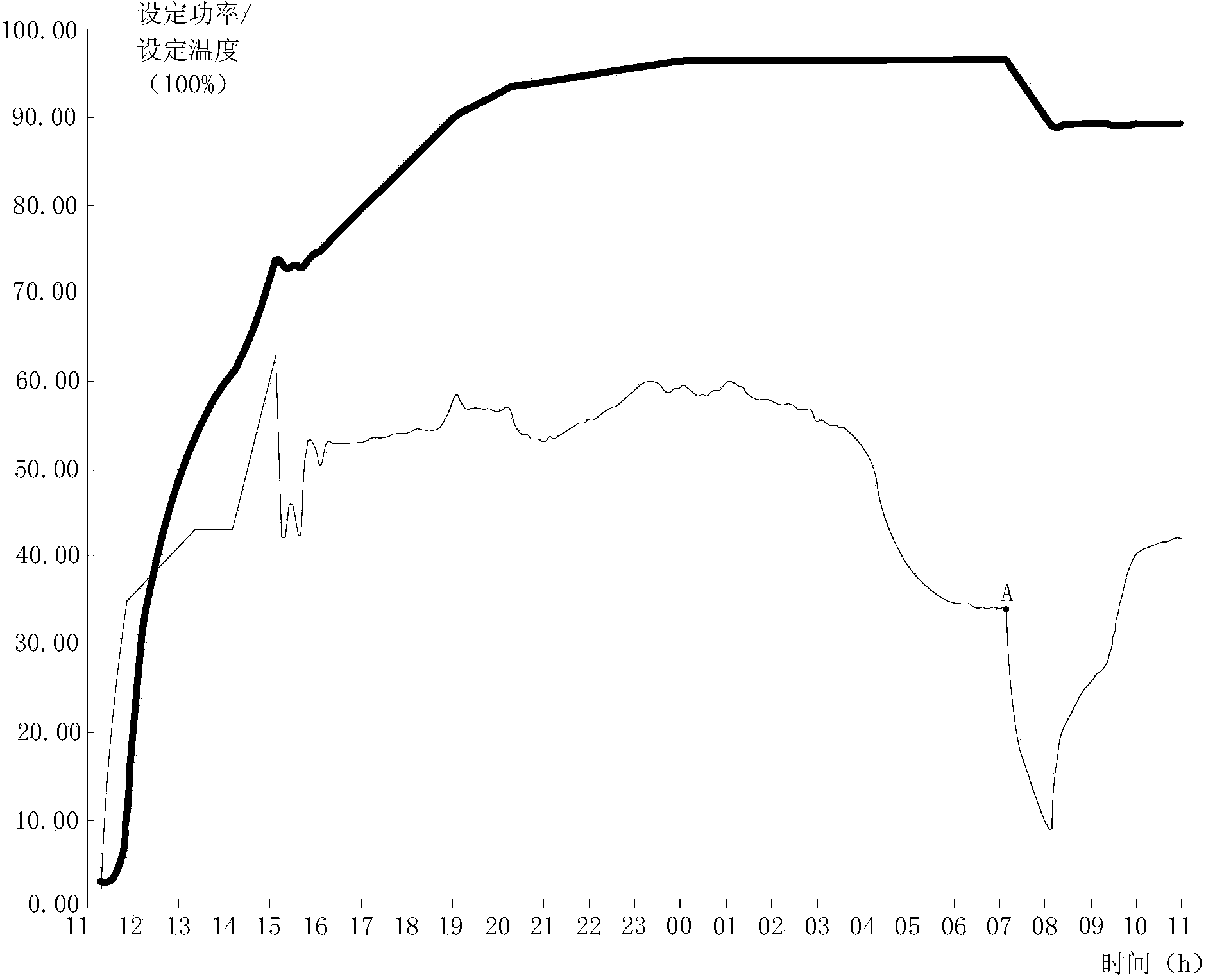

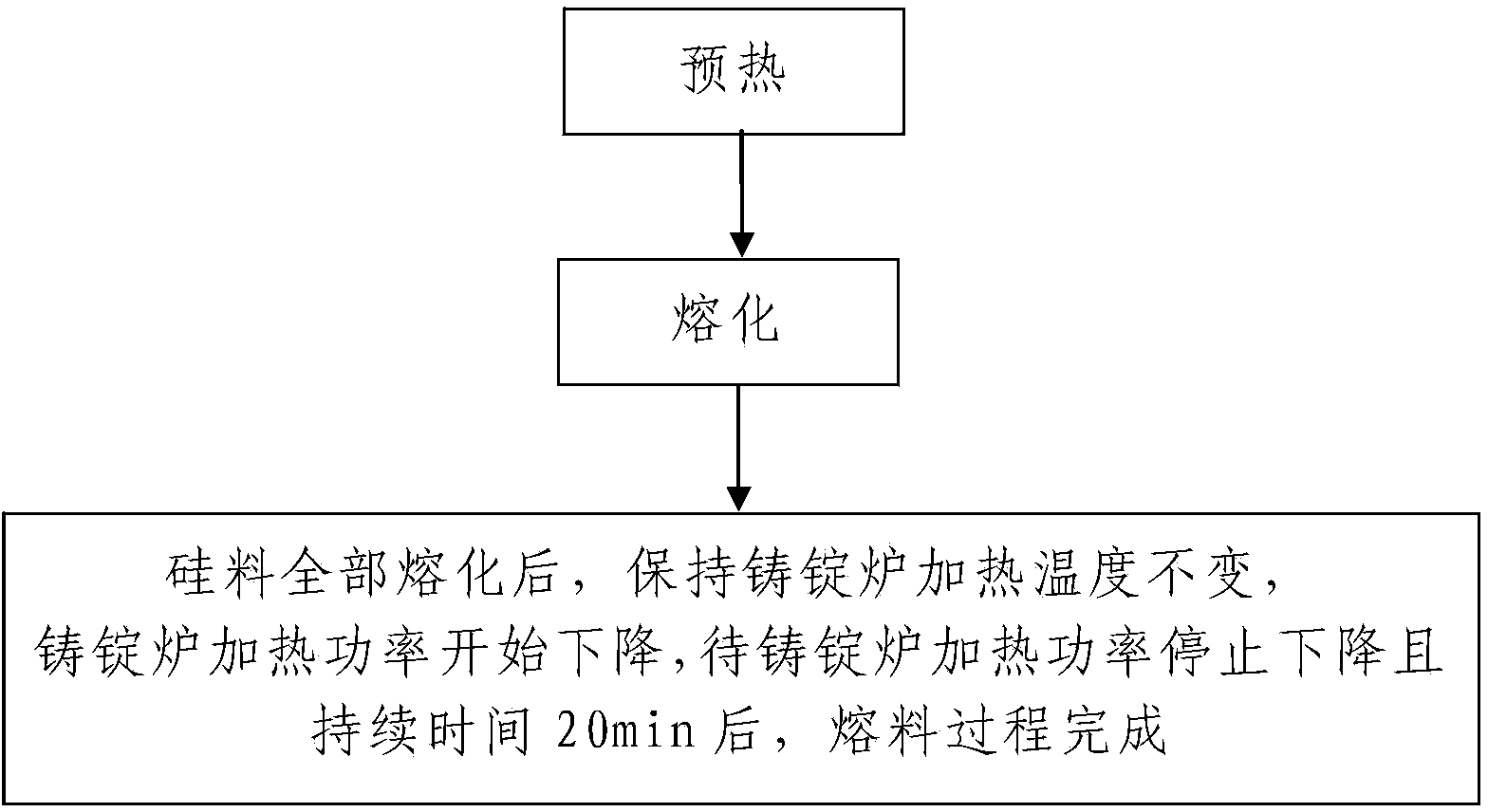

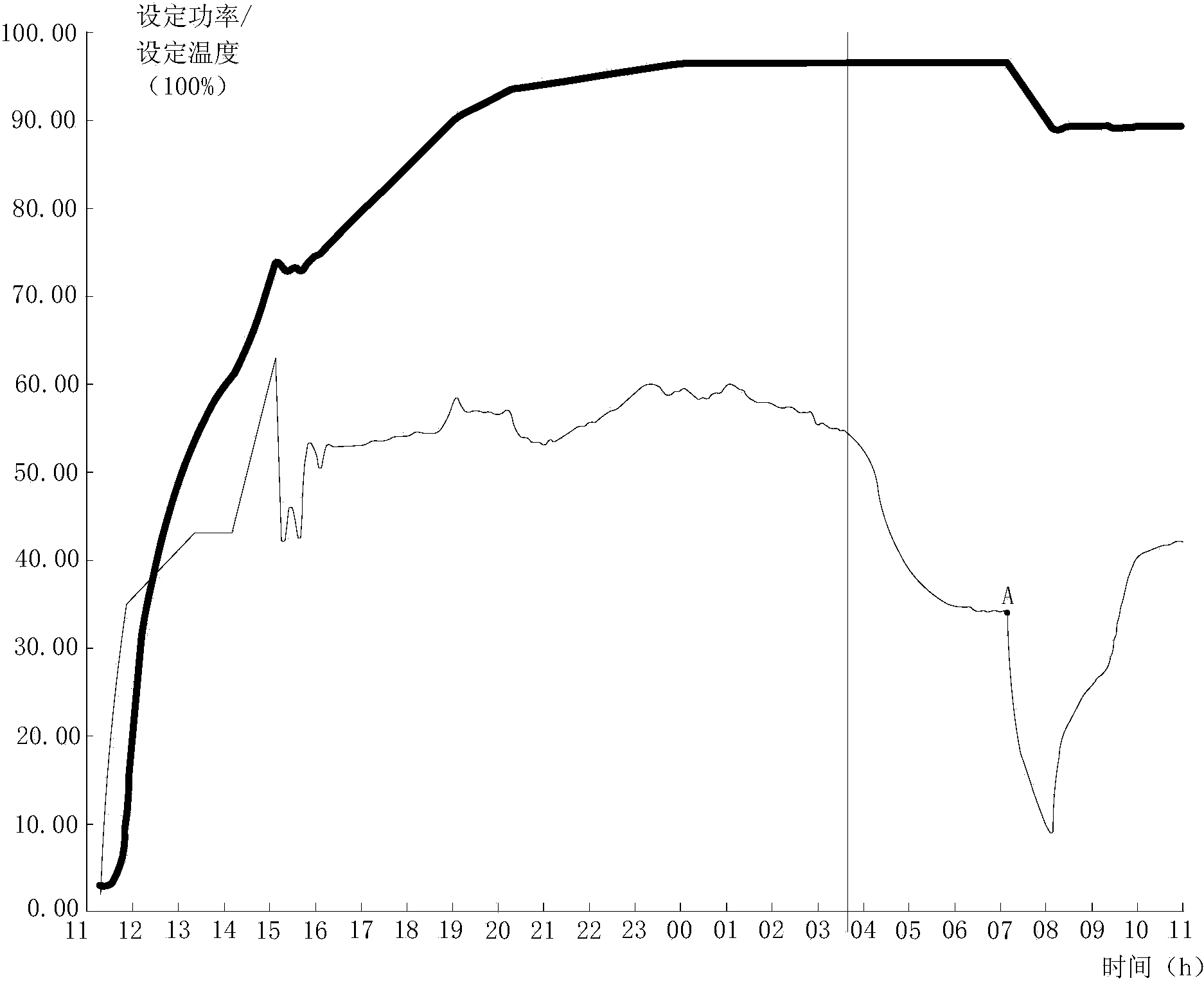

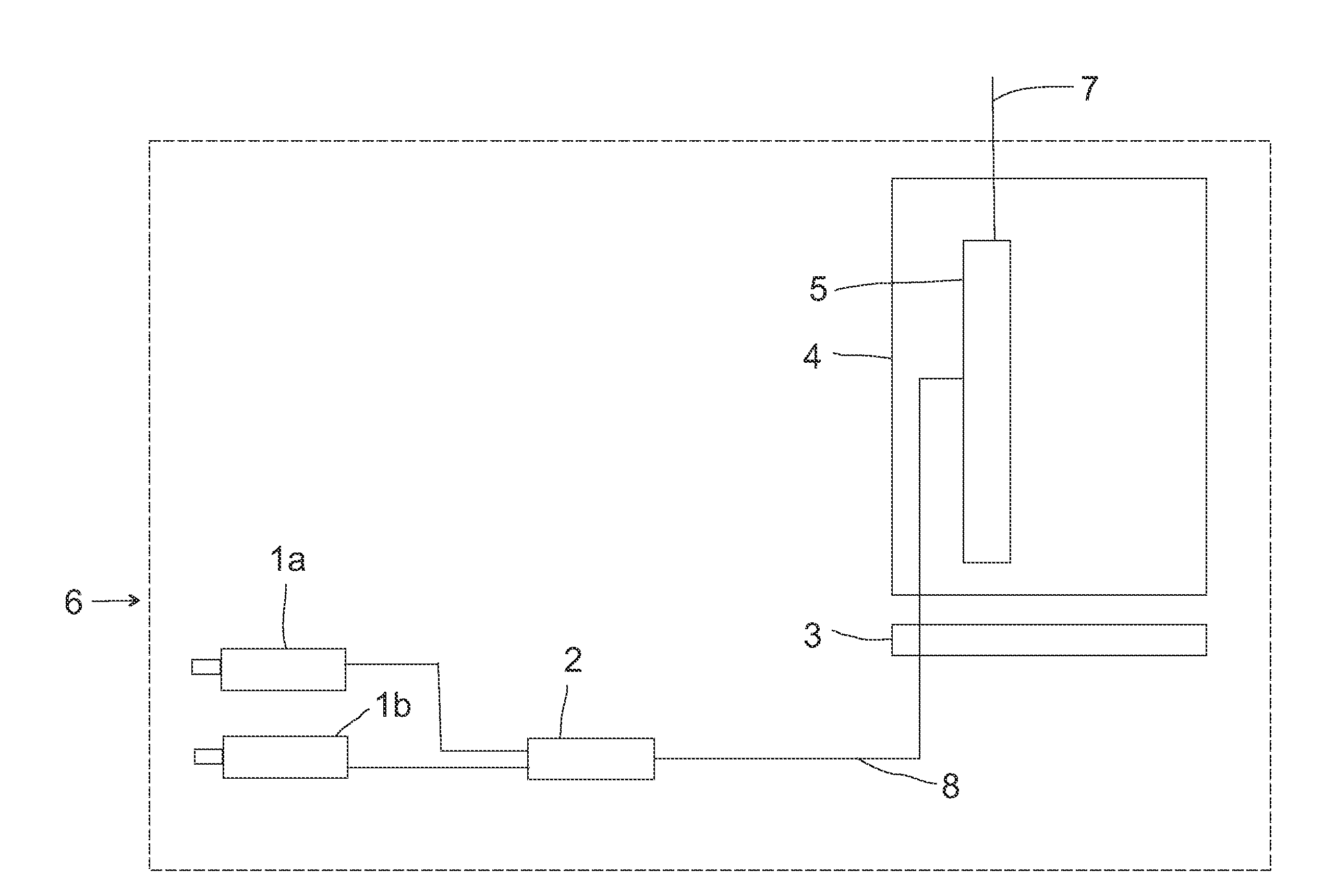

Melting process for polycrystalline silicon cast ingots

InactiveCN103741213AReasonable designThe process steps are simplePolycrystalline material growthSingle crystal growth detailsCrucibleIngot

The invention discloses a melting process for polycrystalline silicon cast ingots. The process comprises the following steps: 1, preheating: an ingot furnace is adopted to preheat a silicon material filled in a crucible, and the heating temperature of the ingot furnace is gradually increased to T1; the preheating time is 6-10h, and T1=1165-1185 DEG C; 2 melting: the silicon material filled in the crucible is melted, the melting temperature is T1-T5, and T5=1540-1560 DEG C; after the silicon material in the crucible is completely melted, the heating temperature of the ingot furnace is controlled to T5, and then the heating power of the ingot furnace begins to decline; after the heating power of the ingot furnace stops declining and lasts for the time t, the melting process is complete; t=18-22min. The process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect and can effectively solve the problem that the quality of the produced polycrystalline silicon cast ingots is reduced as the melting time is deficient or too long.

Owner:XIAN HUAJING ELECTRONICS TECH

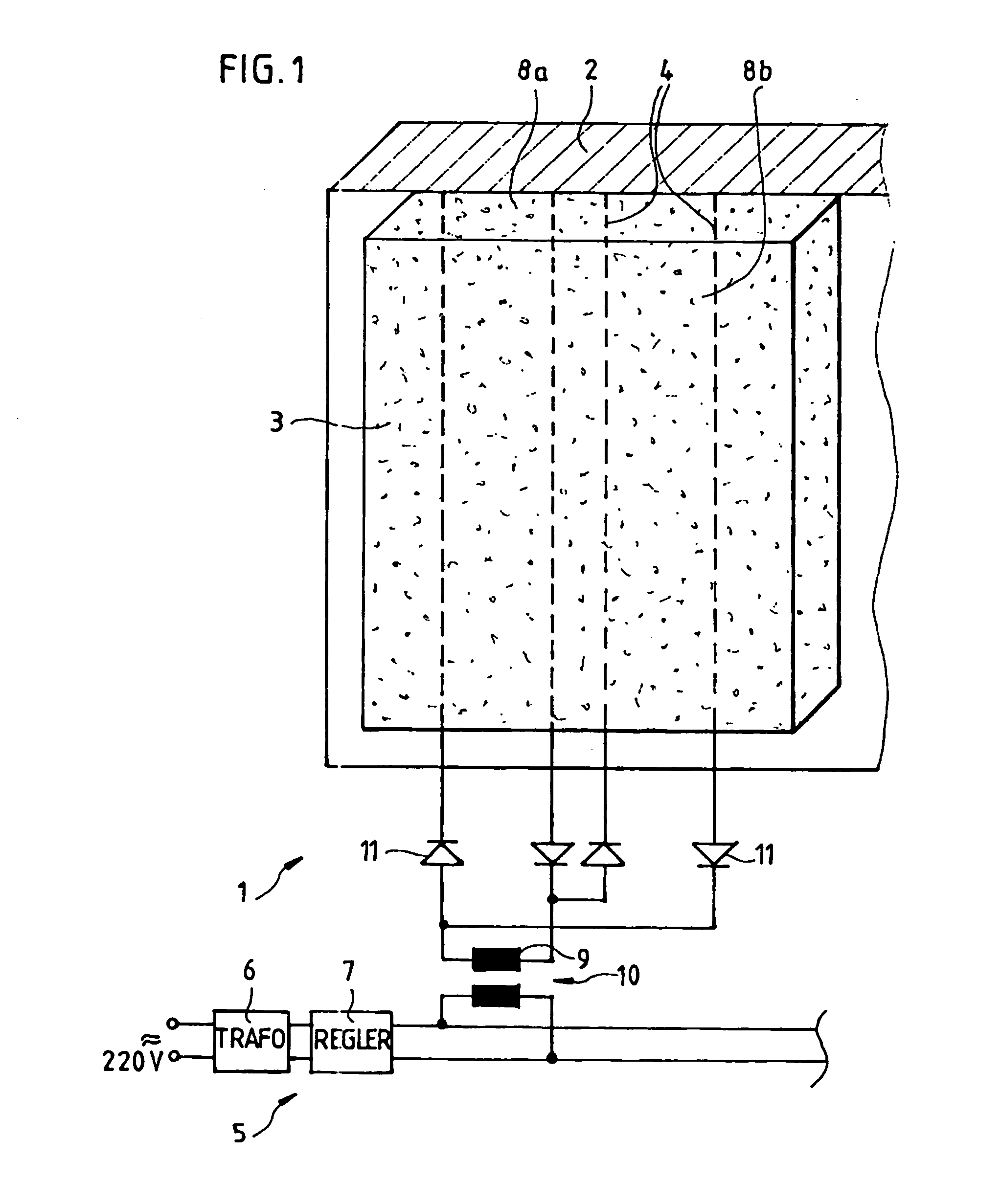

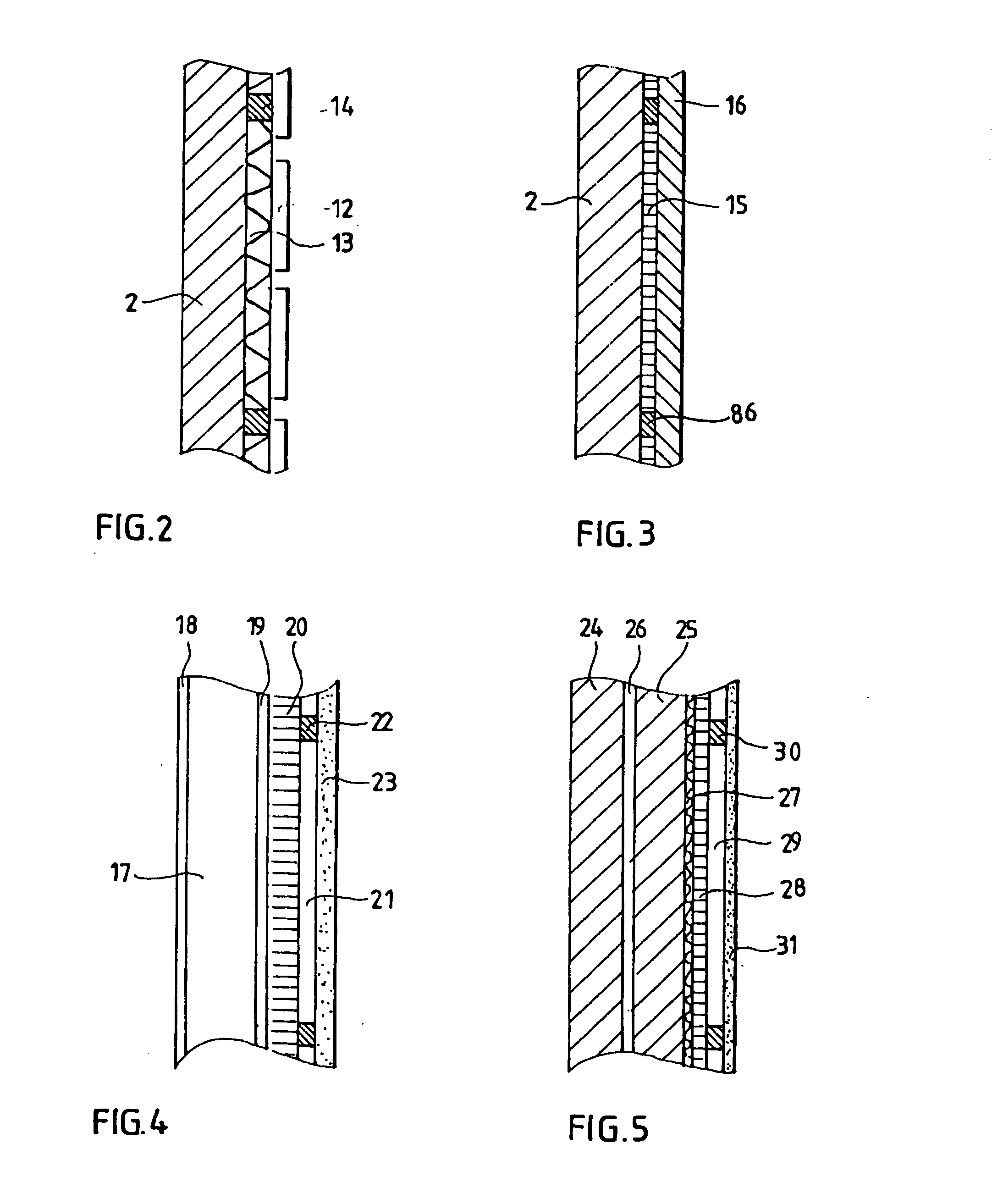

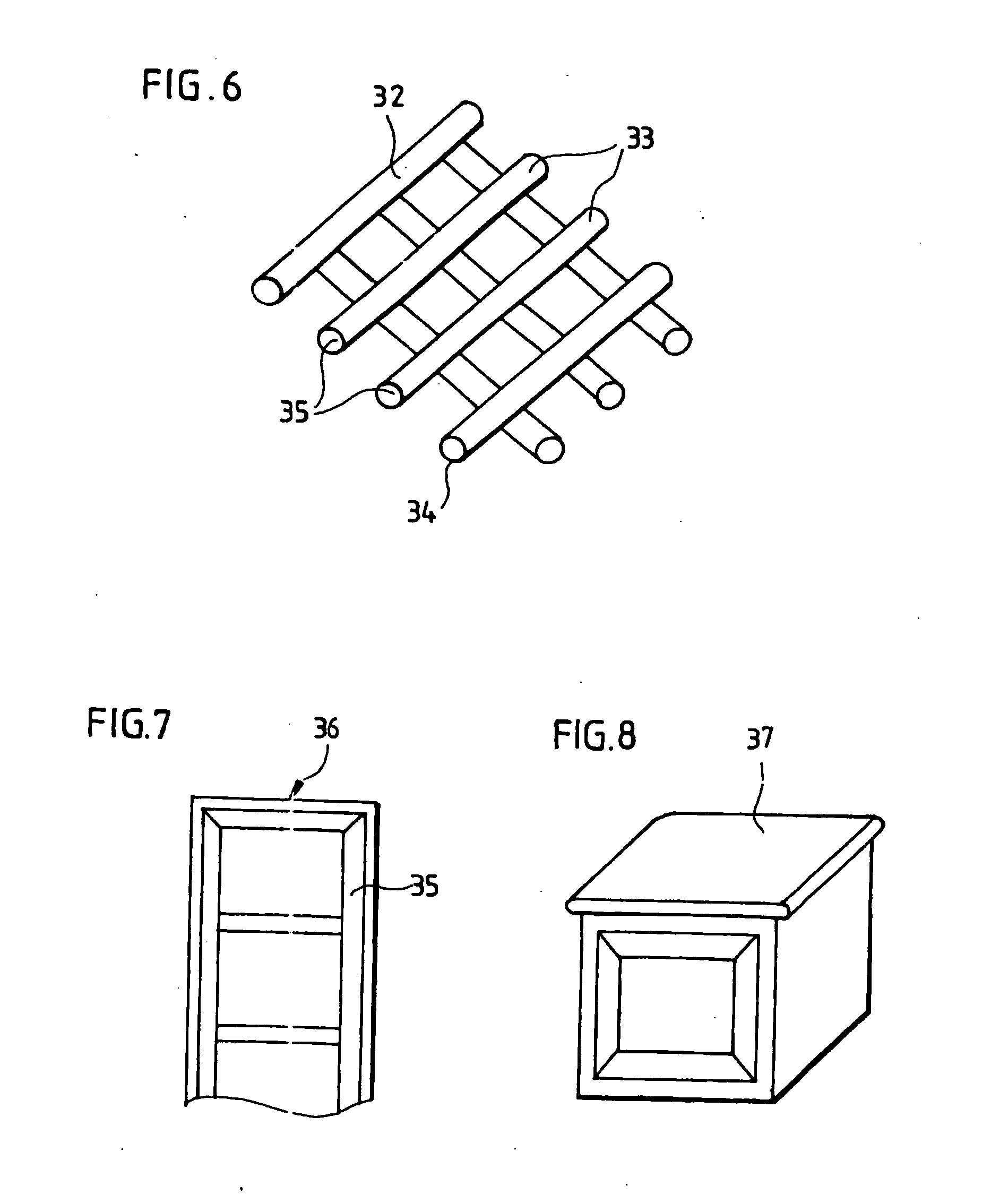

Electrical panel heating device and method and building materials for the protection thereof

ActiveUS20120175359A1Reduce proportionEliminate costNon-metal conductorsLighting and heating apparatusGypsumBuilding material

The invention relates to an electrical panel heating device and to a method and a material for the production thereof; the panel heating device is produced by curing a liquid or pasty material, comprising at least one inorganic binding agent, for example cement and / or gypsum, at least one electrically non-conductive additive, for example sand and / or rock flour, and at least one further additive composed of electrically conductive particles, for example carbon fibres and / or trips; after mixing this material in the liquid or pasty state, it is processed to form a product in the form of a panel which is provided with low-impedance contacts for feeding in a current distributed over an panel.

Owner:ZIMMERER WILHELM +1

Skate-Wheel Positioning Structure

Owner:CHEN PO FENG

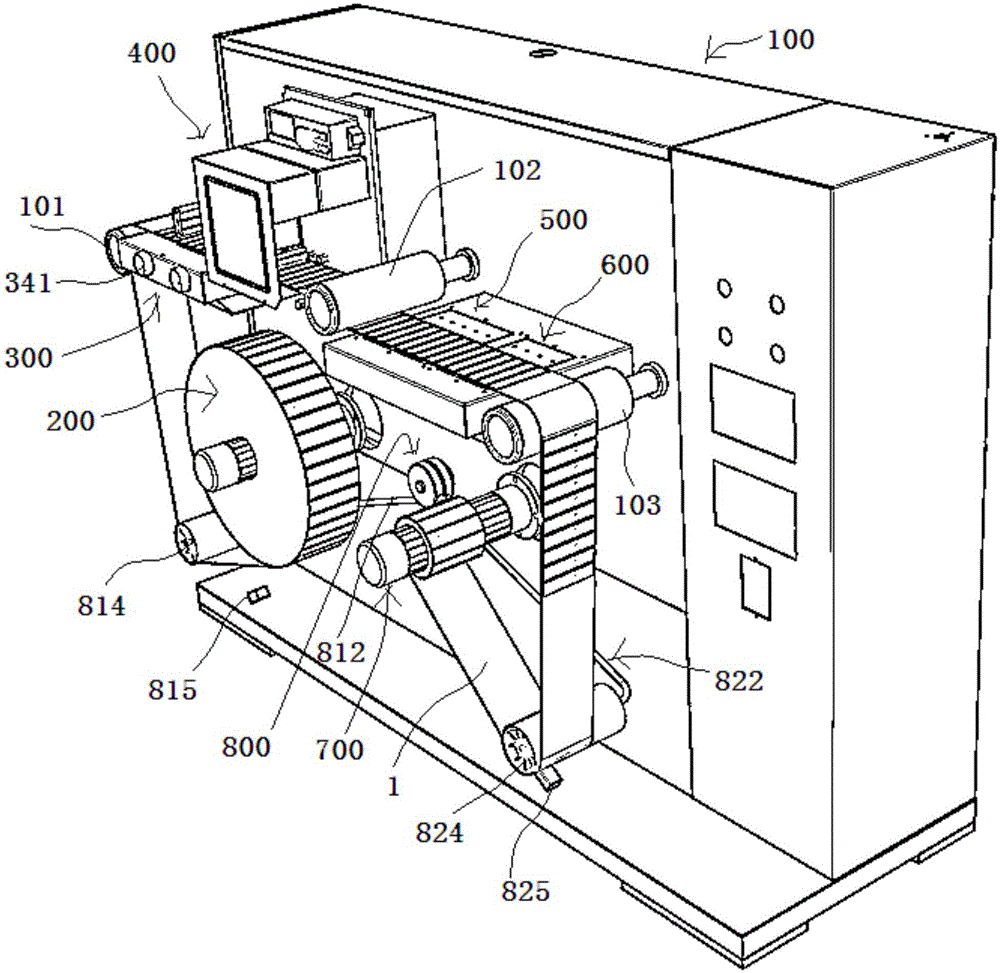

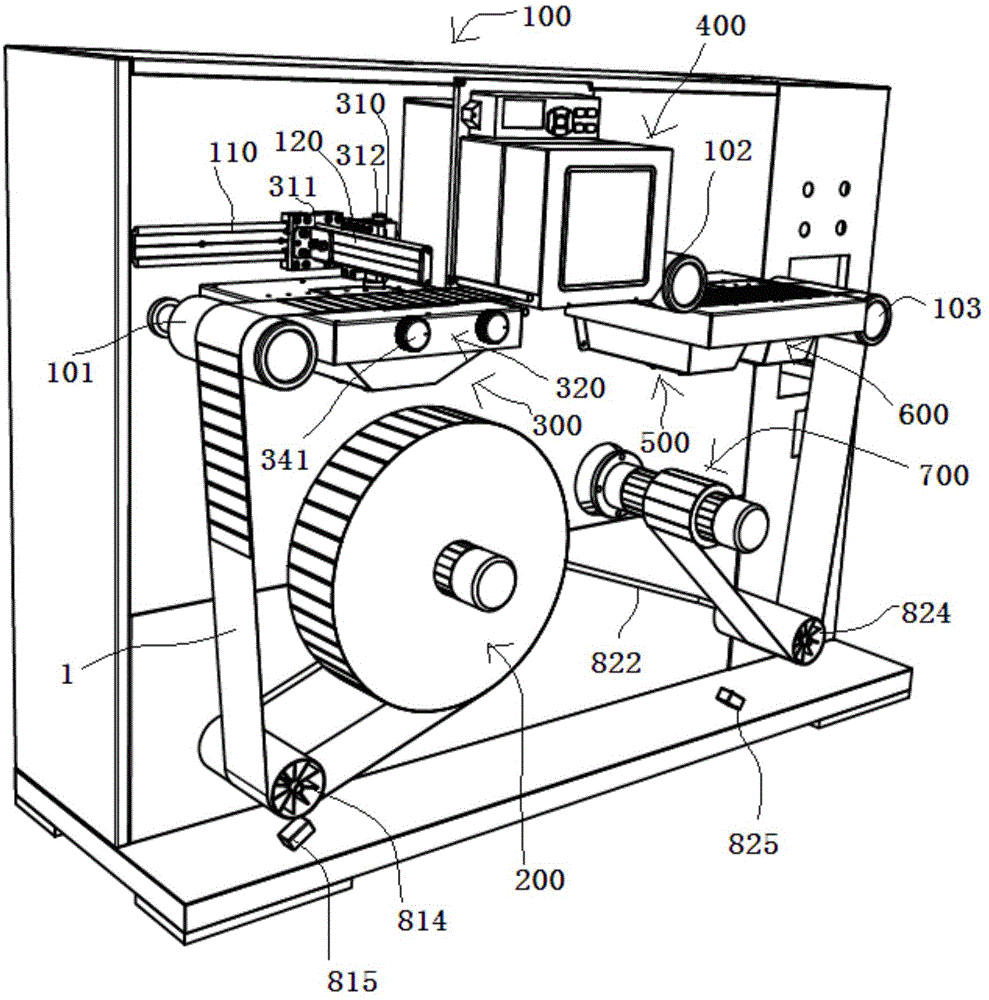

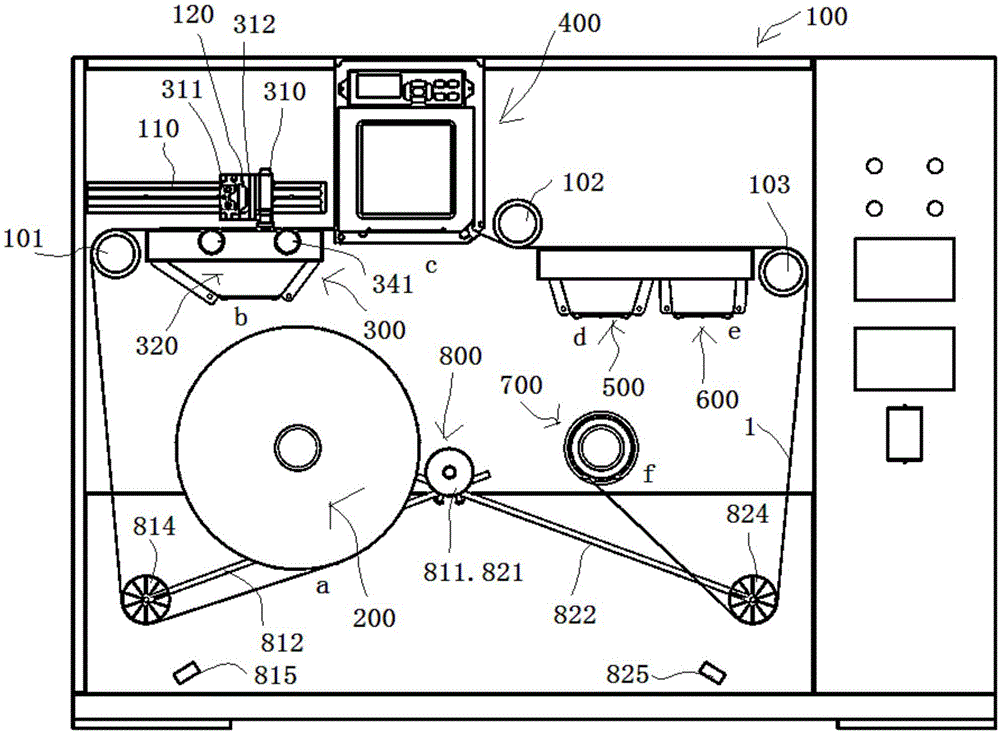

RFID (Radio Frequency Identification) electronic tag code-writing and detection integrated apparatus

ActiveCN105046298APrinting is accurateEliminate efficiencyCo-operative working arrangementsCode writingControl system

The invention discloses an RFID (Radio Frequency Identification) electronic tag code-writing and detection integrated apparatus, comprising a main control system and a frame, wherein a plurality of guide rolls for allowing RFID electronic tags to wind are arranged on the frame; the frame is sequentially provided with an unwinding station, a chip ID reading station, a plain EPC (Electronic Product Code) printing station, an EPC writing station, a detection station and a winding station in a forward direction of the RFID electronic tags; a first read-write apparatus is arranged on the chip ID reading station; a plain EPC printer is arranged on the plain EPC printing station; a second read-write apparatus is arranged on the EPC writing station; a detection apparatus is arranged on the detection station; the unwinding apparatus, the first read-write apparatus, the second read-write apparatus, the plain code printer, the second read-write apparatus, the detection apparatus and the winding apparatus are connected with the main control system; and when the detection apparatus detects that a chip ID is not matched with an EPC, a signal is fed back to the main control system, and the main control system is used for controlling a system to suspend the running.

Owner:SHANGHAI BOING INFORMATION TECH CO LTD

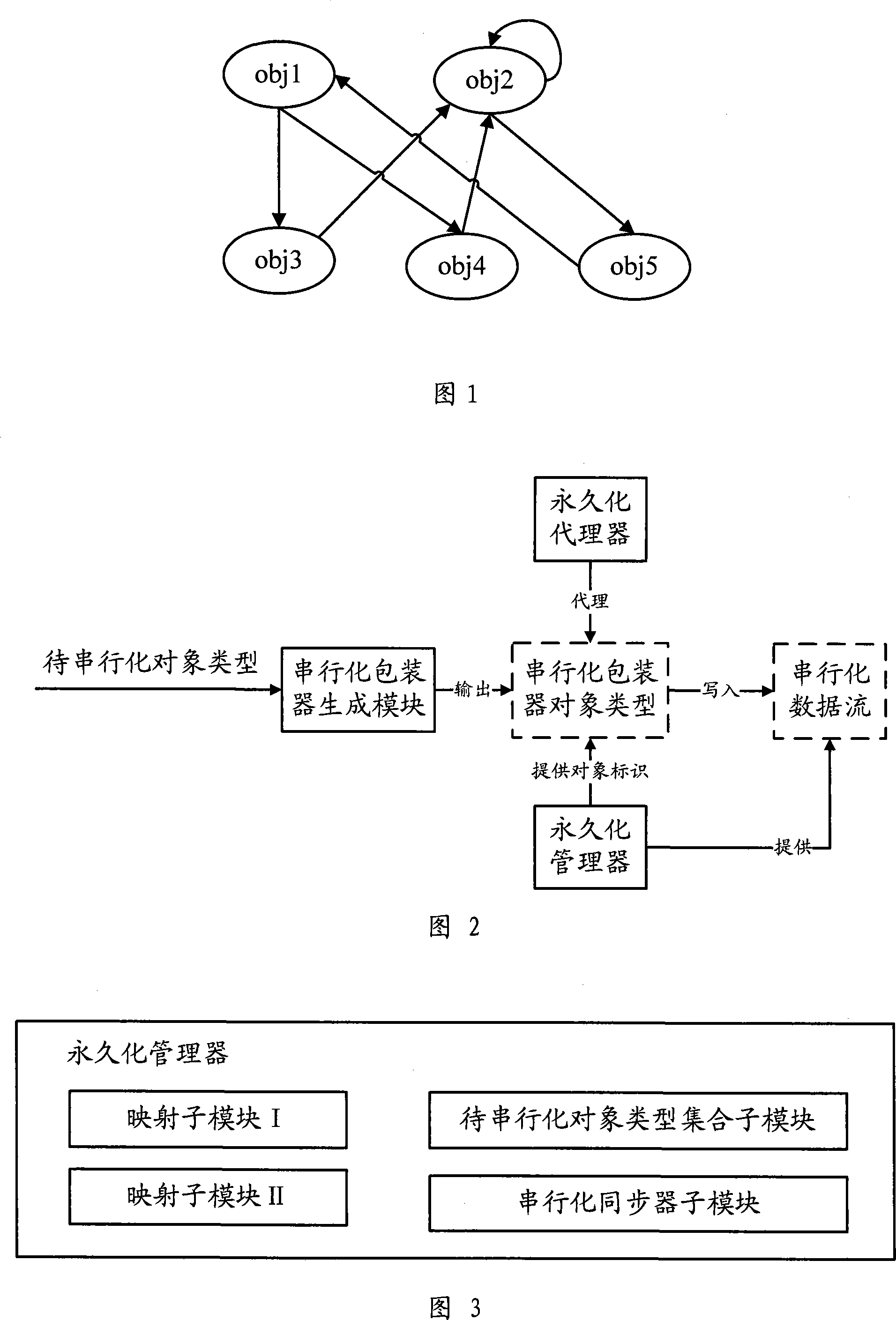

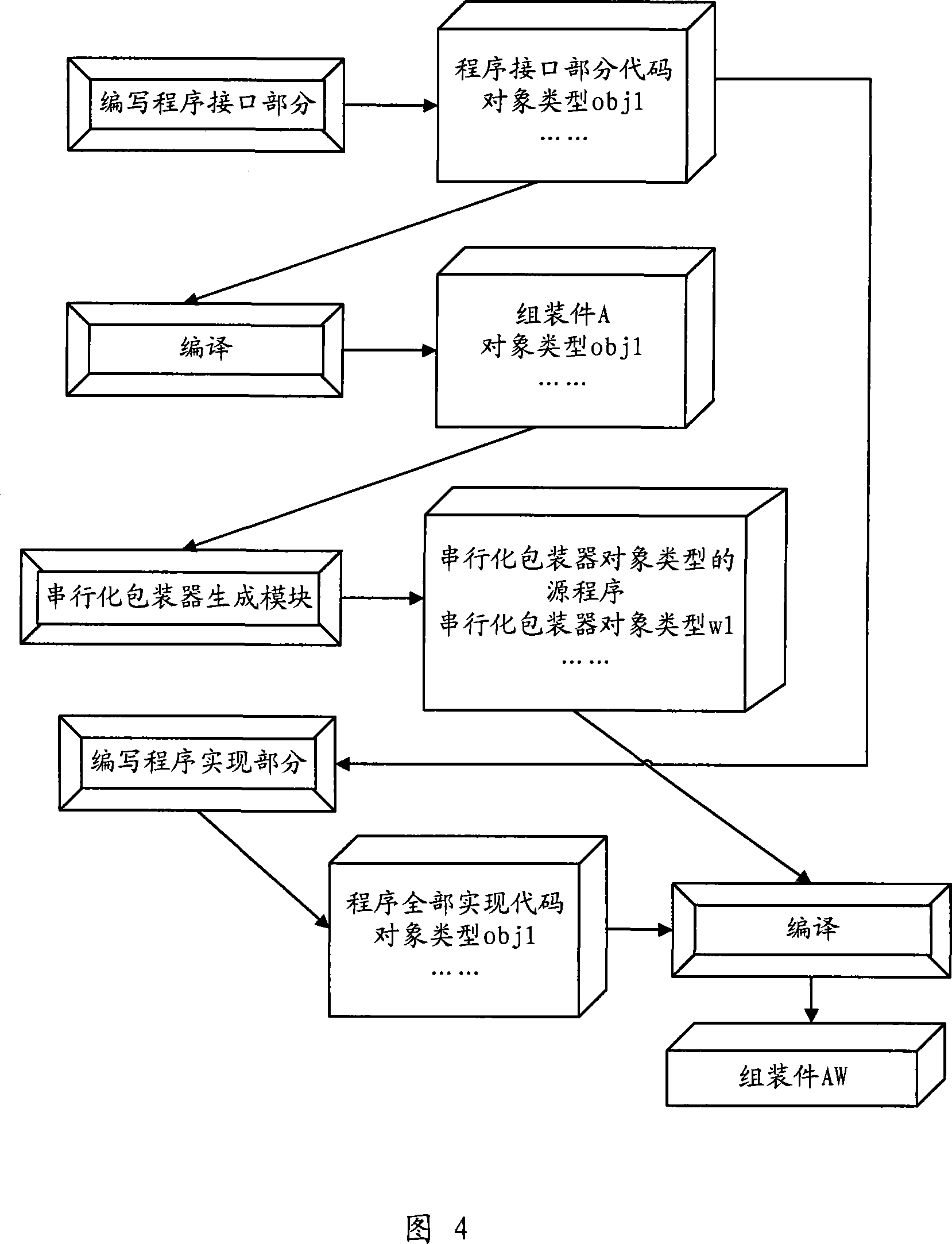

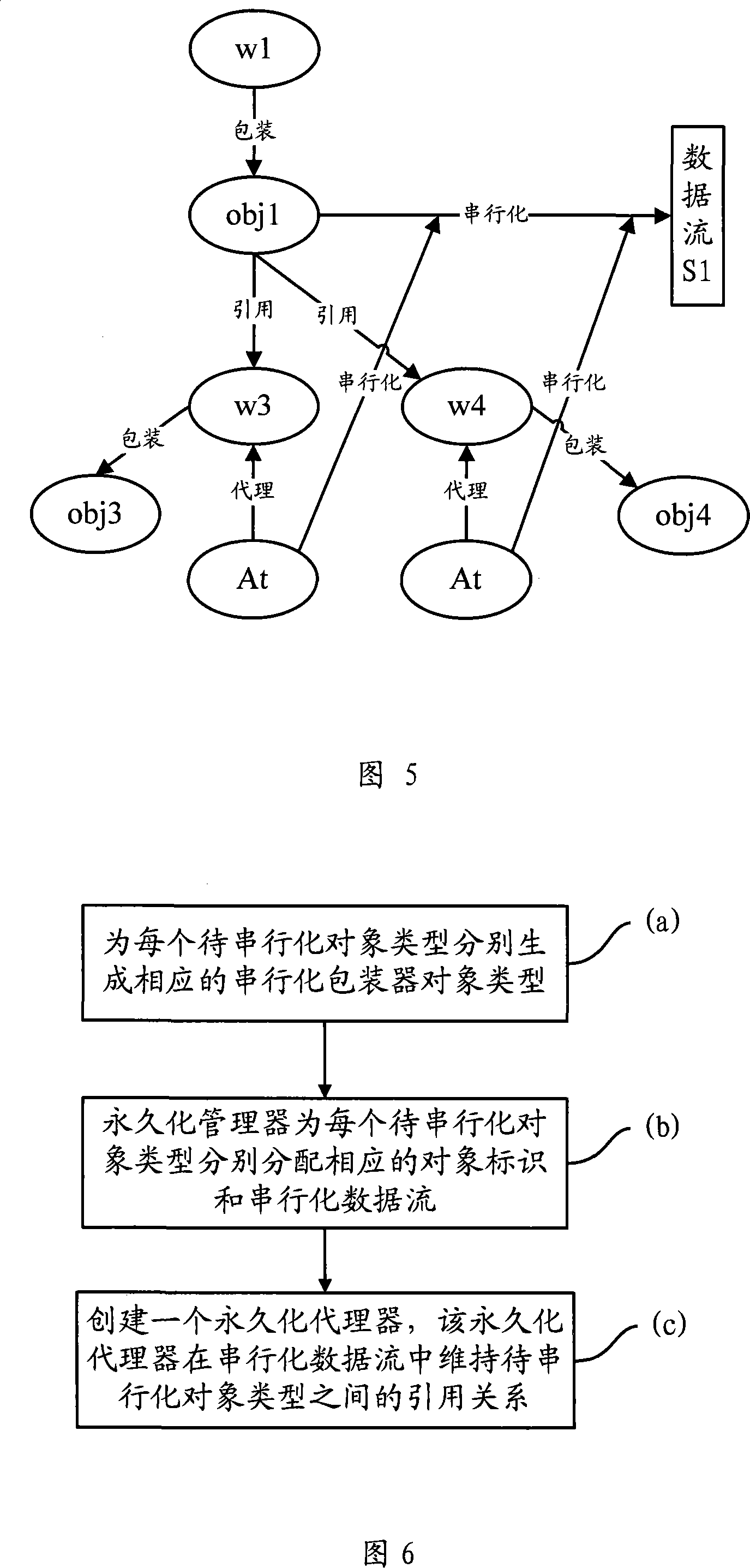

Serializing storage of objects and recovering system and method thereof

InactiveCN101082866AEliminate costEasy to controlSpecific program execution arrangementsSerializationDistributed object

The invention discloses a serialization storing and restoring system and method of object, which comprises the following parts: serialization packer generating mode, which is used to generate corresponding serialization packer object pattern for each serialized object pattern separately; permanent manager, which distributes object mark and serialization data flow for each serialization packer object pattern; permanent deputy device, which maintains reference relationship among serialized object patterns in the serialization data flow. The invention makes the serialization object pattern consistent to control the serialization grain, which can be applied in the NET development platform and all editable development platforms.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +2

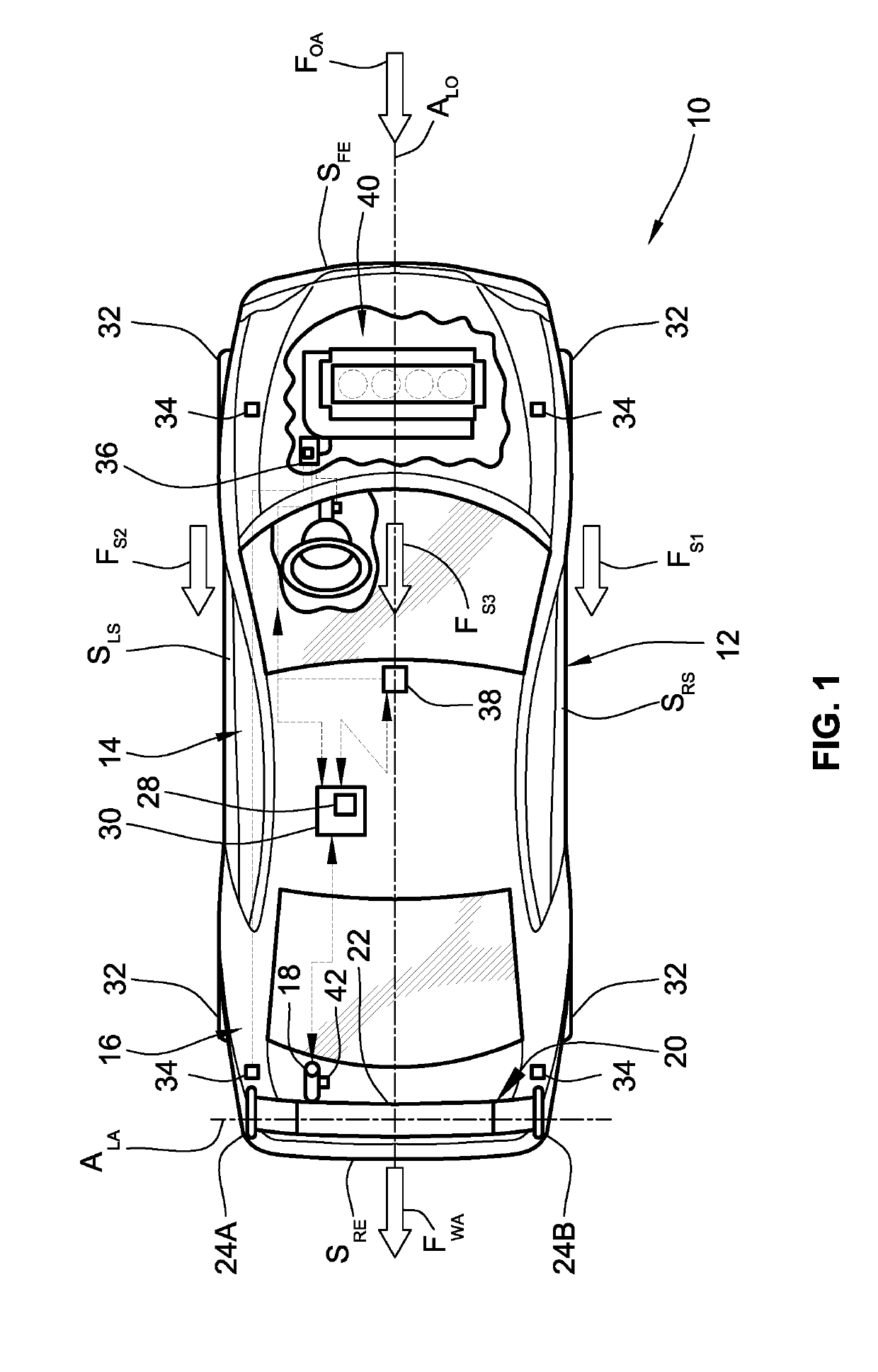

Downforce feedback systems and control logic for active aerodynamic devices of motor vehicles

ActiveUS20190092403A1Eliminate costImprove awarenessVehicle body stabilisationComputer controlOperant conditioningFluid pressure

Disclosed are downforce feedback systems for active aerodynamic devices, methods for making / using such systems, and vehicles equipped with a closed-loop downforce feedback system to govern operation of the vehicle's active aero device(s). A feedback control system for operating an active aerodynamic device of a motor vehicle includes one or more pressure sensors for detecting fluid pressures in one or more pneumatic or hydraulic actuators for moving the active aero device. A vehicle controller receives fluid pressure signals from these sensor(s), and calculates an actual downforce value from these signal(s). The controller retrieves a calibrated downforce value from mapped vehicle downforce data stored in memory, and determines if the actual downforce value differs from the calibrated value. If so, the controller determines a target position for a target downforce value for a current vehicle operating condition, and commands the actuator(s) to move the active aero device to the target position.

Owner:GM GLOBAL TECH OPERATIONS LLC

Substrateless packages with scribe disposed on heat spreader

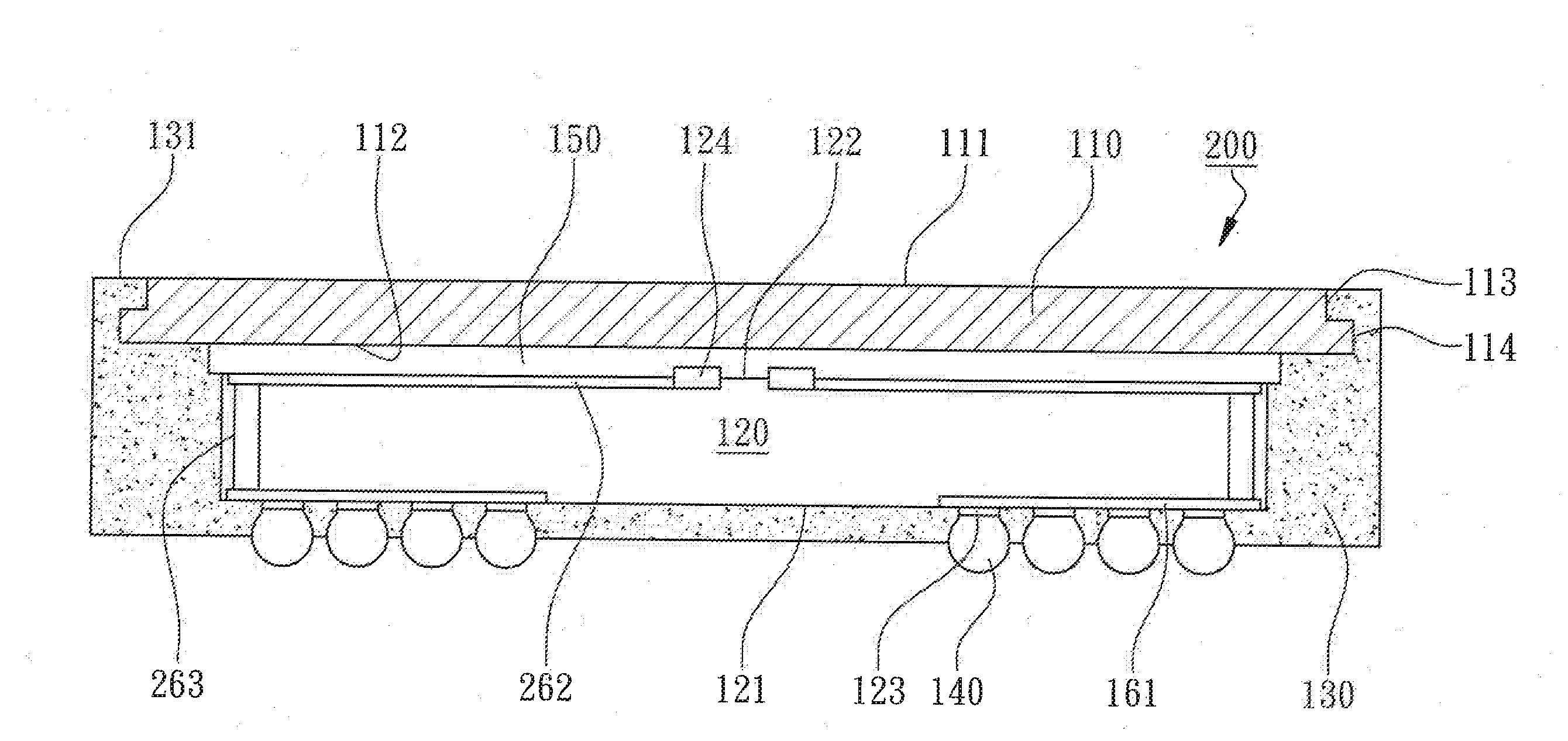

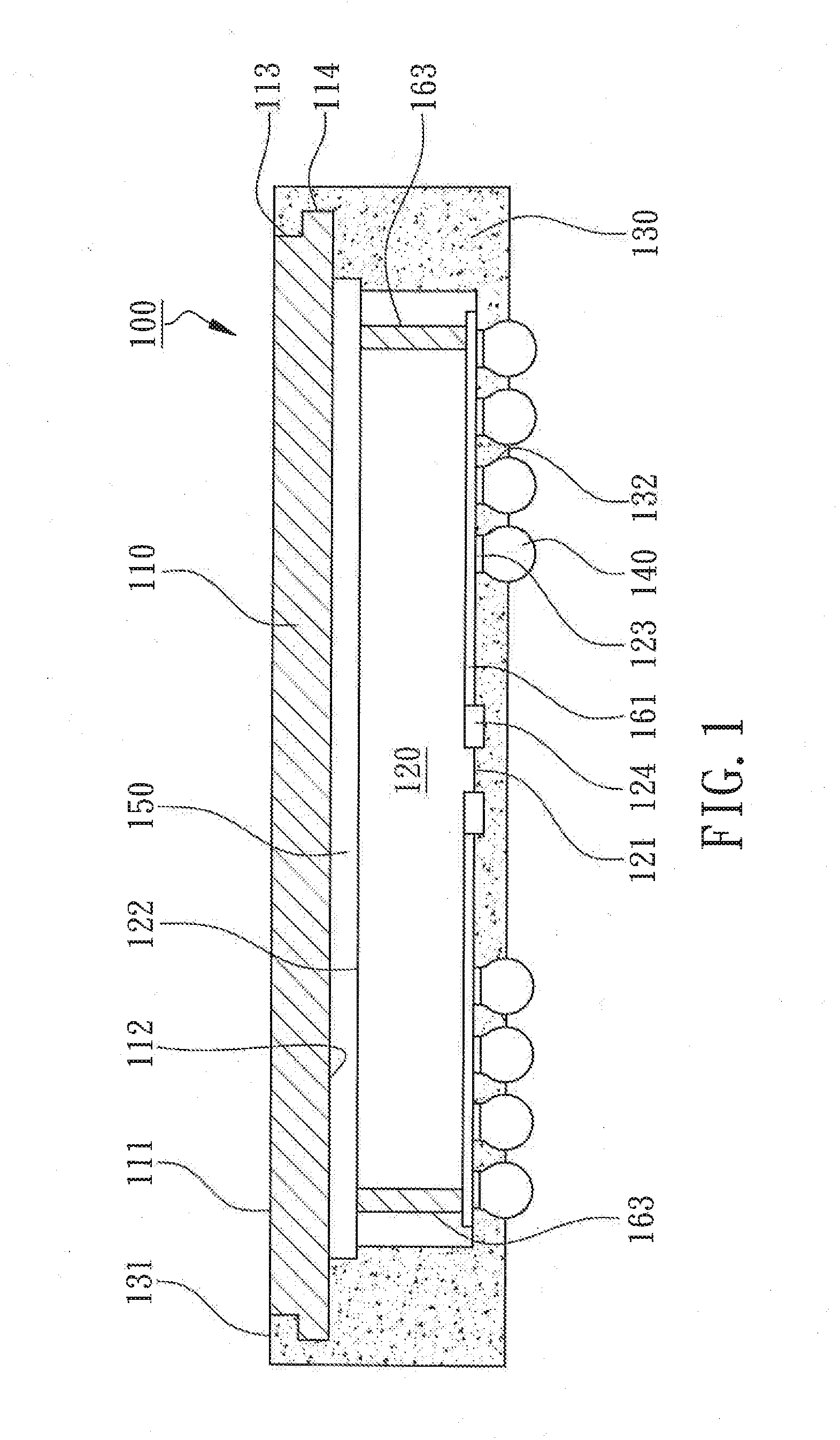

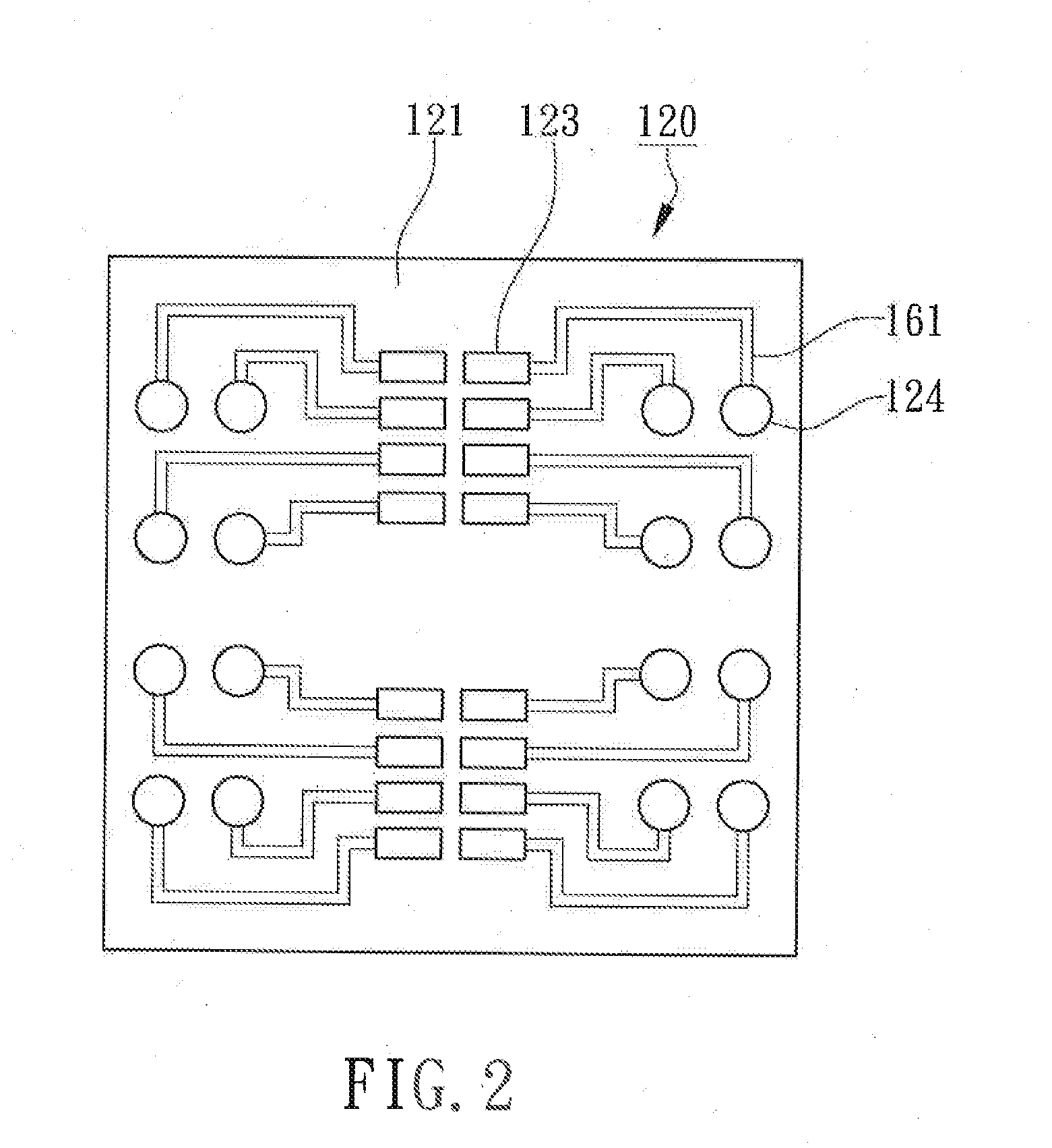

InactiveUS20150091154A1Eliminate costSmall footprintSemiconductor/solid-state device detailsSolid-state devicesEngineeringSealant

Disclosed is a substrateless semiconductor package having a plurality of scribe lines formed on a heat spreader, primarily comprising the heat spreader, a chip disposed on the heat spreader and an encapsulant. Formed on a thermally dissipating surface of the heat spreader are a plurality of scribe line grooves with a plurality of openings formed inside to penetrate through the die-attaching surface of the heat spreader. The chip is disposed on the die-attaching surface and the encapsulant is formed on the die-attaching surface to encapsulate a first surface of the chip on which a plurality of external pads are formed Without being covered by the encapsulant. Therein, the encapsulant is filled in the scribe line grooves via the openings so that a scribe line pattern exposed from the thermally dissipating surface is formed.

Owner:POWERTECH TECHNOLOGY +1

Treatment of contaminated activated charcoal

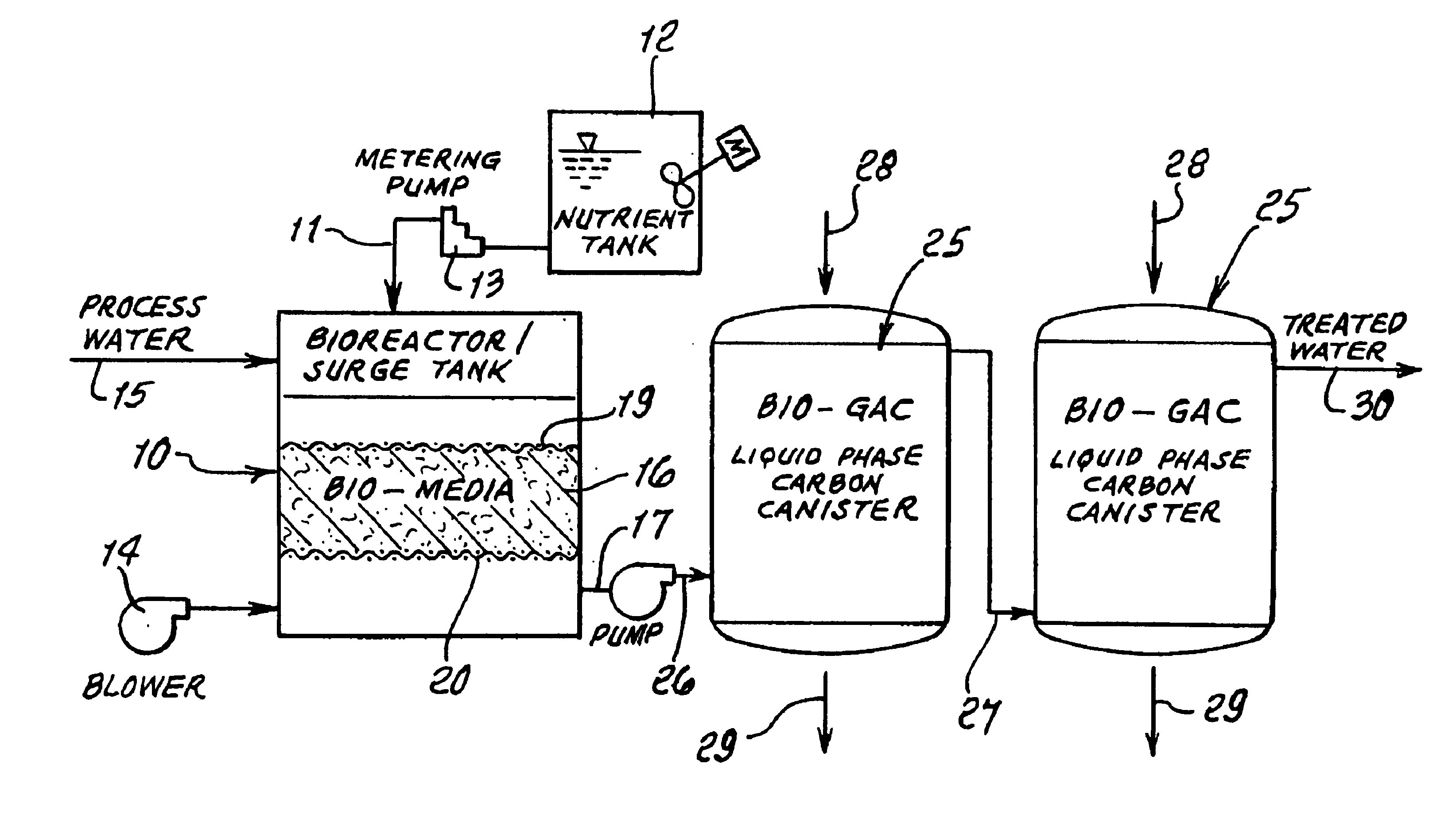

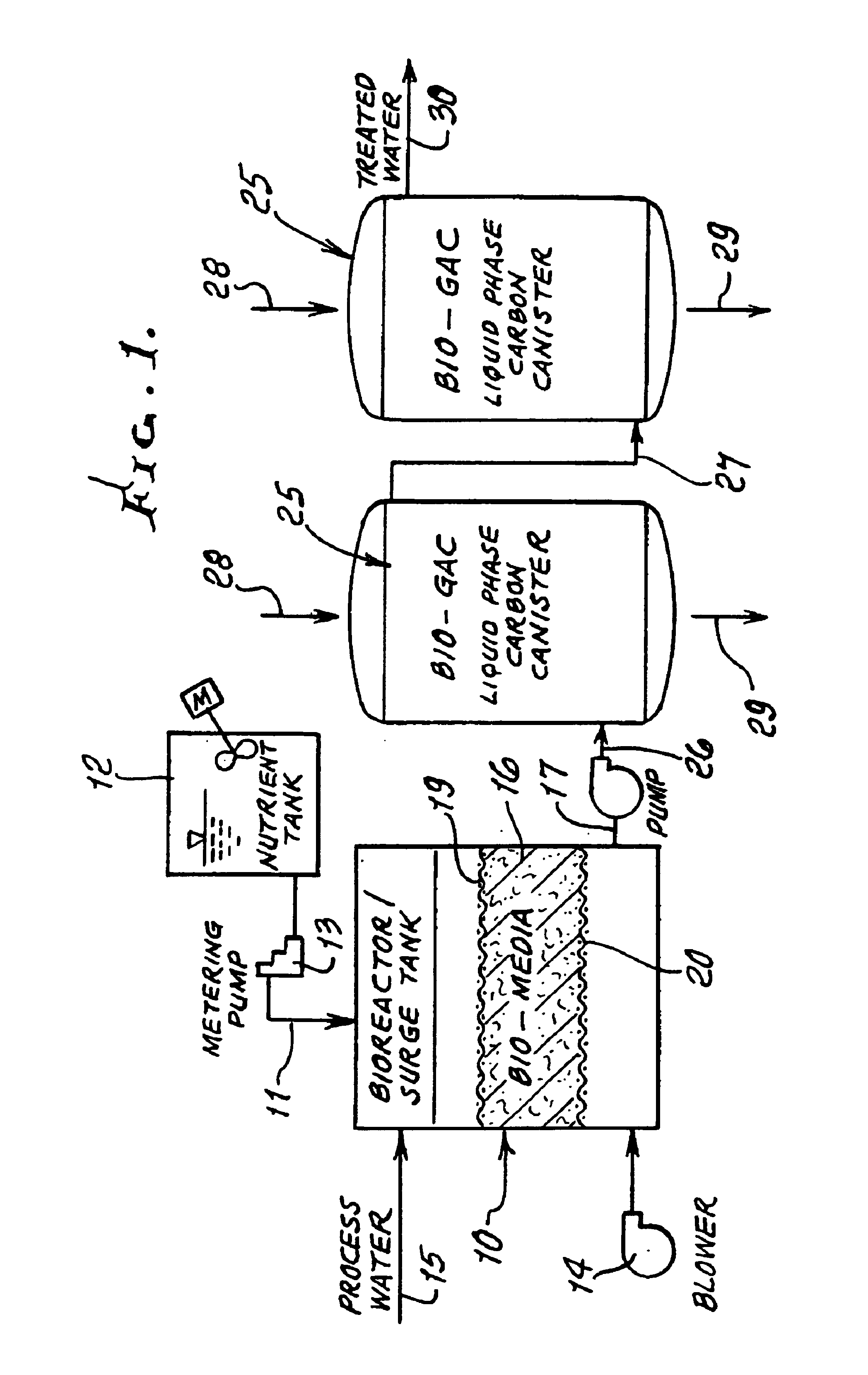

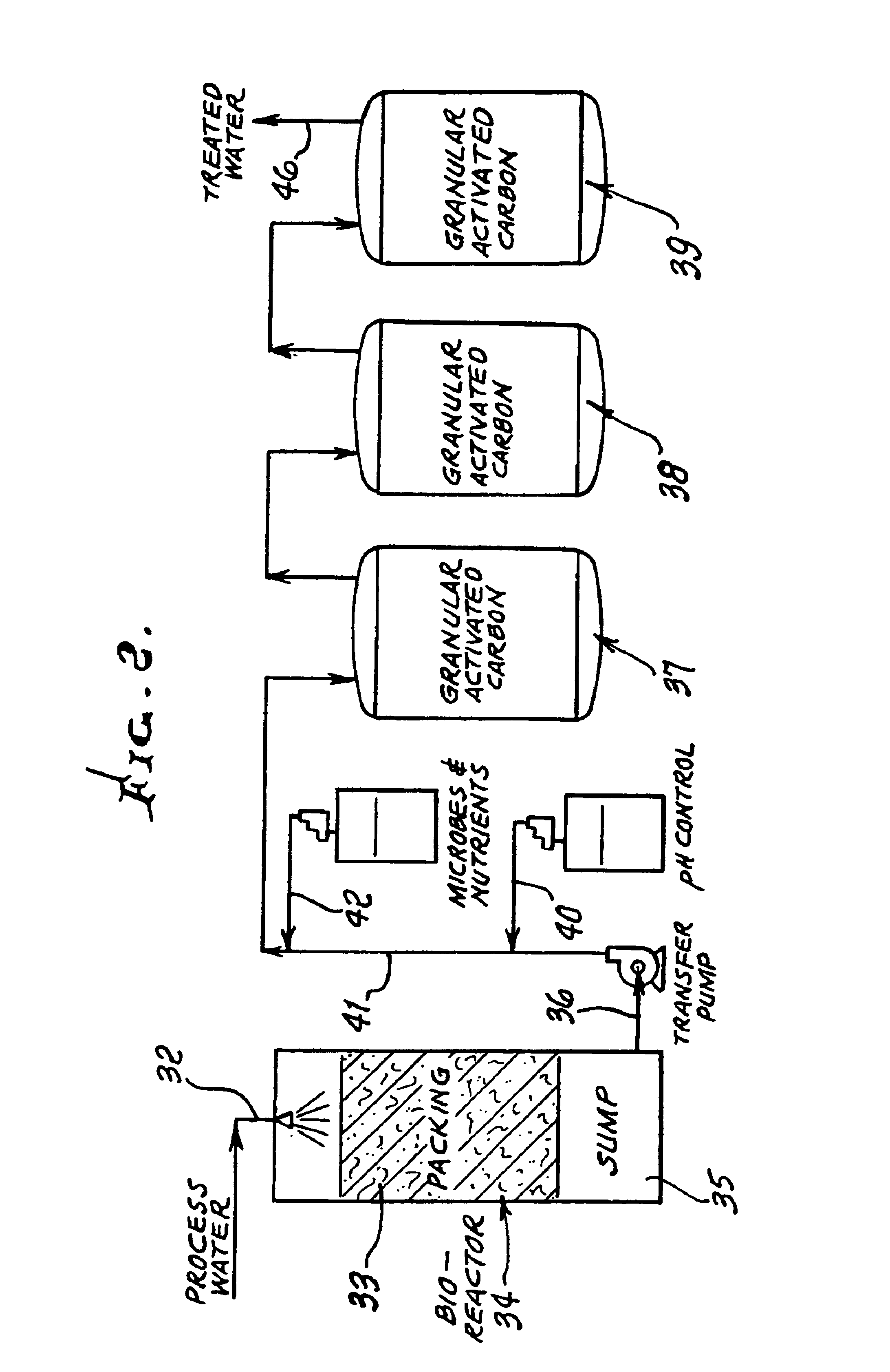

InactiveUS6905603B2Cost savingEliminate costTreatment using aerobic processesWater contaminantsNutrientPollutant

The method of providing for a fluid treatment, that includes providing a treatment zone containing granular activated charcoal, and providing a stream of water containing nutrients, contaminant degrading microbes and dissolved oxygen, and introducing the stream to a treatment zone to effect adsorption of nutrients and microbes onto the granular activated charcoal, thereby to provide a contaminant treatment matrix, whereby contaminant in fluid flow through the matrix is reduced.

Owner:XYCLONYX

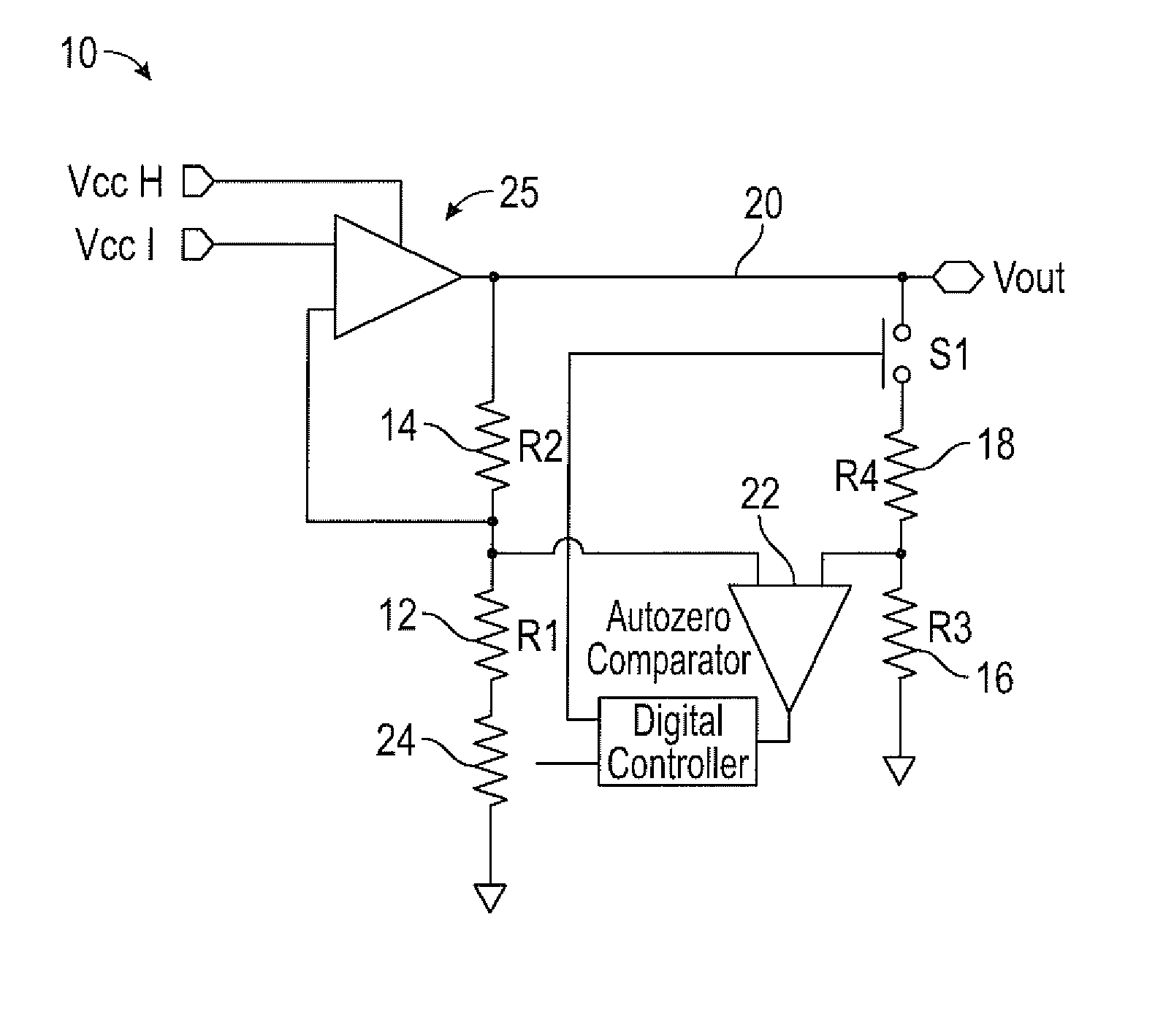

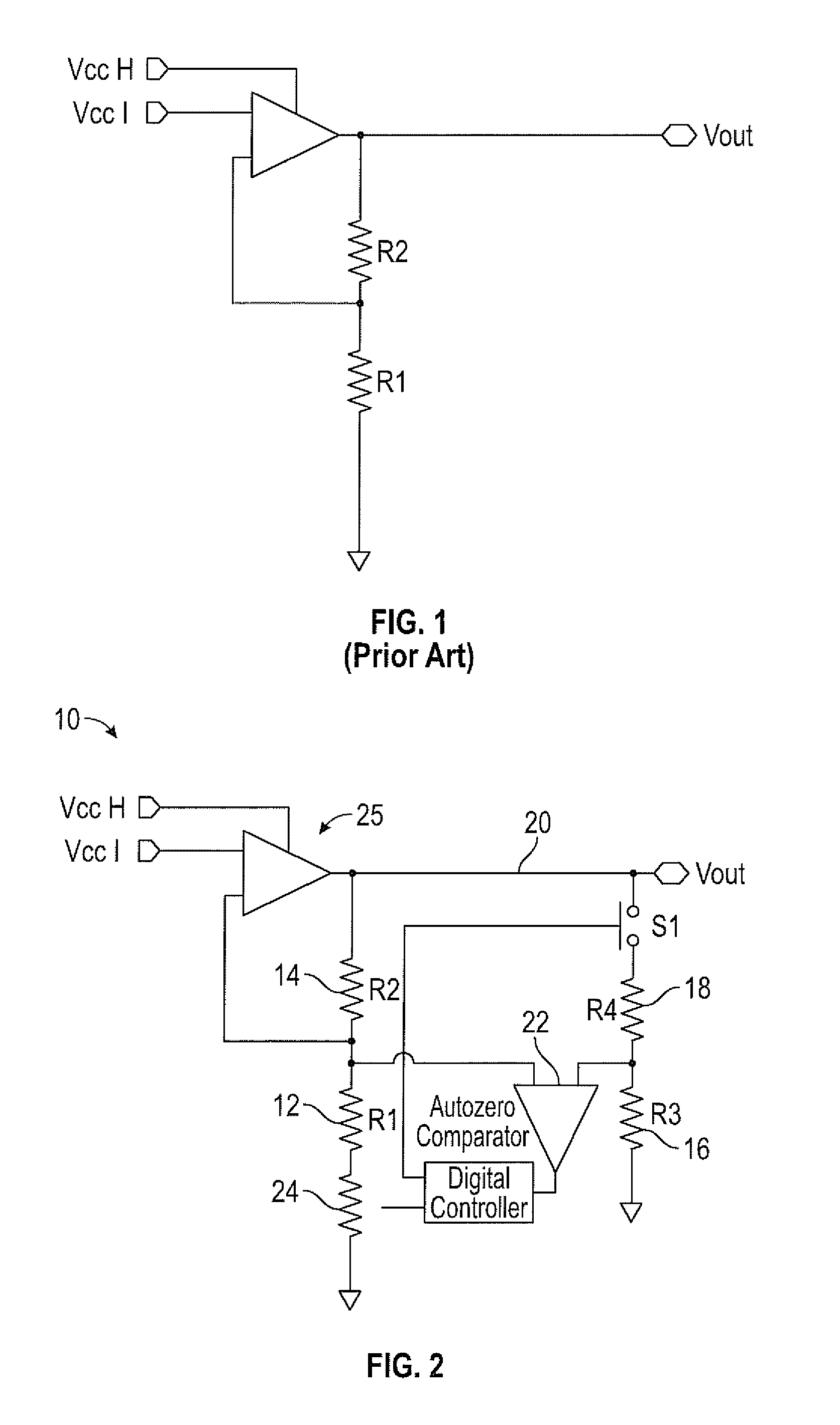

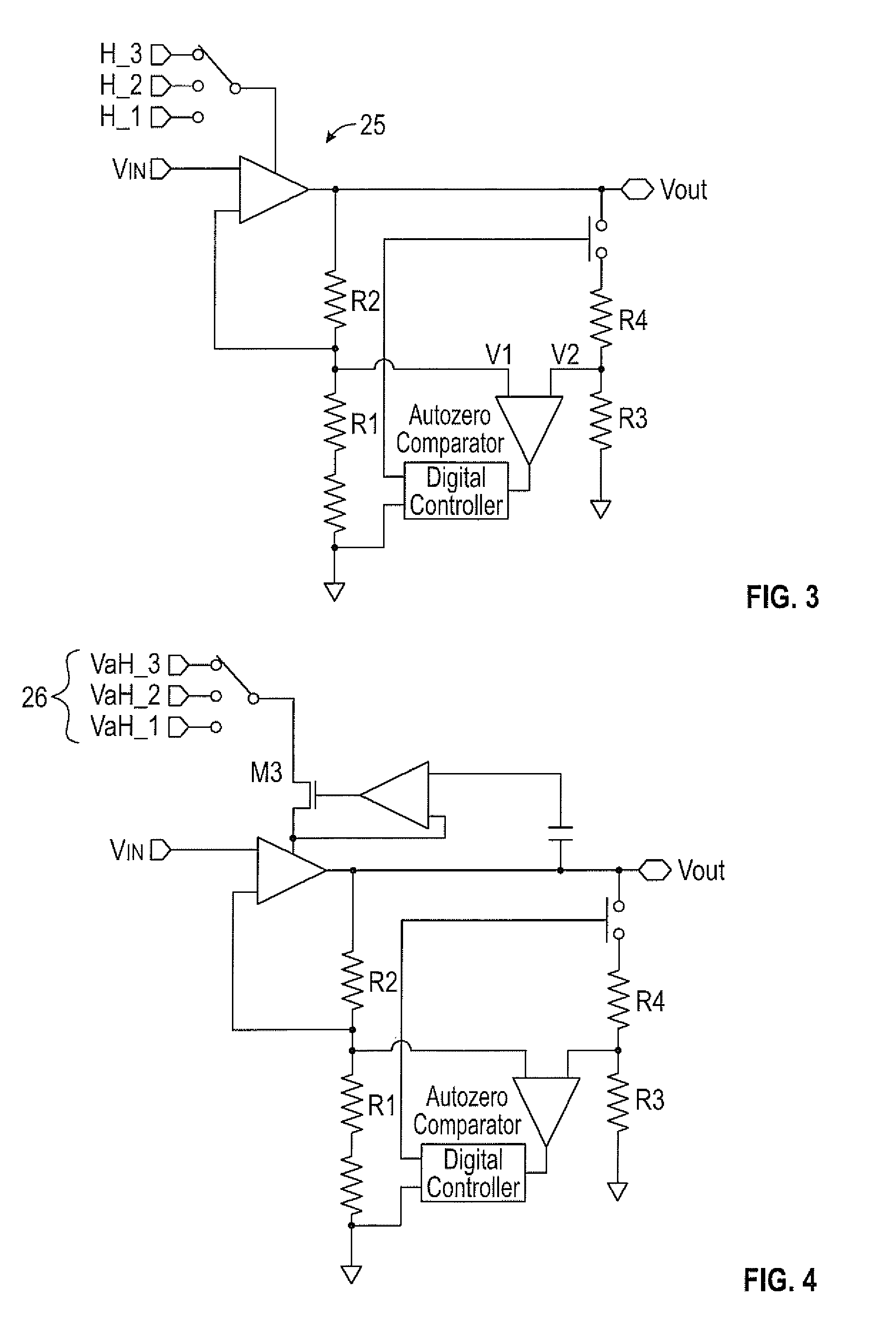

Trim method for high voltage drivers

ActiveUS20150381176A1Eliminate costReduce powerInput/output impedence modificationMultiple input and output pulse circuitsPrinted circuit boardChip resistor

Methods and circuits are provided to create small, power minimizing, multi-channel high voltage drivers for micro-electromechanical systems (MEMS). A resistor calibration circuit is introduced to allow on chip resistor dividers to be calibrated against a single precision high voltage resistor divider, eliminating the cost and printed circuit board real estate associated with multiple resistor dividers connected to each channel. Additionally, a multiple-power rail configuration is provided to reduce power to the overall system by producing several rails generated by a boost converter or a capacitive charge pump, where the voltage output of the rails is produced to group rails of lesser voltage requirement rather than connecting all channels to the same high voltage rail on a dynamic basis.

Owner:SCHIE DAVID +2

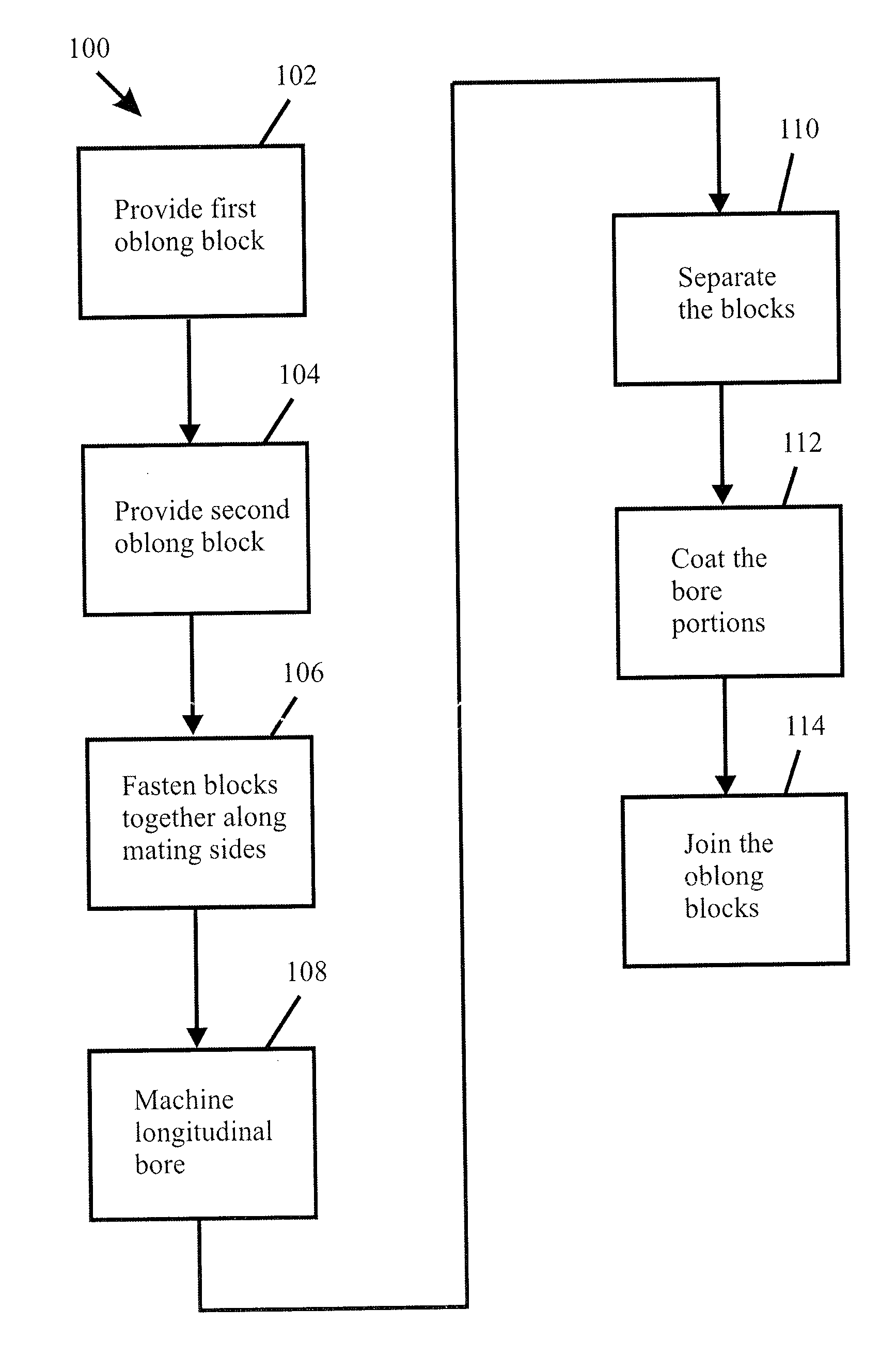

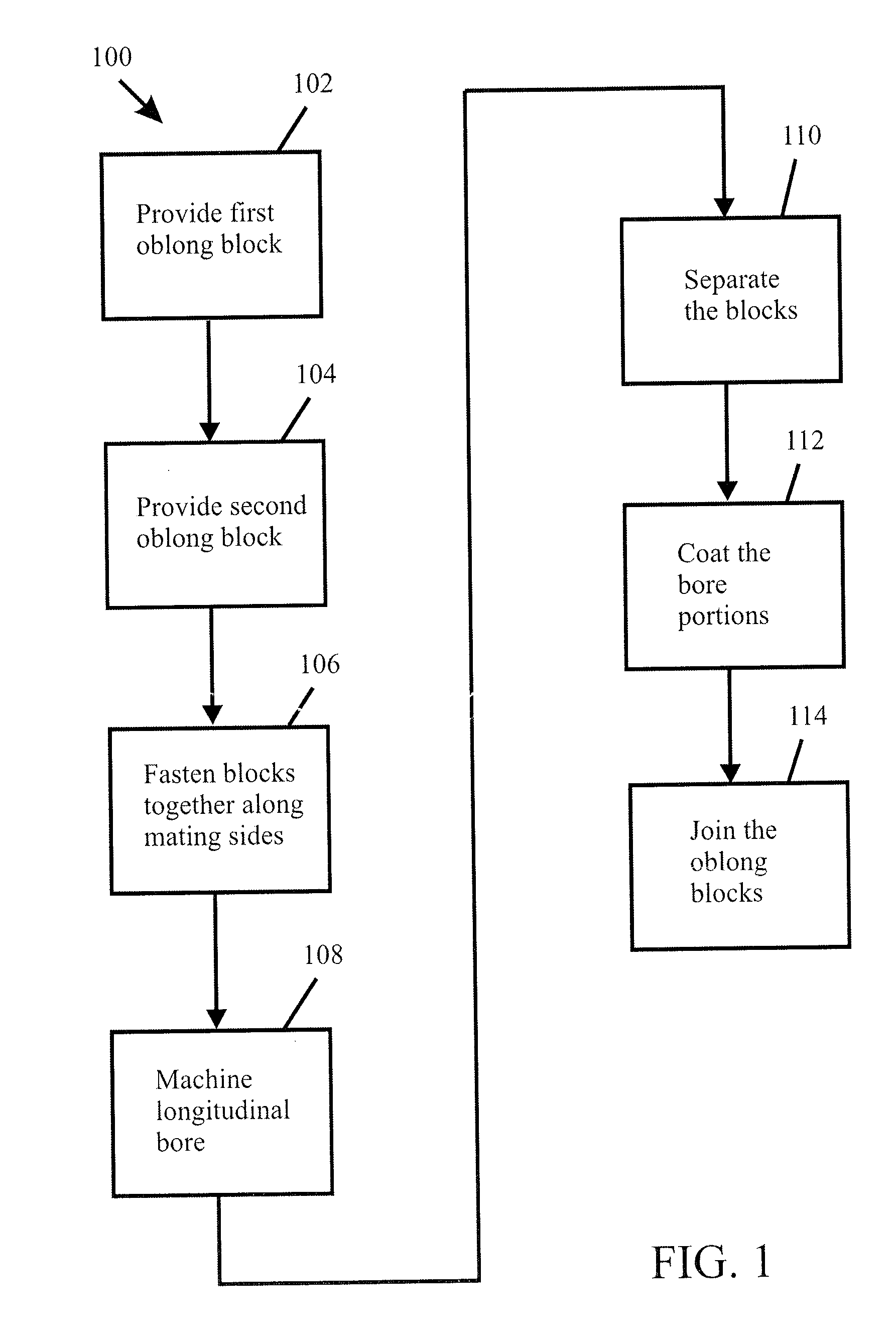

Method for preparing abrasive waterjet mixing tubes

InactiveUS20100088894A1Eliminate costHigh precisionBlast gunsMetal working apparatusAbrasive water jetMechanical engineering

A method for making an AWJ mixing tube having a longitudinal bore coated with an abrasion-resistant material, such as diamond. Two blocks having mating longitudinal sides are fastened together prior to machining the longitudinal bore along the junction of their mating surfaces. The blocks are separated and the complementary portions of the longitudinal bore are coated with an abrasion-resistant material. The two blocks are then joined together with the complementary portions of the longitudinal bore aligned to form the longitudinal bore.

Owner:KENNAMETAL INC

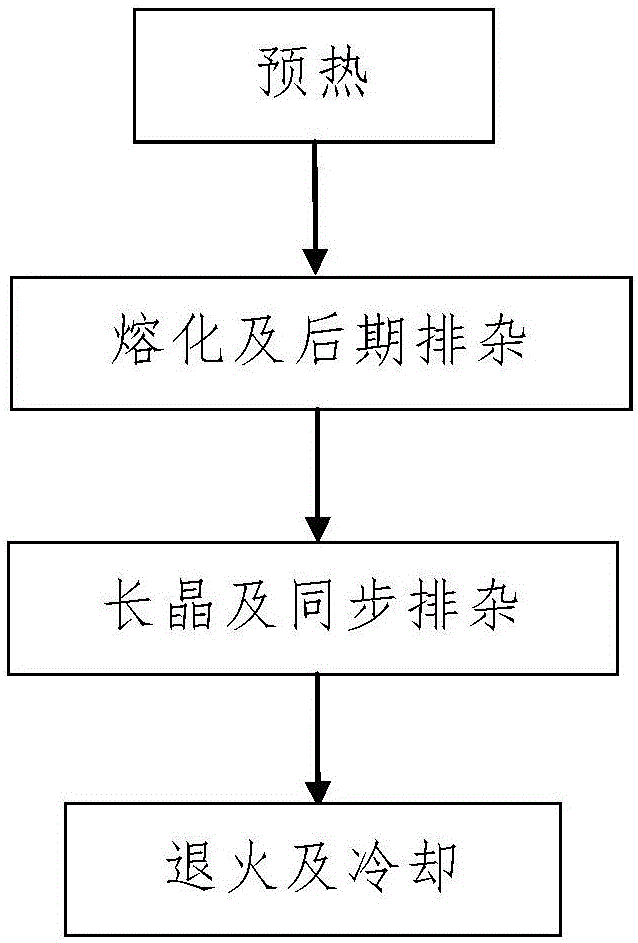

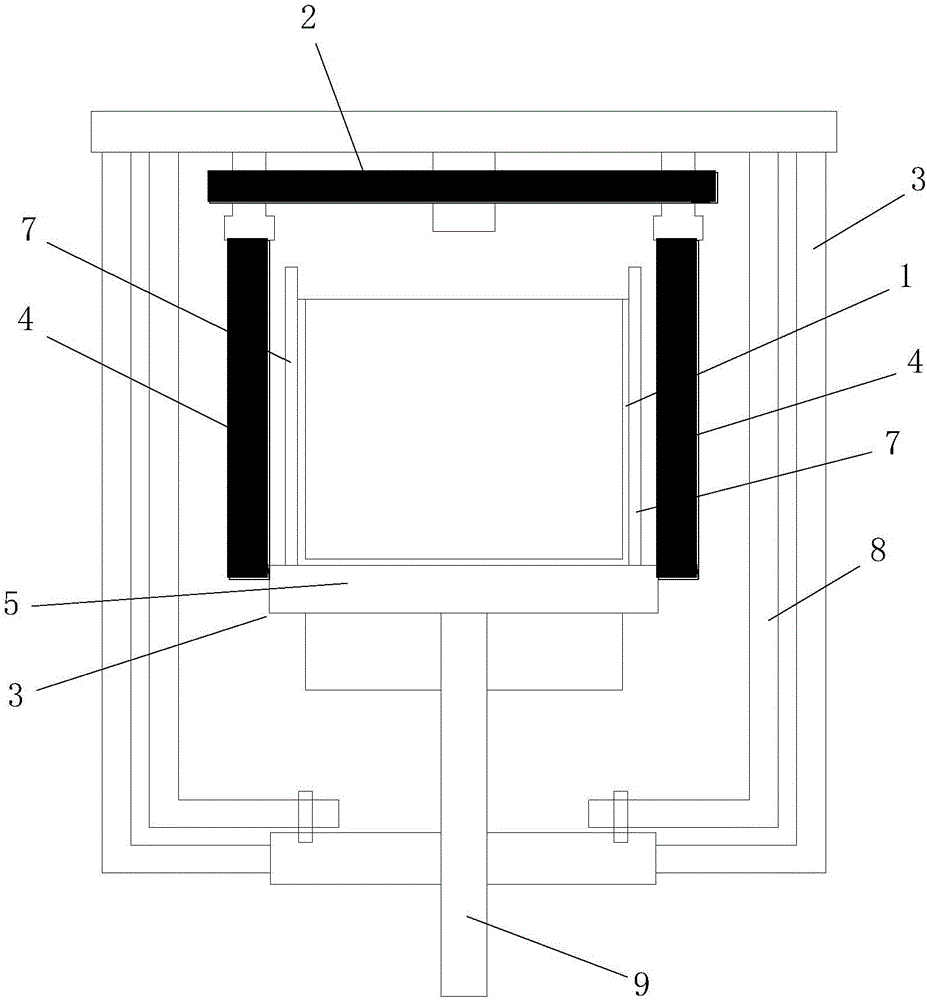

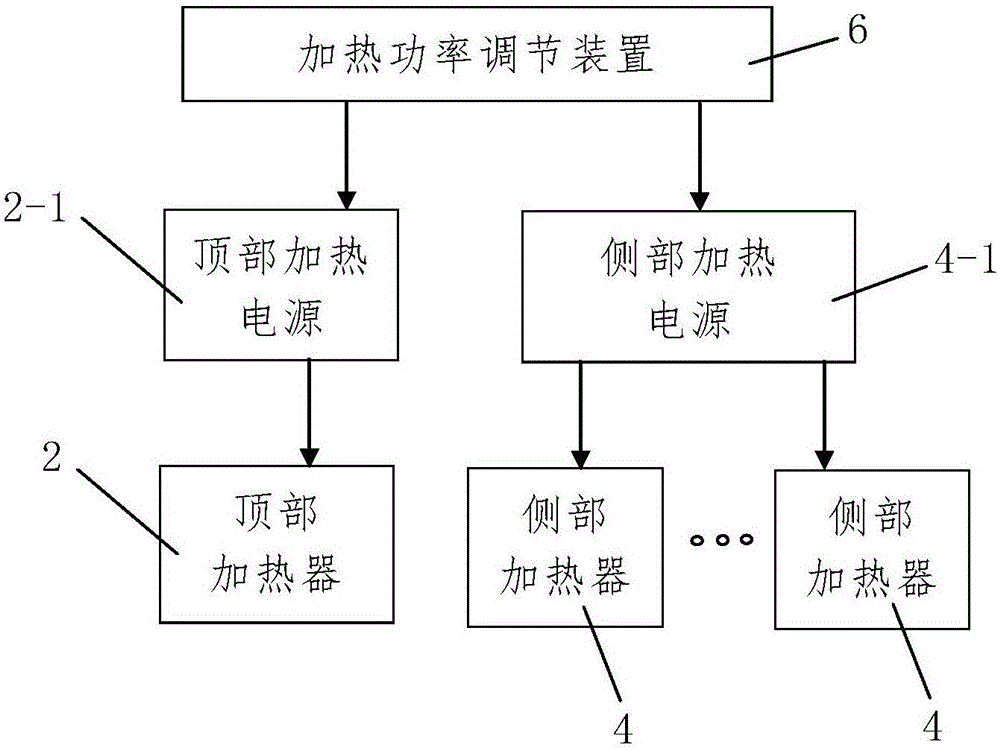

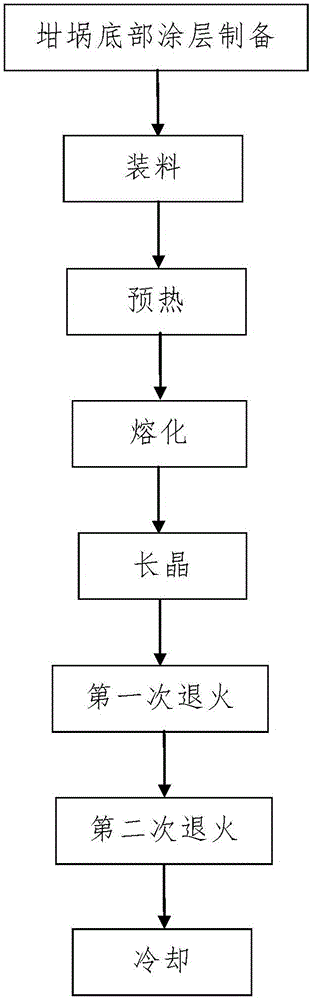

Polycrystalline silicon semi-melting ingot casting method

InactiveCN106119956AReasonable designThe process steps are simplePolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The present invention discloses a polycrystalline silicon semi-melting ingot casting method, comprising the steps of first, preheating: using a polycrystalline silicon ingot furnace to preheat silicon material charged in a crucible, with a top-side ratio coefficient c of the polycrystalline silicon ingot furnace being 1; second, melting and discharging impurities later: 201, melting; 202, discharging impurities in later stage of melting; using the polycrystalline silicon ingot furnace to continuously melt the silicon material for 15-40 min; during melting, adjusting heating power of a top heater and / or four side heaters so as to obtain 0.8> / =c<1; third, growing crystal and discharging impurities at the same time; during crystal growth, adjusting the heating power of the top heater and / or four side heaters so as to obtain 0.3< / =c<0.9; fourth, annealing and cooling. The method of the invention has simple steps and reasonable design, is convenient to implement and effective to use, and may provide a solution to the problems that existing polycrystalline silicon semi-melting ingot casting process has poor impurity-discharging effect and inability to ensure quality of finished ingots.

Owner:XIAN HUAJING ELECTRONICS TECH

Cathodic protection monitoring

ActiveUS20110129302A1Quickly detect and rectifyEliminate costWeather/light/corrosion resistanceResistance/reactance/impedenceElectricityEngineering

A method of monitoring cathodic protection of an item located underwater at a facility, the facility further including a processing means, comprises the steps of providing a pair of first and second electrodes, the first electrode being electrically connected to the item and the second electrode being in contact with water proximate the item, measuring the potential between the first and second electrodes, producing an electrical signal indicative of the cathodic protection level, converting the signal into a communications format compatible with the processing means and passing it to the processing means, and transmitting the converted signal from the processing means to a surface location.

Owner:BAKER HUGHES ENERGY TECH UK LTD

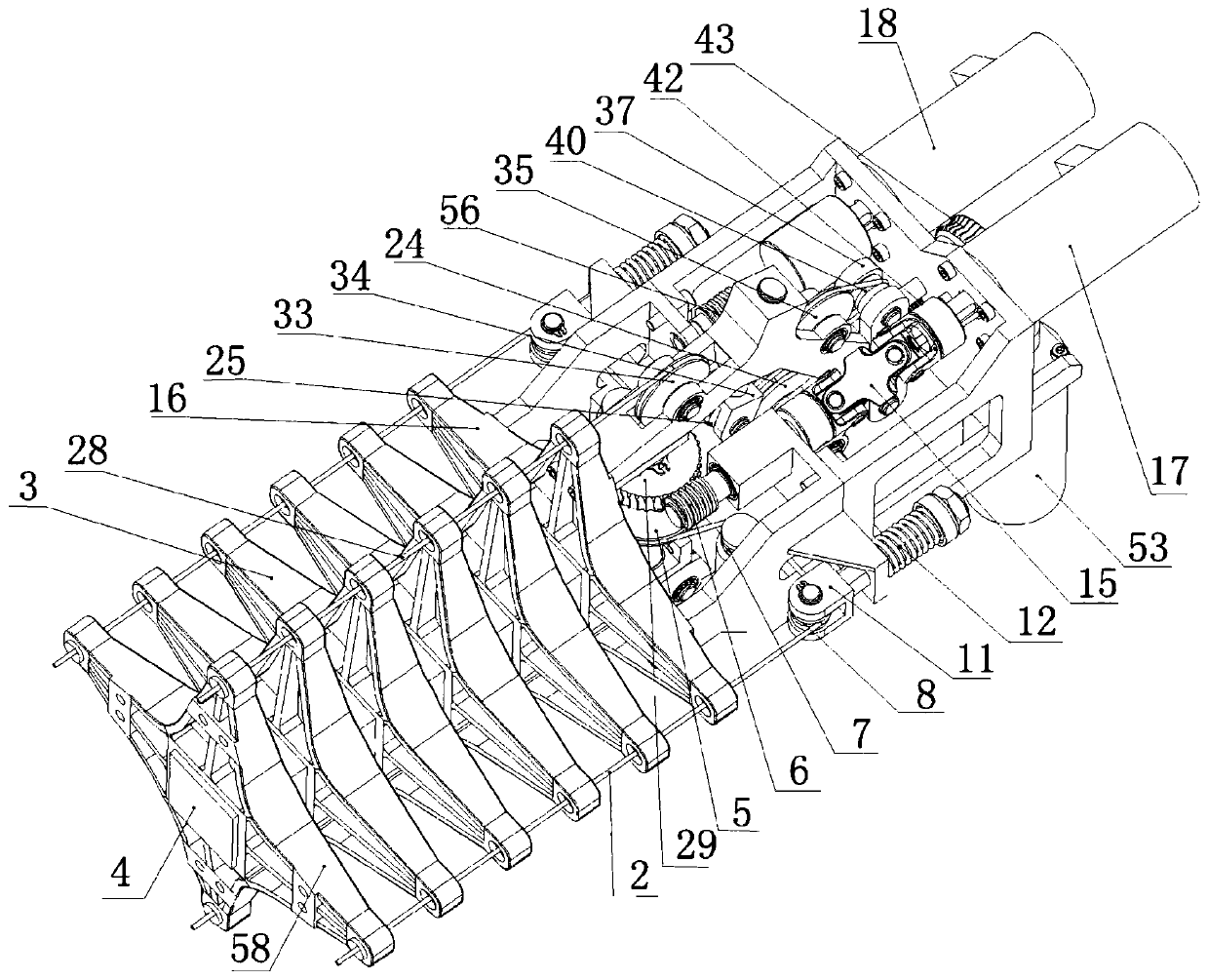

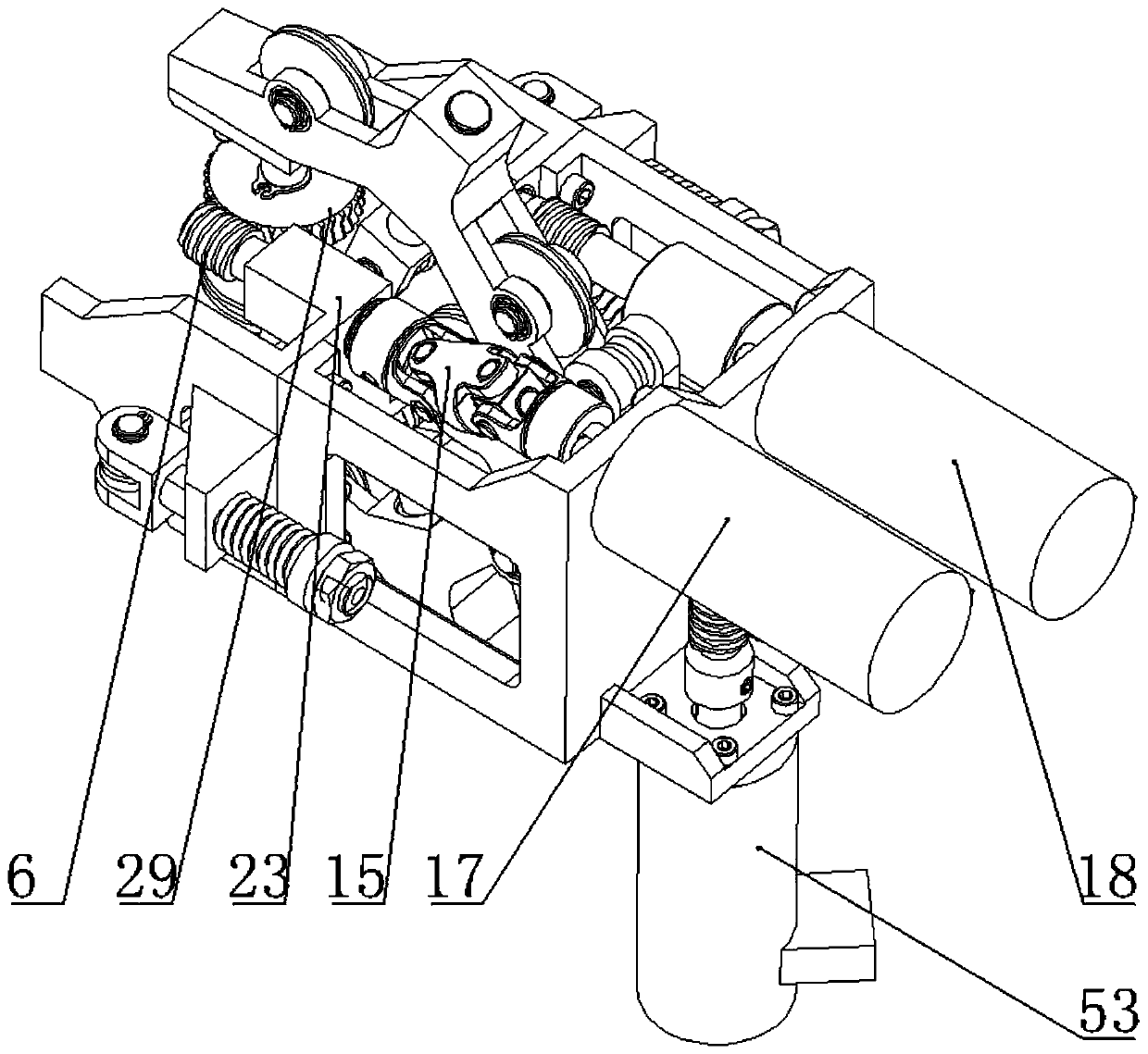

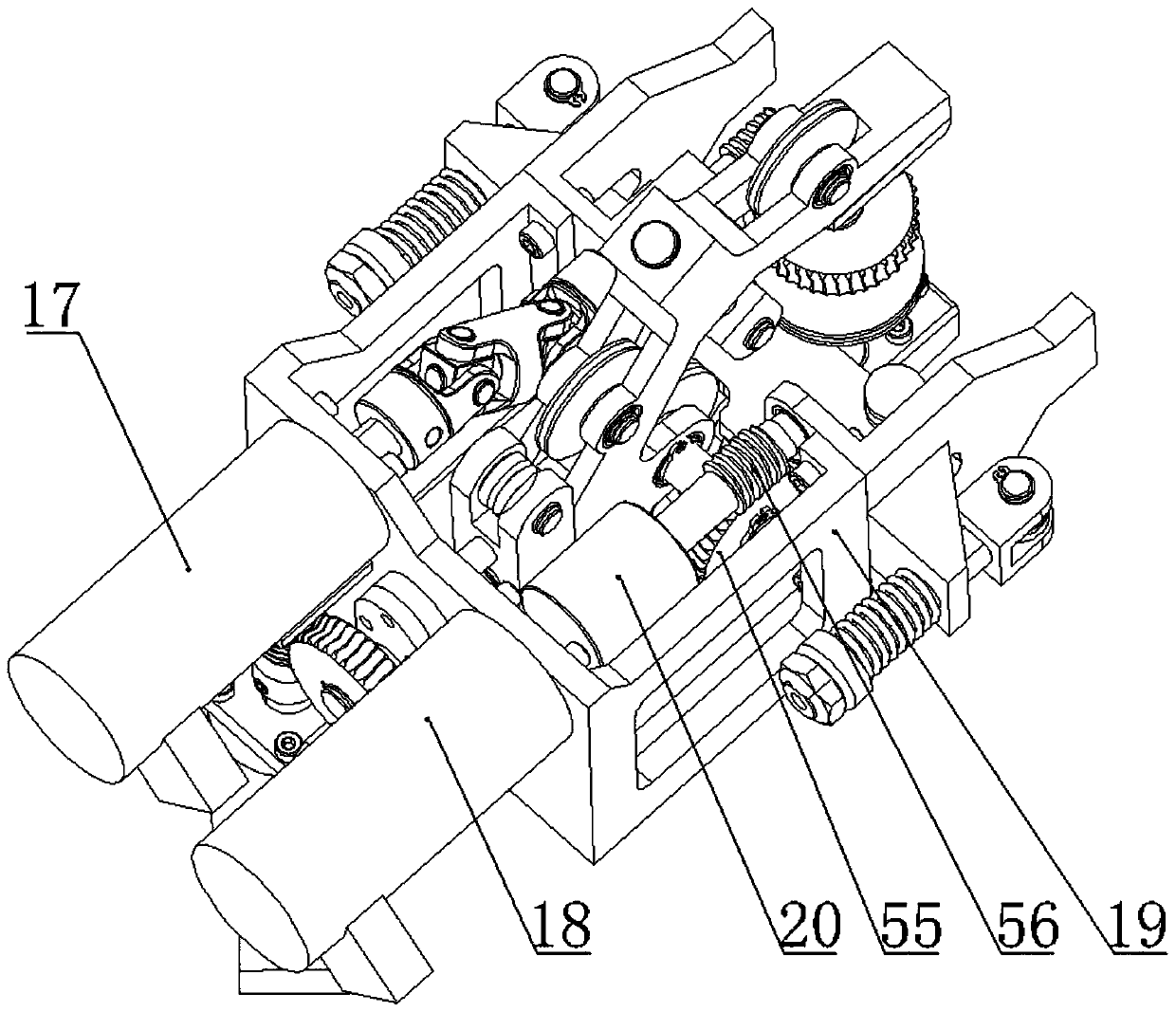

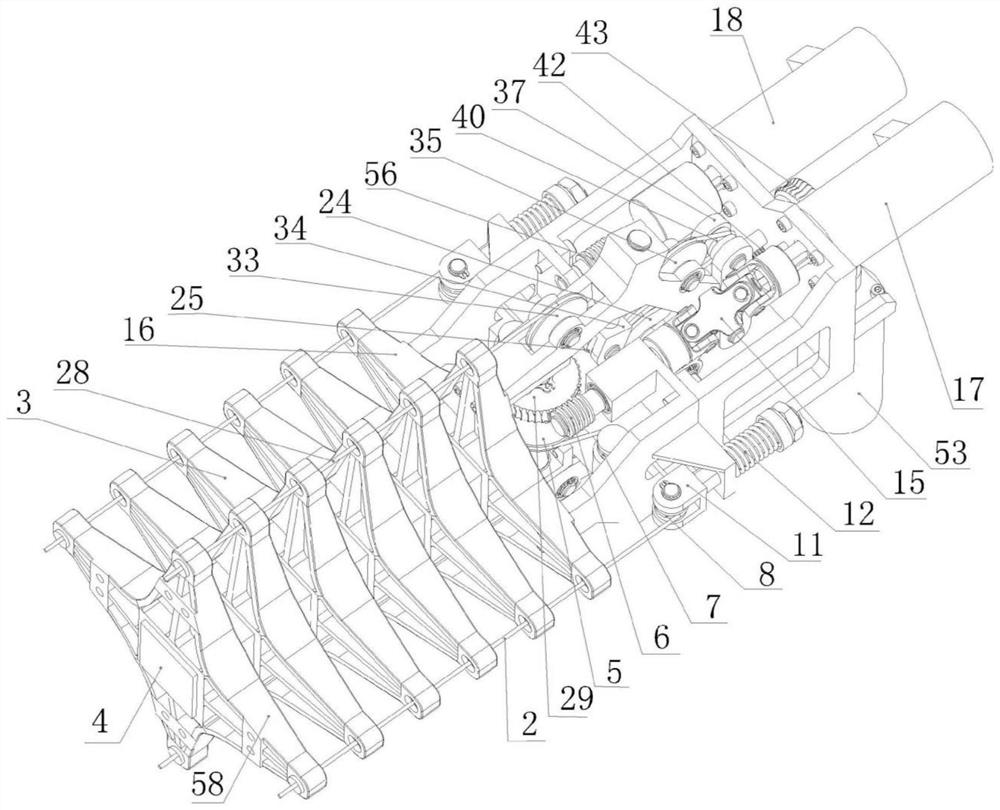

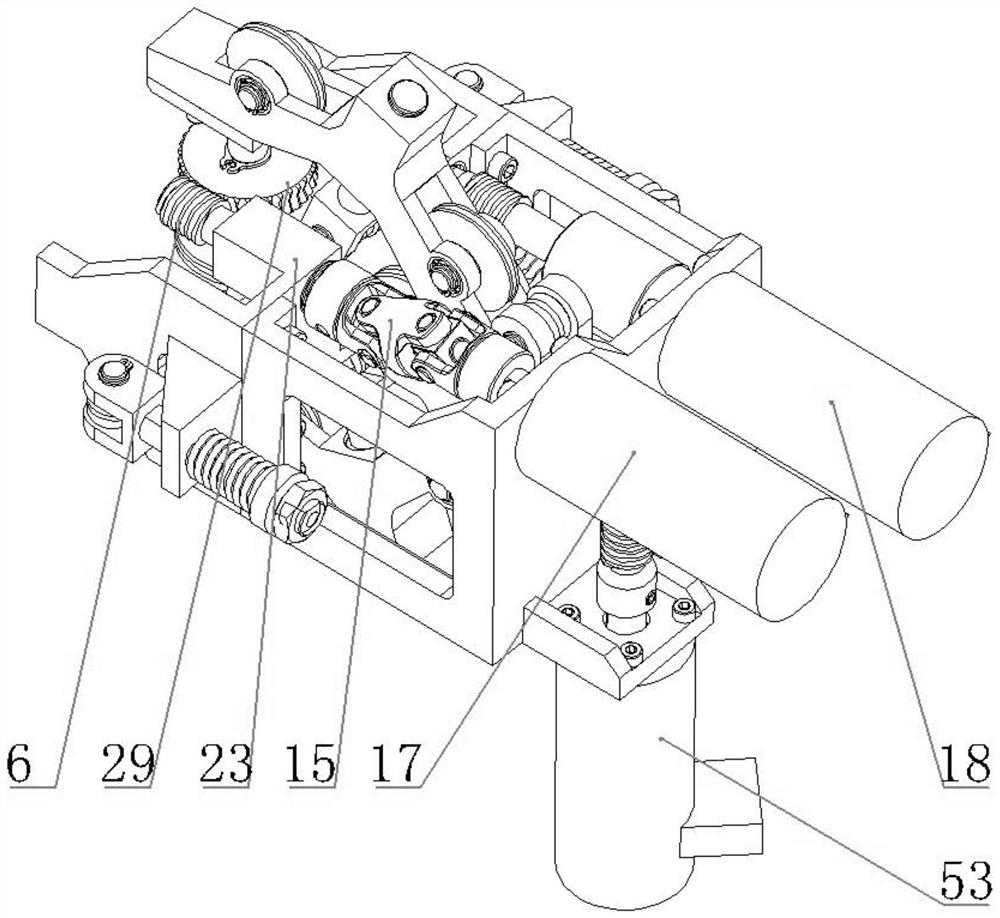

Variable stiffness quadruped bionic quadruped robot flexible continuous body spine mechanism

The invention belongs to the field of robots and more specifically relates to a variable stiffness quadruped bionic quadruped robot flexible continuous body spine mechanism. According to the variable stiffness quadruped bionic quadruped robot flexible continuous body spine mechanism, two pairs of driving steel cables are symmetrically placed on the two sides of the transverse direction and the longitudinal direction of cross-shaped knuckle supports fixed on a square rubber strut in an equally paced manner; a differential driving spine is bent in the horizontal or vertical direction to realize flexible bending of the spine in the horizontal or vertical direction so that the motion flexibility and motion performance of a quadruped robot are improved; by oppositely placing two specially designed elastic elements with nonlinear force-deformation characteristics on the two sides of the longitudinal direction of the spine mechanism, a linear relation is established between an adjusting variable (steel cable telescopic amount) and the stiffness of a spine within an effective stiffness adjusting range; and therefore, the accurate stiffness control ability is obtained.

Owner:WUHAN UNIV OF TECH

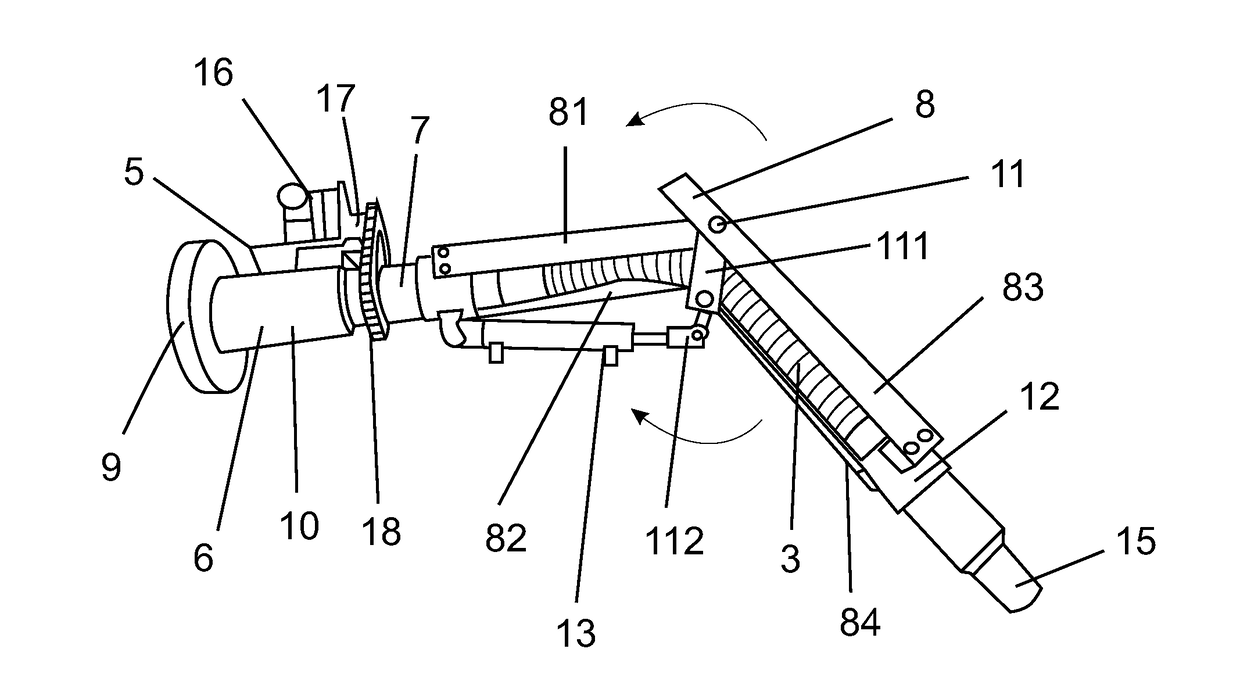

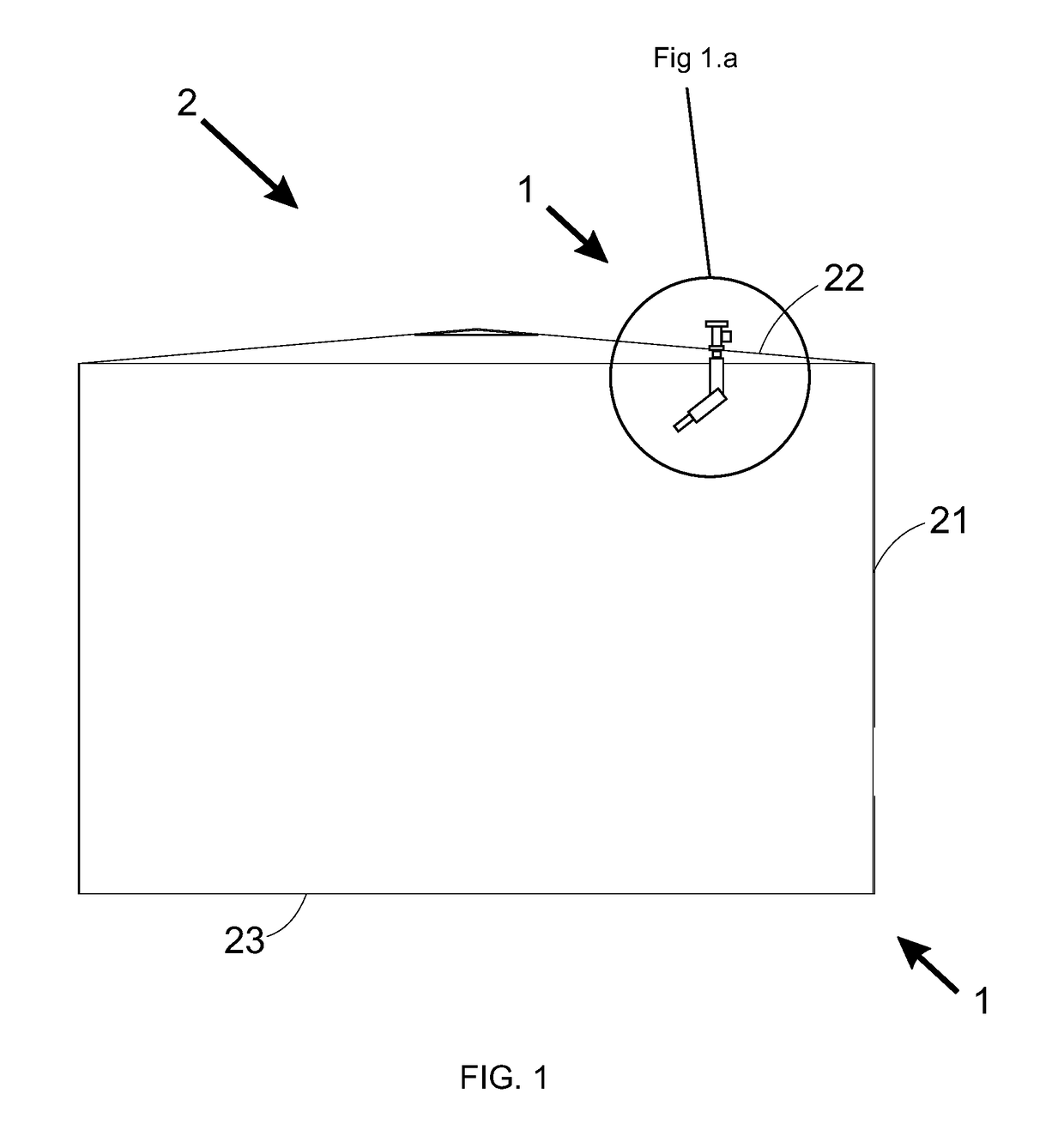

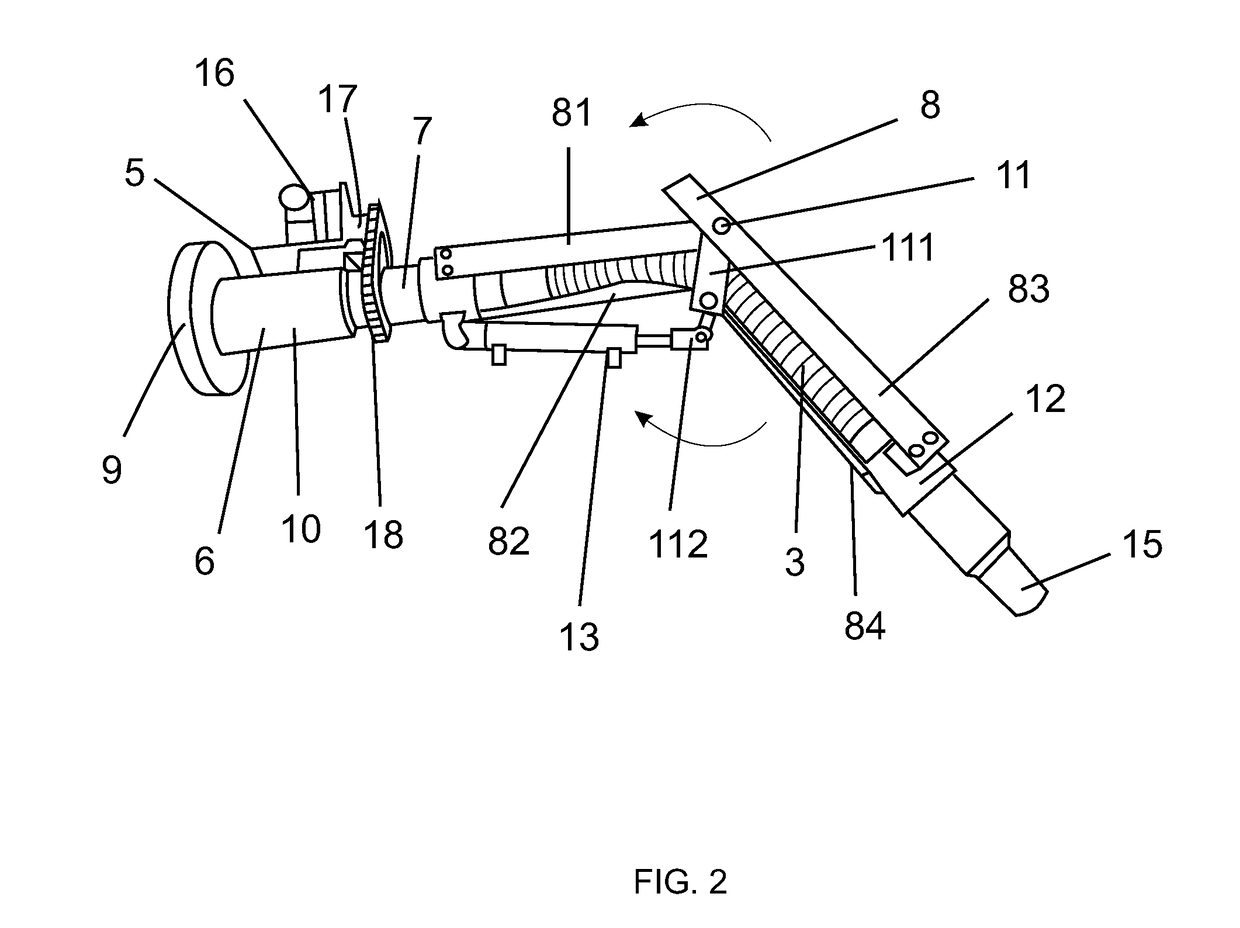

Device for recovering residues and homogenizing fluids in a vessel, and a fluid storage vessel

ActiveUS20180236507A1Eliminate costLow costFlow mixersTransportation and packagingRotary actuatorEngineering

Owner:VARGAS JUNIOR JOEL LIGIERO

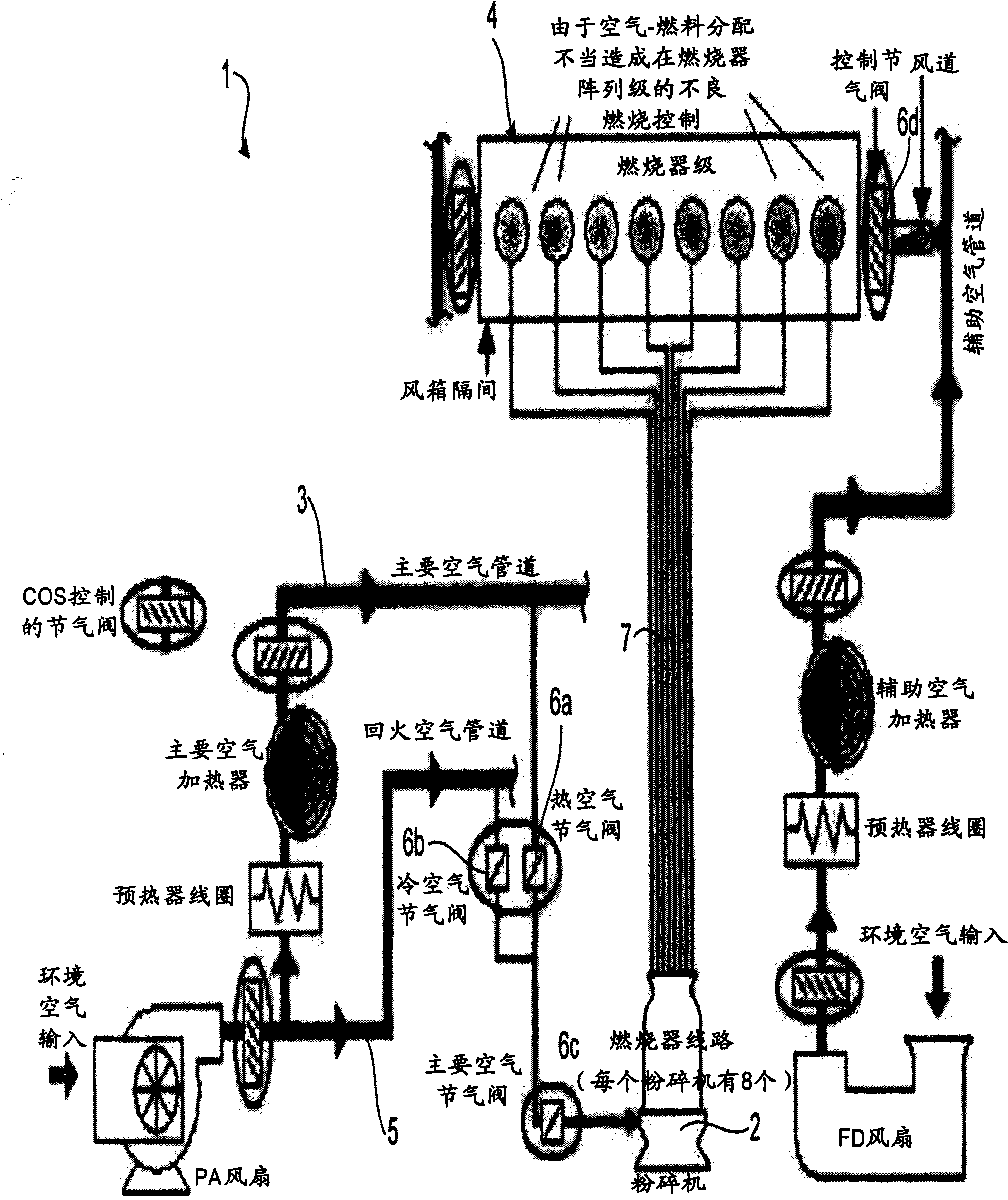

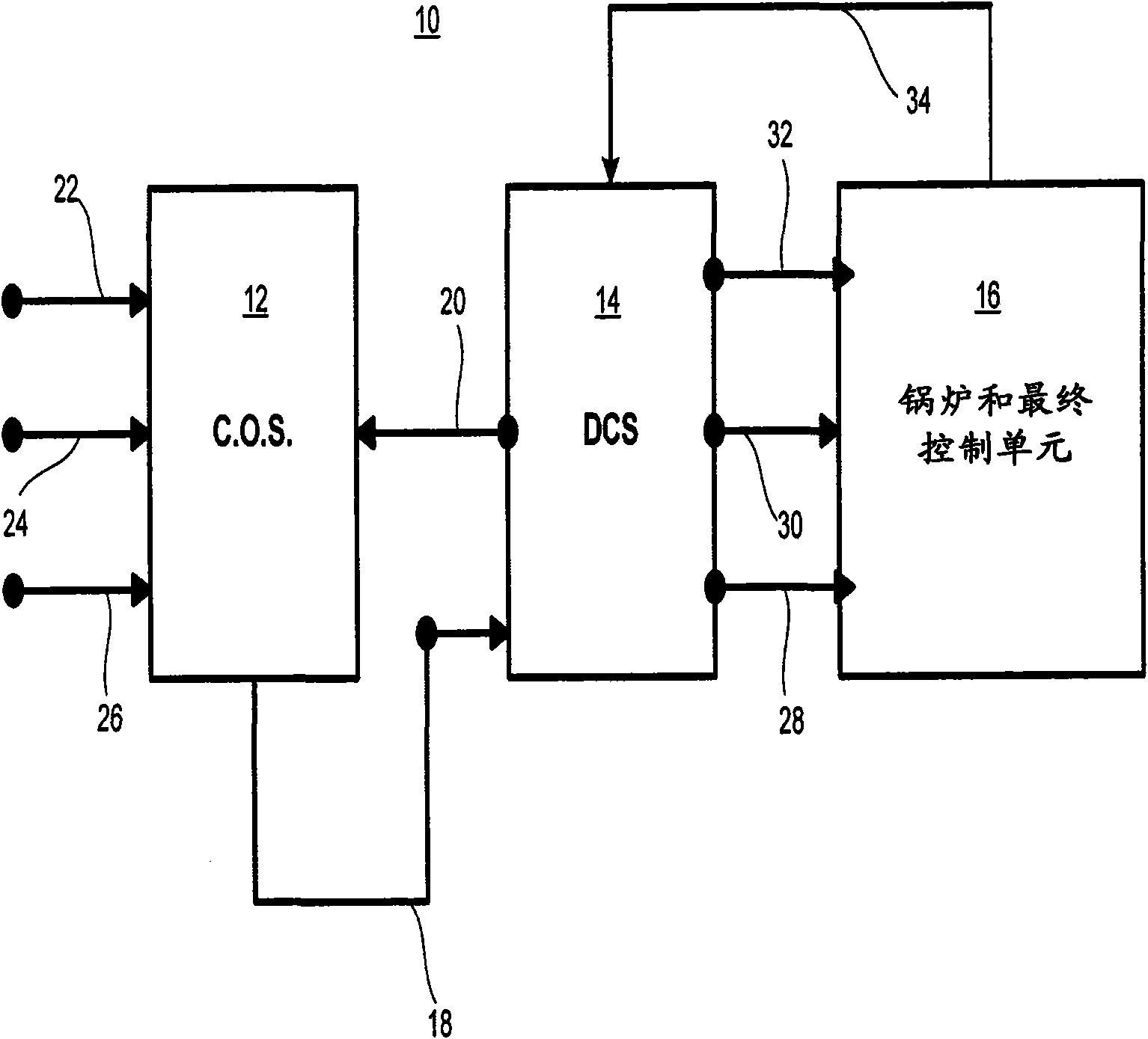

A system and method for full combustion optimization for pulverized coal-fired steam boilers

ActiveCN101939591AReduce usageReduce consumptionFuel supply regulationFuel feeding arrangementsCombustorDistributed control system

A method and system for controlling a pulverized coal fired boiler wherein the flow of a coal / air mixture flowing to each burner is monitored and transmitted to a distributed control system. The distributed control system also monitors and controls the position of dampers in a splitter that feeds the coal / air mixture to the burners. The dampers are controlled in a closed loop fashion to achieve a optimal boiler performance.

Owner:ABB (SCHWEIZ) AG

A Flexible Continuum Spine Mechanism of Biomimetic Quadruped Robot with Variable Stiffness

ActiveCN110254552BIncrease flexibilityImprove athletic abilityVehiclesSpinal columnClassical mechanics

The invention belongs to the field of robots, and more specifically relates to a flexible continuum spine mechanism of a bionic quadruped robot with variable stiffness. In the present invention, two pairs of driving steel cables are symmetrically arranged on both lateral and longitudinal sides of the cross-shaped joint bracket fixed at equal intervals on the square rubber pillar, and the differential drive spine bends in the horizontal or vertical direction, realizing the horizontal or vertical direction of the spine. The flexible bending of the quadruped robot improves the flexibility and motion performance of the quadruped robot. By arranging two specially designed elastic elements with nonlinear force-deformation characteristics opposite to each other in the longitudinal direction of the spine mechanism, within its effective stiffness adjustment range Inside, a linear relationship is established between the adjustment variable (stretch of the steel cable) and the stiffness of the spine, and a precise stiffness control capability is obtained.

Owner:WUHAN UNIV OF TECH

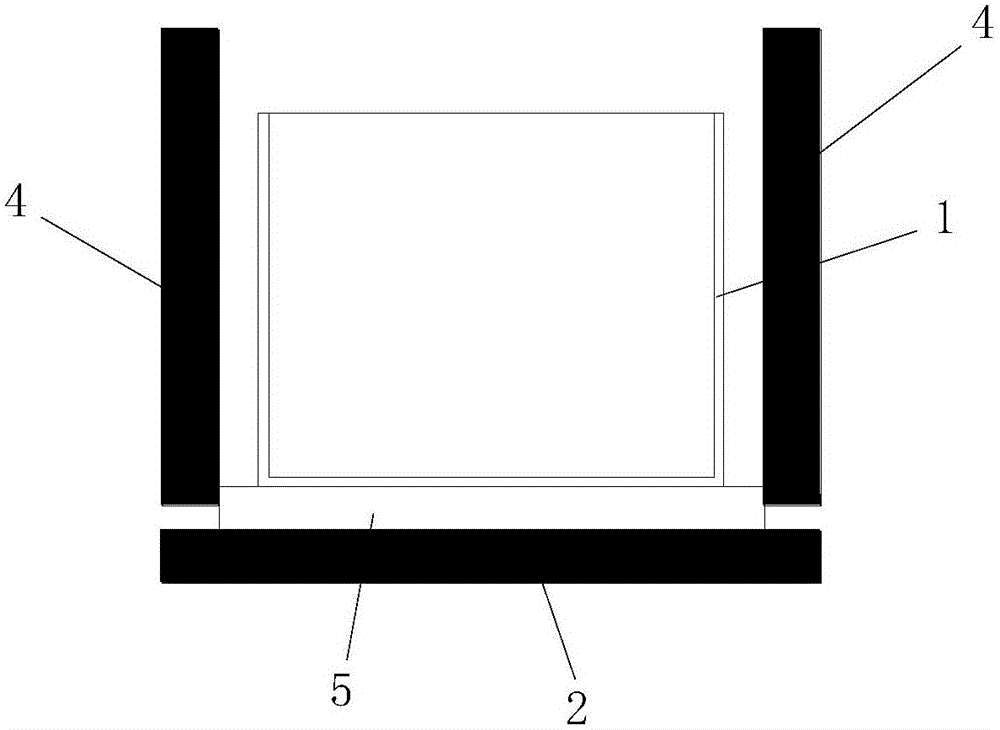

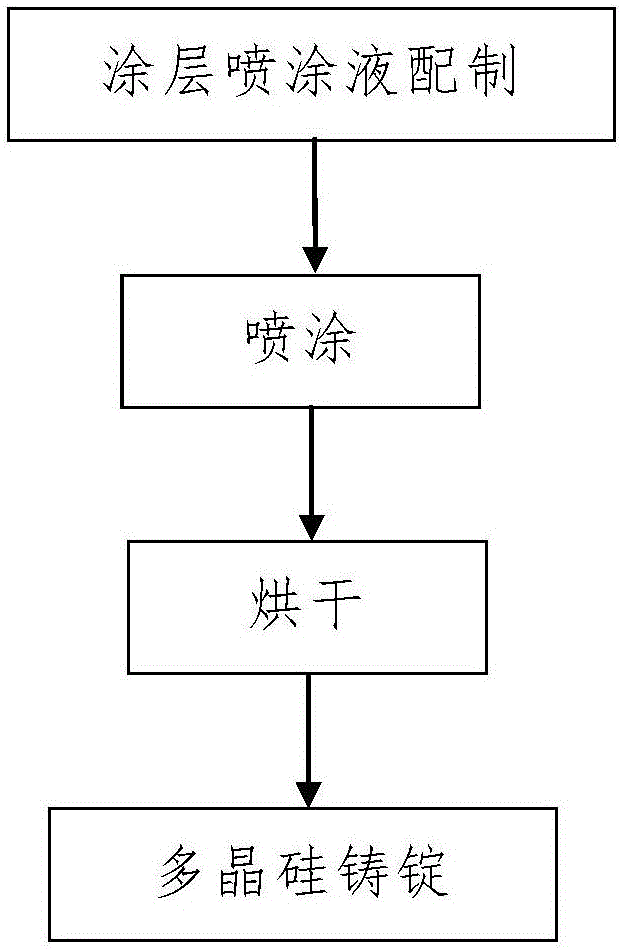

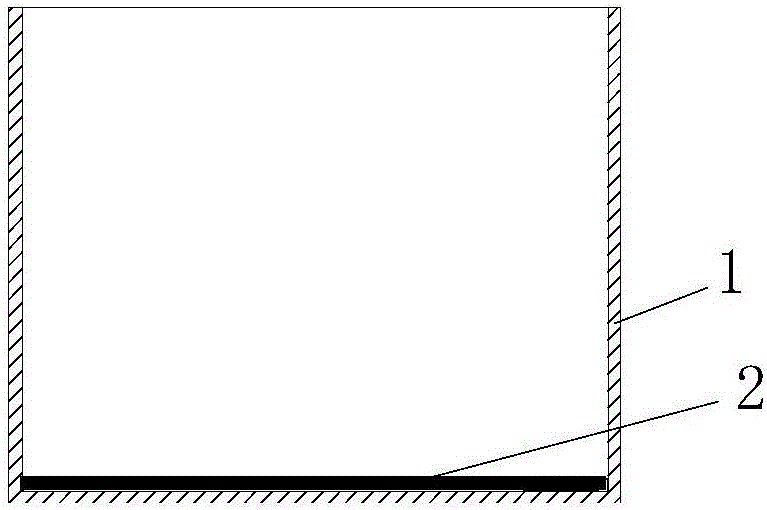

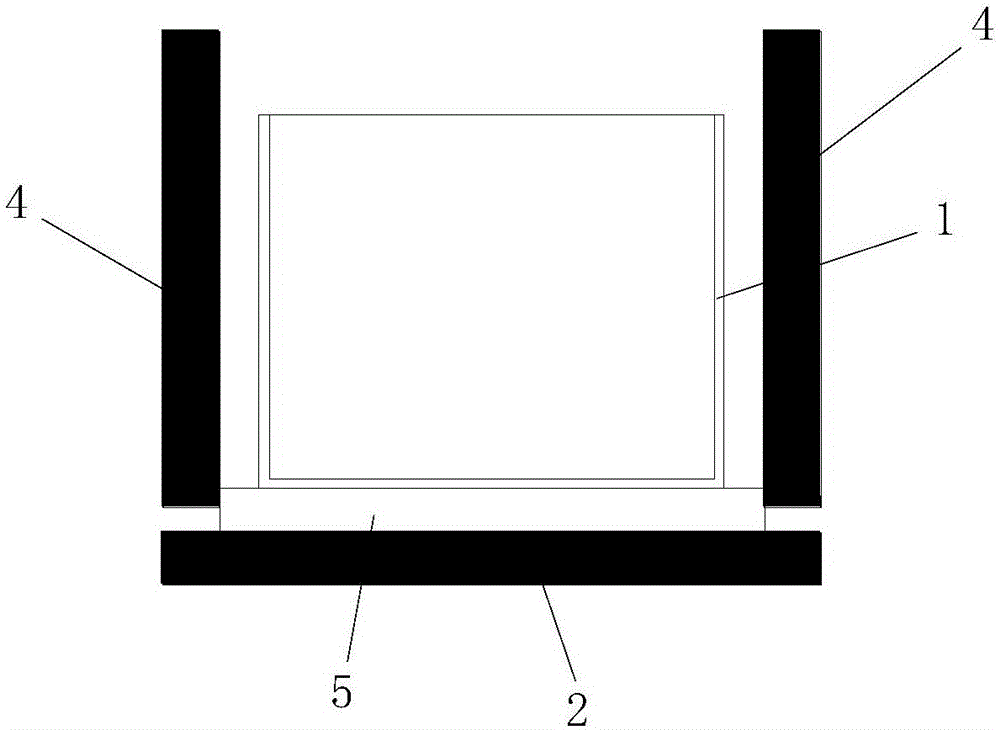

Polycrystalline silicon ingot casting process based on boron nitride coating

InactiveCN106283183AThe process steps are simpleReasonable designPolycrystalline material growthAfter-treatment detailsCrucibleIngot casting

The invention discloses a polycrystalline silicon ingot casting process based on a boron nitride coating. The process includes the first step of preparing a coating at the bottom of a crucible and the second step of conducting polycrystalline silicon ingot casting, wherein filling, preheating, melting, nucleating, and annealing and cooling are conducted in sequence, and the annealing and cooling step includes the substeps of primary annealing, wherein the heating temperature of a polycrystalline silicon ingot casting furnace is lowered to T4 and the temperature is kept for 2-3 h, and T4 is 1250-1280 DEG C; secondary annealing, wherein the heating temperature of the polycrystalline silicon ingot casting furnace is lowered to T5 from T4 and the temperature is kept for 2-3 h, and T5 is 900-950 DEG C; cooling. The process is simple in step, reasonable in design, easy and convenient to implement and good in use effect; by coating the bottom of the crucible with a layer of bottom coating with boron nitride as the main raw material, the oxygen content of the bottom of the crucible can be effectively reduced, the hard point of a finished ingot casting product can be effectively reduced, the annealing process is adjusted, and the quality of the finished ingot casting product can be improved.

Owner:XIAN HUAJING ELECTRONICS TECH

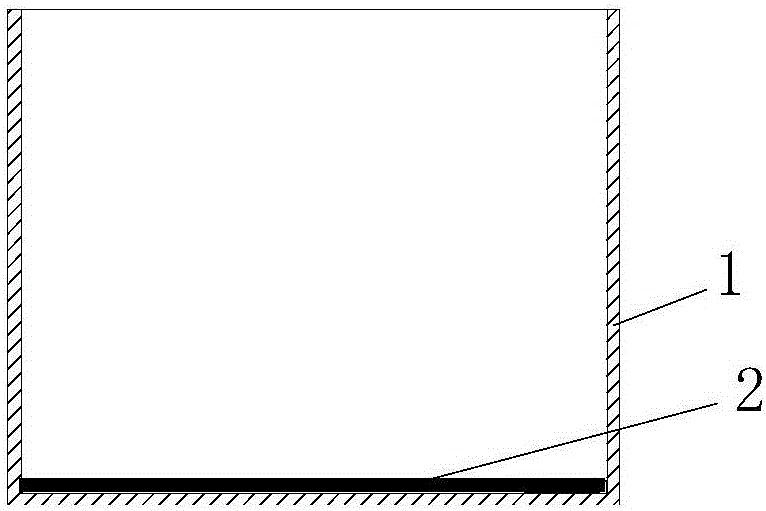

Method for reducing bottom oxygen content of polycrystalline silicon ingot casting

InactiveCN106087048AThe method steps are simpleReasonable designPolycrystalline material growthPretreated surfacesIngot castingCrucible

The invention discloses a method for reducing bottom oxygen content of polycrystalline silicon ingot casting. The method comprises the following steps: 1, preparation of a crucible bottom coating, wherein a preparation process comprises: 101, preparing a coating spraying solution: uniformly mixing an organic grouting agent, de-ionized water and boron nitride at the mass ratio of 1 to (2 to 2.5) to (0.8 to 1.2) to obtain the coating spraying solution; 102, spraying: uniformly spraying the coating spraying solution on an inner bottom surface of a crucible by adopting spraying equipment and drying to obtain the bottom coating; 103, drying: drying the coating spraying solution sprayed on the inner bottom surface of the crucible by adopting drying equipment to obtain the bottom coating; 2, polycrystalline silicon ingot casting: carrying out the polycrystalline silicon ingot casting by utilizing the crucible with the bottom coating. The method disclosed by the invention is simple in steps, reasonable in design, simple and convenient to realize and good in use effect; one layer of the bottom coating taking the boron nitride as a main raw material covers the bottom of the crucible, so that the bottom oxygen content of the crucible can be effectively reduced, hard inclusion of an ingot casting finished product can be effectively reduced and the quality of the ingot casting finished product is improved.

Owner:XIAN HUAJING ELECTRONICS TECH

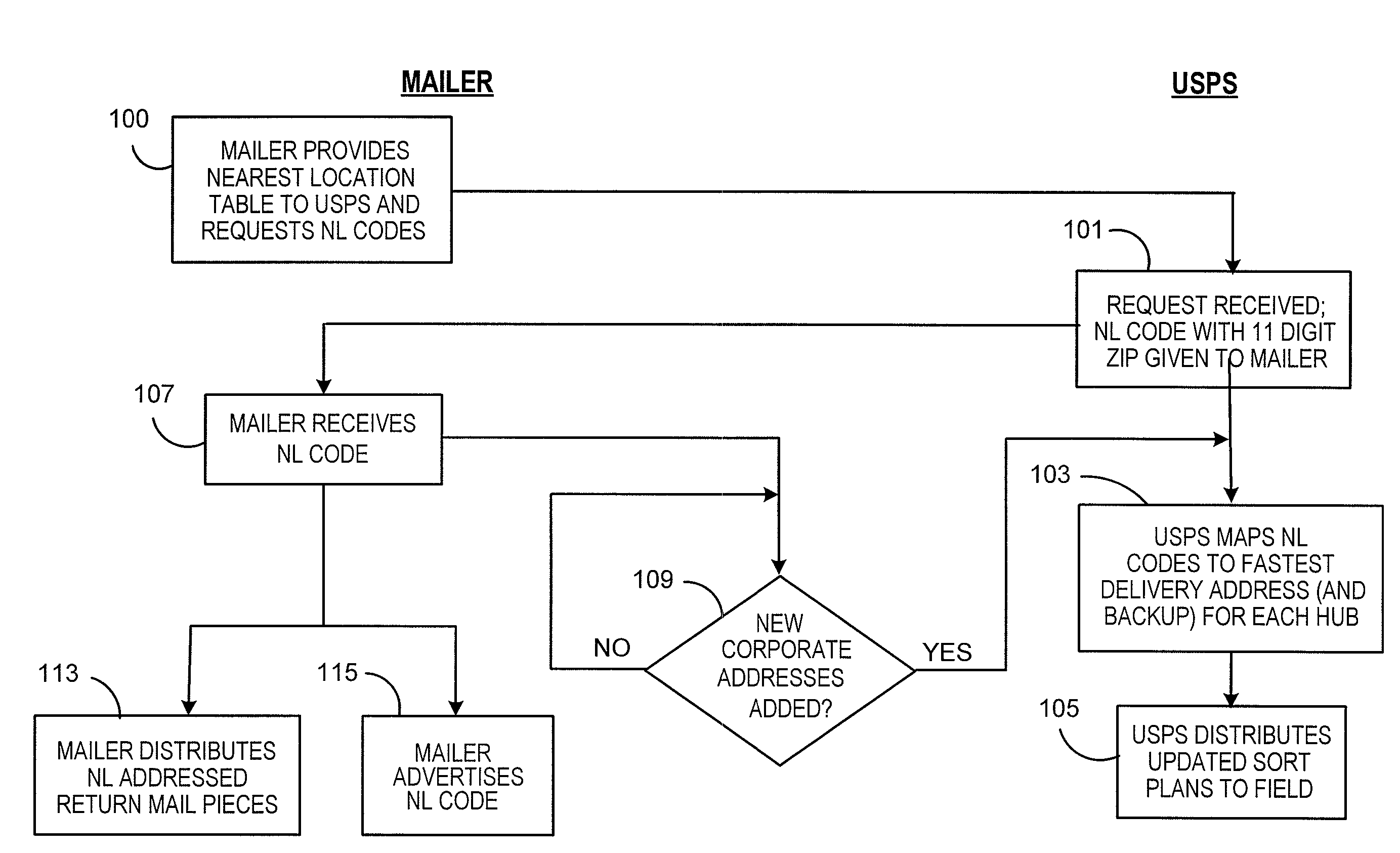

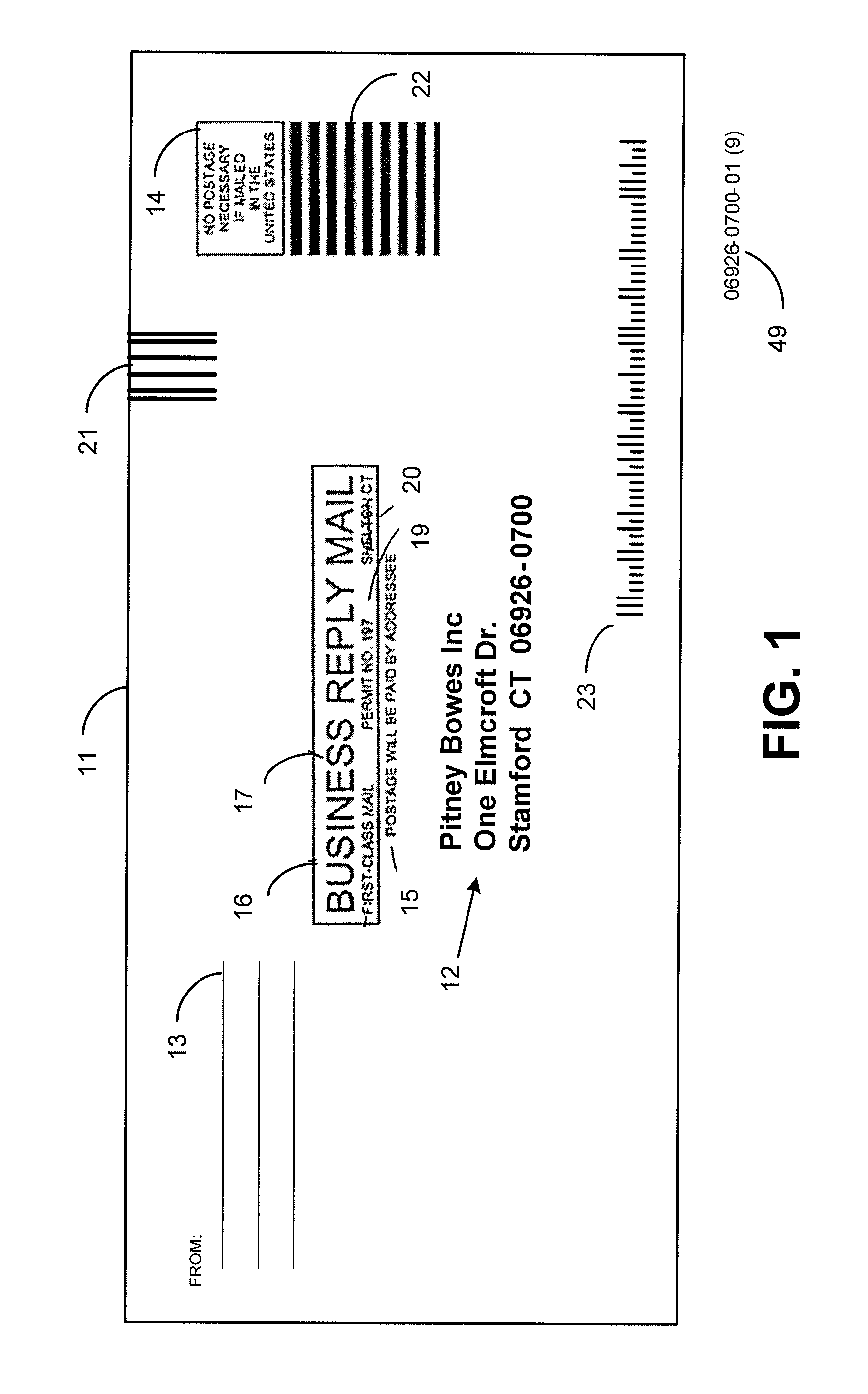

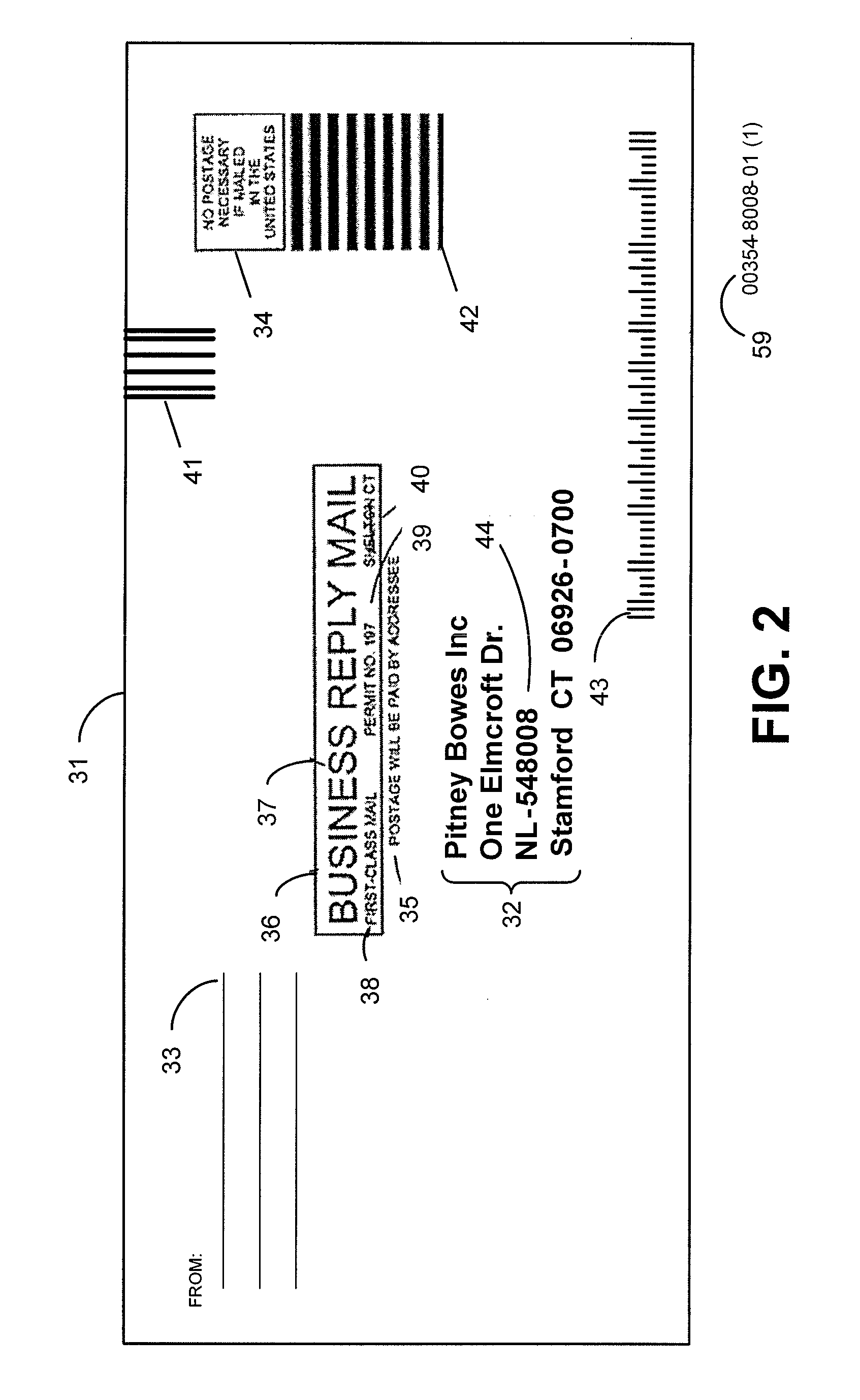

Virtual code for delivery to the nearest building of organizations having multiple buildings

InactiveUS20090069928A1Easy to rememberEliminate costCharacter and pattern recognitionData sortingPost Office BoxWorld Wide Web

A method that enables the post to deliver mail addressed to a recipient nearest location virtual address to be delivery directly to the recipient's nearest designated location or facility to the place the mail was posted. Mail addressed to the nearest location virtual address (mapping to a street address or post office box) would be captured by the post during the post's sortation process and routed to the nearest location or facility to the place the mail was posted. This enables the recipient to receive their mail more quickly since the amount of delivery time is reduced.

Owner:PITNEY BOWES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com